Formula and preparation technology of composite silicone rubber insulator

A technology for compounding silicone rubber and insulators, applied in insulators, suspension/strain insulators, electrical components, etc., can solve the problem of electrical tracking resistance, mechanical properties and hydrophobic attenuation of insulators, reduced electrical and mechanical properties of insulators, and easy damage. Insulator integrity structure and other issues, to achieve excellent tracking resistance and mechanical properties and hydrophobicity, improve insulation and anti-aging properties, improve electrical strength and volume resistivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

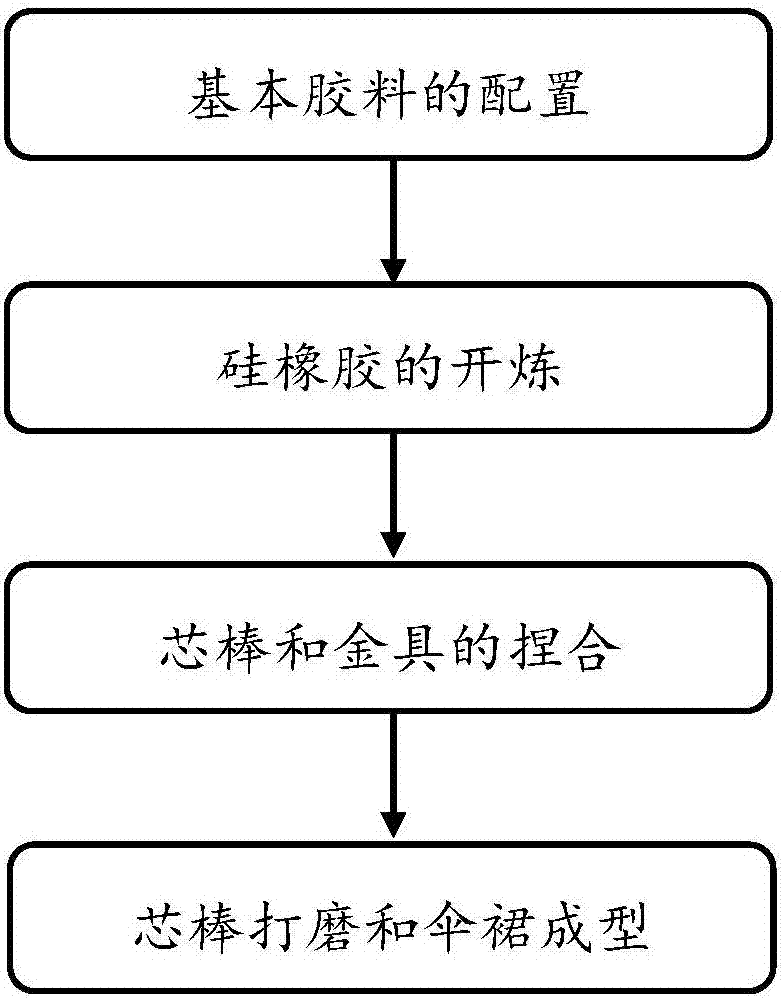

Method used

Image

Examples

Embodiment 1

[0021] A composite silicone rubber insulator, the formula of which consists of the following raw materials in parts by weight:

[0022] 30 parts of epoxy resin, 20 parts of methyl vinyl silicone rubber, 10 parts of vinyl, 5 parts of precipitated silica, 4 parts of aluminum hydroxide, 2 parts of hydroxyl silicone oil, 2,5-dimethyl-2,5- 4 parts of dihexane, 4 parts of silicon micropowder, 1 part of hexamethyldisilazane, 3 parts of median diameter alumina powder, and 5 parts of nano-alumina.

Embodiment 2

[0024] A composite silicone rubber insulator, the formula of which consists of the following raw materials in parts by weight:

[0025] 35 parts of epoxy resin, 25 parts of methyl vinyl silicone rubber, 15 parts of vinyl, 7 parts of precipitated silica, 5 parts of aluminum hydroxide, 3 parts of hydroxyl silicone oil, 2,5-dimethyl-2,5- 5 parts of dihexane, 5 parts of silicon micropowder, 2 parts of hexamethyldisilazane, 4 parts of median diameter alumina powder, 6 parts of nano-alumina.

Embodiment 3

[0027] A composite silicone rubber insulator, the formula of which consists of the following raw materials in parts by weight:

[0028] 40 parts of epoxy resin, 30 parts of methyl vinyl silicone rubber, 20 parts of vinyl, 10 parts of precipitated silica, 6 parts of aluminum hydroxide, 4 parts of hydroxyl silicone oil, 2,5-dimethyl-2,5- 6 parts of dihexane, 6 parts of silicon micropowder, 3 parts of hexamethyldisilazane, 5 parts of median diameter alumina powder, and 8 parts of nano-alumina.

[0029] In above-mentioned embodiment 1 to embodiment 3:

[0030] Preferably, the specific surface area of the precipitated silica is 200m 2 / g; the average particle diameter of the aluminum hydroxide is 1um, and the purity is 99.6%, and the silicon micropowder adopts the silicon dioxide with an active median diameter of 10-15um and a purity of 99.5%; the median diameter is oxidized The average particle size of aluminum powder is 12-22um. And the purity is 99.5%, and the average parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com