Patents

Literature

101results about How to "Excellent tracking resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-retardant resin composition

InactiveUS20060247339A1Avoid bleedingProportion of the flame retardant is lowAnti-corrosive paintsGreenhouse cultivationPolymer scienceMetallic sulfide

A flame-retardant resin composition comprises a base resin (e.g., a polyester-series resin), a flame retardant (A) comprising a salt of an amino group-containing triazine compound with a sulfuric acid and / or a sulfonic acid, a flame-retardant auxiliary (B). The flame-retardant auxiliary (B) includes an aromatic resin, acyclic urea-series compound or a derivative thereof [e.g., acetyleneurea, uric acid, a salt of melamine or a condensate thereof (e.g., melam, melem, and melon) with cyanuric acid], an amino group-containing triazine compound (e.g., melamine or a condensate thereof), and / or an inorganic metal-series compound (e.g., a metal salt of an oxygen acid having no sulfur atom, a metal oxide, a metal hydroxide, and a metal sulfide). The present invention provides a flame-retardant resin composition to which flame retardancy is imparted without using a halogen-series flame retardant and an organic phosphorus-series flame retardant.

Owner:POLYPLASTICS CO LTD

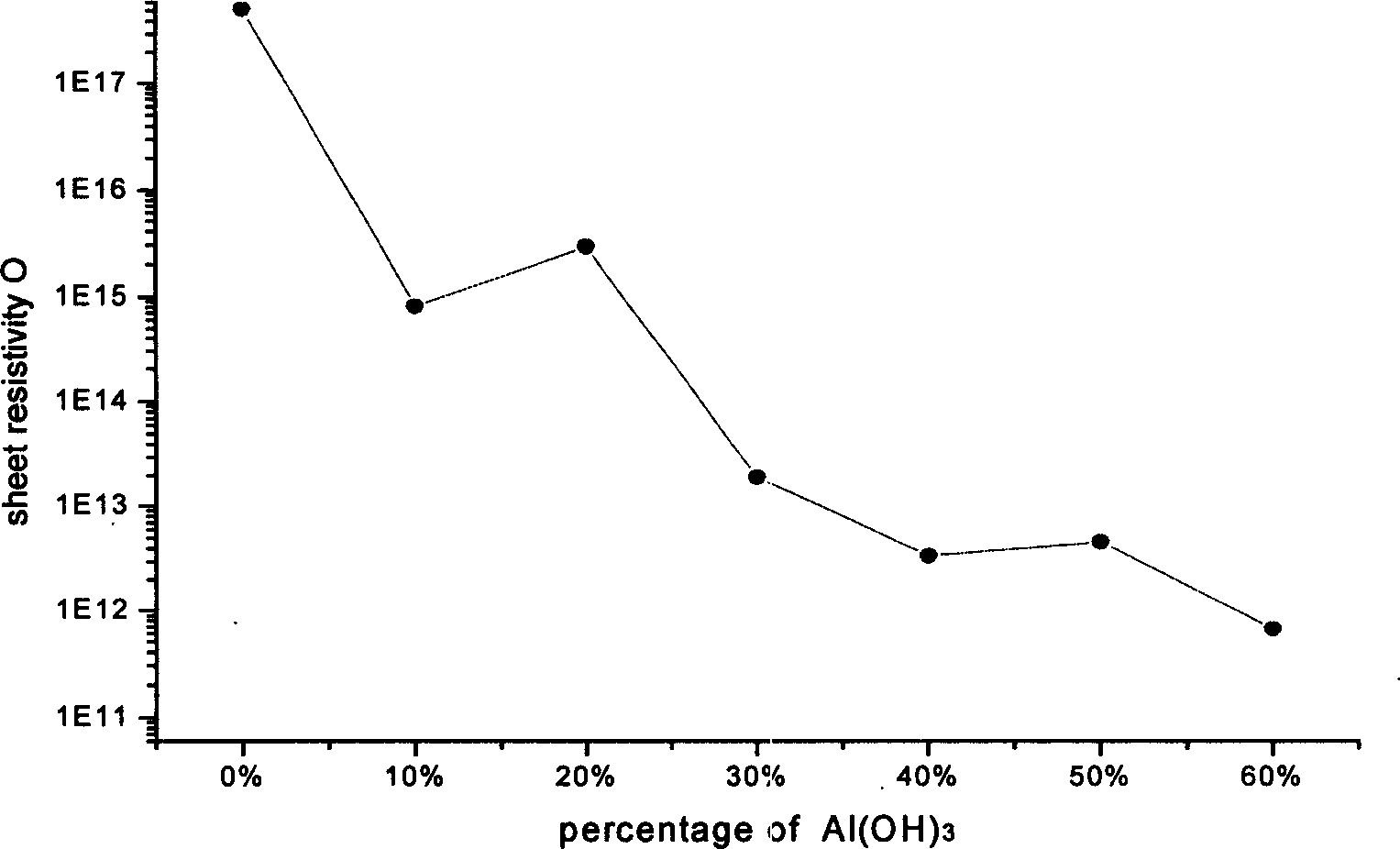

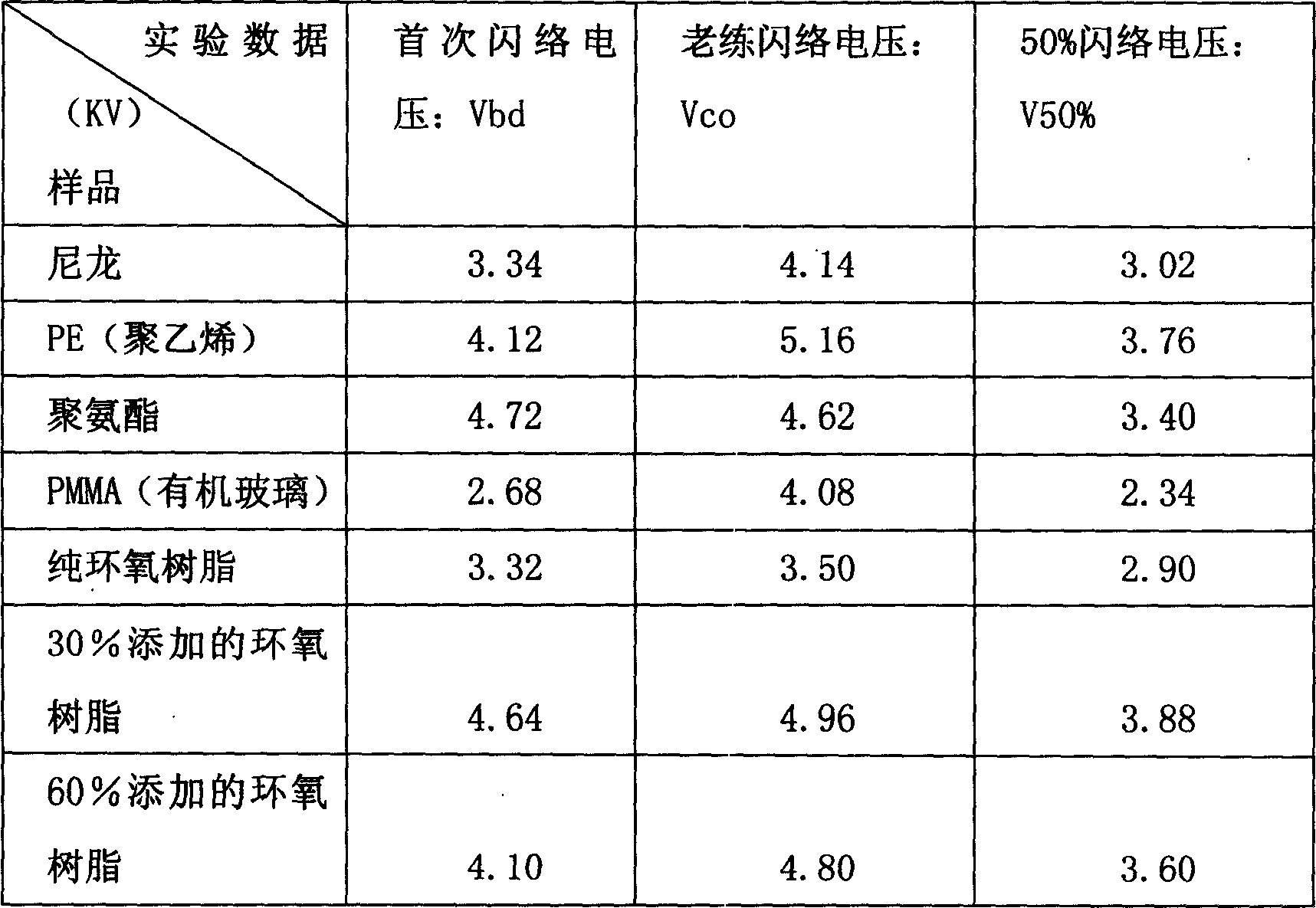

Vacuum insulator coating capable of increasing flashover voltage and method of preparation thereof

InactiveCN1604237AExcellent tracking resistanceImprove thermal conductivityPlastic/resin/waxes insulatorsFirming agentHigh surface

This invention relates to a vacuum isolation sub-coating and its process to improve the surface flashover voltage, wherein, the coating is composed of epoxide resin, aluminum hydroxide, modified synthesized amine firming agent, butyl epihydrin aether thinner. The process comprises the steps of materials, bacon, vacuum, mixture, heating and solidifying and cooling and demoulding Comparing with current material, the coating in this invention has higher surface flashover voltage and high flash burn endurance.

Owner:XI AN JIAOTONG UNIV

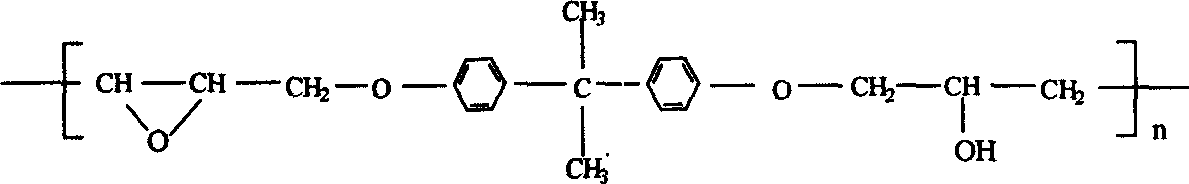

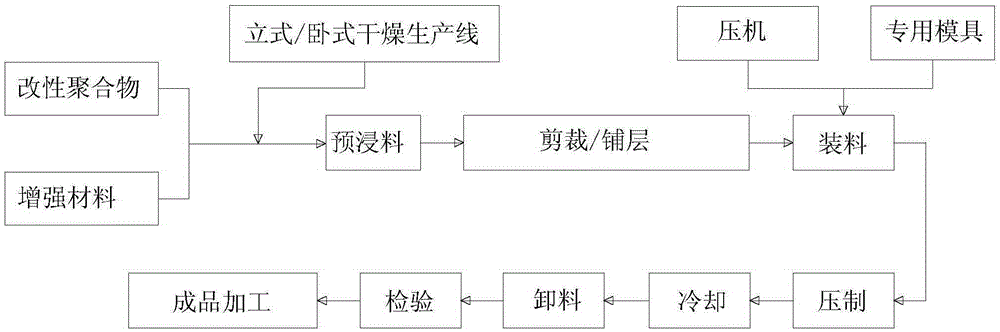

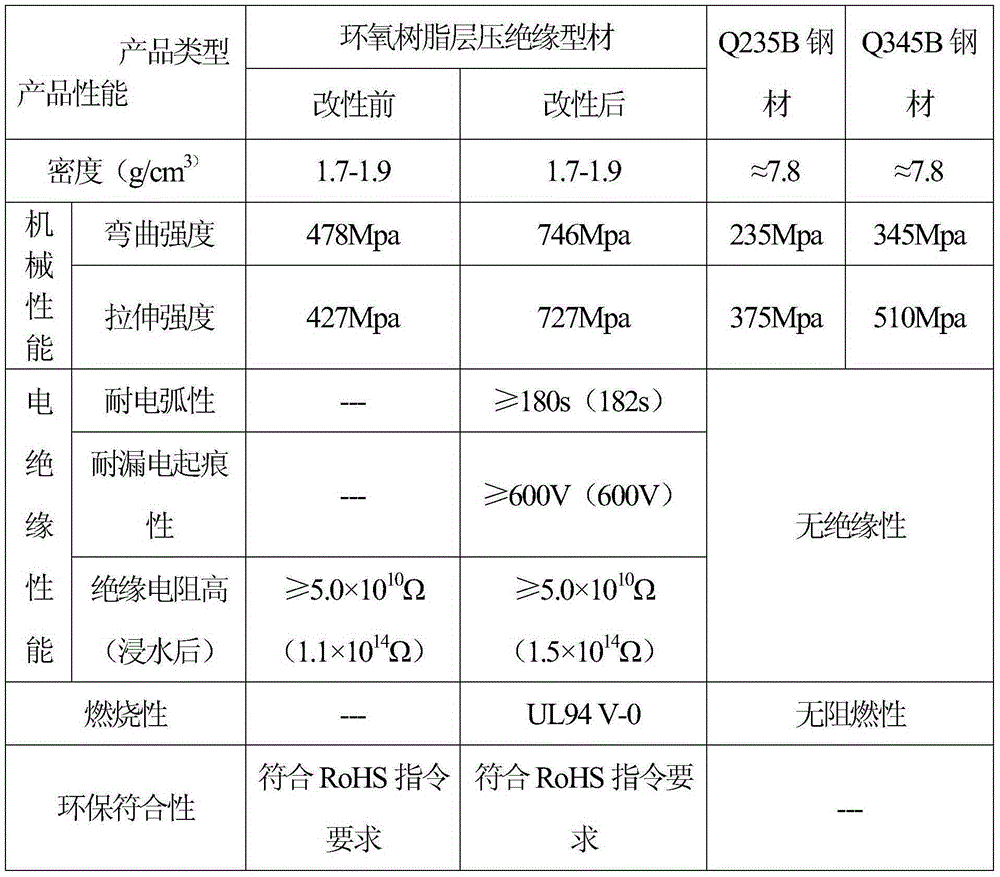

Epoxy resin-enhanced laminated insulating profile and preparation method thereof

The invention discloses an epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile comprises modification polymers and a reinforcing material, wherein the modification polymers include epoxy resin, a curing agent, a promoting agent, a flame retardant, a wetting dispersant and a solvent; the reinforcing material is a fiber material; the components of the modification polymers are mixed to form a modification polymer solution, the reinforcing material is soaked into the modification polymer solution and is finally subjected to hot press molding to form the epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile is integrated with lightness, flame retardance, corrosion resistance and insulativity, has extremely high mechanical property, excellent electrical insulation property and halogen-free flame retardance, is environmentally friendly, is high in use safety and can be applied to industries and fields including State Grid Corporation of China, new energy resources, energy conservation, consumption reduction and track traffic which have high requirements to material performance and special working conditions and environments.

Owner:SICHUAN D&F ELECTRICAL TECH

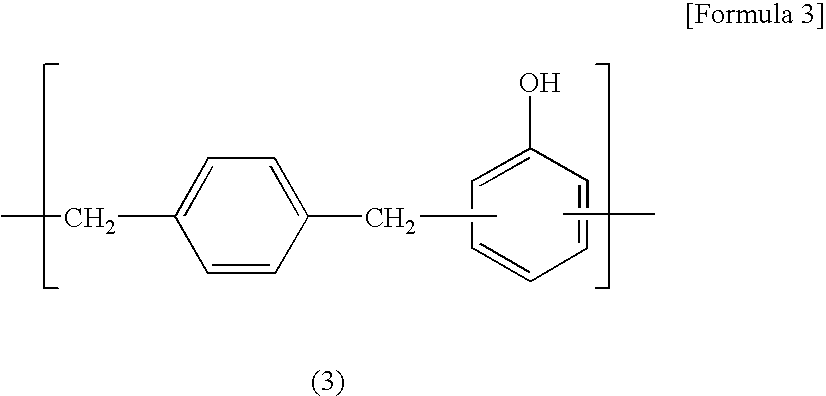

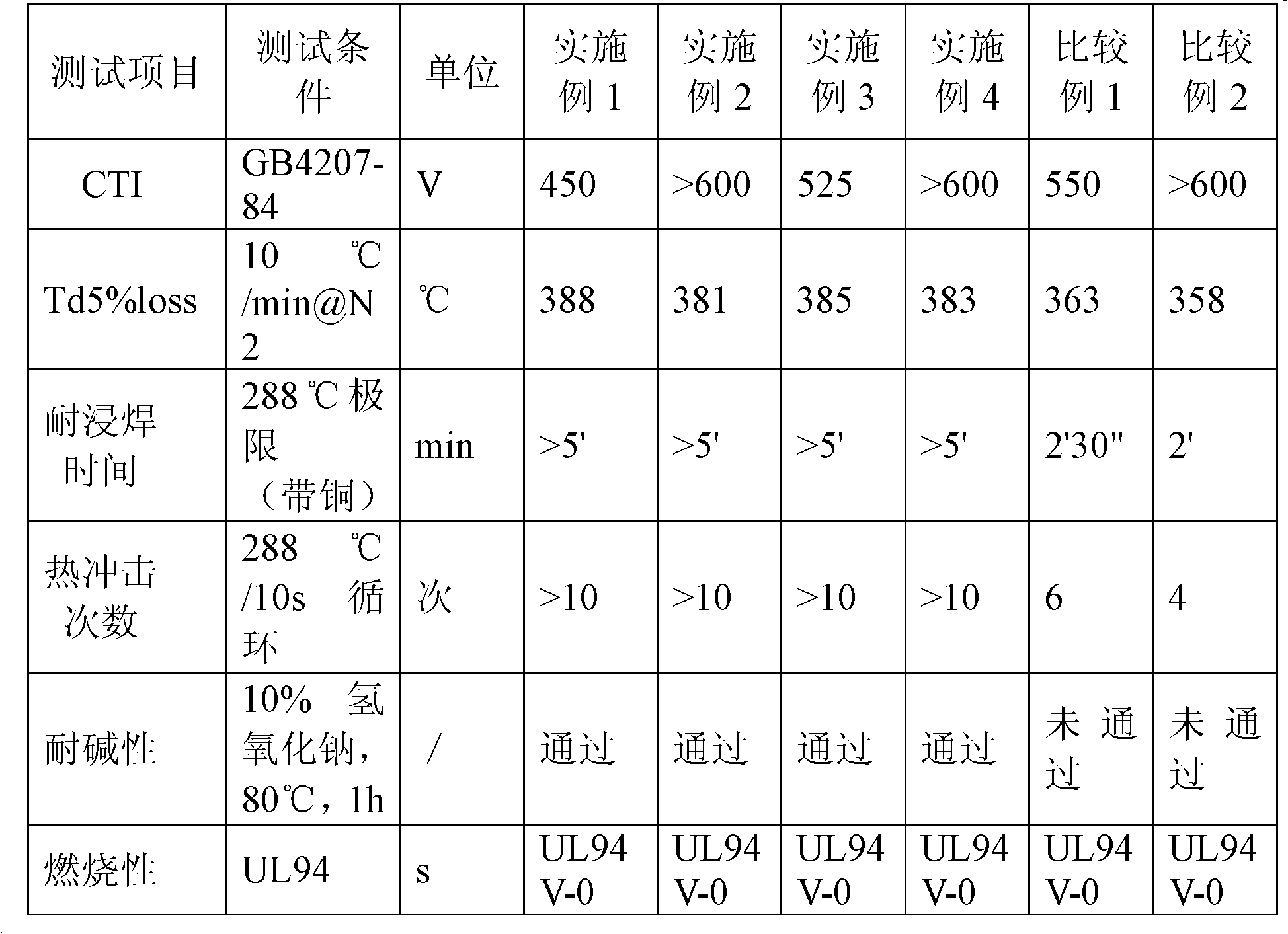

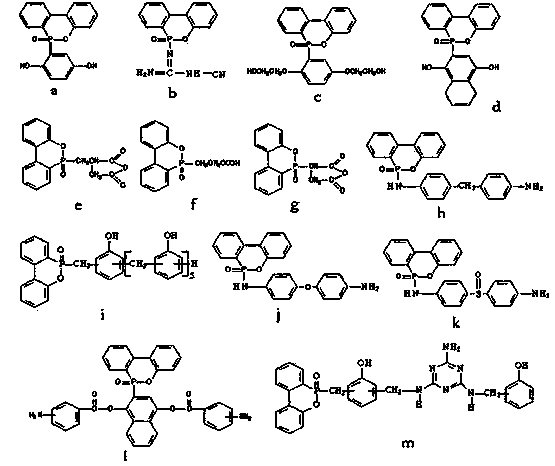

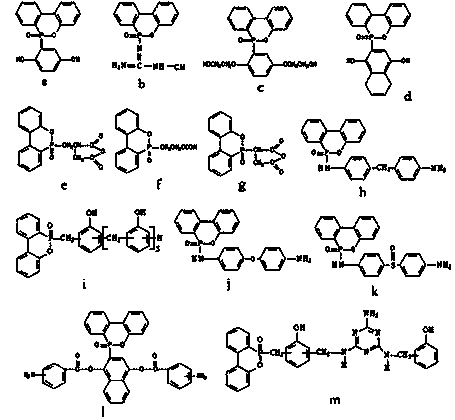

Halogen-free resin composition and resin-coated copper foil and copper-clad plate prepared from same

ActiveCN102051023AExcellent tracking resistanceImprove heat resistanceMetal layered productsHeat resistanceComparative Tracking Index

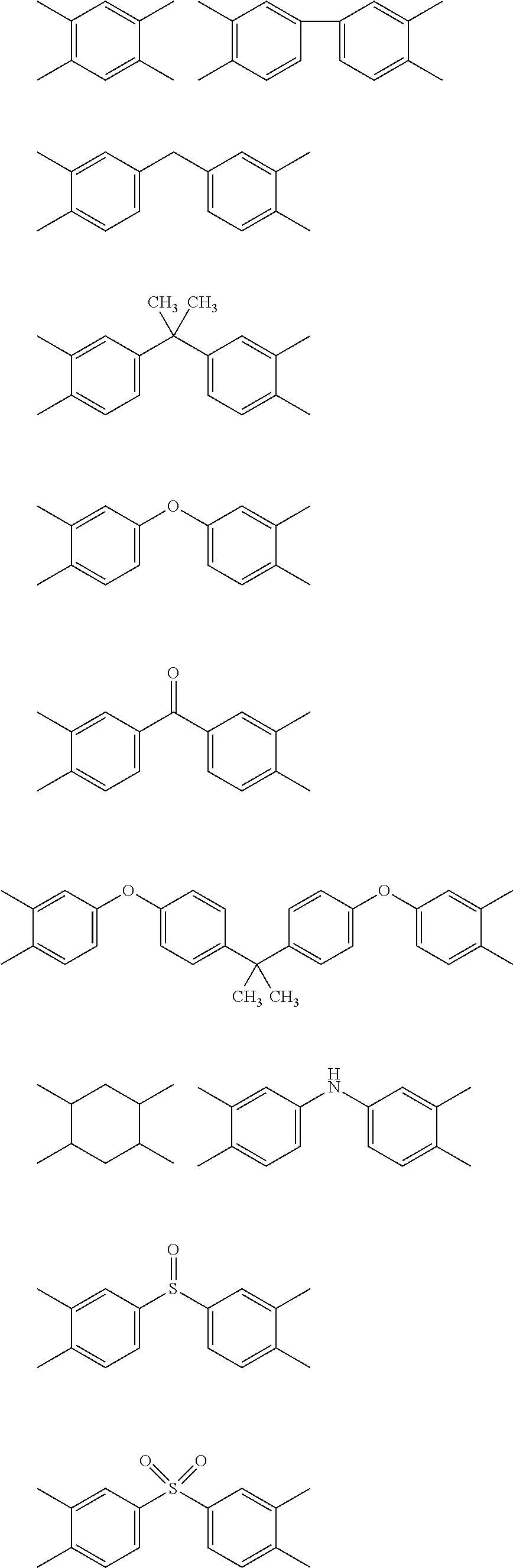

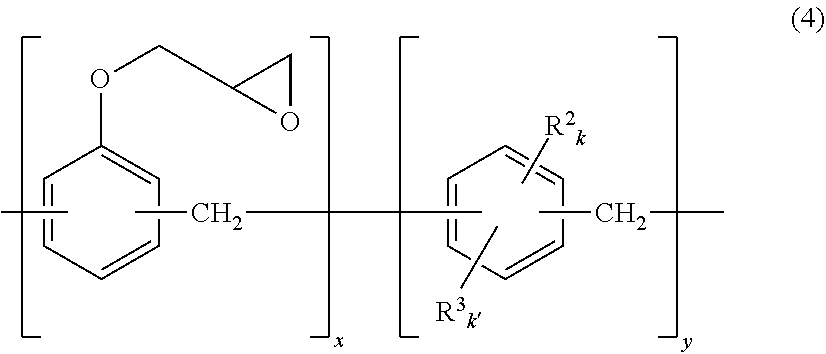

The invention relates to a halogen-free resin composition and a resin-coated copper foil and copper-clad plate prepared from the same. The halogen-free resin composition comprises the following components in parts by weight: 20-30 parts of phosphorous epoxy resin, 5-15 parts of bisphenol A epoxy resin, 10-20 parts of novolac epoxy resin, 10-20 parts of phenoxy resin, 35-50 parts of barium sulphate filler and 0.5-1.5 parts of dicyandiamide; the resin-coated copper foil prepared from the resin composition comprises a copper foil and the halogen-free resin composition coated on the copper foil; and the copper-clad plate prepared from the halogen-free resin composition comprises a plurality of superimposed bonding sheets and the resin-coated copper foil compounded at one side or the two sides of the bonding sheets. The halogen-free resin composition provided by the invention has excellent tracking resistance, heat resistance and alkali resistance; the resin-coated copper foil and copper-clad plate prepared from the halogen-free resin composition have high comparative tracking index, thus meeting the requirement of high comparative tracking index; and meanwhile, the heat resistance and alkali resistance are excellent, thus meeting the halogen-free flame retarding requirement.

Owner:GUANGDONG SHENGYI SCI TECH

High-strength insulating support beam and preparation method thereof

The invention discloses a high-strength insulating support beam and a preparation method thereof. The problem that the existing insulating support beam is low in mechanical strength and poor in electric performance is solved. The insulating support beam comprises a glass cloth layer, wherein the glass cloth layer is immersed with flame-retardant epoxy resin glue solutions or common epoxy resin glue solutions; the flame-retardant epoxy resin glue solutions are glue solutions which are prepared by adding curing agents, curing accelerators, solvents and flame-retardant agents into flame-retardant epoxy resins; and the common epoxy resin glue solutions are glue solutions which are prepared by adding curing agents, curing accelerators, solvents and flame-retardant agents into common epoxy resins. The insulating support beam has the characteristics of high mechanical strength and high electric performance, can be suitable for supporting large-scale and super-huge type electric equipment in an insulating mode, and can be simultaneously suitable for supporting electric facilities with high voltage and extra-high voltage.

Owner:SICHUAN D&F ELECTRICAL TECH

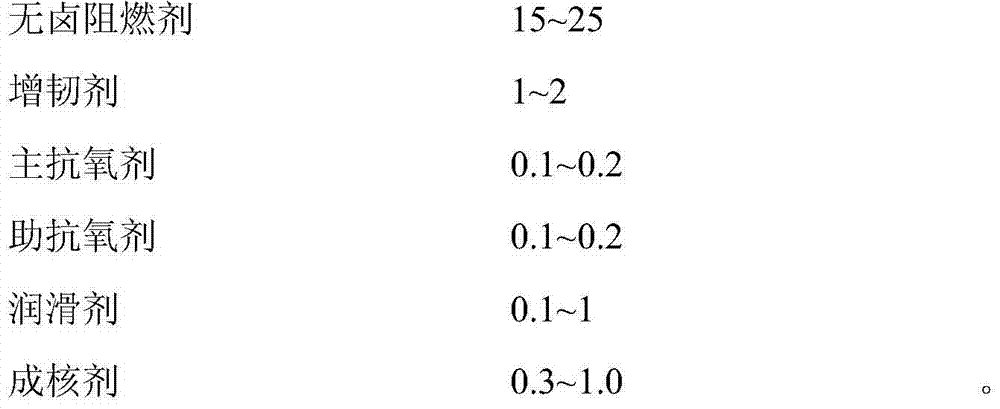

Halogen-free and phosphorus-free PBT enhanced composite material and preparation method thereof

ActiveCN104231575AExcellent resistance to precipitationImprove flame retardant performanceGlass fiberAntioxidant

The invention discloses a halogen-free and phosphorus-free PBT (polybutylece terephthalate) enhanced composite material and a preparation method thereof, and belongs to the technical field of composite flame-retardant enhanced materials. The halogen-free and phosphorus-free PBT enhanced composite material consists of the following components: 45-65 pats of PBT, 15-30 parts of glass fibers, 15-25 parts of a halogen-free flame retardant, 1-2 parts of a toughening agent, 0.1-0.2 part of a main antioxidant, 0.1-0.2 part of an auxiliary antioxidant, 0.1-1 part of a lubricating agent and 0.3-1.0 part of a nucleating agent. The preparation method comprises the steps of uniformly mixing PBT, the halogen-free flame retardant, the toughening agent, the main antioxidant, the auxiliary antioxidant, the lubricating agent and the nucleating agent according to the weight part to obtain a mixture, and performing melting, coblending and extruding granulation on the mixture and the glass fibers to obtain the halogen-free and phosphorus-free PBT enhanced composite material. The halogen-free and phosphorus-free PBT enhanced composite material prepared by the method is excellent in anti-separation performance, flame retardancy, mechanical property and creepage cracking resistance, does not release hydrogen phosphide poisonous gas and can totally meet a limiting requirement of Samsung on hydrogen phosphide emission concentration.

Owner:JINAN TAIXING FINE CHEM

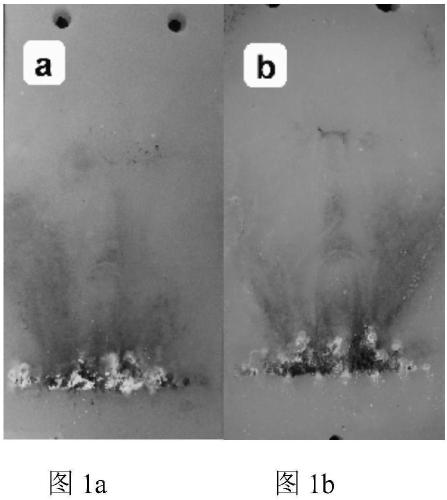

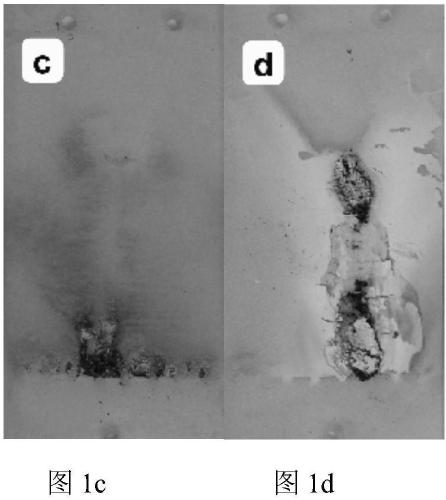

Process for preparing power transmission composite cross arm with electric mark corrosion tolerance and high hydrophobic property

The invention relates to a process for preparing a power transmission composite cross arm with electric mark corrosion tolerance and high hydrophobic property, which comprises preparation of a core rod and preparation of a climb increasing parachute cluster. The process is characterized in that: the core rod of the cross arm is a high-strength epoxy resin composite core rod; and the climb increasing parachute cluster is an electric mark tolerant aliphatic epoxy resin climb increasing parachute cluster at the end part of the core rod. The preparation process has the characteristics of simple and quick operation and the like; the prepared insulated cross arm has good hydrophobic property, mechanical property, chemical corrosion resistance, fatigue resistance, fouling and flashing resistance and the like besides excellent electric mark corrosion tolerance, continuous and stable production and physical and chemical stability; and the application range of the composite in the insulating field is further broadened.

Owner:CHINA ELECTRIC POWER RES INST +1

Arc-resistant silicon composite material, preparation method and use thereof

The invention provides an arc-resistant silicon composite material, a preparation method and use thereof. The composite material is mainly prepared and obtained by the following raw materials: (A) at least one silicon rubber; (B) modified nano-expanded vermiculite; and the weight percentage of the component (B) modified nano-expanded vermiculite accounts for 9% to 39% of the sum of the weight percentages of the component (A) and the component (B). The preparation method comprises the following steps: firstly adding a silane coupling agent to the modified nano-expanded vermiculite in a ball-milling machine, and then mixing with silicon rubber. The composite material provided by the invention has excellent anti-creepage trace performance and mechanical performance, also has high electrical performance such as disruptive strength, flame retardant performance and machinable performance, and can be used for preparing HVDC transmission line composite insulators.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

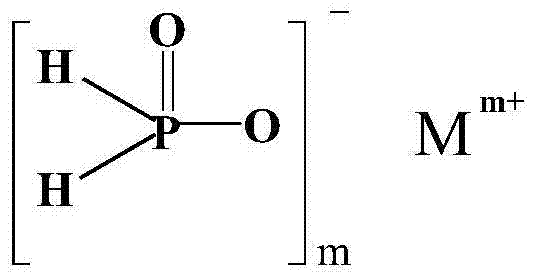

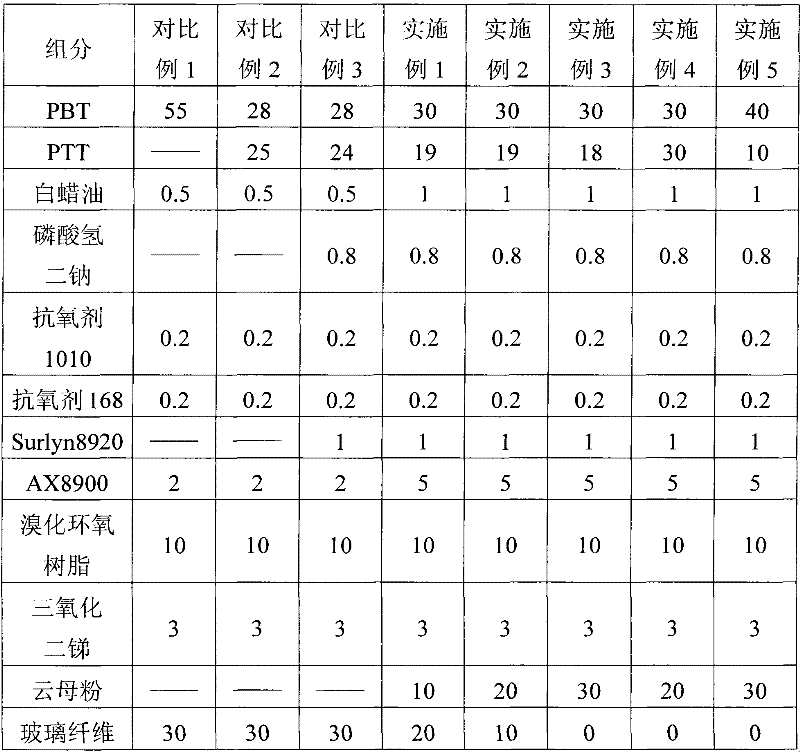

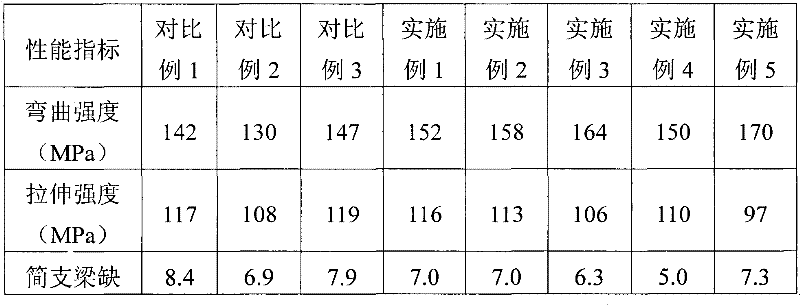

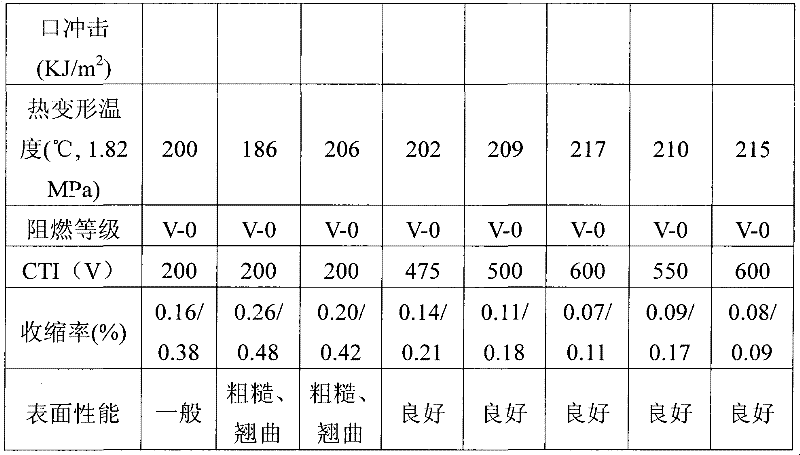

Flame-retardant reinforced warping-resistance PBT/PTT (polybutylene terephthalate/polytrimethylene terephthalate) alloy material and preparation method thereof

ActiveCN102532824AImprove flame retardant performanceHigh CTI value is highPolyethylene terephthalateComparative Tracking Index

The invention discloses a flame-retardant reinforced warping-resistance PBT / PTT (polybutylene terephthalate / polytrimethylene terephthalate) alloy material, which comprises the following components in parts by weight: 30-40 parts of PBT, 10-30 parts of PTT, 0.3-1 part of lubricating agent, 0.1-0.8 part of ester exchange inhibitor, 0.3-0.8 part of antioxidant, 0.5-5 parts of nucleating agent, 5-10 parts of flame retardant, 1-5 parts of flame-retardant synergist, 2-10 parts of toughening agent, 0-30 parts of glass fiber and 10-30 parts of mineral powder. According to the invention, the PBT and the PTT are blended to be made into the alloy material, and the flame-retardant reinforced warping-resistance PBT / PTT alloy material has the advantage of low cost, solves the problem that high fire resistance and high CTI (comparative tracking index) value as well as high mechanical property of the PBT / PTT alloy material are difficult to coexist and has the characteristics of strong warping resistance and heat resistance. The flame-retardant reinforced warping-resistance PBT / PTT alloy material has good mechanical property, high flame retardance and high CTI value; and a product made of the flame-retardant reinforced warping-resistance PBT / PTT alloy material is smooth in smooth and free of warping.

Owner:HEFEI GENIUS NEW MATERIALS

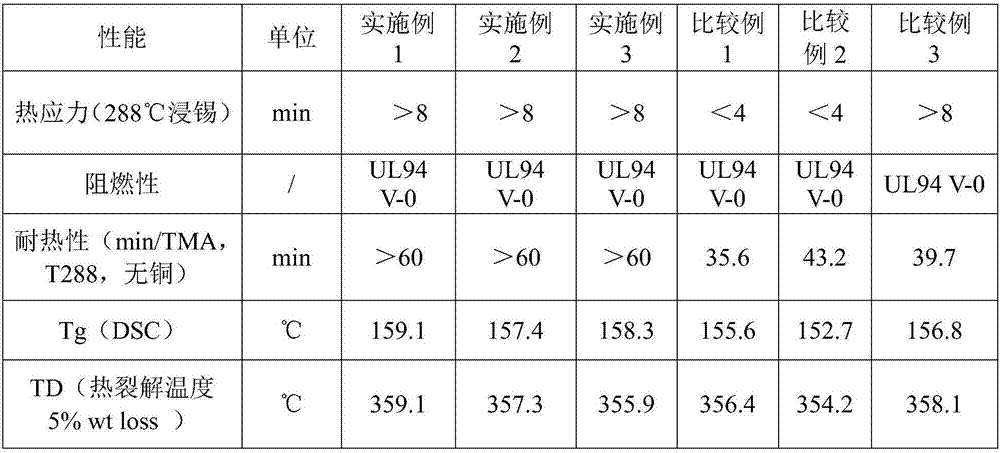

Prepreg for improving electric leakage-resisting tracking index and drilling processing properties and application thereof

InactiveCN107298831AReduce conductivityEasy to processLaminationLamination apparatusGlass fiberCopper foil

The invention relates to a prepreg for improving electric leakage-resisting tracking index and drilling processing properties and an application thereof. The prepreg is prepared according to the method which comprises the following steps: controlling a coating linear velocity at 6-15m / min, circularly loading an adhesive onto a gluing machine, uniformly coating a glass fiber cloth with the adhesive by presoaking and primarily soaking, baking the glass fiber cloth coated with the adhesive in a drying box at 100 DEG C-250 DEG C, evaporating the solvent, preliminarily reacting and curing the adhesive, thereby acquiring the prepreg. Compared with the prior art, the invention not only can promote the electric leakage-resisting tracking index of a Tg unleaded coated copper foil plate, but also can obviously improve the drilling processing properties of a sandwich plate prepared from the prepreg.

Owner:NANYA NEW MATERIAL TECH CO LTD

Preparation method of silicon-rubber composite molding material

InactiveCN107815121AReliable mechanical strengthGood electrical performanceVulcanizationAluminium hydroxide

The invention relates to the field of silicon-rubber composite materials, and particularly relates to a preparation method of a silicon-rubber composite molding material. The method adopts methylvinylsilicon rubber, fumed silica, precipitated silica, hydroxyl silicone oil, silane coupling agent surface treatment type active aluminium hydroxide, titanate coupling agent surface treatment type aluminium hydroxide, zinc stearate, iron oxide red, cerium oxide and 2,5-dimethyl-2,5-dihexane as raw materials to prepare the silicon-rubber composite molding material with reliable mechanical strength, excellent electrical performance, good hydrophobicity and flame retardance and better outdoor-aging resistance. The silicon-rubber composite molding material is designed for a hot die-pressing vulcanization molding production process, can be applied in production and manufacture of electrical-equipment insulation sleeves and products in related fields, and also can be applied to sealing products and damping and shock-absorbing products for hot die-pressing vulcanization molding.

Owner:董绍光

Preparation method of halogen-free CEM-1 copper-clad plate with high peeling strength

ActiveCN106739376AIncrease crosslink densityReduce dosagePaper coatingLaminationBisphenol AChemistry

The invention belongs to the technical field of copper-clad plate production, and especially relates to a preparation method of a halogen-free CEM-1 copper-clad plate with a high peeling strength. Phosphor containing epoxy resin and bisphenol A type epoxy resin are taken as the main resin; phosphor containing linear phenolic resin is taken as the curing agent, polyfunctional epoxy resin is used to enhance the heatproof performance; a certain ratio of aluminum hydroxide is added to increase the electric tracking resistant index of the copper-clad plate; a nitrogen and phosphor containing fire retardant is added, and through the synergistic effect between nitrogen and phosphor, the fireproof performance of the copper-clad plate is enhanced and can reach the FV0 grade. By processing the surface of used filling material and controlling the particle size, the filling material can be evenly dispersed into resin glue to obtain uniform glue dipped sheets, the toughness of sheets is improved, the obtained copper-clad plate can reach the environment protection requirements and does not contain any halogen, the contents of chlorine and bromine are low, the peeling strength is high, the characteristic of resisting tracking caused by electric leakage is excellent, and CTI>=600V.

Owner:SHANDONG JINBAO ELECTRONICS

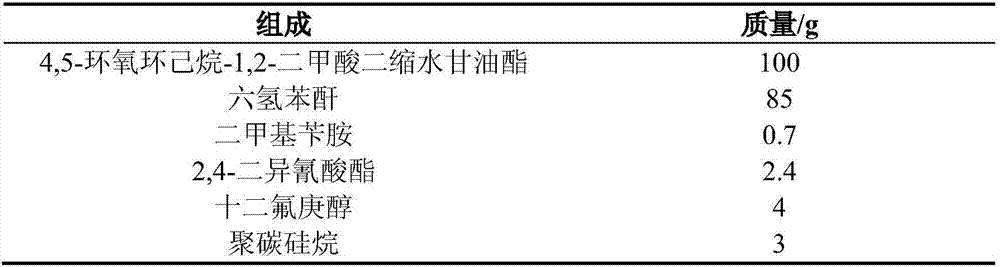

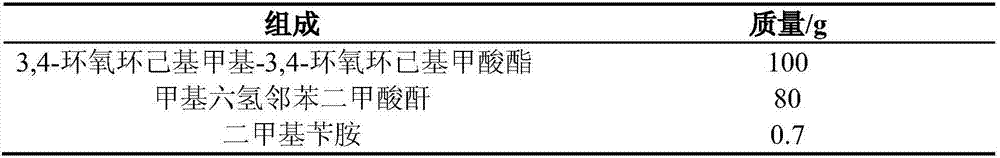

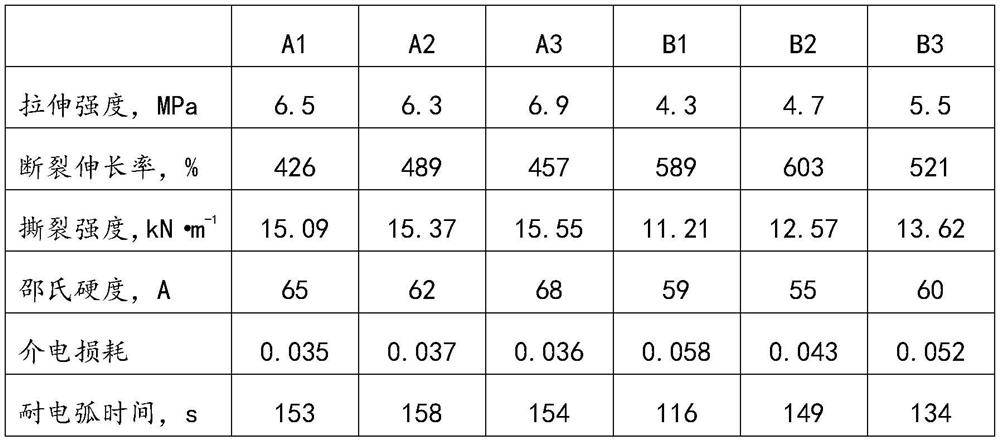

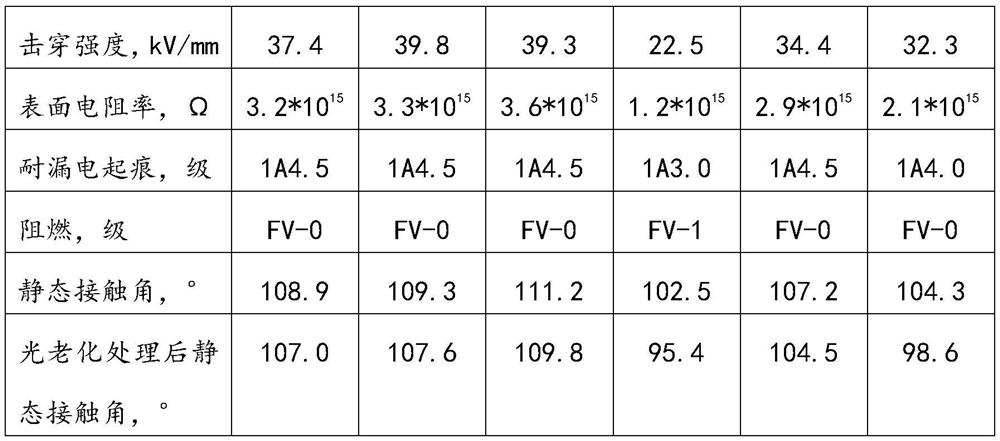

Hydrophobic electrical insulation epoxy resin composition

ActiveCN107418147ARealize joint modification of fluorine and siliconImprove hydrophobicityPlastic/resin/waxes insulatorsEpoxyHardness

The invention belongs to the technical field of electrical insulation materials, and specifically relates to a hydrophobic electrical insulation epoxy resin composition. By adding a fluorine-containing modifier and a silicon-containing modifier into raw materials to realize fluorine-silicon union modification on epoxy resin, the epoxy resin is endowed with excellent hydrophobicity and toughness, wherein low molecular weight silicon oil having the molecular weight not more than 998 is adopted as the silicon-containing modifier, so that a demixing phenomenon can be better inhibited while the toughness is improved; and a low molecular weight fluoride having the molecular weight not more than 850 is adopted as the fluorine-containing modifier, so that the hydrophobicity of the composition is greatly improved. Meanwhile, the hardness and the electric mark resistance of the composition are improved by filling a proper amount of inorganic filler, so that the epoxy resin composition has good hydrophobicity, electrical insulation property and mechanical properties at the same time, and can be used as an umbrella skirt material of insulators.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

Silicone rubber umbrella skirt for extra-high voltage composite insulator and preparation method thereof

The invention discloses a silicone rubber umbrella skirt for an extra-high voltage composite insulator and a preparation method thereof, and relates to the technical field of silicone rubber materials. According to the silicone rubber umbrella skirt for the extra-high voltage composite insulator, the silicone rubber umbrella skirt is prepared from the following raw materials in parts by weight: 100 parts of methyl vinyl phenyl silicone rubber raw rubber, 40-80 parts of an Mg-SiC compound, 50-70 parts of modified diatomite, 1.5-4 parts of a silane coupling agent, 3-5 parts of hydroxyl silicone oil, 4-7 parts of cyclic trisilazane, 5-8 parts of nano ZnO, 2-5 parts of titanium dioxide, 1.5-3 parts of a dispersing agent and 1-3 parts of a vulcanizing agent. The invention also discloses the preparation method of the silicone rubber umbrella skirt for the extra-high voltage composite insulator. The silicone rubber umbrella skirt has excellent electrical insulativity, flame retardance, hydrophobicity, high and low temperature resistance and mechanical strength, the pollution flashover resistance and aging resistance of the silicone rubber umbrella skirt are improved, the silicone rubber umbrella skirt is not easy to damage, and the service life of the composite insulator is prolonged.

Owner:醴陵市东方电瓷电器有限公司

Tracking-resistant polyethylene sheath material for power wire and preparation method thereof

InactiveCN103540000AExcellent tracking resistanceGood physical and mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesGas releaseMechanical property

The invention discloses a tracking-resistant polyethylene sheath material for a power wire and a preparation method thereof. The tracking-resistant polyethylene sheath material for the power wire is prepared from the following substances in parts by weight: 50-70 parts of high-density polyethylene, 30-40 parts of linear low-density polyethylene, 15-25 parts of ethylene-propylene-diene monomer, 3-6 parts of polytrifluoropropyl methylsiloxane, 10-15 parts of nano wollastonite, 20-25 parts of sediment white carbon black, 5-10 parts of nano-montmorillonite, 4-6 parts of ferrocene, 10-15 parts of magnesium hydroxide, 8-12 parts of methyl phenyl silicone oil, 2-3 parts of dibutyltin dilaurate, 3-5 parts of phosphoguanidine and 5-10 parts of borax. The sheath material is excellent in tracking resistance, so that the electric erosion phenomenon on the surface of the power wire in extra-high voltage can be solved; meanwhile, the sheath material is good in physical and mechanical properties, electrical insulation property, environmental stress crack resistance, ageing resistance and heat resistance, durable in use, long-term in operation in outdoor severe environment without failure, good in flame retardant effect, low in smoke during combusting without harmful gas release, free of environmental pollution, safe and environment-friendly.

Owner:天长市富达电子科技股份有限公司

Emulsion of bitumen in a colloidal clay and water slurry

InactiveUS6776833B2Convenient and efficient applicationEasy and efficient to manufactureBuilding insulationsBituminous coatingsSodium BentoniteBitumen emulsion

An emulsion for sealants, coatings and / or mastics including a bitumen and a slurry of water and substantially fully hydrated colloidal clay is disclosed. The preferred emulsions include bentonite and a bitumen in preferred ratios such that the composition has characteristics adapted to cold application processes. Such emulsions are also disclosed as capably emulsifying high melt bitumens. Furthermore, a method of preparing such emulsions is disclosed.

Owner:GARDNER ASPHALT CORP

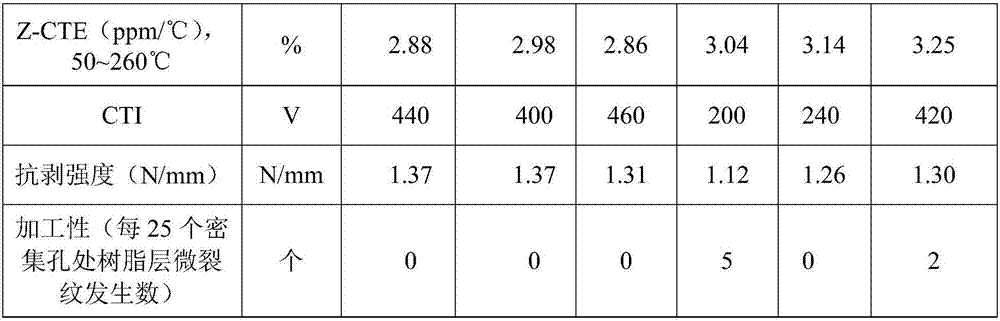

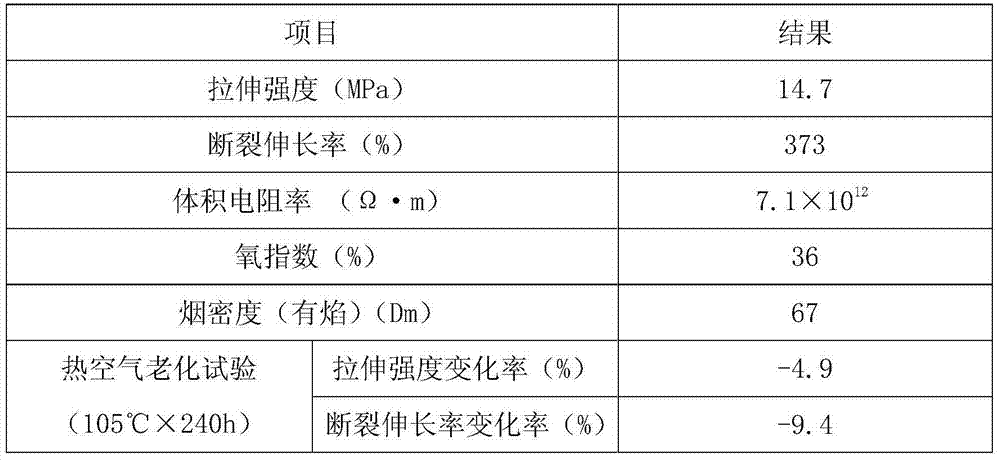

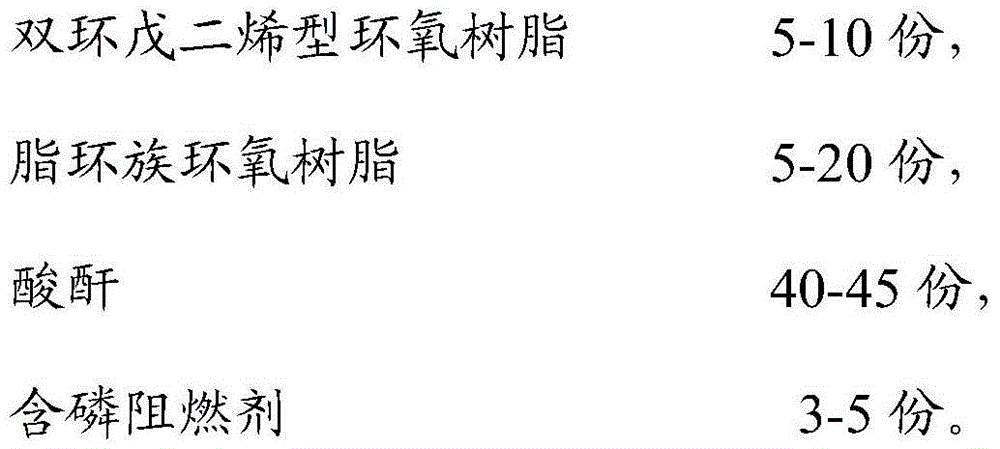

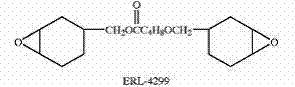

Halogen-free resin composition and copper-clad plate prepared by using composition

InactiveCN104479295AReduce processing stepsAvoid heat resistanceSynthetic resin layered productsMetal layered productsHeat resistanceCopper

The invention provides a halogen-free resin composition and a copper-clad plate prepared by using the composition. The halogen-free resin composition is prepared from the following components in parts by weight: 25-45 parts of phosphorus-containing epoxy resin, 5-10 parts of dicyclopentadiene epoxy resin, 5-20 parts of alicyclic epoxy resin, 40-45 parts of acid anhydride and 3-5 parts of a phosphorus-containing flame retardant. According to the halogen-free resin composition and the copper-clad plate prepared by using the composition disclosed by the invention, the halogen-free resin composition is used for solving problems from the angle of the resin structure; the common epoxy resin and the alicyclic epoxy resin as well as the dicyclopentadiene epoxy resin are matched for use, and cured through the acid anhydride, so that the CTI of the copper-clad plate reaches the requirements greater than 600V. Moreover, aluminum hydroxide filler is not needed to be added into the composition, so that the problem that the processing performance, the heat resistance and the alkali resistance of the copper-clad plate are lowered due to filler addition is avoided.

Owner:GUANGDONG SHENGYI SCI TECH

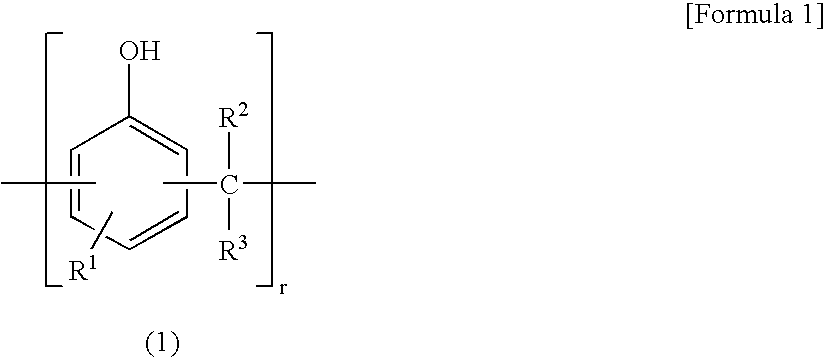

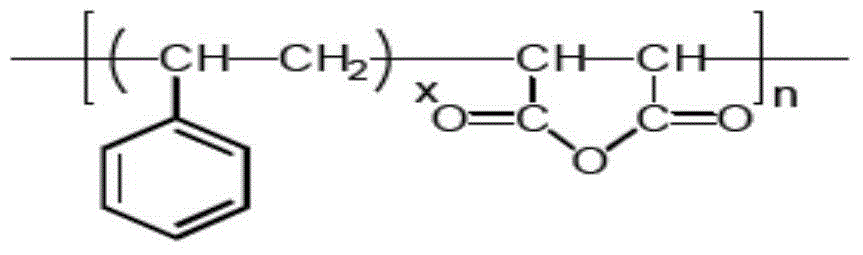

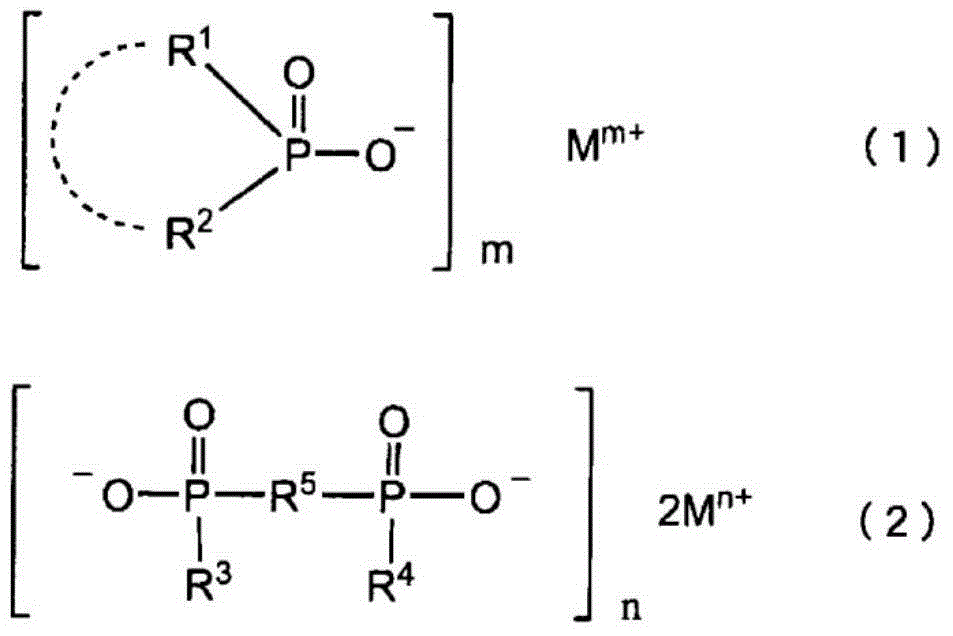

Flame-retardant thermoplastic polyester resin composition and molded article

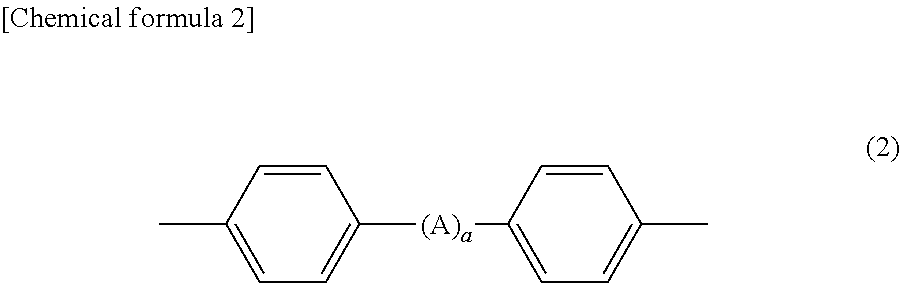

ActiveUS20150225564A1Improve balanceImprove tracking resistance performanceEster polymer adhesivesPhosphoric Acid EstersNitrogen

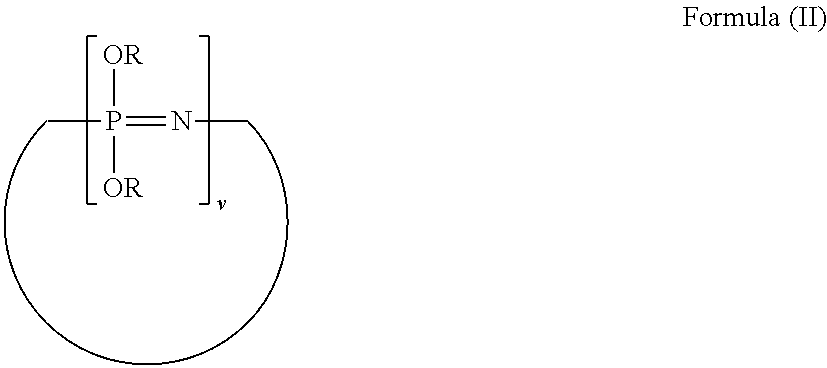

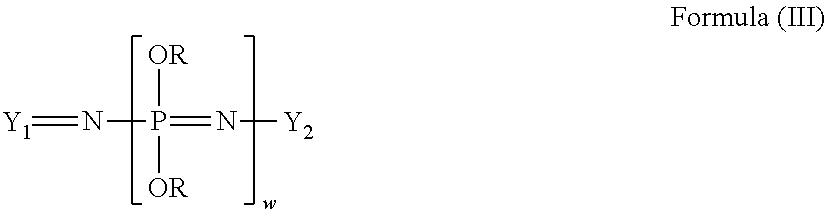

The present invention includes a flame-retardant thermoplastic polyester resin composition which provides a molded article having excellent tracking resistance and excellent mechanical characteristics, while maintaining high flame retardancy; and a molded article which is obtained by molding the flame-retardant thermoplastic polyester resin composition. A flame-retardant thermoplastic polyester resin composition of an embodiment of the present invention contains 1-70 parts by weight of two or more (C) phosphorus-containing flame retardants that are selected from the group consisting of (C-1) condensed phosphoric acid esters, (C-2) phosphazene compounds and (C-3) organic metal phosphinates and 1-90 parts by weight of (D) a nitrogen-containing flame retardant per 100 parts by weight of the total of 50-95 parts by weight of (A) a thermoplastic polyester resin and 5-50 parts by weight of (B) a methacrylic resin.

Owner:TORAY IND INC

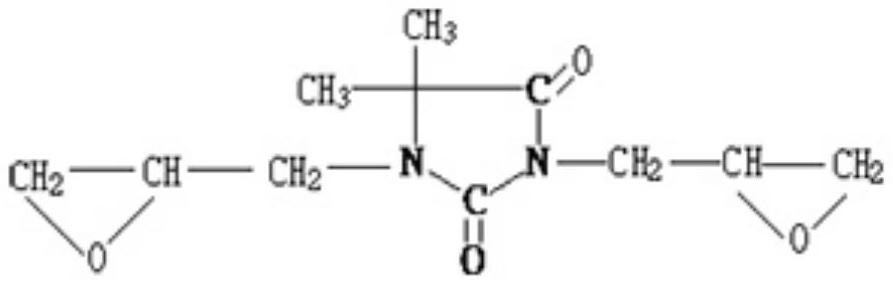

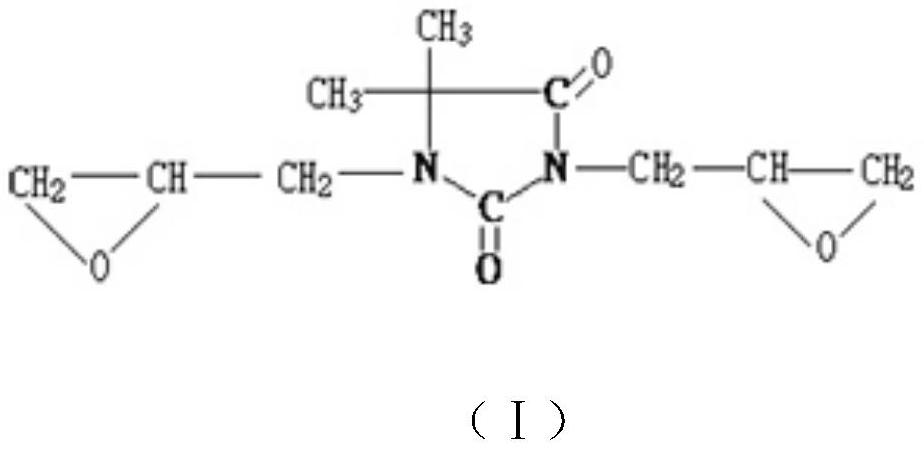

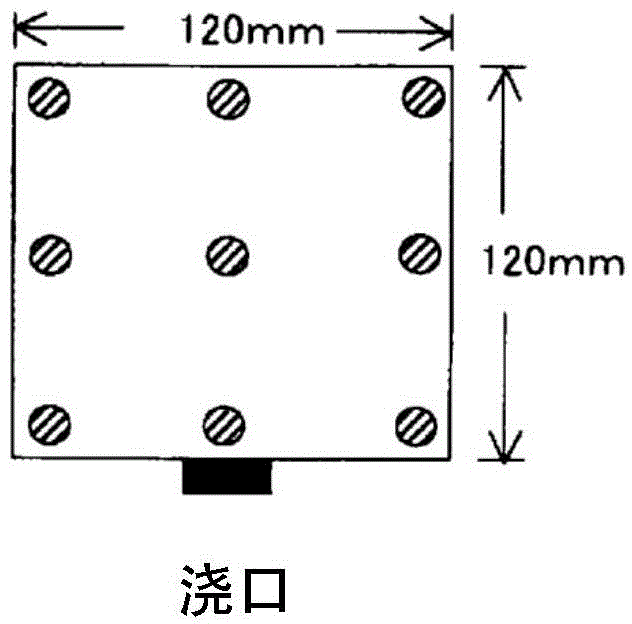

High-temperature-resistant and high-tracking-resistant rotating insulator and preparation method thereof

PendingCN112745637AHigh mechanical strength requirementsSolve the problem that the arc resistance of 180s or more cannot be met at the same timePlastic/resin/waxes insulatorsYarnFiber

The invention discloses a high-temperature-resistant and high-tracking-resistant rotating insulator and a preparation method thereof. The high-temperature-resistant and high-tracking-resistant rotating insulator is characterized in that the rotating insulator is a composite material prepared by curing and molding overlapped high-strength resin fiber prepreg at the temperature of 175-265 DEG C; the high-strength resin fiber prepreg is a fiber impregnated material which is formed by coating a high-strength resin adhesive on fiber yarns through a gluing machine and then baking the fiber yarns and is provided with a resin prepreg on the fiber yarns; the high-strength resin adhesive is prepared by mixing matrix epoxy resin, hydantoin epoxy resin, modified resin, a curing agent, filler, an accelerant and a solvent. According to the invention, the bending strength retention rate of the rotating insulator at the temperature of 200 DEG C is greater than or equal to 50%, the immersion resistance is greater than or equal to 106 Momega, PTI600V passes through the rotating insulator, and the arc resistance is greater than or equal to 180 seconds; and the insulator is suitable for being used as an insulation stress piece in large power transmission and transformation fields such as ultra-high voltage electrical appliances and high-voltage electrical appliances.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Enhanced composite insulator umbrella skirt sheath

InactiveCN103077786AExcellent tracking resistanceImprove mechanical propertiesInsulatorsComposite insulatorsAdditive ingredient

The invention provides an enhanced composite insulator umbrella skirt sheath, which consists of the following ingredients in parts by mass: 95 to 105 parts of methyl vinyl silicone rubber, 4 to 6 parts of ferric oxide, 4 to 6 parts of hydroxy silicone oil, 1.5 to 2.5 parts of sulfurizing agents, 58 to 77 parts of ceramic powder, 62 to 83 parts of aluminum hydroxide and 1 to 3 parts of coloring agents. The ceramic powder is proportionally added in the umbrella skirt sheath, and the ceramic powder is obtained through crushing the recovered waste and abandoned ceramic insulator ceramic bodies and processing the recovered waste and abandoned ceramic insulator ceramic bodies into powder. The ceramic powder is added into the umbrella skirt sheath to be used as reinforcing agents for totally replacing white carbon black and partially replacing aluminum hydroxide, and the mechanical intensity and the electric performance of the silicon rubber can be improved. The waste and abandoned ceramic insulator ceramic bodies are effectively utilized to be used as raw materials for producing the umbrella skirt sheath, the reasonable cyclic utilization of the resources are realized, and good economic benefits and environment benefits are realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

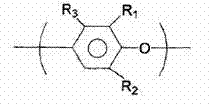

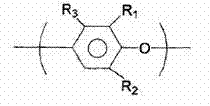

Tracking-resistant polyphenylether resin composition

The invention discloses a tracking-resistant polyphenylether resin composition which comprises the following components in percentage by weight: 40-90% of polyphenylether, 1-50% of styrene resin, 0.1-5% of epoxy compound, 3-20% of flame retardant and 0.1-10% of other functional additives. The polyphenylether resin composition disclosed by the invention has the characteristics of excellent impact property, high rigidity, high tracking resistance, simple preparation technique, low price and wide practical applicability, and is widely used in the industries of electric appliances, office supplies, automobile accessories and the like.

Owner:KINGFA SCI & TECH CO LTD +1

High-hydrophobicity fluorocarbon composition as well as preparation method and application thereof

PendingCN111944364AImprove hydrophobicityGood practical application valueFireproof paintsAntifouling/underwater paintsFluorocarbon ResinsFlame resistance

The invention provides a high-hydrophobicity fluorocarbon composition as well as a preparation method and application thereof, and belongs to the technical field of polymer insulating materials. The high-hydrophobicity fluorocarbon composition is prepared from the following raw materials in parts by weight: 60 parts of fluorocarbon resin; 10 to 25 parts of a reinforcing filler; 50 to 100 parts ofan inorganic flame retardant; 0.2-1 part of a dispersing agent; 12-20 parts of curing agent. The composition can resist electric corrosion and high-temperature damage caused by the electric corrosion,has high hydrophobicity, excellent tracking resistance and flame retardance compared with common silicone rubber coating, and can expand the application field of fluorocarbon coating in the aspect ofelectrical equipment insulation, so that the high-hydrophobicity fluorocarbon composition has a good practical application value.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Polycarbonate composition

Polycarbonate blends with a combination of high thin wall flame retardance, CTI Class 2 tracking resistance, and high dimensional stability are disclosed. The blends are a combination of a polycarbonate polymer, a polycarbonate-polysiloxane co polymer, and a phosphazene flame retardant. The polycarbonate blends may be used in various applications.

Owner:SABIC GLOBAL TECH BV

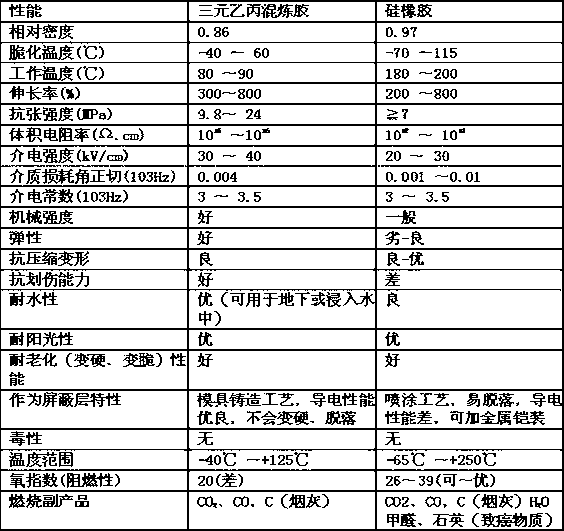

EPDM (Ethylene-Propylene-Diene Monomer) compound rubber

InactiveCN103214746AImprove insulation performanceImprove machineryRubber insulatorsPlasticizerEPDM rubber

The invention relates to EPDM (Ethylene-Propylene-Diene Monomer) compound rubber which is characterized by comprising the following raw materials: EPDM rubber, calcined argil, stearic acid, anti-aging agent, talcum powder, zinc oxide, anti-aging agent, vulcanizing agent, accelerating agent, plasticizer and high-pressure cable oil. The EPDM compound rubber disclosed by the invention has excellent ozone resistance, thermal-ageing resistance, weather resistance, electric insulation property and corona resistance and is particularly can be used for manufacturing high-pressure and extra-high-pressure electric insulation products.

Owner:吉林市吉福新材料有限责任公司

Preparation method of additive applied in addition type liquid silicone rubber

The invention discloses a preparation method of an additive applied in an addition type liquid silicone rubber. The additive is an organic matter or organic mixture particle which is sealed by polymers and contains one or more of N, P, and S. When the additive is applied in the addition type liquid silicone rubber, a platinum catalyst can not get poisoned. The additive can improve the flame resistance, heat conduction, high temperature resistance, electrical trace resistance, low compression set, static electricity resistance and other performances of the addition type liquid silicone rubber. The sealing process improves the compatibility between the additive and the rubber compound, and is beneficial to the uniform dispersing of the additive in the rubber compound and the improvement of the performances of the material.

Owner:东莞市贝特利新材料有限公司

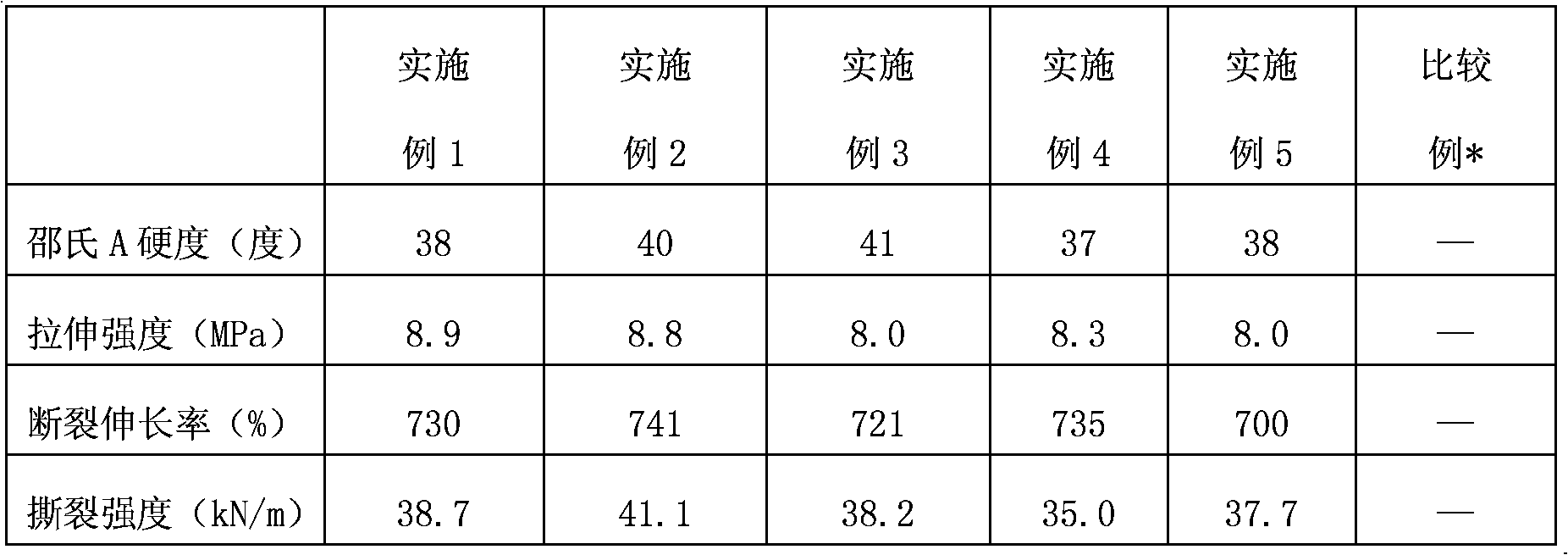

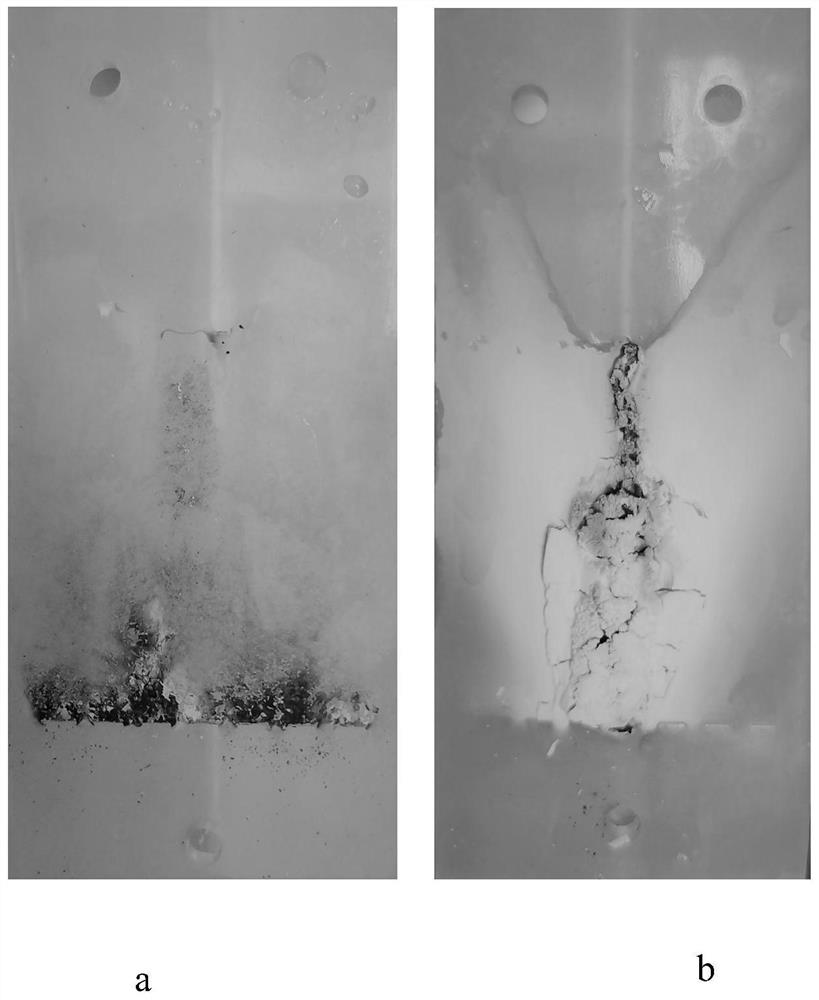

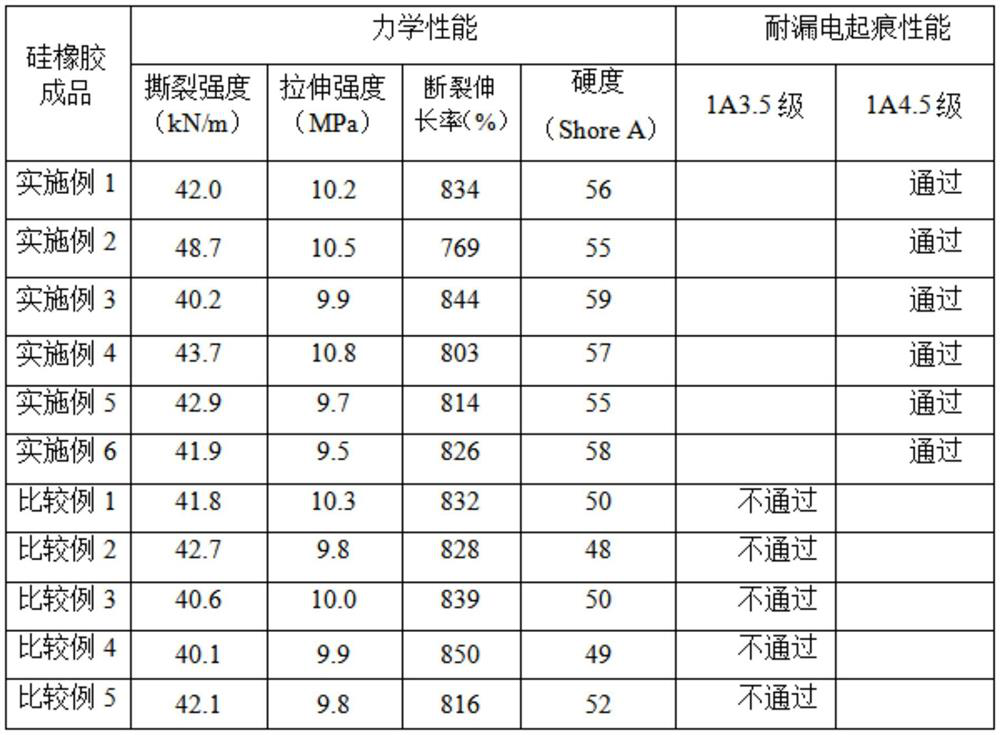

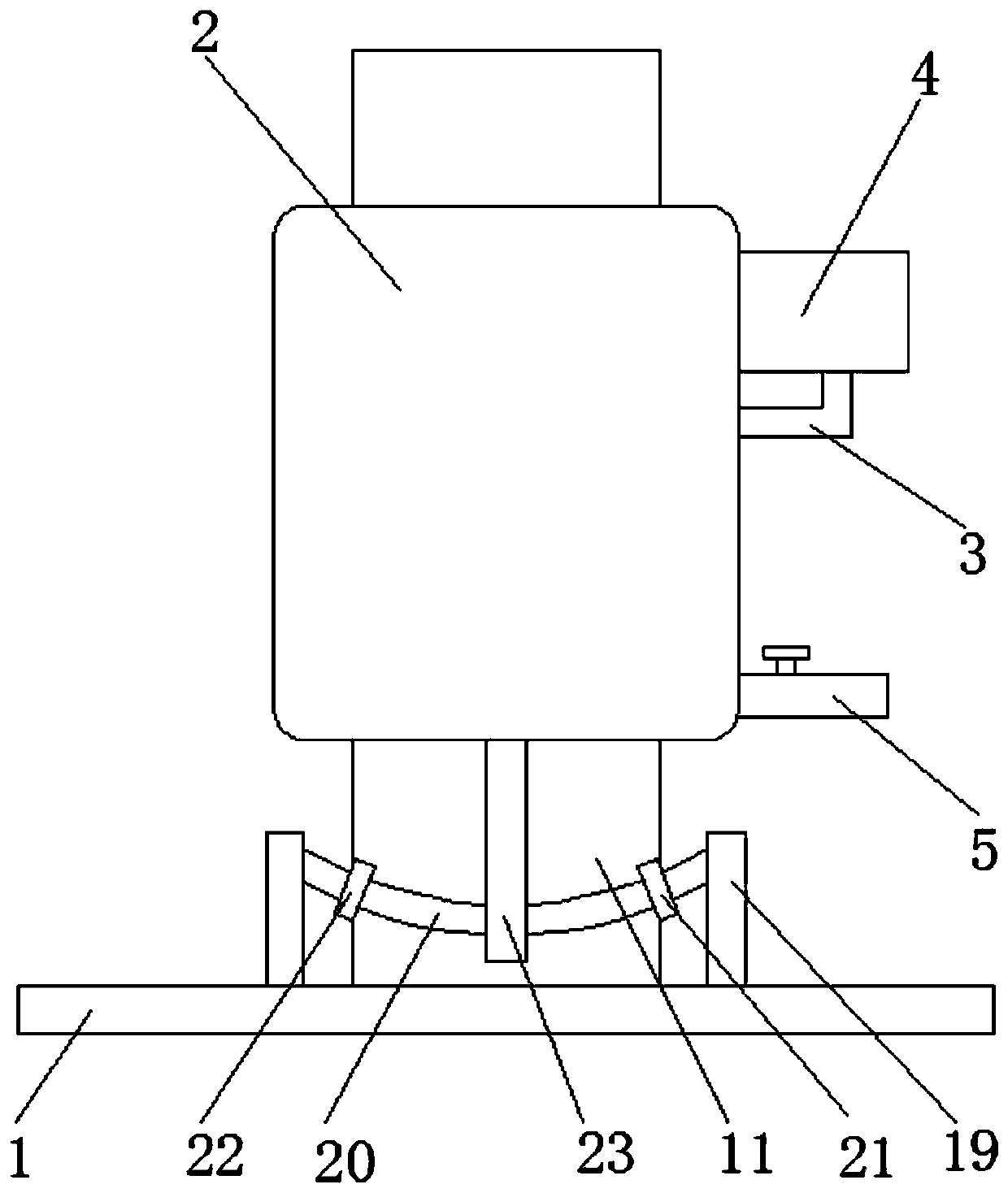

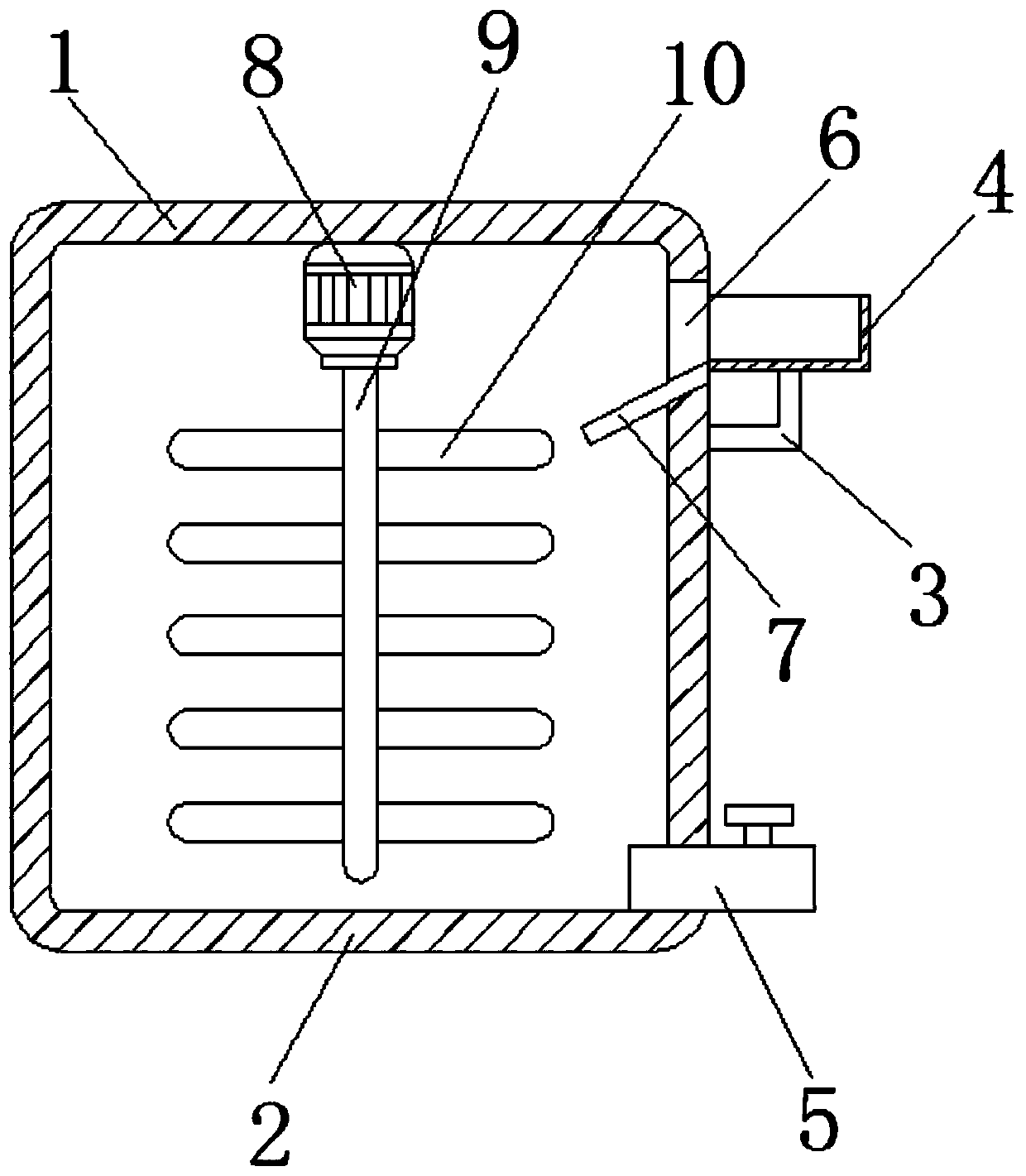

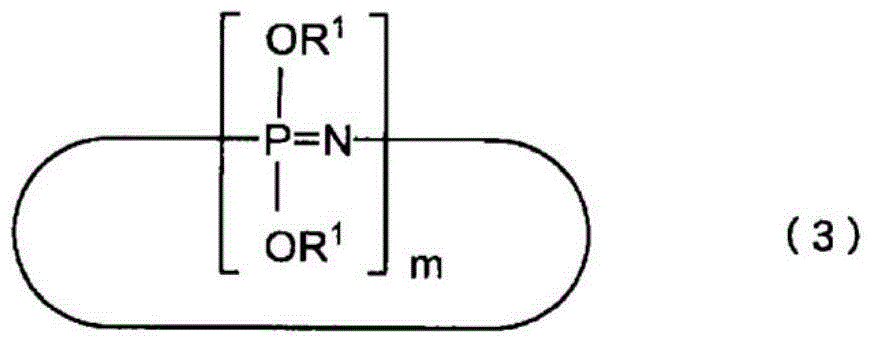

Tracking-resistant silicone rubber and preparation method and application thereof

InactiveCN112251029AOvercome the disadvantages of poor mechanical propertiesExcellent tracking resistancePolymer sciencePlatinum complex

The invention belongs to the technical field of silicone rubber, and discloses a tracking-resistant silicone rubber, and a preparation method and application thereof, the tracking-resistant silicone rubber is mainly prepared from the following raw materials: polysilazane, a platinum complex, basic silicone rubber, white carbon black, silicone oil and a vulcanizing agent. According to the invention, a small amount of polysilazane and platinum complex is added, and the structural formula of polysilazane is as follows: (R1R2Si-NH) x (R3R4Si-NH) y, x and y are both integers of 0-300, and x and y are not 0 at the same time; R1, R2, R3 and R4 independently represent any one of H, CH3 and CmH2m + 1 respectively, and m is an integer between 1-7; and when the mass ratio of platinum atoms in the total formula raw materials is 5-15 ppm, the tracking resistance of the obtained silicone rubber finished product can reach 1A 4.5 grade, the system compatibility is good, the mechanical property is excellent, and the defect of poor mechanical property of the current tracking-resistant silicone rubber is overcome. The preparation method is simple, raw materials are easy to obtain, the application prospect is good, and thetracking-resistant silicone rubber is suitable for being applied to the field of high-voltage insulation.

Owner:FOSHAN UNIVERSITY

Production formula and production process of silicone rubber

The invention discloses a production formula and a production process of silicone rubber, and belongs to the technical field of silicone rubber production. The formula comprises the following raw materials: silicone rubber, magnesium hydroxide, an A-171 silane coupling agent, simethicone, fumed silica, an A-151 silane coupling agent, an activating agent and vinyl silicone oil. The activating agentis a magnesium oxide activating agent, the magnesium oxide activating agent can improve the vulcanization speed of the rubber material and can improve the strength and the hardness of the vulcanizedrubber. The weight ratio of the raw materials are as follows in parts by weight: 100 parts of silicon rubber, 90-115 parts of magnesium hydroxide, 1-6 parts of the A-171 silane coupling agent, 3-6 parts of simethicone, 28-35 parts of fumed silica, 1-6 parts of A-151 the silane coupling agent, 4-10 parts of the activating agent and 1-6 parts of vinyl silicone oil. The prepared silicone rubber has the advantages of high temperature resistance, ozone resistance, weather resistance, electrical properties, favorable hydrophobicity, simple production technique and high efficiency, and is convenientfor adding raw materials and taking out the silicone rubber.

Owner:张国洋

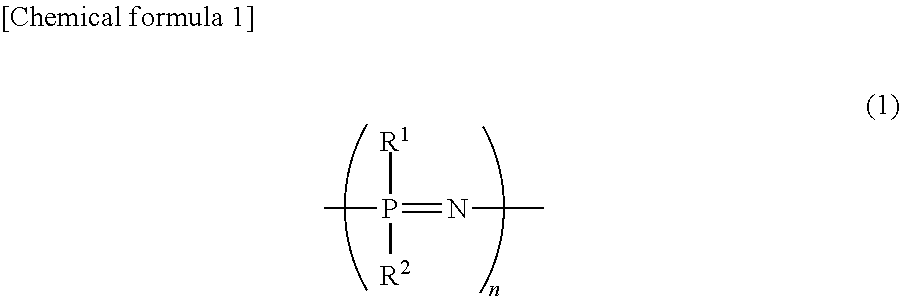

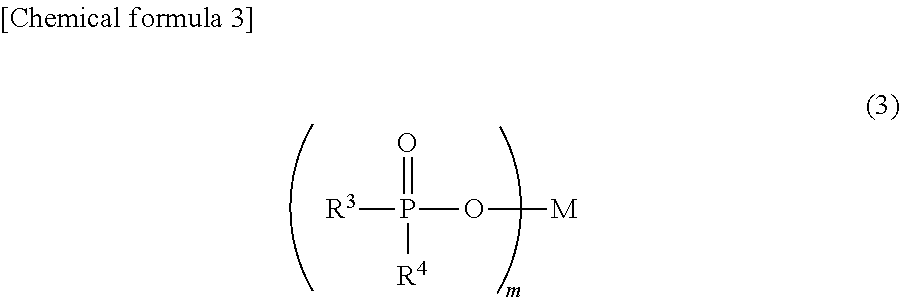

Flame-retardant polybutylene terephthalate resin composition, and molded product thereof

ActiveCN104812838AImprove ignition performanceImprove flame retardant performancePolytetramethylene terephthalateCombustion

Provided are: a flame-retardant polybutylene terephthalate resin composition which exhibits excellent flame retardancy, glow-wire properties (GWIT), tracking resistance and bleed resistance in spite of a fact that a polybutylene terephthalate resin is used as a sole resin component; and a molded product of the resin composition. A flame-retardant resin composition comprising (A) a polybutylene terephthalate resin, (B) a phosphinic acid salt, (C) a phosphazene compound and (D) a nitrogenated cyclic compound, said resin composition being characterized in that the level of the flame retardancy as measured in accordance with a UL94 combustion test is V-0, the glow-wire ignition temperature (GWIT) as measured in accordance with IEC60695-2-13 standard is 775˚C or higher, the comparative tracking index (CTI) as measured in accordance with IEC60112 standard is 400 V or more, and bleed out does not occur when the resin composition is treated at 110˚C for 20 hours.

Owner:POLYPLASTICS CO LTD

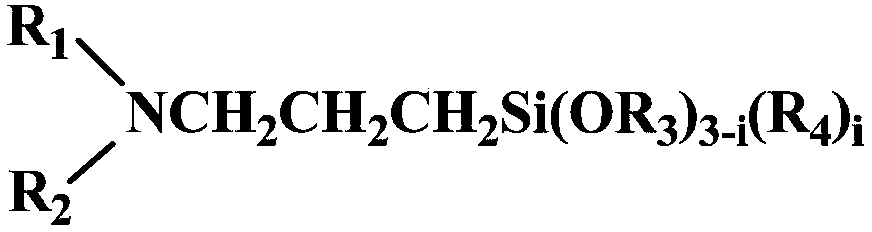

Supported silicon rubber electric-leakage-resistance tracking agent and preparation method and application thereof

ActiveCN109096542AImprove mechanical propertiesImprove synergistic catalytic activitySilanesSilicon rubber

The invention discloses a supported silicon rubber electric-leakage-resistance tracking agent and a preparation method and application thereof. The method comprises the steps that firstly, a silane coupling agent is prepared for modifying white carbon black, then a platinum compound is added, and finally the supported silicon rubber electric-leakage-resistance tracking agent is obtained through washing and vacuum drying. Platinum and the nitrogenous silane coupling agent are subjected to complexation and supported on the white carbon black, the cooperative catalytic activity of platinum and nitrogenous silane can be effectively improved, and accordingly platinum and the nitrogenous silane coupling agent are evenly and stably dispersed in silicon rubber; through complexation of platinum andthe nitrogenous silane coupling agent, the cooperative catalytic effect of platinum and the nitrogenous silane coupling agent is improved, white carbon black is used as common reinforcement filler ofsilicone rubber, a silicone rubber molecular chain is adsorbed on the surface of white carbon black through a hydrogen-bond effect, the mechanical property of silicone rubber is improved, a cross-linking reaction, for catalyzing the silicone rubber molecular chain, of platinum and the nitrogenous silane coupling agent under the effect of arc discharging is also conveniently conducted, a compact protection layer is formed, and arc erosion is avoided. According to the supported silicon rubber electric-leakage-resistance tracking agent, the electric-leakage-resistance tracking performance of silicone rubber can be obviously improved, the raw materials are low in price, and the agent is easy to prepare and can be applied to industrial production.

Owner:FOSHAN UNIVERSITY

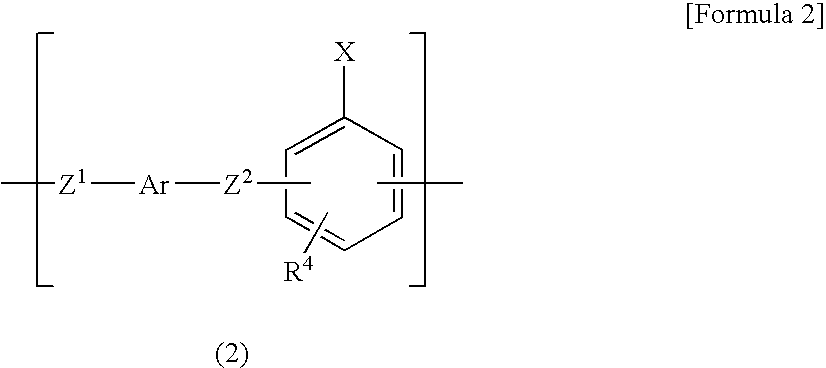

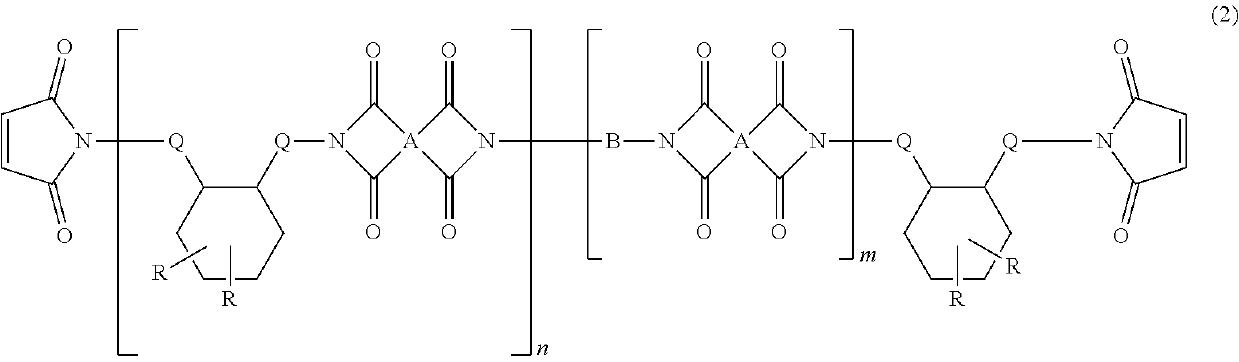

Heat-curable resin composition for semiconductor encapsulation and semiconductor device

ActiveUS10793712B2Excellent tracking resistanceExcellent continuous formabilitySemiconductor/solid-state device detailsSolid-state devicesEpoxyImide

Provided are a heat-curable resin composition for semiconductor encapsulation that is capable of yielding a cured product superior in tracking resistance and dielectric property, and has a favorable continuous moldability; and a semiconductor device encapsulated by a cured product of such resin composition. The heat-curable resin composition for semiconductor encapsulation contains:(A) an epoxy resin other than a silicone-modified epoxy resin, being solid at 25° C.;(B) a silicone-modified epoxy resin;(C) a cyclic imide compound having, in one molecule, at least one dimer acid backbone, at least one linear alkylene group having not less than 6 carbon atoms, at least one alkyl group having not less than 6 carbon atoms, and at least two cyclic imide groups;(D) an organic filler; and(E) an anionic curing accelerator.

Owner:SHIN ETSU CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com