Tracking-resistant polyethylene sheath material for power wire and preparation method thereof

A technology of polyethylene sheath and electric tracking resistance, which is applied in the direction of circuits, electrical components, insulating cables, etc., can solve the problem of harsh electric corrosion resistance of the sheath, achieve good physical and mechanical properties, do not pollute the environment, and flame retardant effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

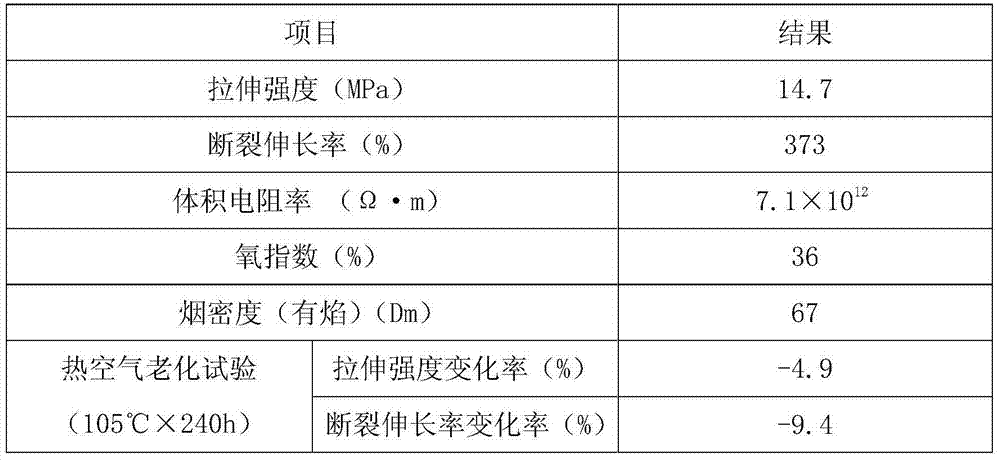

Examples

Embodiment Construction

[0012] A tracking-resistant polyethylene sheath material for power cords, made of the following raw materials in weight (kg): high-density polyethylene 60, linear low-density polyethylene 40, EPDM rubber 20, polytrifluoropropyl Methyl siloxane 4, nano wollastonite 15, precipitated silica 20, nano montmorillonite 8, ferrocene 5, magnesium hydroxide 12, methyl phenyl silicone oil 10, dibutyltin dilaurate 2, phosphoric acid Guanidine 4, Borax 8, Vinyl Tris(β-methoxyethoxy)silane 1.5, N-(β-Aminoethyl)-γ-aminopropyltrimethoxysilane 0.5, Processing Aid PPA2, Ortho-Phenyl Dimethoxyethyl diformate 8, paraffin wax 4, antioxidant 10761, composite filler 5;

[0013] The preparation method of the composite filler is as follows: a. Take the following raw materials by weight (kg): pyrophyllite 10, diopside 8, opalite 6, N-2-(aminoethyl)-3-aminopropyltrimethoxy Silane 1.5, calcium lignosulfonate 2, sodium silicate 4, tourmaline slag 5, nano-diamond 4, germanium stone powder 3, sodium steara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com