Tracking-resistant silicone rubber and preparation method and application thereof

A technology of tracking resistance and silicone rubber, which is applied in the field of silicone rubber, can solve the problems of damage to the mechanical properties of silicone rubber, poor compatibility of silicone rubber, and the performance of tracking resistance of silicone rubber cannot meet the requirements of power systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

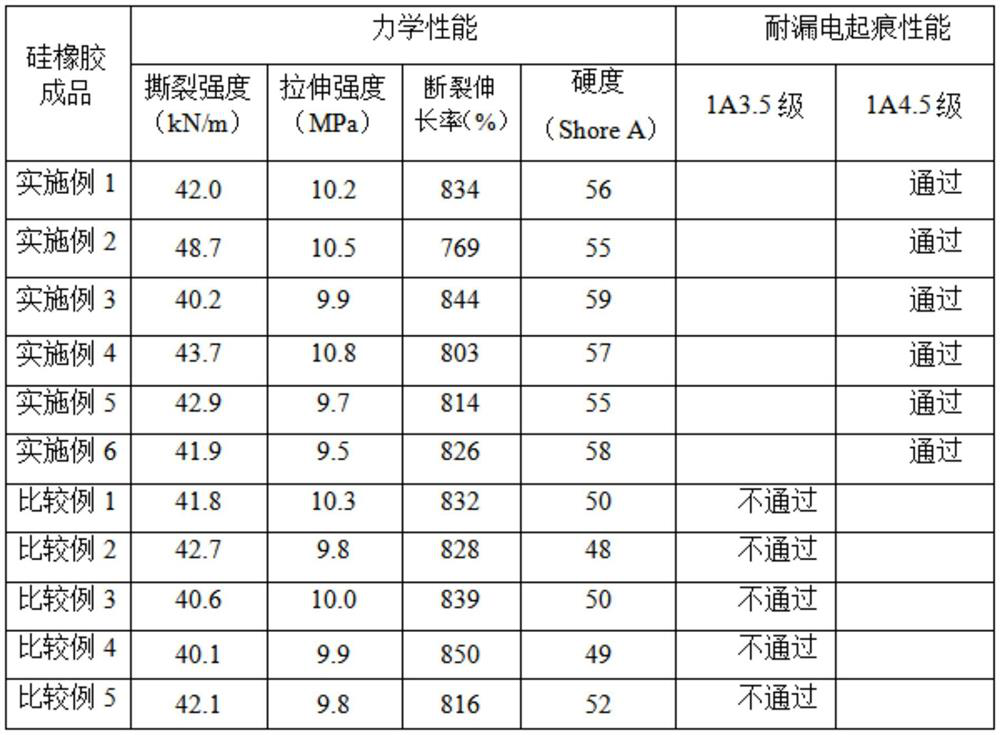

[0023] Example 1 Preparation of anti-tracking silicone rubber

[0024] 90 parts of methyl vinyl silicone rubber (molecular weight 560,000) of 0.07mol% vinyl content, 10 parts of methyl vinyl silicone rubber (molecular weight 600,000) of 3mol% vinyl content, 40 parts of fumed silica (compared to Surface area 360m 2 / g), 8 parts of hydroxyl silicone oil (hydroxyl content 6wt%) were mixed in a kneader, and kneaded at room temperature for 4h. Then heat to 150°C and continue kneading for 2h, then vacuum knead for 1h, and cool to room temperature to obtain a silicone rubber base rubber.

[0025] Add the above-mentioned base glue on the open mill by adding 1.5 parts of polysilazane, 0.8 parts of olefin siloxane complex of chloroplatinic acid (wherein, the mass ratio of platinum atoms in the total formula raw material of anti-tracking silicone rubber 10ppm) and 2 parts of dicumyl peroxide, after mixing evenly, go out the sheet. Vulcanize at 165°C for 15 minutes, and then vulcanize ...

Embodiment 2

[0027] Example 2 Preparation of anti-tracking silicone rubber

[0028] 90 parts of methyl vinyl silicone rubber (molecular weight 560,000) of 0.07mol% vinyl content, 10 parts of methyl vinyl silicone rubber (molecular weight 600,000) of 3mol% vinyl content, 40 parts of fumed silica (compared to Surface area 360m 2 / g), 8 parts of hydroxyl silicone oil (hydroxyl content 6wt%) were mixed in a kneader, and kneaded at room temperature for 4h. Then heat to 150°C and continue kneading for 2h, then vacuum knead for 1h, and cool to room temperature to obtain a silicone rubber base rubber.

[0029] Add the above-mentioned base glue on the open mill by adding 1.5 parts of polysilazane, 0.8 parts of olefin siloxane complex of chloroplatinic acid (wherein, the mass ratio of platinum atoms in the total formula raw material of anti-tracking silicone rubber 10ppm) and 2 parts of dicumyl peroxide, after mixing evenly, go out the sheet. Vulcanize at 165°C for 15 minutes, and then vulcanize ...

Embodiment 3

[0031] Example 3 Preparation of anti-tracking silicone rubber

[0032] 50 parts of 0.06 mol% vinyl content (molecular weight 600,000), 50 parts of methyl vinyl silicone rubber with 0.25 mol% vinyl content (molecular weight 600,000), 40 parts of fumed white carbon black (specific surface area 260m 2 / g), 6 parts of hydroxyl silicone oil (hydroxyl content 6wt%) and 0.6 parts of hydrogen-containing silicone oil (hydrogen content 1.2wt%) were mixed in a kneader, and kneaded at room temperature for 4h. Then heat to 150°C and continue kneading for 2h, then vacuum knead for 1h, and cool to room temperature to obtain a silicone rubber base rubber.

[0033] Add 2.2 parts of polysilazane and 0.2 parts of isopropanol solution of chloroplatinic acid to the above-mentioned base rubber on the open mill (wherein, the mass ratio of platinum atoms in the total formula raw material of anti-tracking silicone rubber is 10ppm) And 2 parts of dicumyl peroxide, after kneading evenly, go out sheet. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com