Flame-retardant polybutylene terephthalate resin composition, and molded product thereof

A technology of polybutylene terephthalate and resin composition, which is applied in the field of flame-retardant polybutylene terephthalate resin composition, and can solve the problem that the flame retardancy of nitrogen-containing cyclic compounds is not so high , characteristic influence and other issues, to achieve the effects of excellent tracking resistance and excellent migration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~17、 comparative example 1~12

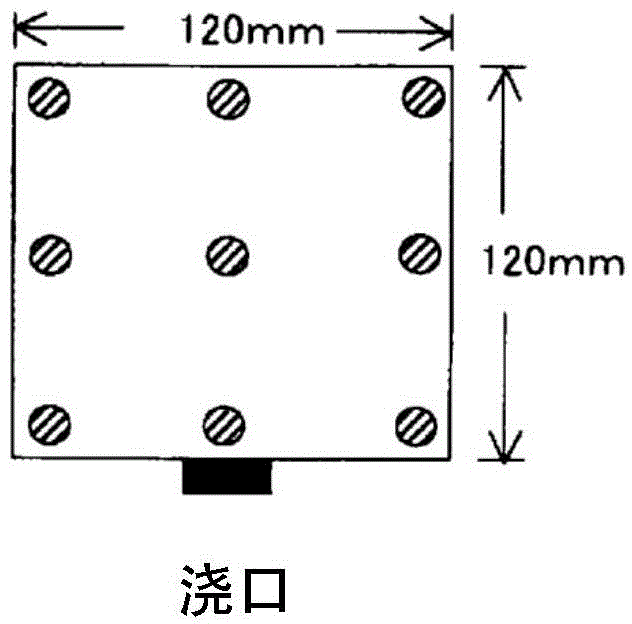

[0166] In each example and comparative example, among PBT resins, phosphinates, phosphazene compounds, nitrogen-containing cyclic compounds, alloy resins, brominated flame retardants, anti-dripping agents and inorganic fillers, the following table 1 It was blended with the components and parts (parts by mass) shown in Table 2, and melt-kneaded at 260°C using a twin-screw extruder with a 30 mmφ screw (manufactured by Nippon Steel Co., Ltd.) to obtain granular flame retardancy. PBT resin composition.

[0167] In addition, each said component is as follows specifically.

[0168] PBT resin: manufactured by Win-tech Polymer Co., Ltd., Duranex (registered trademark), intrinsic viscosity 0.88 dL / g

[0169] Alloy resin (PC): manufactured by Teijin Chemical Co., Ltd., Panlite L-1225WP

[0170] Alloy resin (PET): manufactured by Teijin Fiber Co., Ltd., TRF

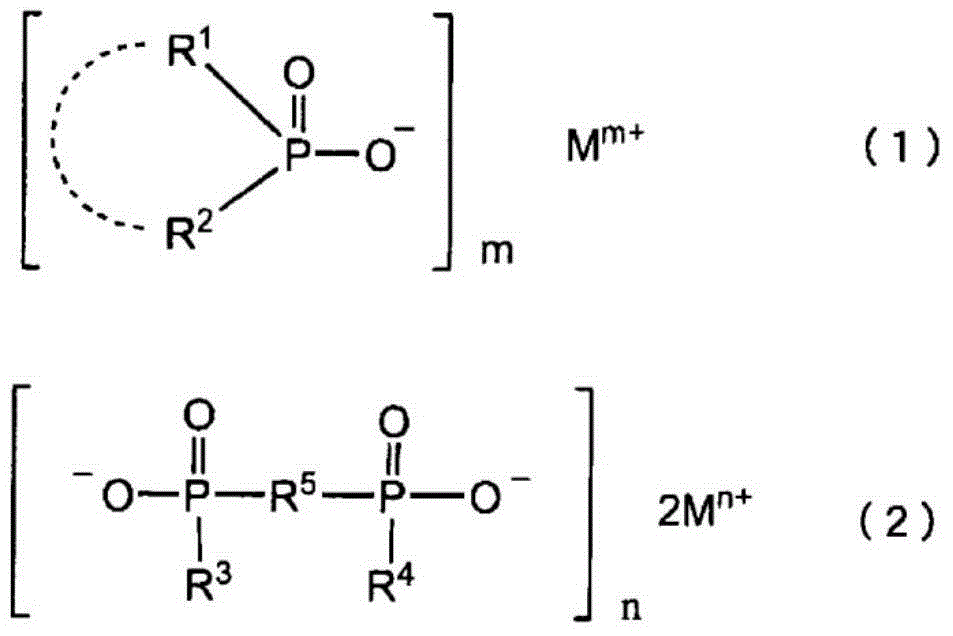

[0171] Phosphinate: Clariant (Japan) Co., Ltd., EXOLITE OP1240

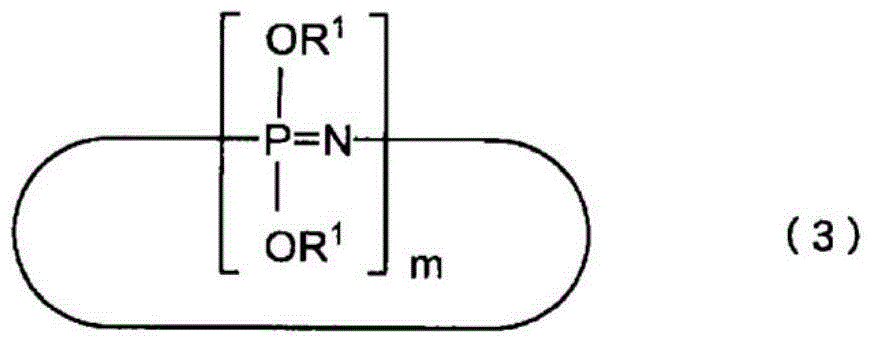

[0172] Phosphazene compound: Rabitle FP-110 manufactured by F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com