Production formula and production process of silicone rubber

A technology of production formula and production process, applied in the field of silicone rubber production, can solve the problems of poor compatibility between aluminum hydroxide and silicone rubber, troublesome addition of raw materials to take out silicone rubber, and reducing the hydrophobicity of composite insulators, so as to improve tear resistance. The effect of improving water repellency and preventing excessive swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

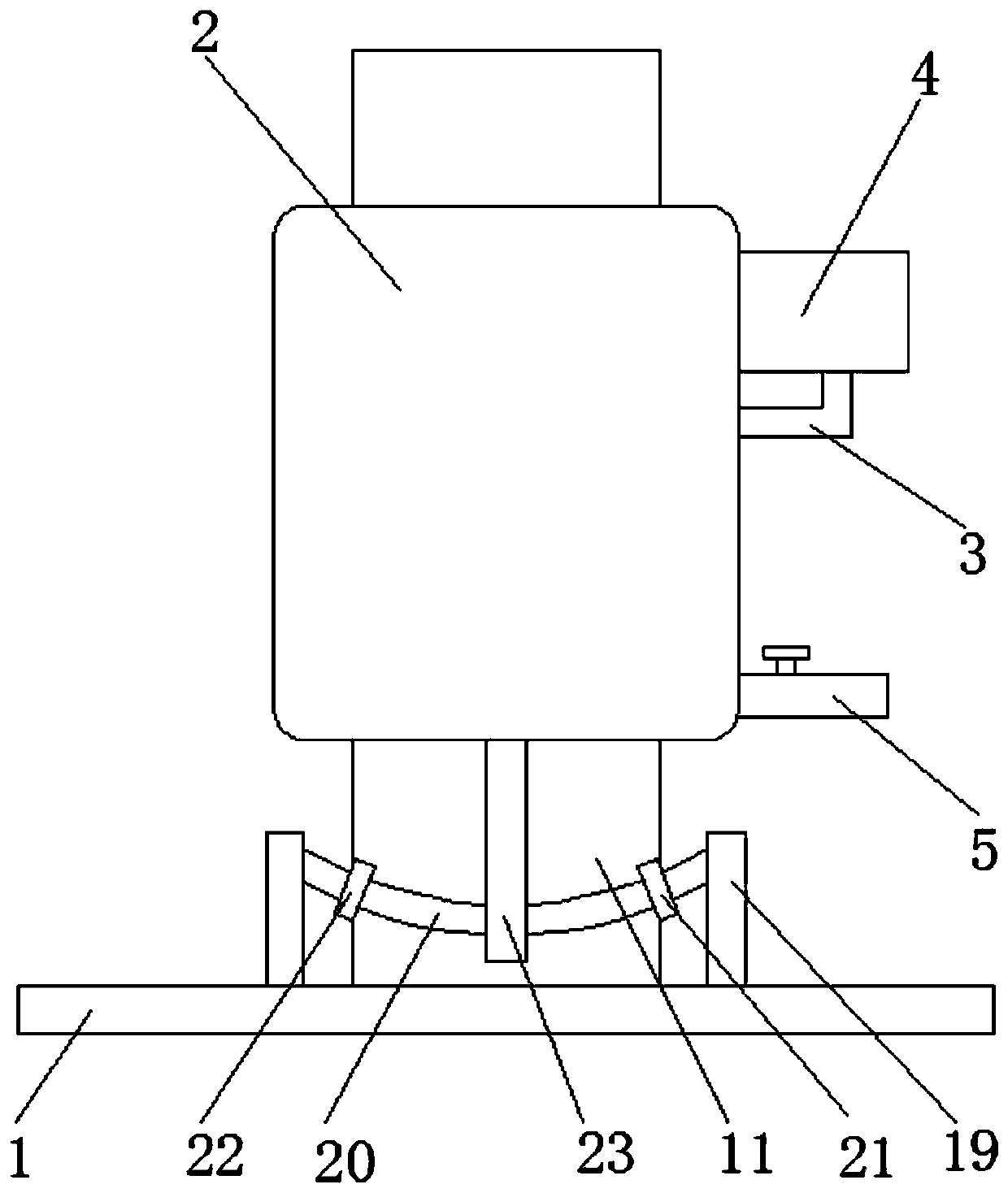

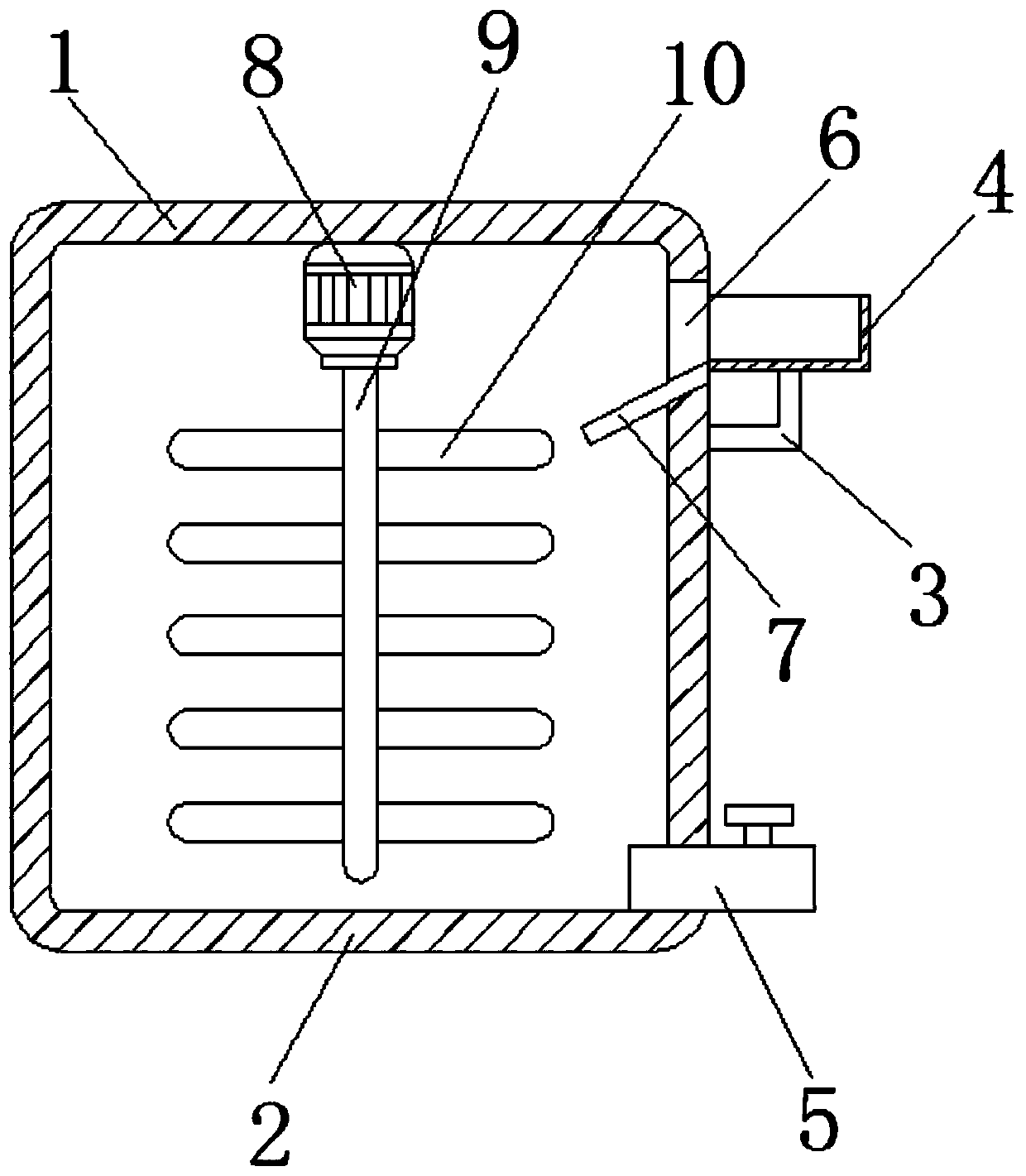

Image

Examples

Embodiment 1

[0044] A production formula for silicone rubber, including the following raw materials: silicone rubber, magnesium hydroxide, A-171 silane coupling agent, dimethyl silicone oil, fumed silica, A-151 silane coupling agent, activator and vinyl Silicone oil, magnesium hydroxide is used in the raw material instead of aluminum hydroxide. Aluminum hydroxide is one of the earliest inorganic flame retardants. As a flame retardant, aluminum hydroxide has good stability, non-toxicity, no corrosive gas, and flame retardant Compared with aluminum hydroxide, magnesium hydroxide has the above advantages of aluminum hydroxide, and its thermal stability and smoke suppression performance are significantly better than aluminum hydroxide; raw materials The weight ratio is: 100 parts of silicone rubber, 90-115 parts of magnesium hydroxide, 1-6 parts of A-171 silane coupling agent, 3-6 parts of dimethyl silicone oil, 28-35 parts of fumed silica, 1 ~6 parts of A-151 silane coupling agent, 4~10 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com