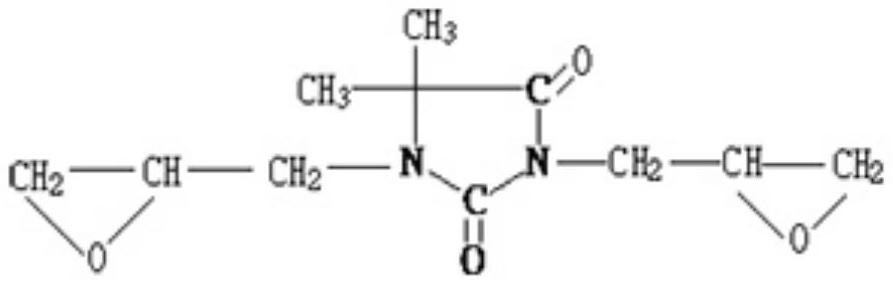

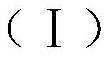

High-temperature-resistant and high-tracking-resistant rotating insulator and preparation method thereof

A technology for insulators and electric tracking resistance, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., to achieve excellent temperature resistance, improve tracking resistance and arc resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0047] Add 7.5 parts of bisphenol A type epoxy resin, 9 parts of hydantoin epoxy resin, and 5.5 parts of naphthalene type epoxy resin into the glue tank respectively, stir at 55°C for 7 hours, add 7 parts of nano talcum powder, Stir at ℃ for 1 hour, add 4 parts of 4,4-diaminodiphenylsulfone, stir at 75℃ for 0.75 hours, then add 23 parts of acetone, 0.01 part of accelerator 2-methylimidazole, continue to stir at 65℃ for 0.35 After making it fully dispersed evenly, take a sample, test the molding time of the glue solution (210°C hot plate) with a knife method for 514 seconds, and the glue solution is prepared.

Embodiment 1-2

[0049] Add 5.5 parts of o-cresol type novolac epoxy resin, 8.3 parts of hydantoin epoxy resin, and 7 parts of triphenylmethane type epoxy resin into the compounding tank respectively, stir at 55°C for 7 hours, and add 11 parts of nano talcum powder part, stirred at 50°C for 1 hour, added 2 parts of 4,4-diaminodiphenylsulfone, stirred at 75°C for 0.75 hour, then added 20 parts of butanone, accelerator 2-ethyl-4-methylimidazole 0.012 parts, continue to stir at 65°C for 0.35 hours to fully disperse evenly, then take a sample, and test the molding time of the glue with a knife method (210°C hot plate) for 484 seconds, and the glue is ready.

Embodiment 1-3

[0051] Add 11 parts of phenol-type novolac epoxy resin, 13 parts of hydantoin epoxy resin, and 9 parts of naphthol-type epoxy resin into the compounding tank, stir at 55°C for 7 hours, add 15 parts of nano-aluminum hydroxide, and Stir at 50°C for 1 hour, add 2.5 parts of dicyandiamide, stir at 75°C for 0.75 hours, add 32 parts of ethylene glycol, 0.018 parts of accelerator aluminum acetylacetonate, and continue stirring at 65°C for 0.35 hours to fully After the dispersion is uniform, take a sample, and use the knife method to test the molding time of the glue solution (210°C hot plate) for 496 seconds, and the glue solution is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com