Patents

Literature

66results about "Top armourings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

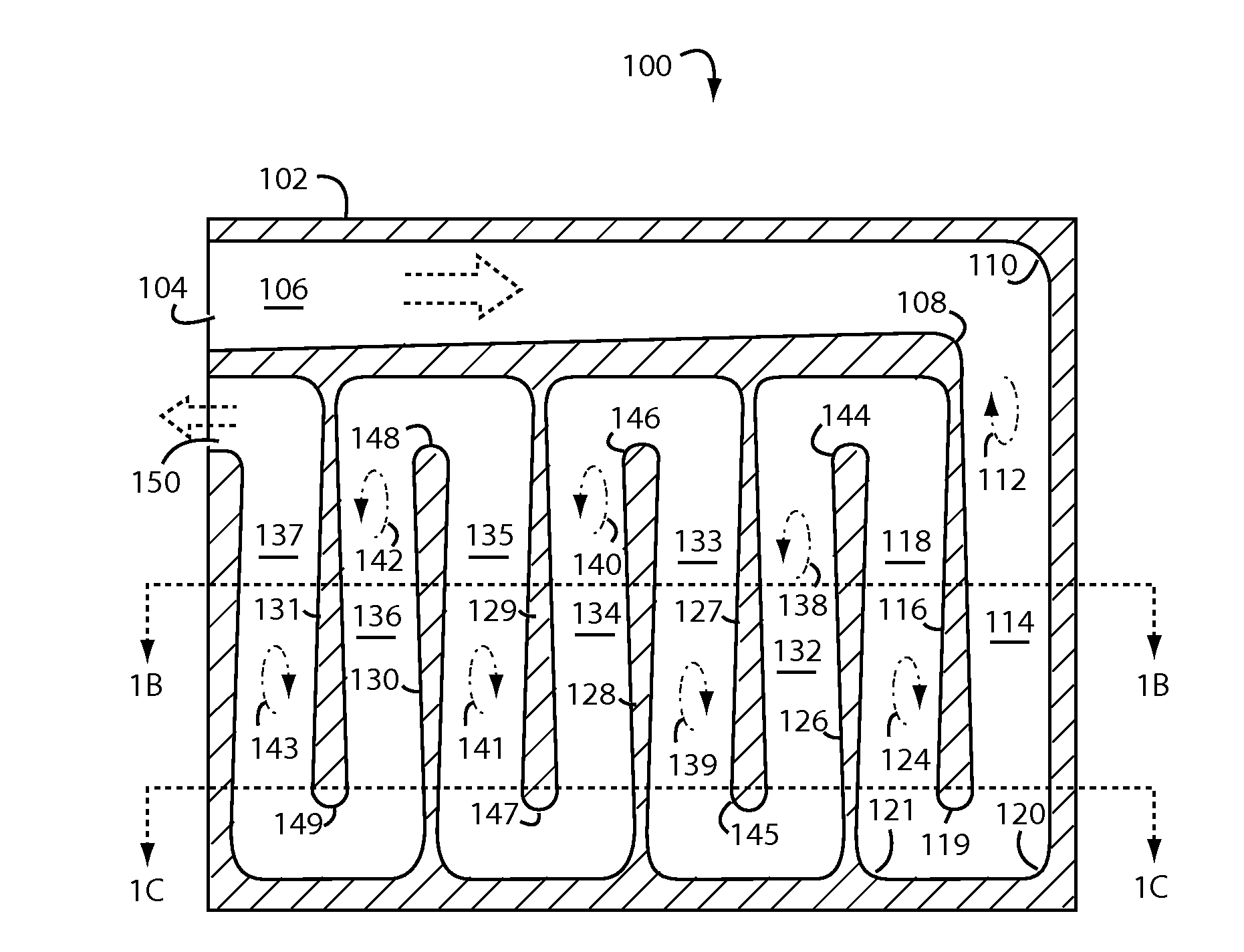

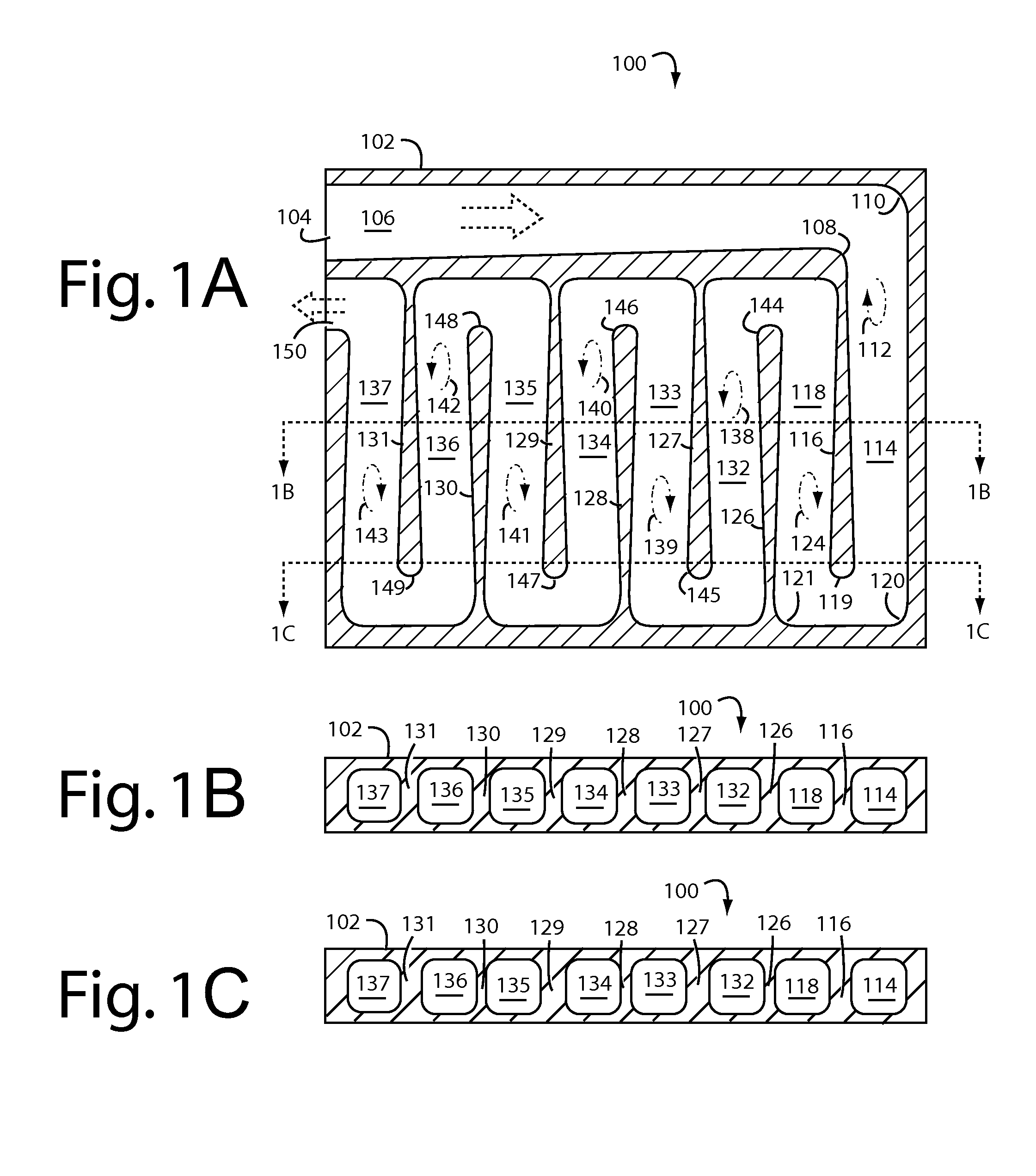

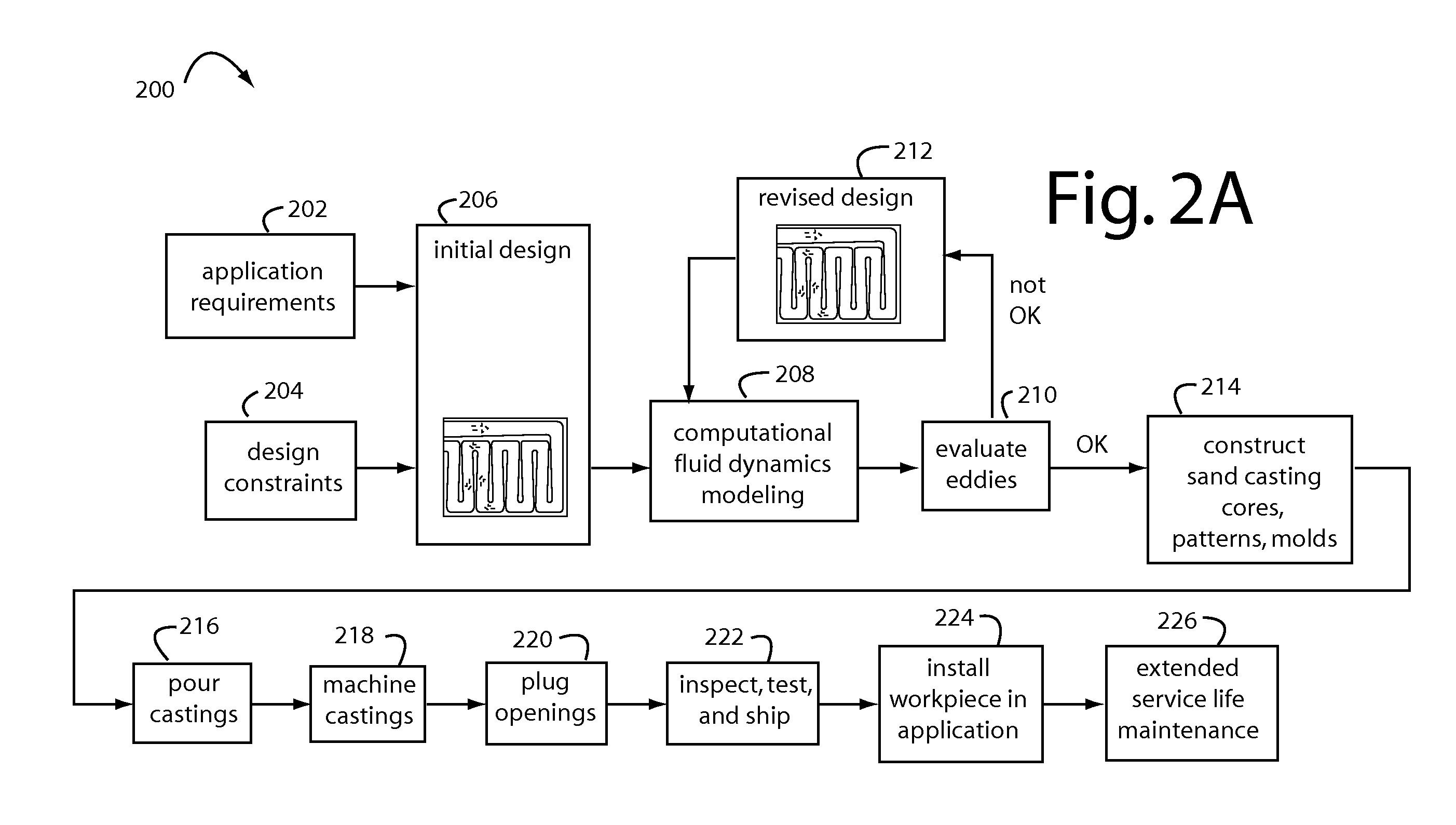

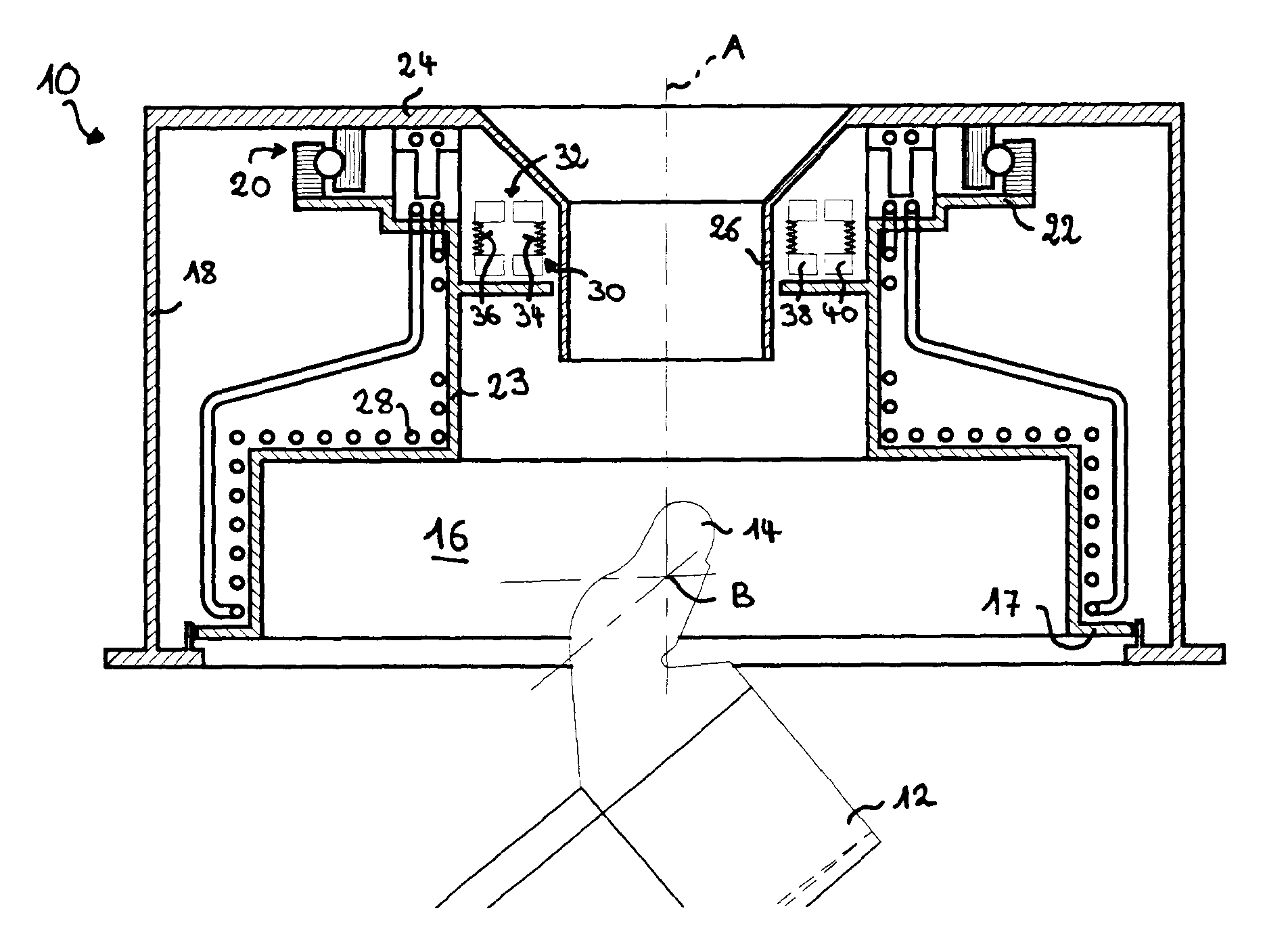

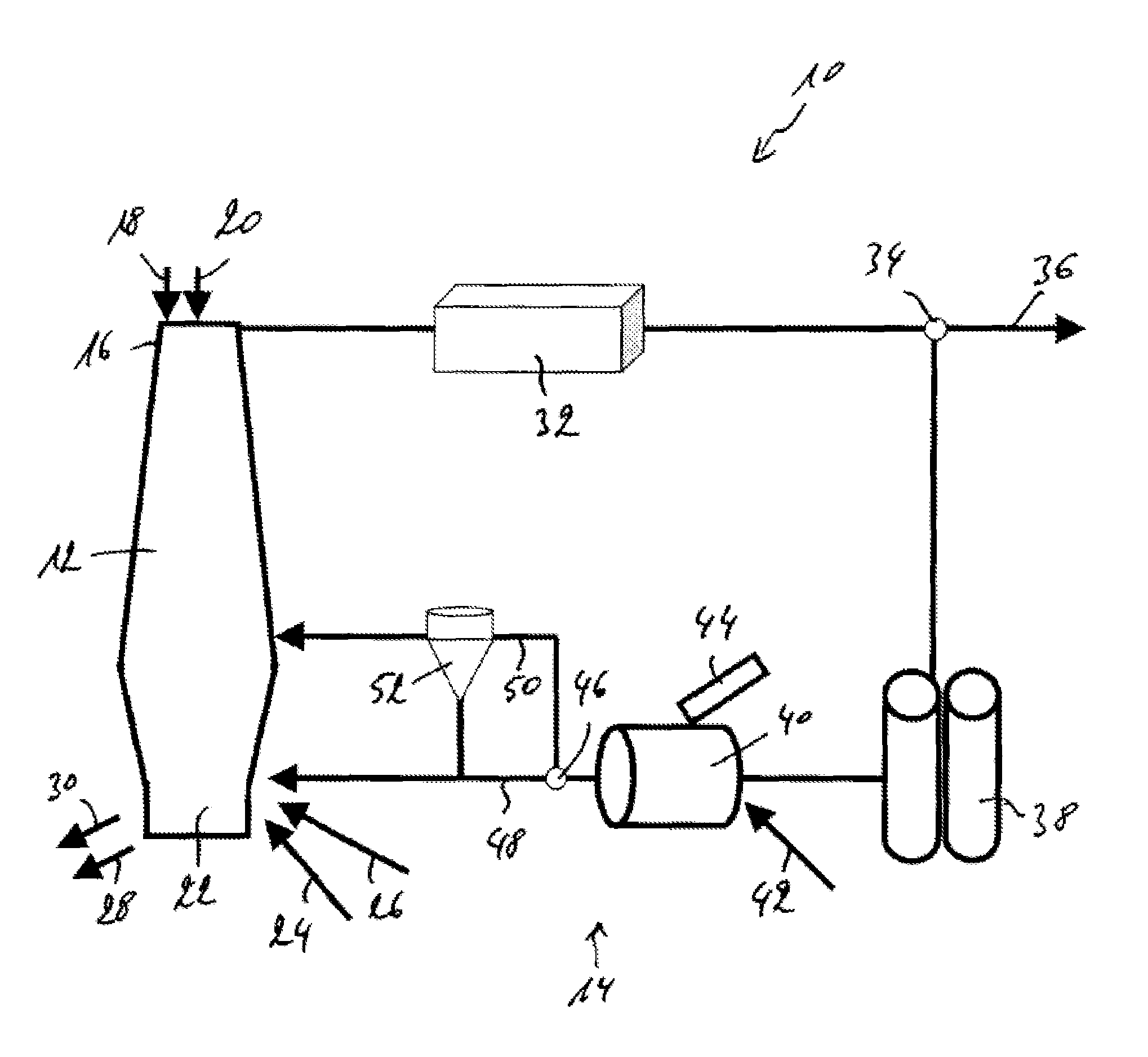

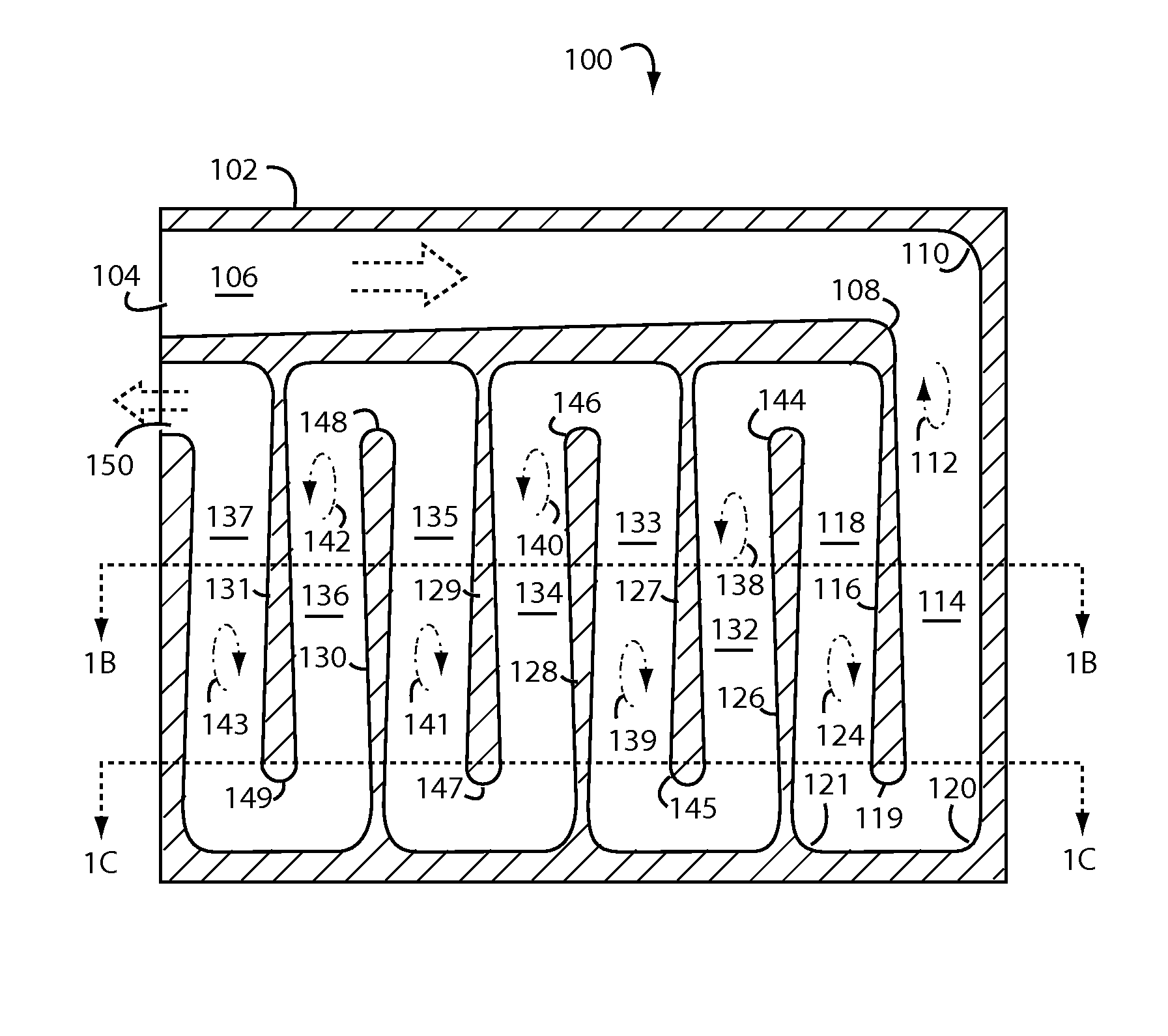

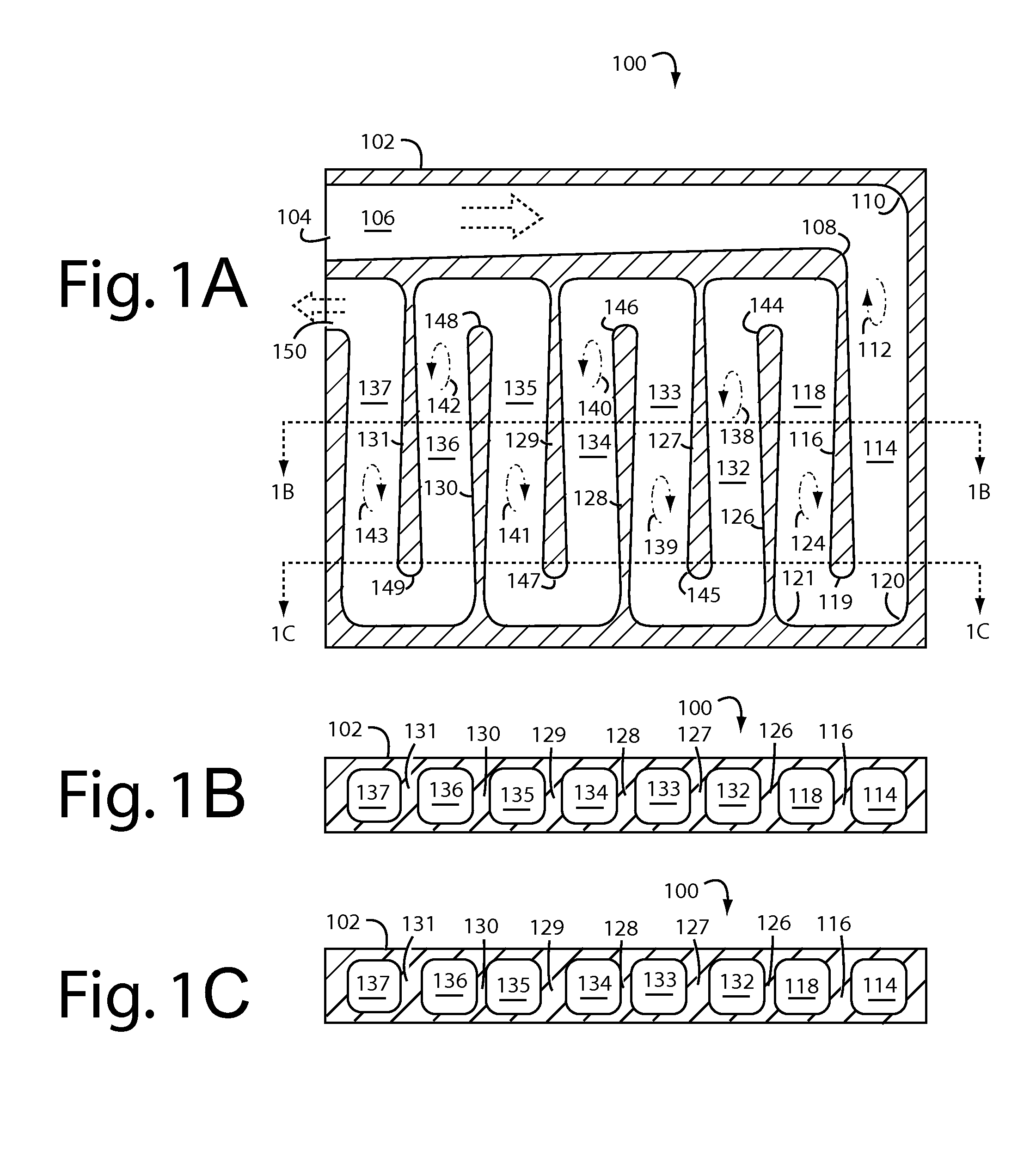

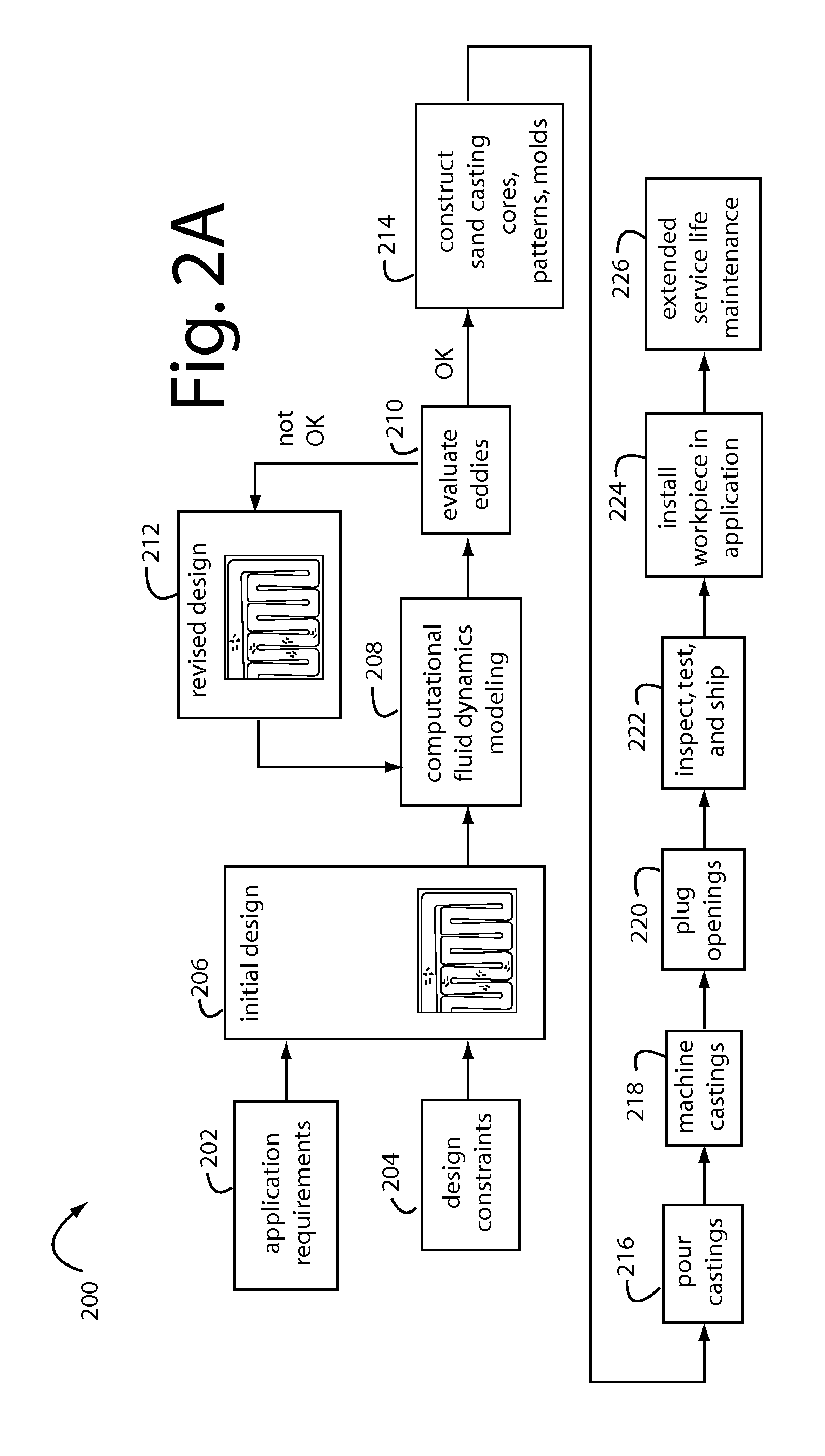

Eddy-free high velocity cooler

A cooling system comprises serpentine cooling fluid passages cast into a work piece with carefully controlled turning radii and profiles. Individual interdigitated baffles are contoured in the plane of coolant flow to have walls that thicken and then round off at their distal ends. The outside radii at these turns is similarly rounded and controlled such that the coolant flow will not be swirled into eddies.

Owner:MACRAE ALLAN J

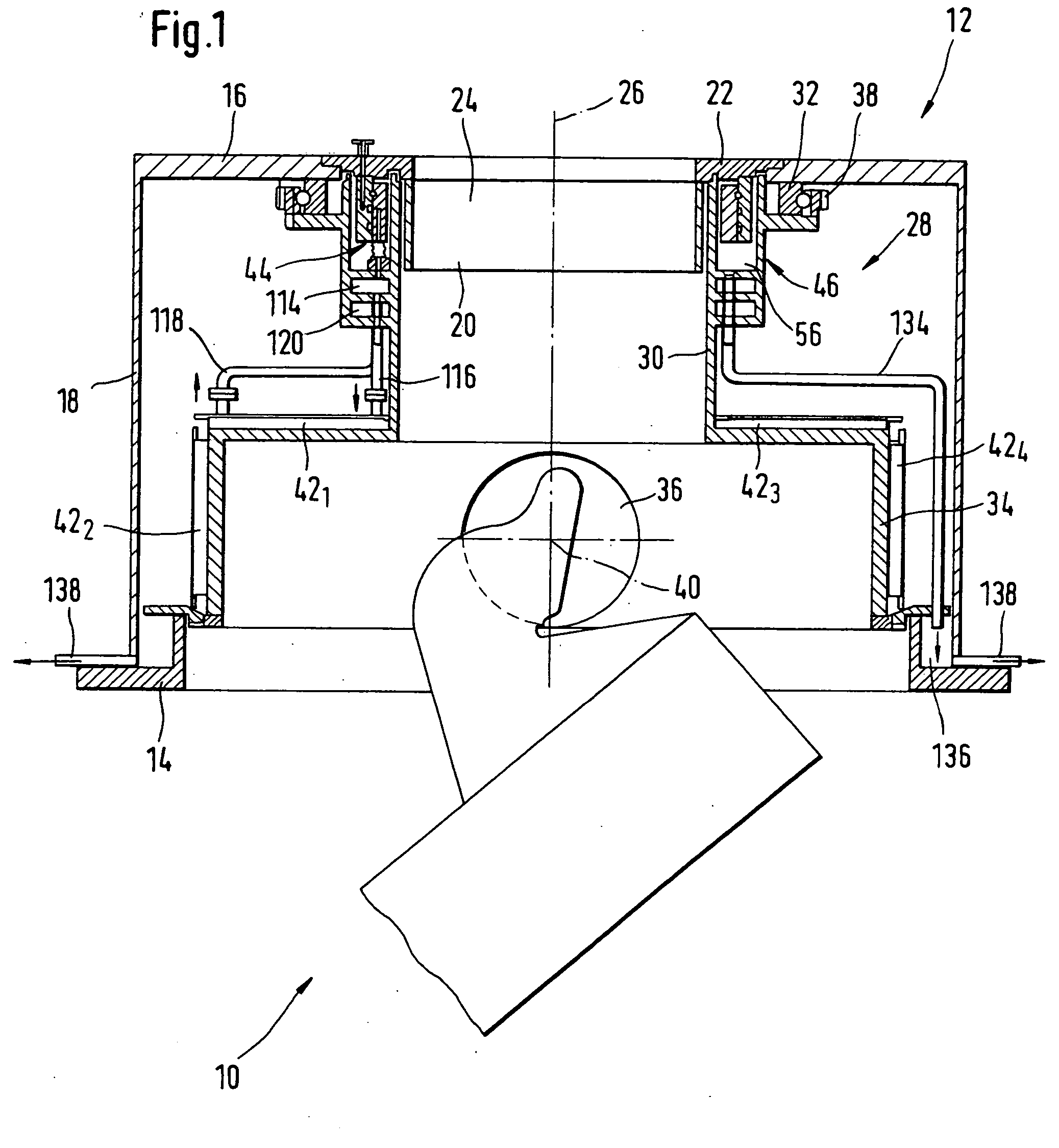

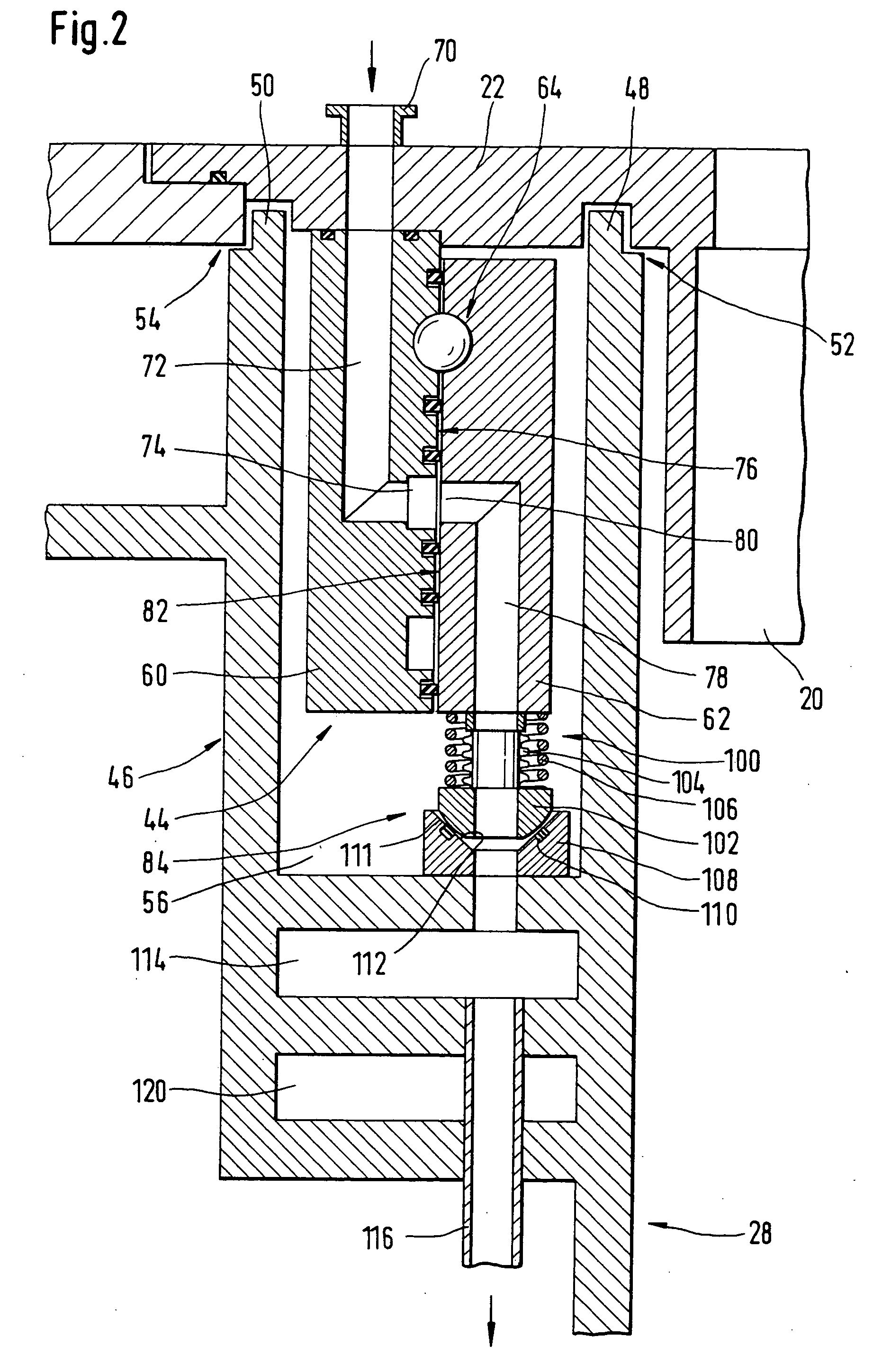

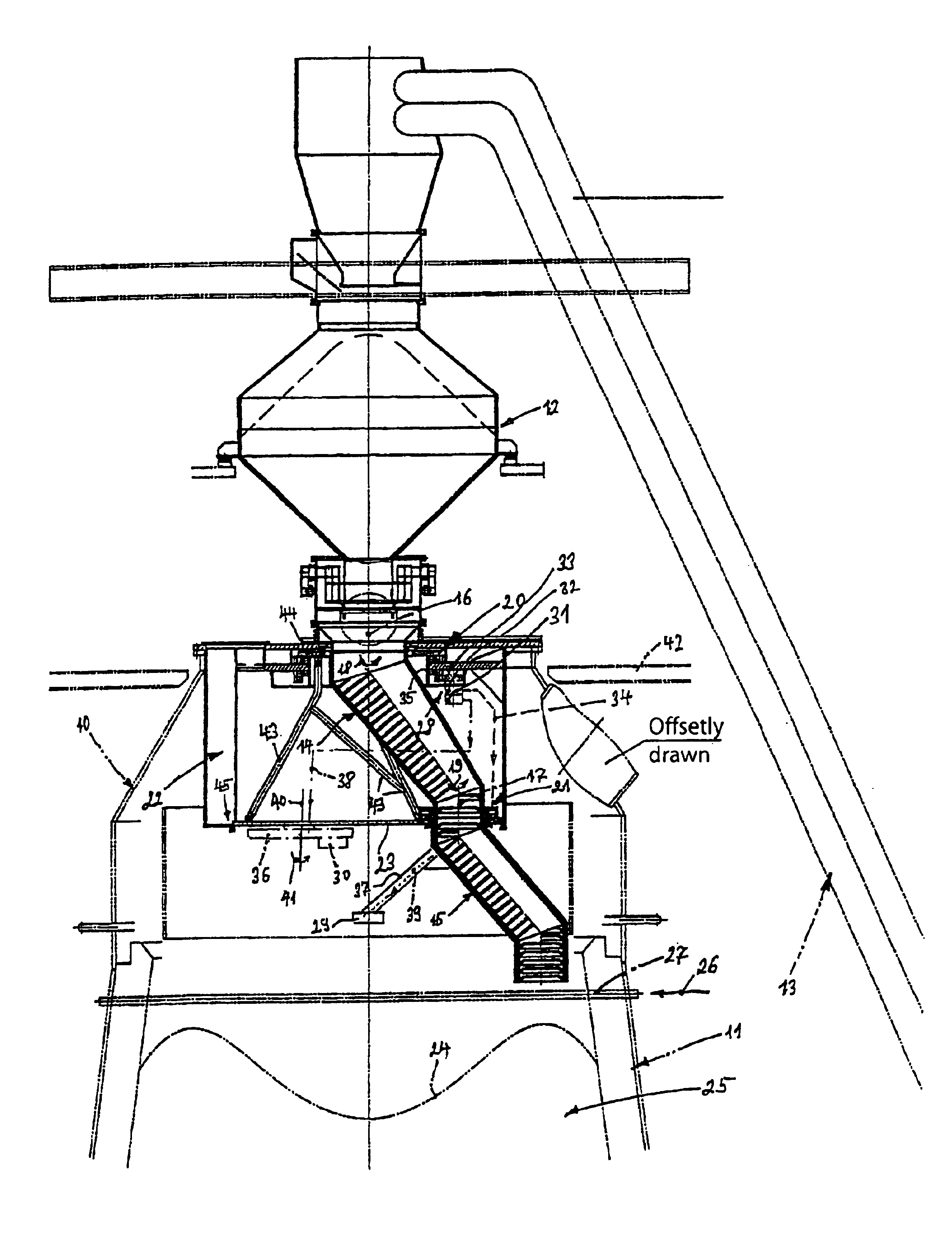

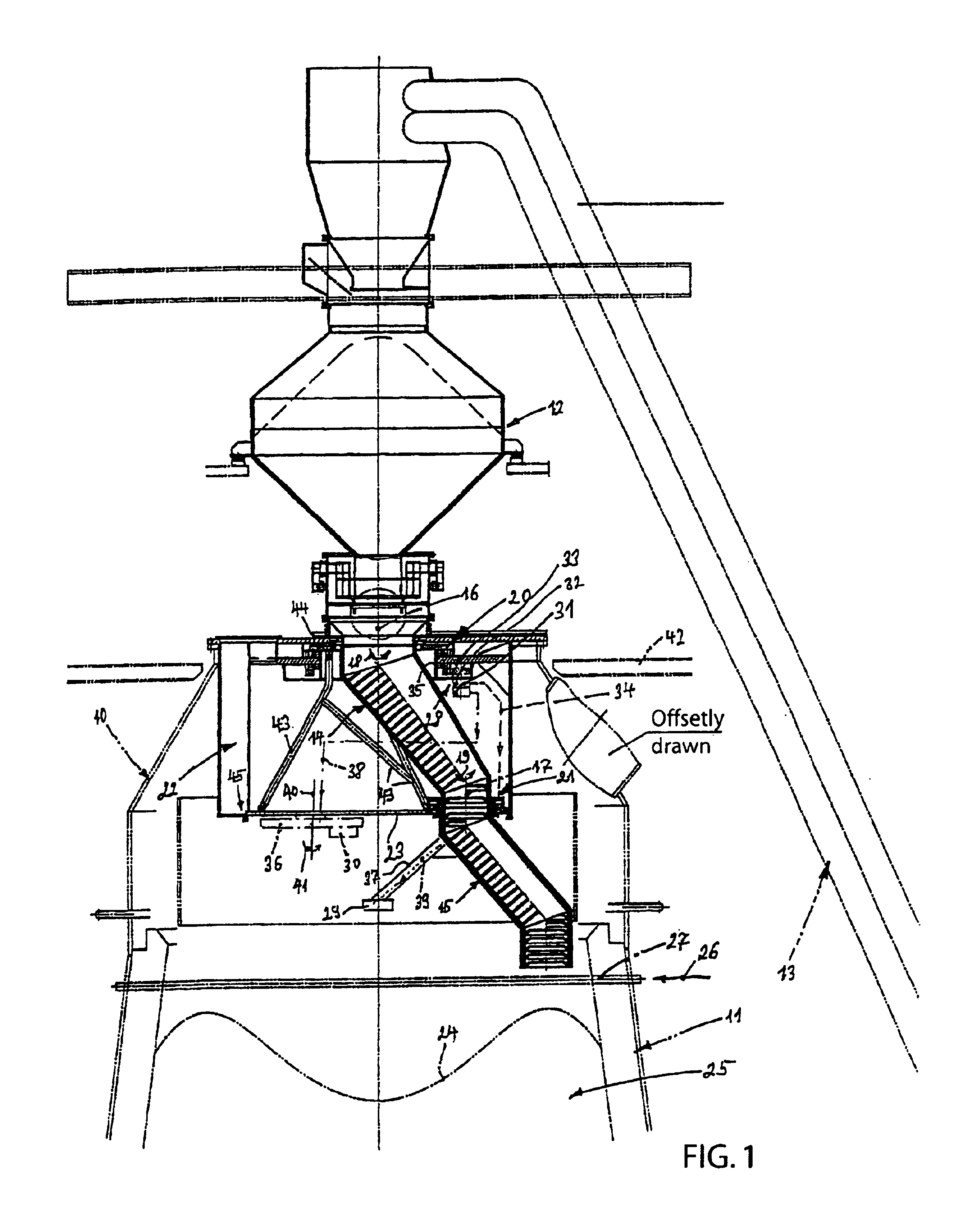

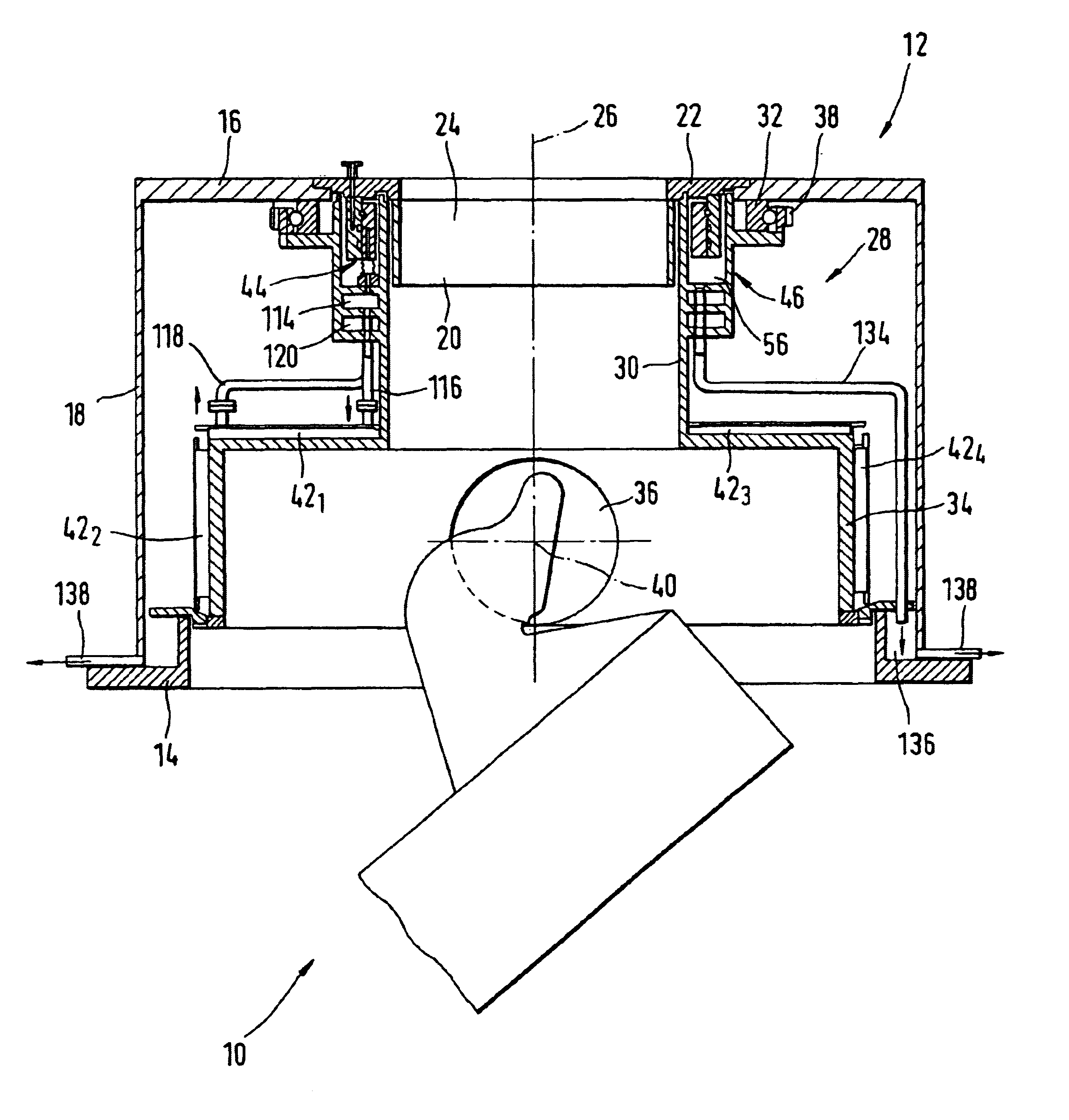

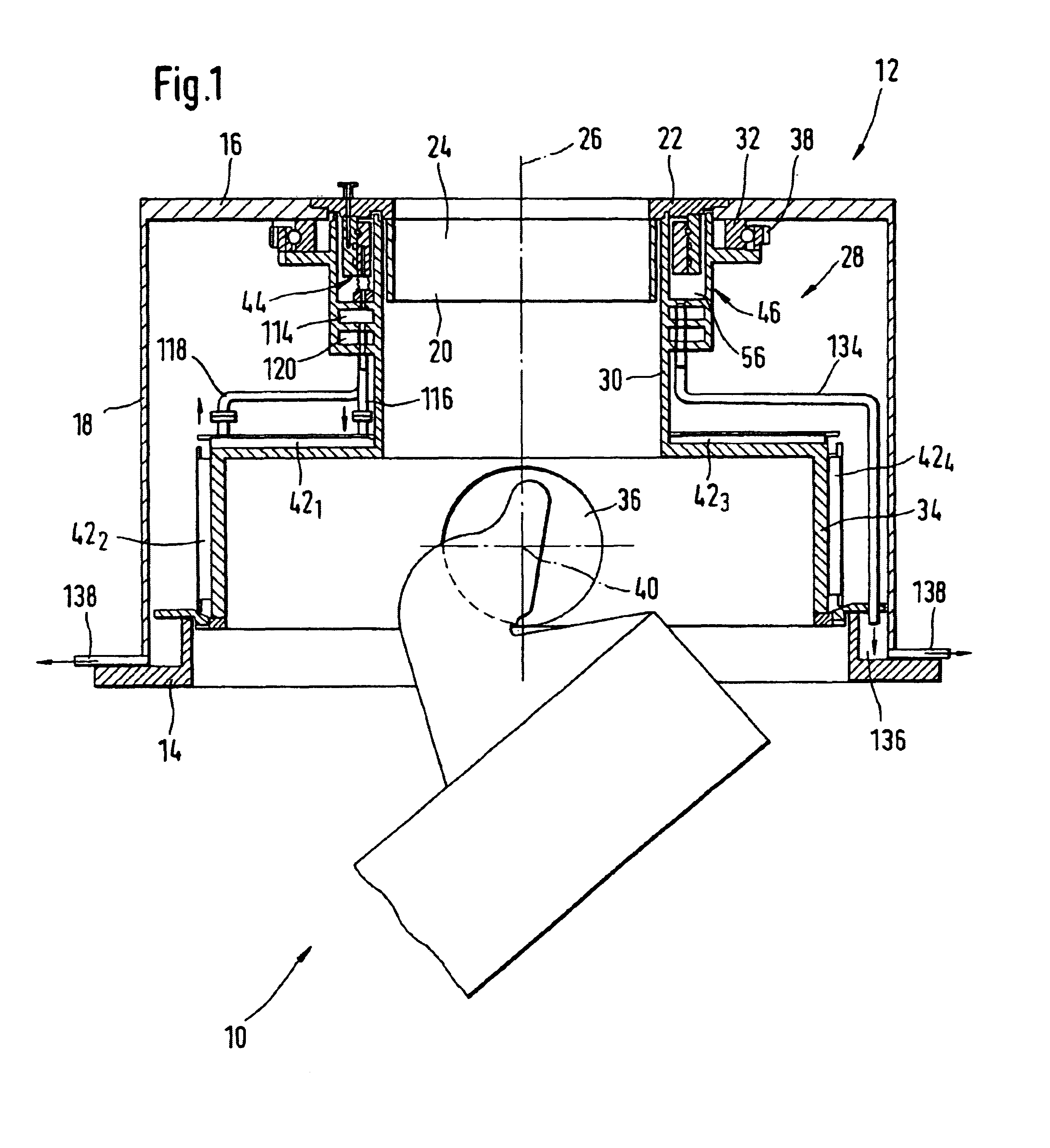

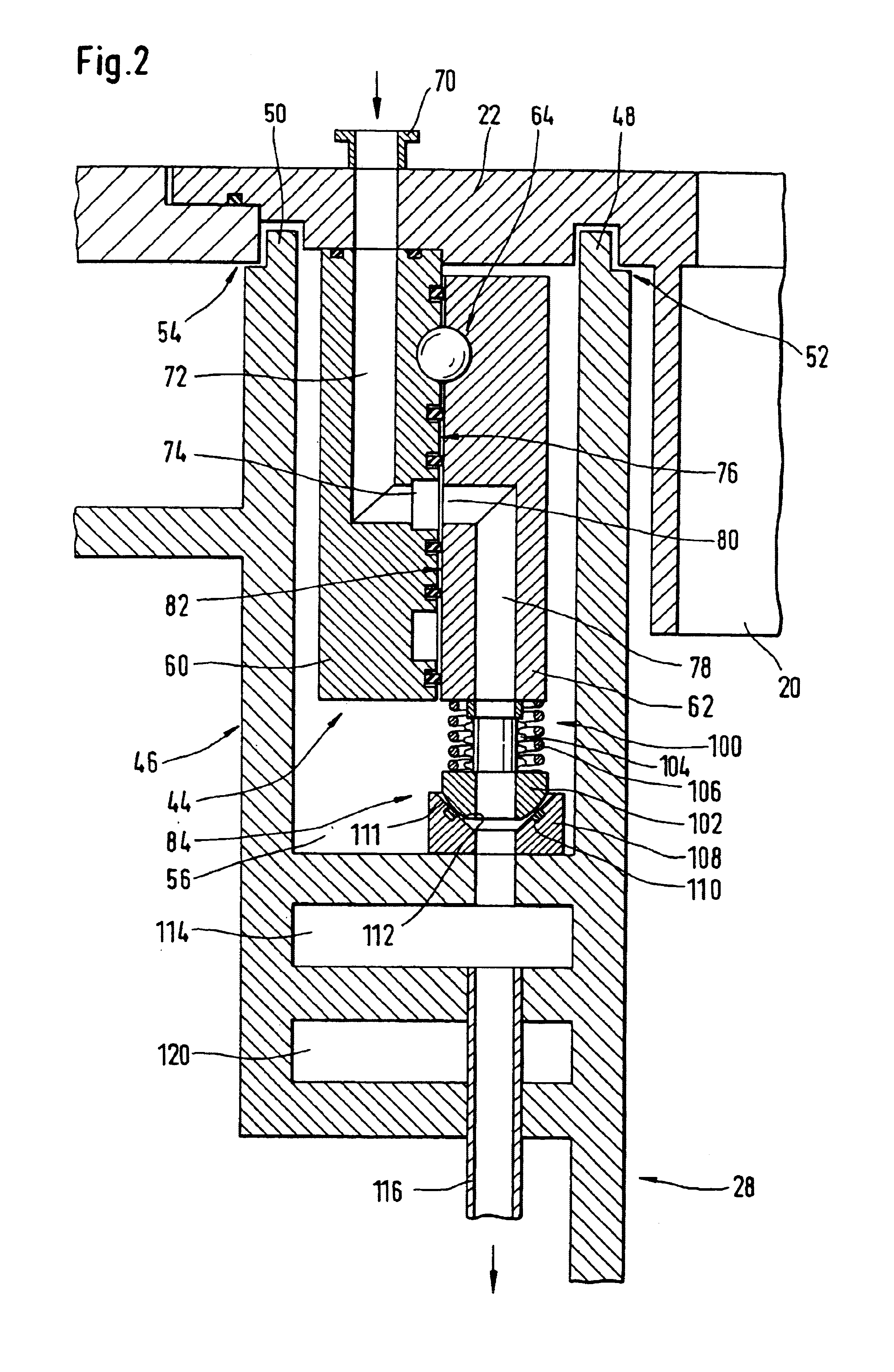

Device for loading a shaft furnace

A loading device for a shaft furnace comprises a chute supported by a suspension rotor (28) in a fixed housing. The rotor (28) is fitted with a cooling circuit, supplied with liquid coolant via a rotating annular joint (44). The latter comprises a fixed ring (60) and a rotating ring (62), and is fitted in an annular leak collecting tank (46) formed by the suspension rotor (28). Fixed ring (60) is supported by the housing (12). Rotating ring (62) is supported entirely by fixed ring (60) via a bearing (64). Selective coupling means (65, 66) connect the rotating ring (62) to the suspension rotor (28) in such a way as to transmit a rotary moment of rotor (28) to rotating ring (62) selectively, while at the same time preventing other forces from rotor (28) being transmitted to rotating ring (62).

Owner:PAUL WURTH SA

Sealing valve arrangement for a shaft furnace charging installation

InactiveUS8568653B2Avoid easy cloggingLess-time-consuming installationConveyorsOperating means/releasing devices for valvesShaft furnaceValve seat

A sealing valve arrangement for a shaft furnace charging installation includes a shutter-actuating device for moving a shutter between a closed position in sealing contact with a valve seat and an open position remote from the valve seat. The shutter-actuating device is of the dual-motion type and includes a primary tilting arm on a first tilting shaft defining the first axis and is equipped with bearings supporting the primary tilting arm. A secondary tilting arm carries the shutter is connected to a second tilting shaft that defines a second substantially parallel axis and has bearings that support the secondary tilting arm on the primary tilting arm. The shutter-actuating device has a mechanism configured to tilt the secondary tilting arm when the primary tilting arm is tilted.The first tilting shaft is configured as hollow sleeve shaft and the shutter-actuating device includes a reference rod extending through the first tilting shaft.

Owner:PAUL WURTH SA

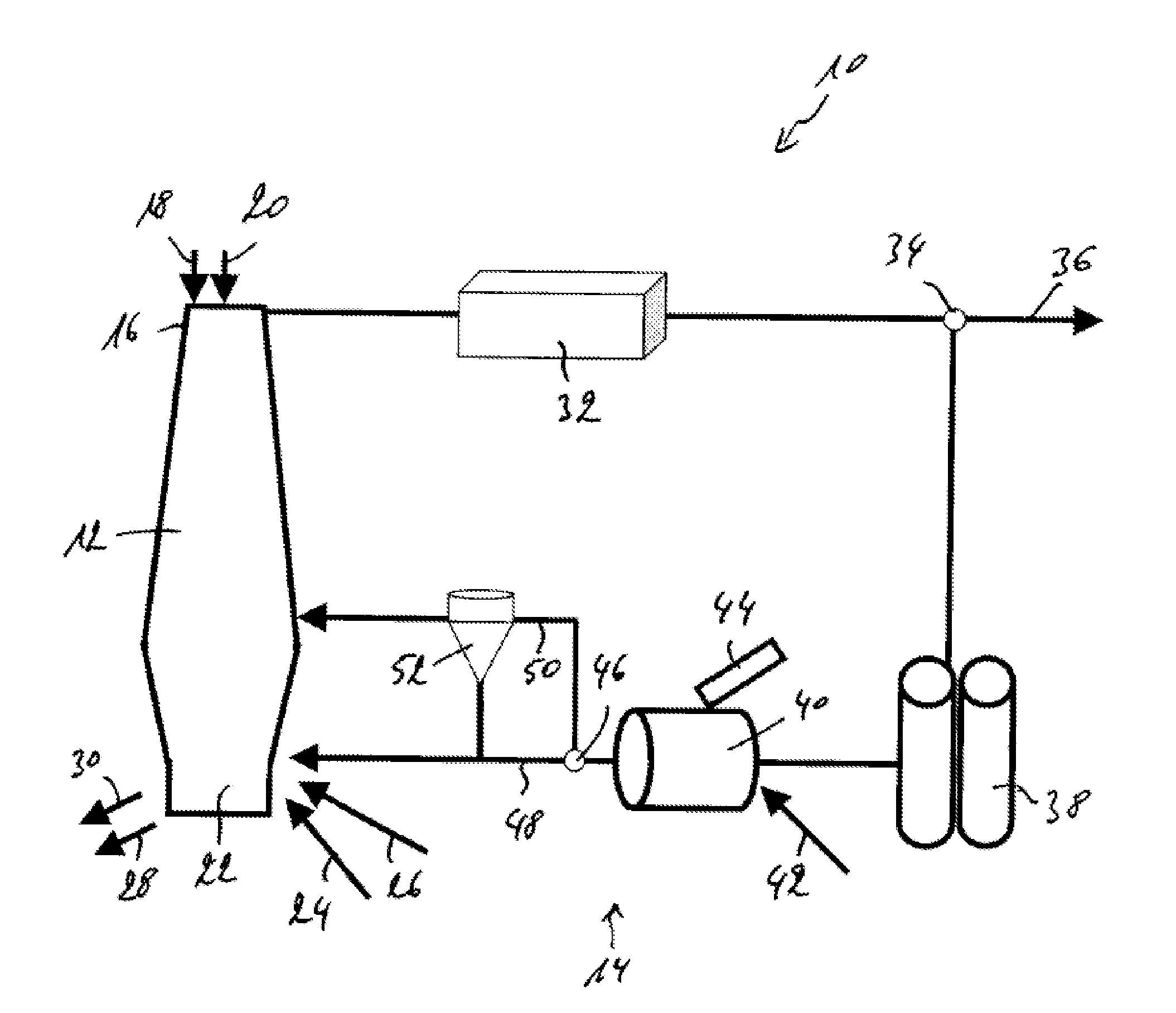

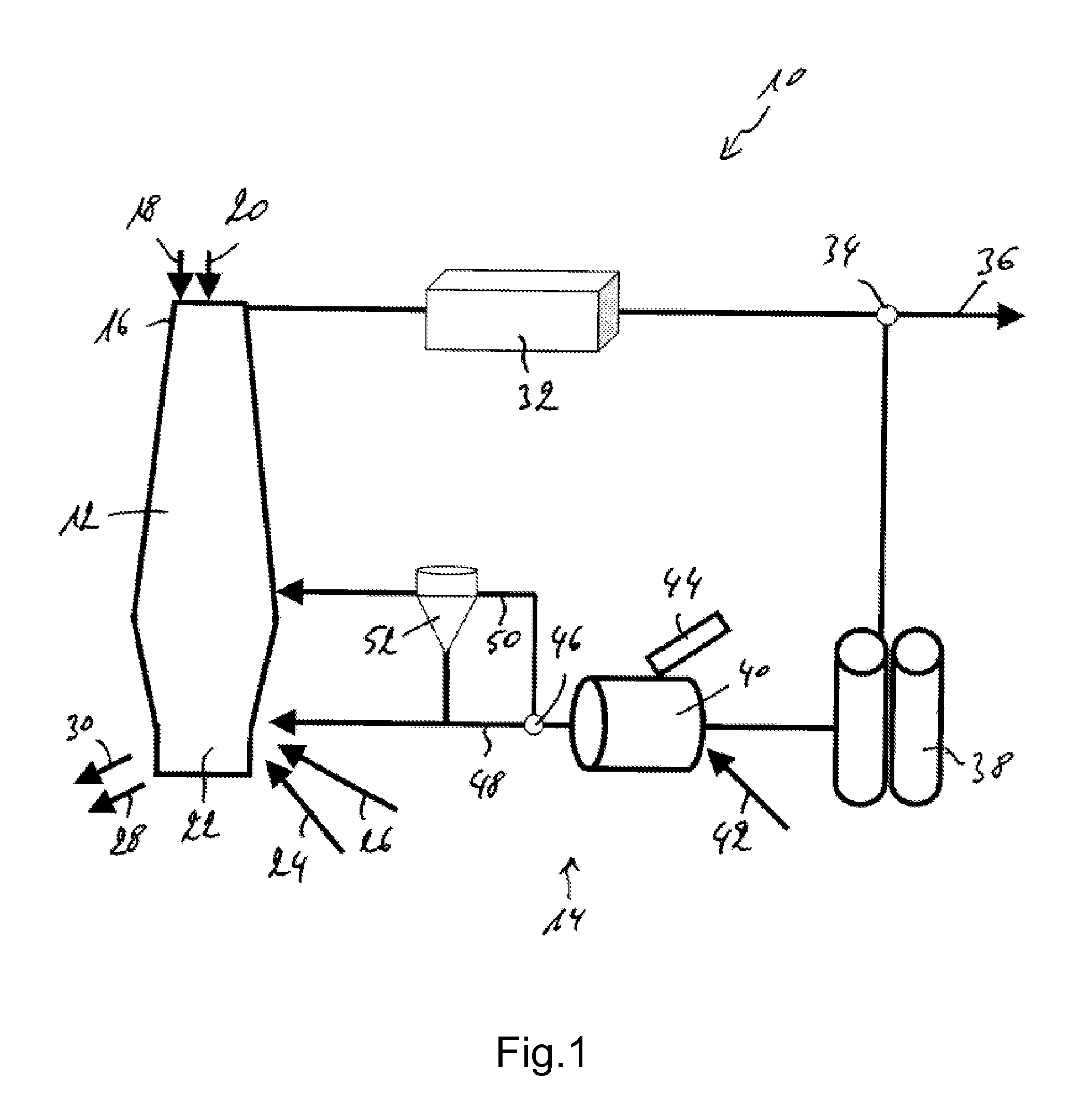

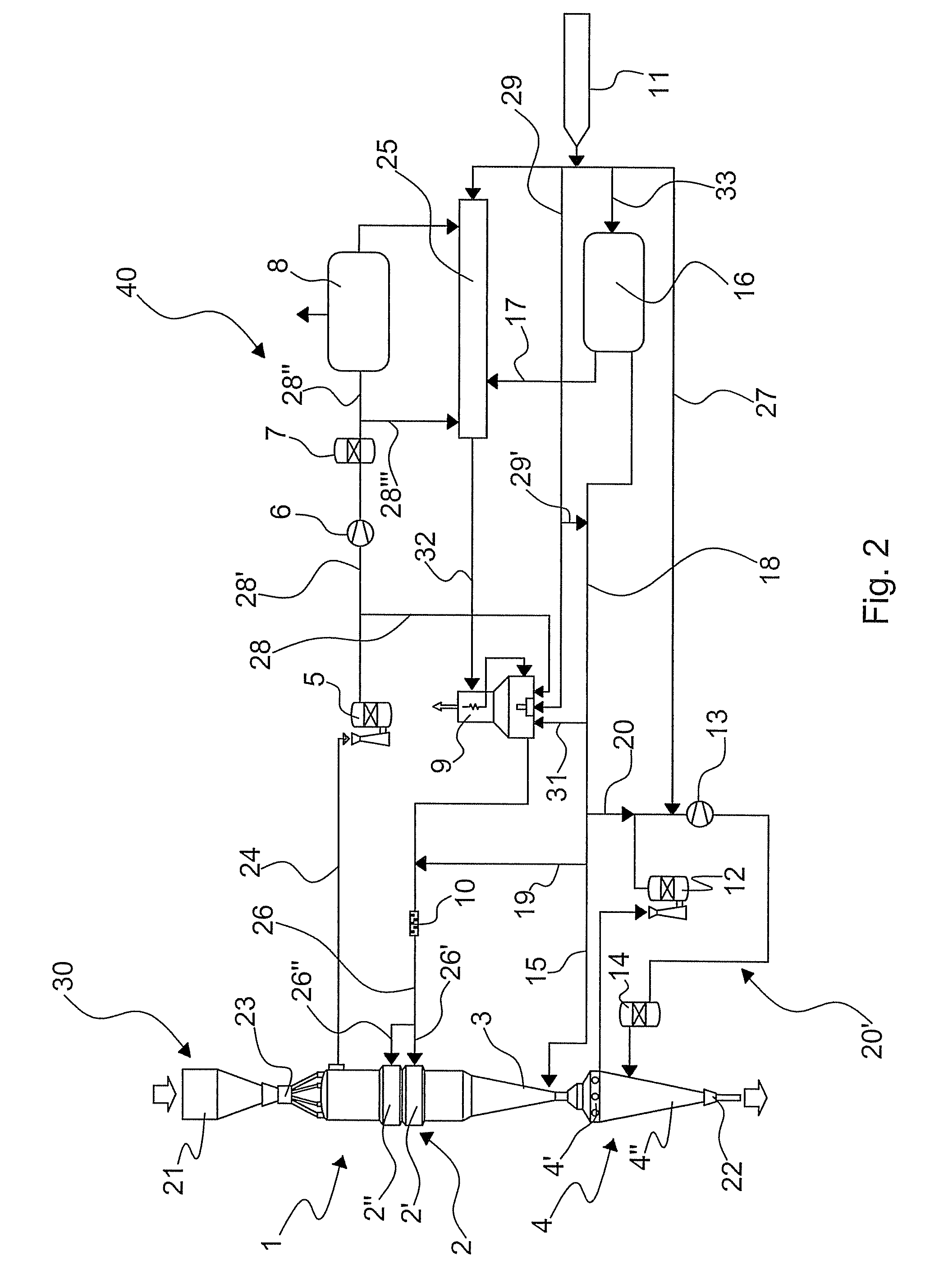

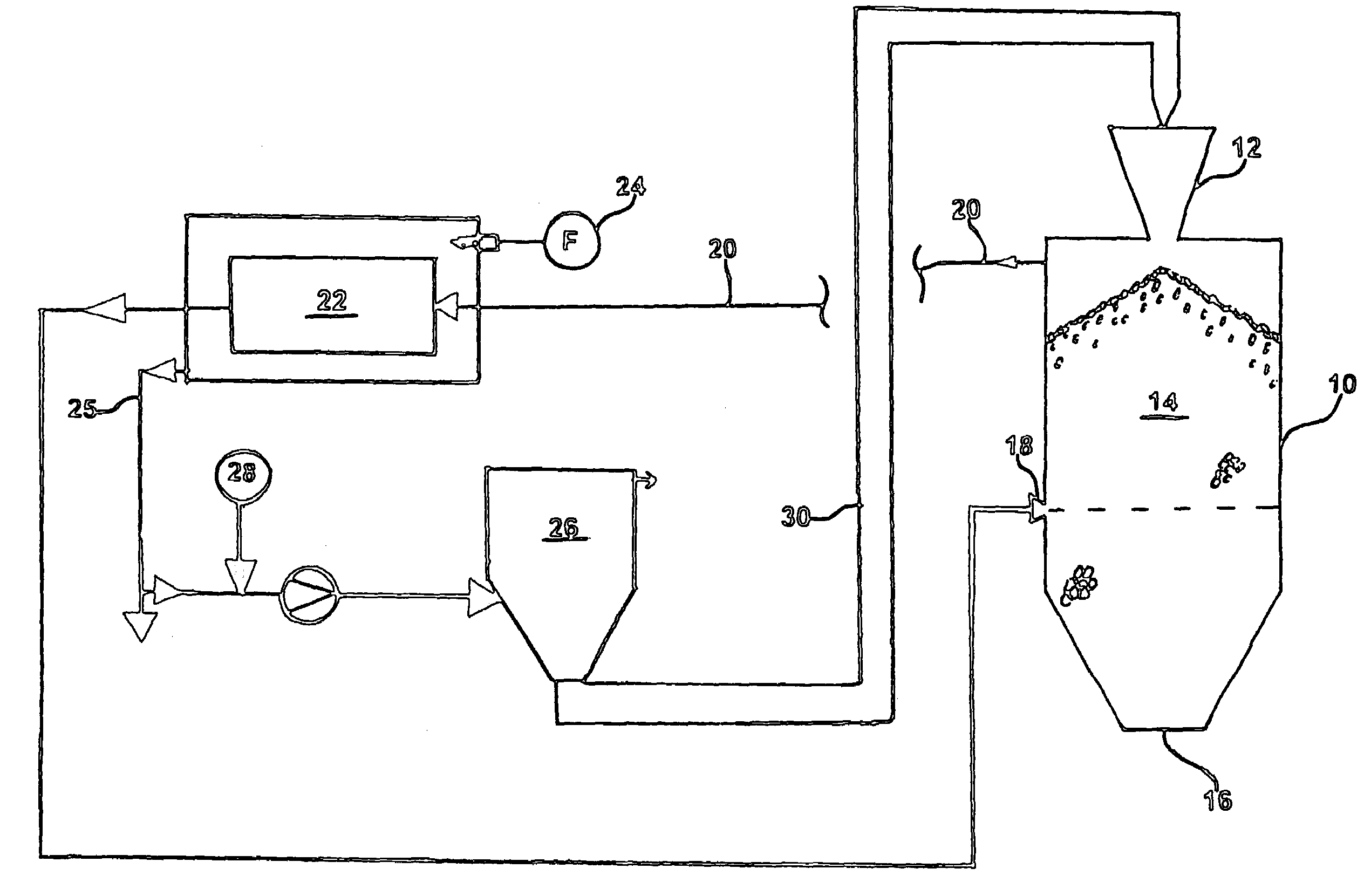

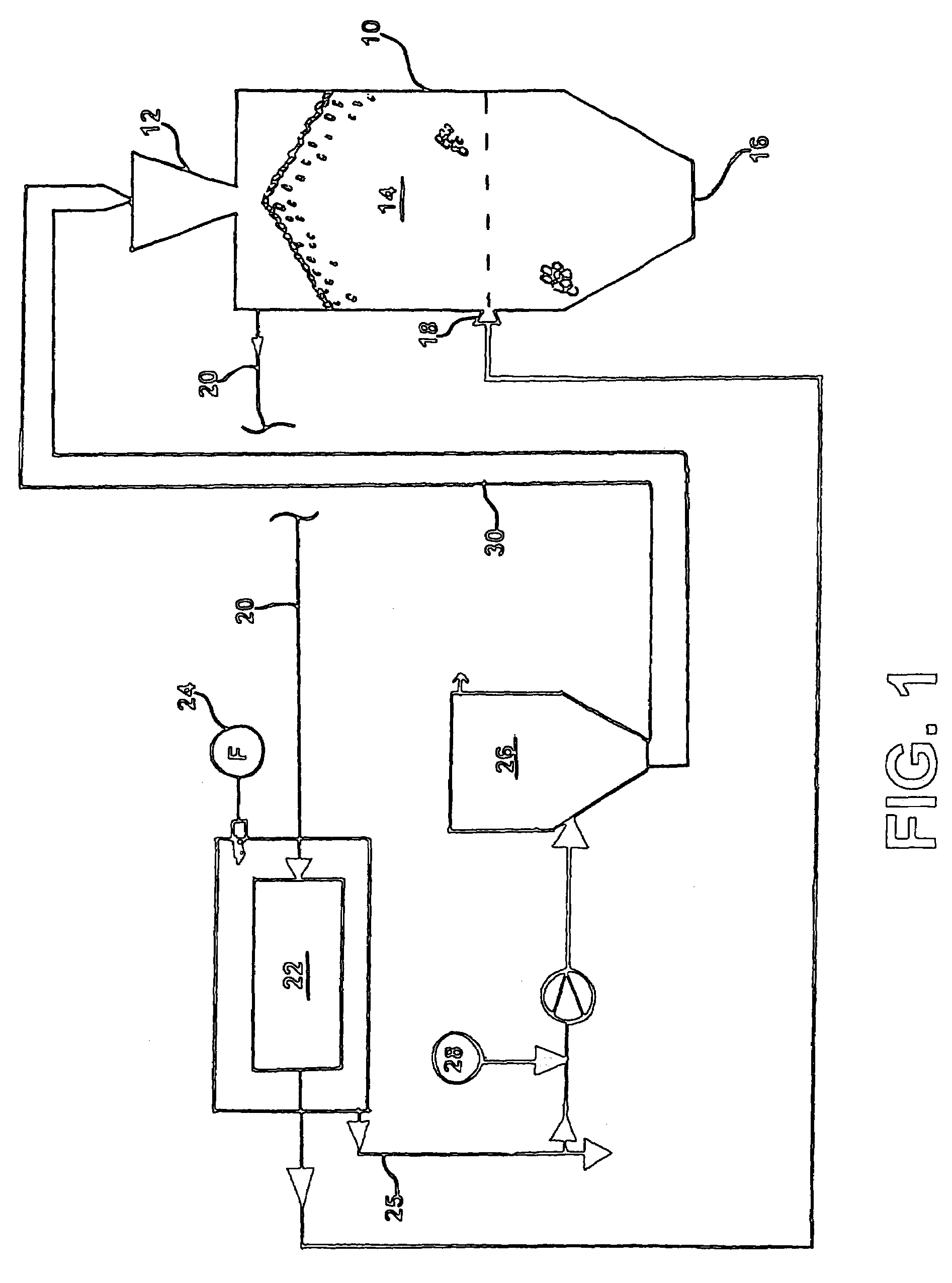

Method for operating a blast furnace and blast furnace installation

InactiveUS20110209576A1Easy to installSimple methodDirect heating destructive distillationBiofuelsMaterials scienceBlast furnace

A method for operating a blast furnace and a corresponding blast furnace, the method including recovering top gas from the blast furnace, submitting at least a portion of the top gas to a recycling process, and feeding the recycled top gas back into the blast furnace, where the recycling process includes feeding the recovered top gas to a reformer unit, feeding volatile carbon containing material to the reformer unit, proceeding to flash gasification of the volatile carbon containing material in the reformer unit, at a temperature between 1100 and 1300° C., and thereby producing devolatised carbonaceous material and synthesis, and allowing the devolatised carbonaceous material and synthesis gas to react with the recovered top gas.

Owner:PAUL WURTH SA

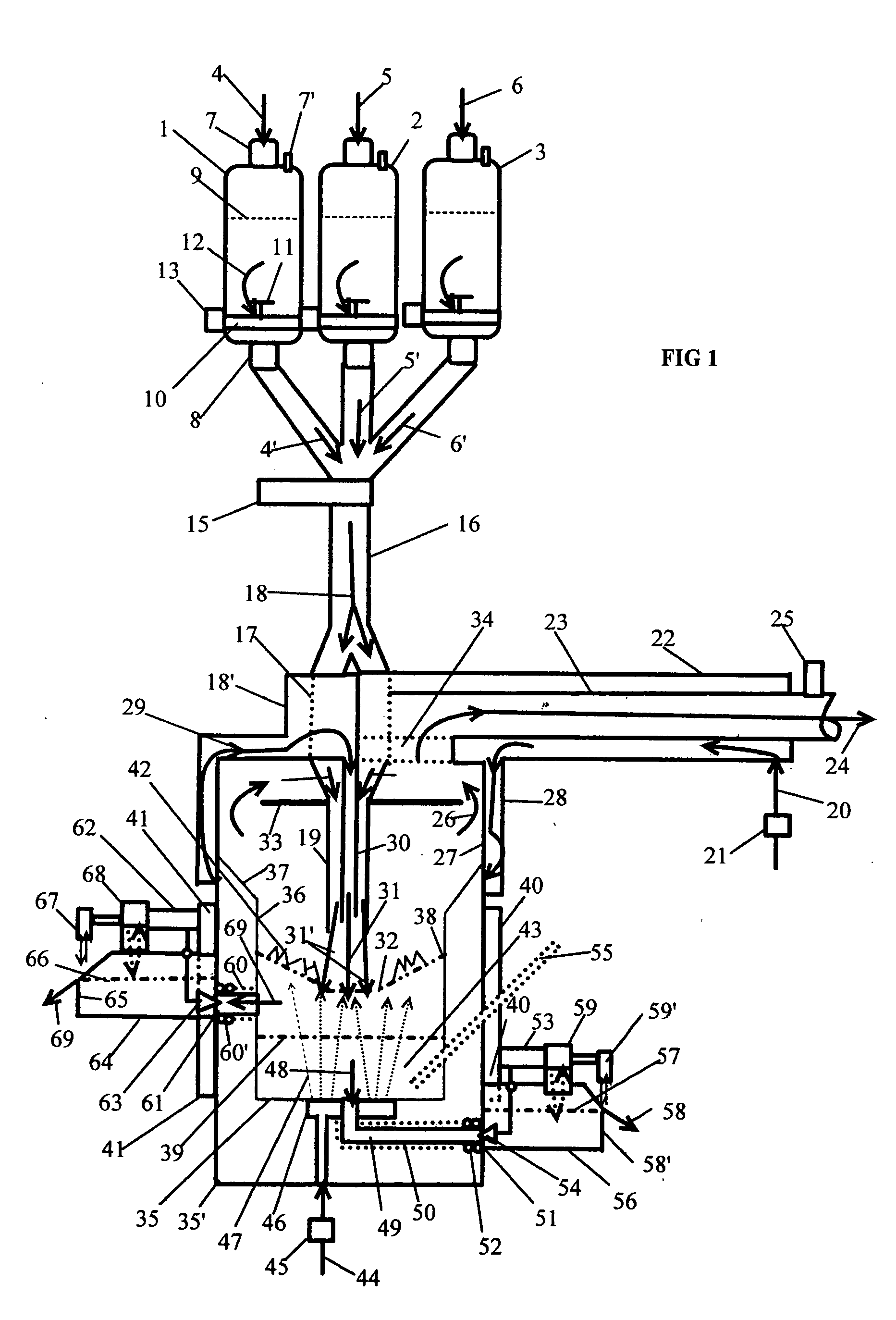

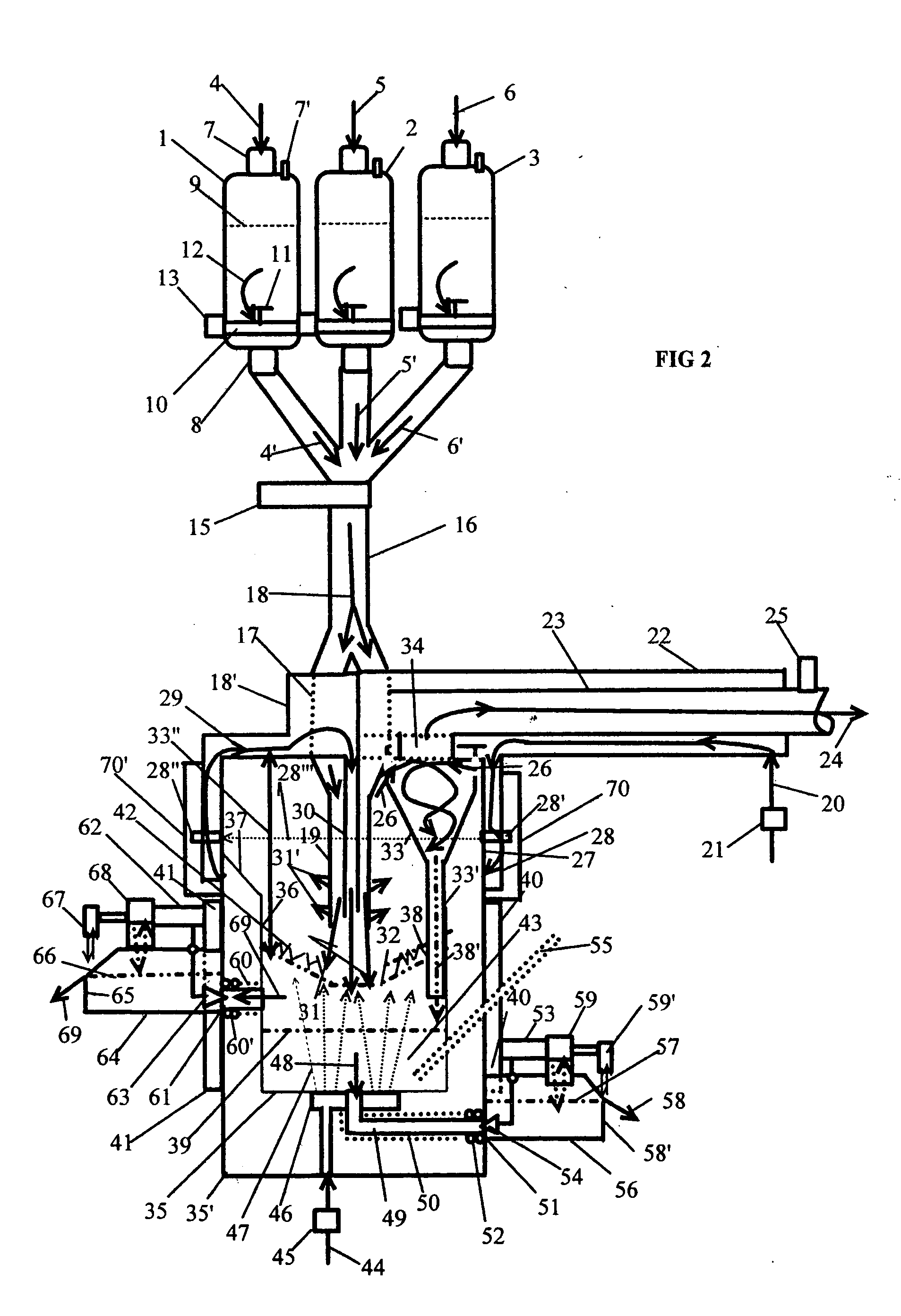

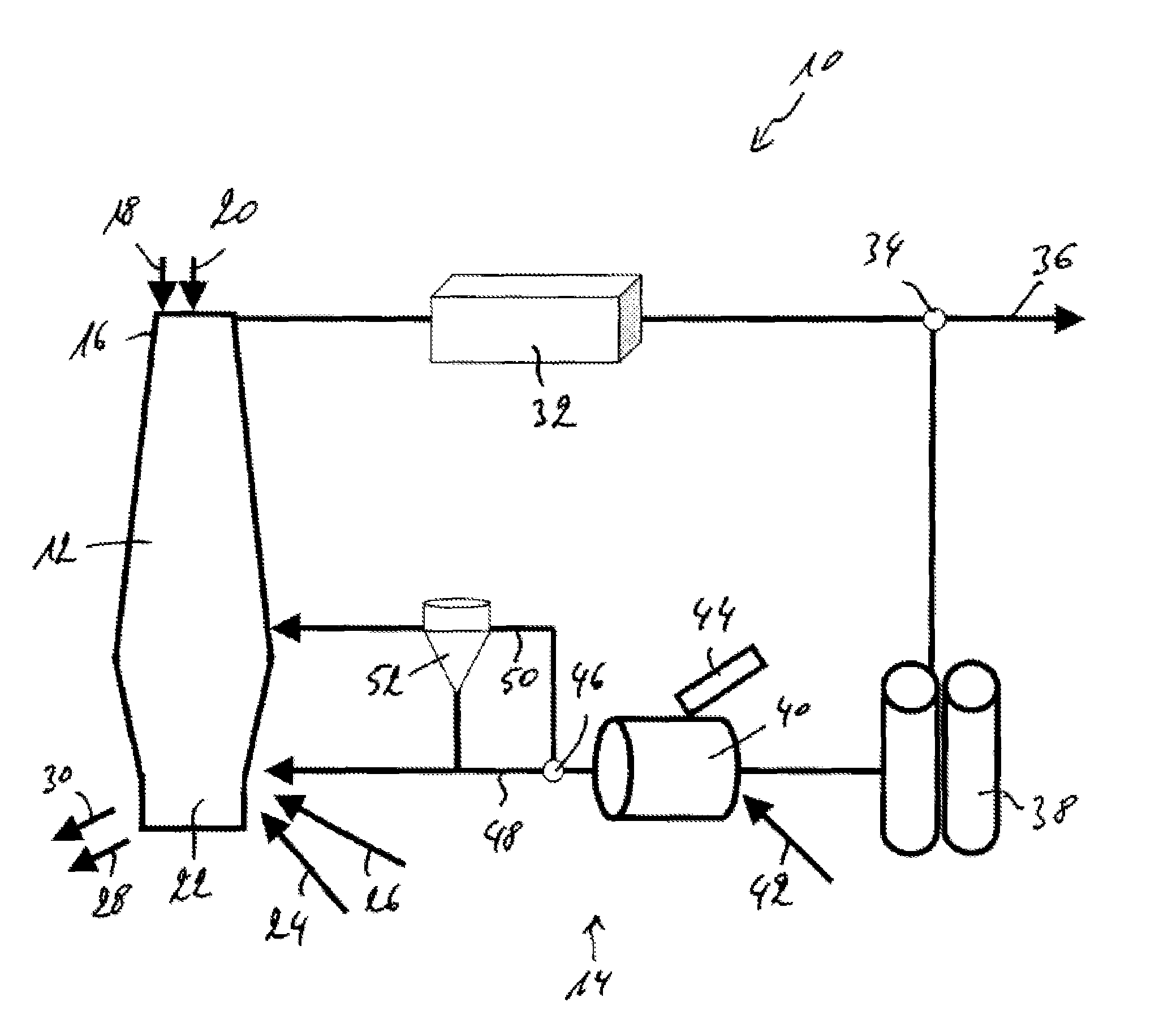

Single vessel blast furnace and steel making/gasifying apparatus and process

InactiveUS20060108721A1Precise maintenanceAdequate flowCharge manipulationBlast furnace detailsSingle vesselCrucible

A blast furnace for use in an apparatus such as a steel making apparatus or a gasifier includes a crucible having a tap hole for discharging molten slag therefrom. The furnace includes a lance for introducing fuel and oxygen into the crucible and instrumentation for continuously measuring characteristics of molten slag discharged through the tap hole to control processing of fuel and oxygen in the crucible. In one application, a single vessel steel-making apparatus includes a crucible having a first tap hole for discharging molten slag therefrom and a second tap hole for discharging molten steel therefrom and includes an additional lance for introducing a carbon reducing oxygen blast into a mass of molten steel in the crucible.

Owner:LEW HLDG

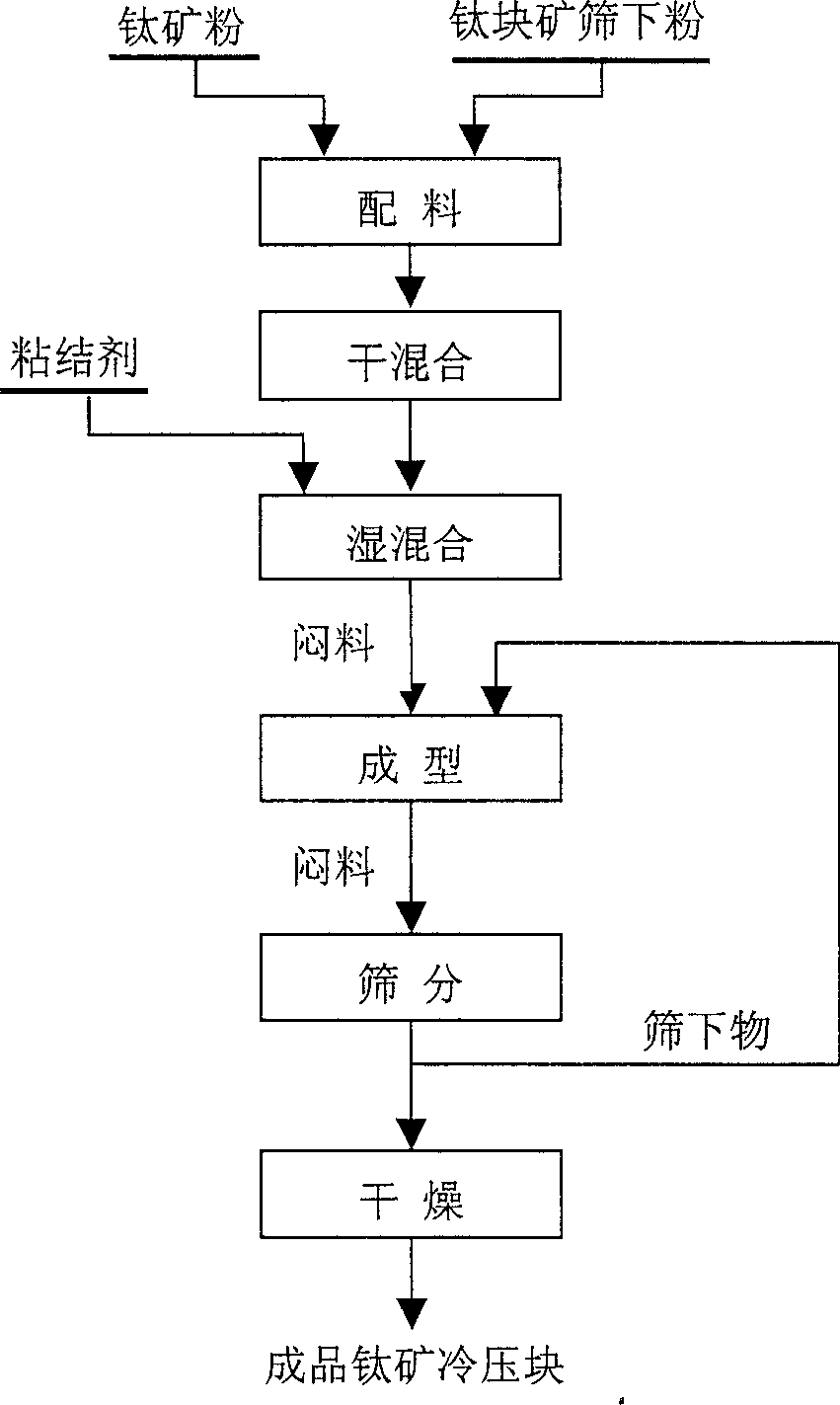

Titanium ore cold briquetting for protecting blast furnace and its production method

ActiveCN1766129AThe occurrence of powder rate is reducedHigh temperature strengthTop armouringsEpoxyCellulose

The chill-pressing titanium block to protect blast furnace comprises: 90~98% titanium powder, 2~10wt% composite adhesive composed of cement, polyvinyl alcohol and phosphodiester by proportion as 4~8:1~5:0~1; wherein, cement: cellulose is 5~10:1~5,epoxy resin:sodium humate is 8~10í†0~2, waste molasses liquid:lime hydrate is 7~10í†0~3, and waterglass:bentonite:silicasol is 7~10í†0~2í†0~1. The preparation method comprises: mixing material with adhesive, rolling, covering tightly the material, pressing to form; screening the crude block to re-press the powder less than 10mmm and form product. Compared with prior art, this invention increases mechanical strength, and reduces greatly the powder rate when screening powder.

Owner:BAOSHAN IRON & STEEL CO LTD +1

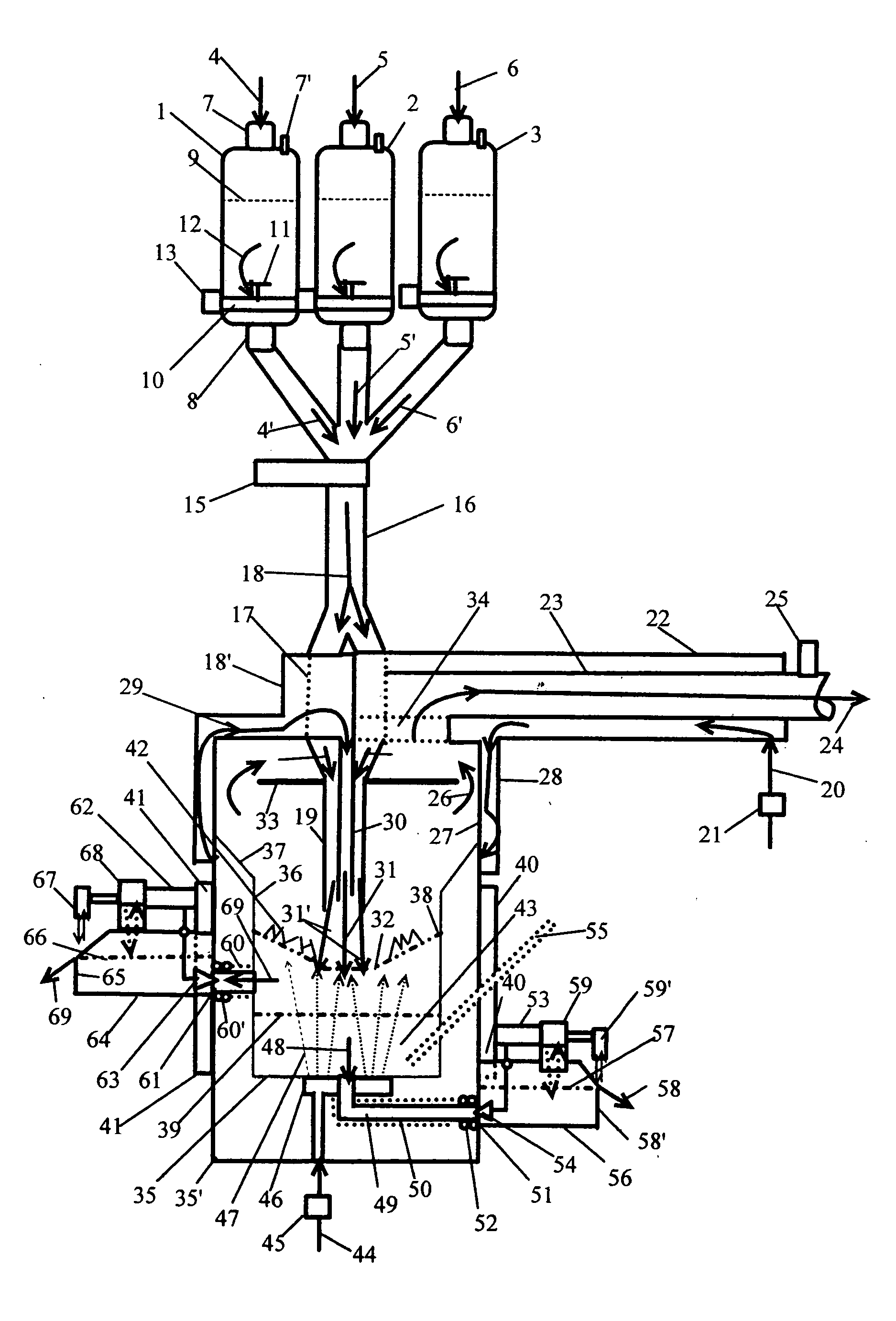

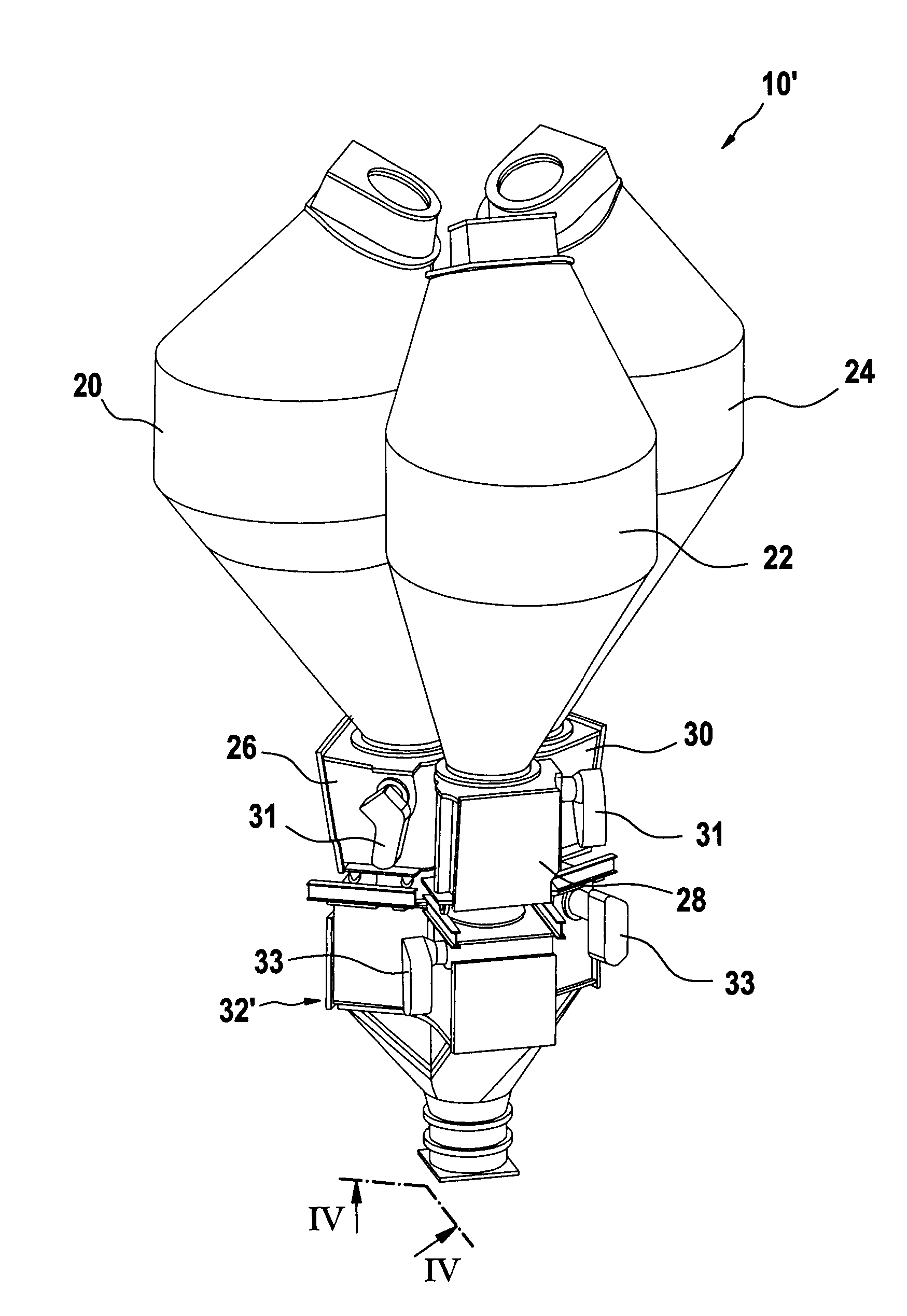

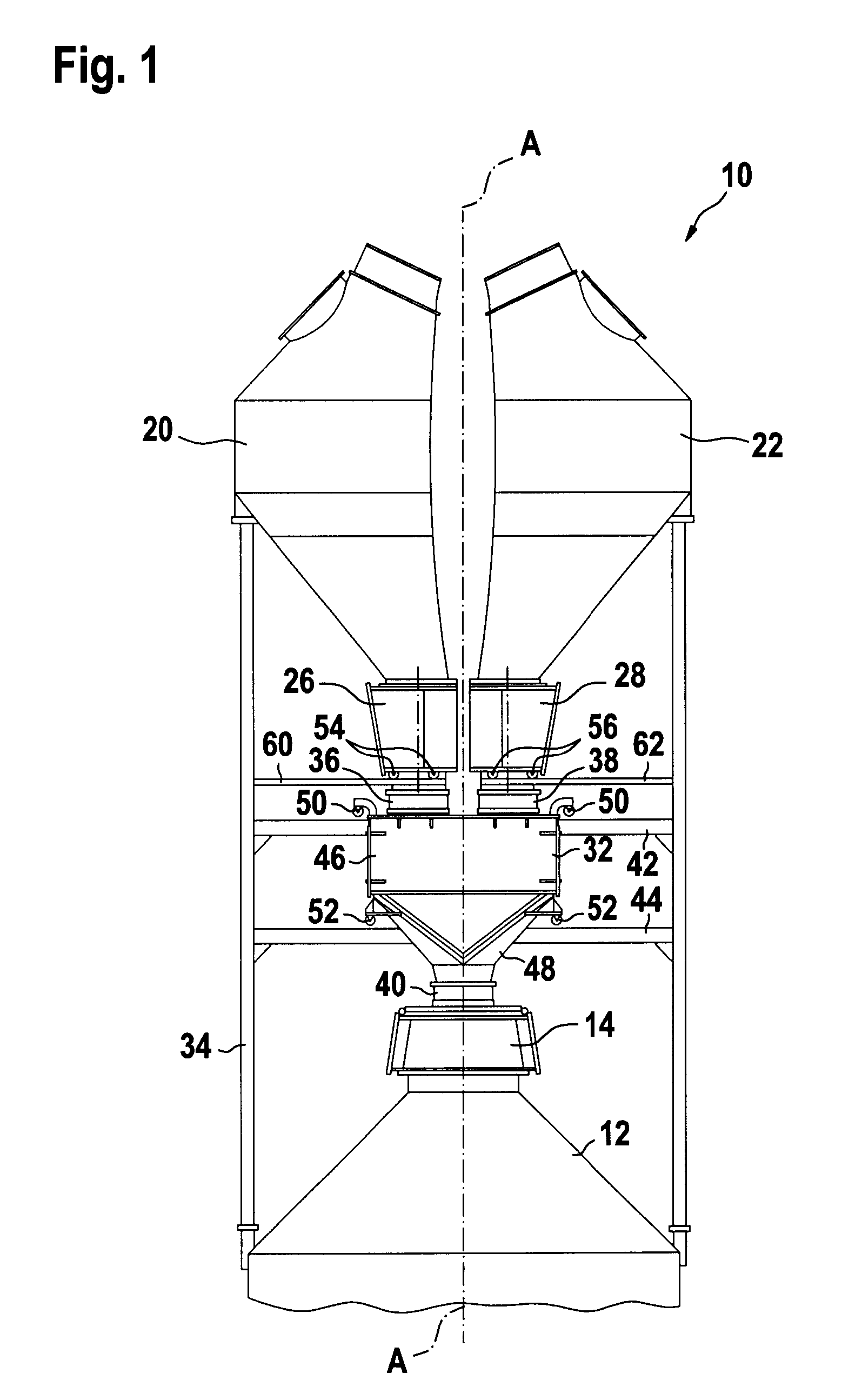

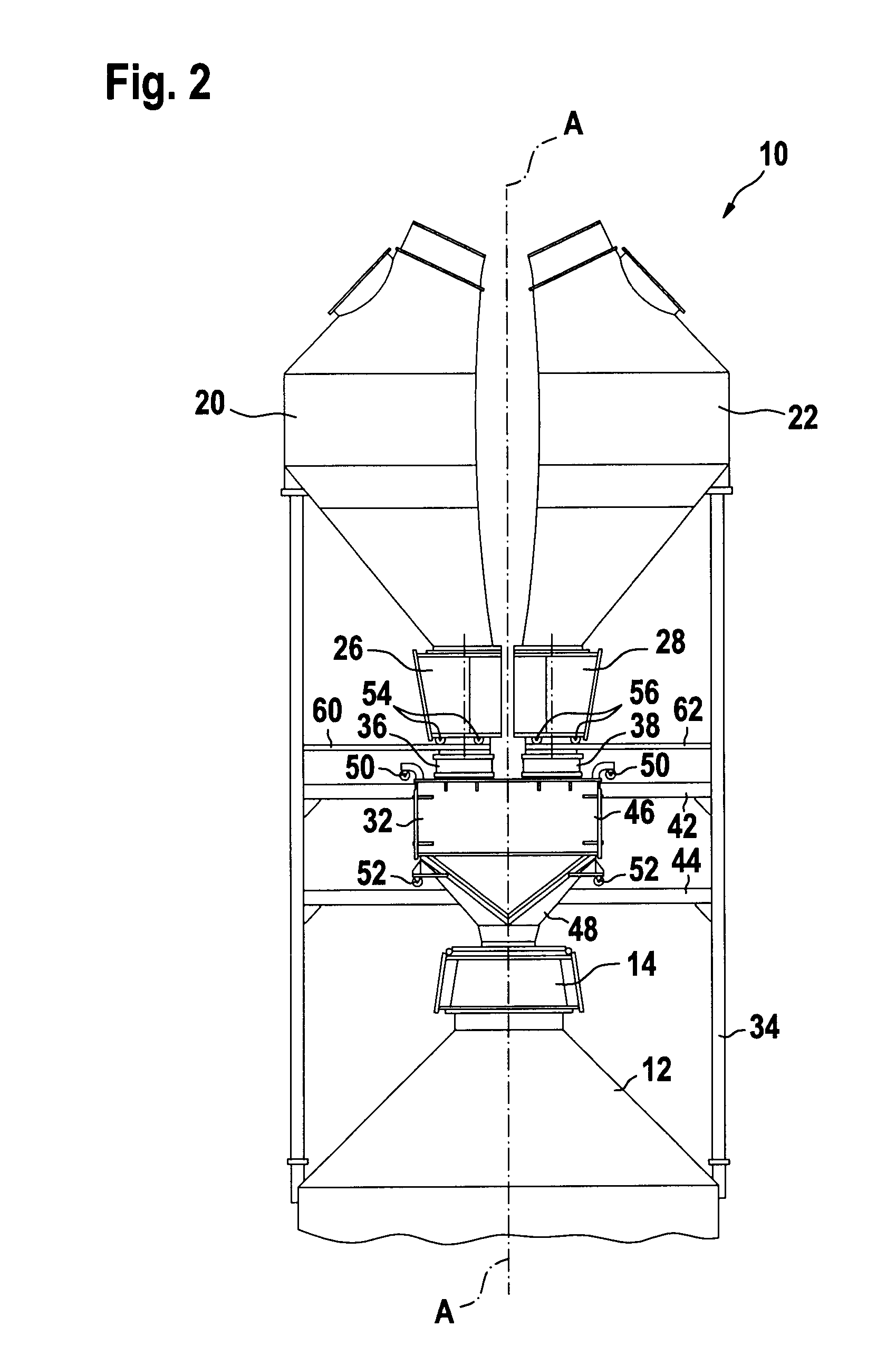

Three hopper charging installation for a shaft furnace

InactiveUS20090087284A1Smooth connectionExtend the flow pathConveyorsLarge containersEngineeringShaft furnace

A three hopper charging installation for a shaft furnace includes a rotary distribution device for distributing bulk material in the furnace by rotating a distribution member about the furnace central axis and a first, a second and a third hopper arranged in parallel above the rotary distribution device and offset from the central axis. A sealing valve housing is arranged between the hoppers and the distribution device. It has a top part with a first, a second and a third inlet respectively communicating with the first, the second and the third hopper. A first, a second and a third sealing valve are provided in the top part. Each sealing valve includes a flap which is pivotable between a closed sealing position and an open parking position. The sealing valve housing also has a funnel shaped bottom part with an outlet communicating with the distribution device. According to the invention, the top part of the sealing valve housing has a tripartite stellate configuration in horizontal section with a central portion, in which the inlets are arranged adjacently in triangular relationship about the central axis, and with a first, a second and a third extension portion, each sealing valve being adapted such that its flap opens outwardly with respect to the central axis by pivoting into a parking position located in the first, second or third extension portion respectively.

Owner:PAUL WURTH SA

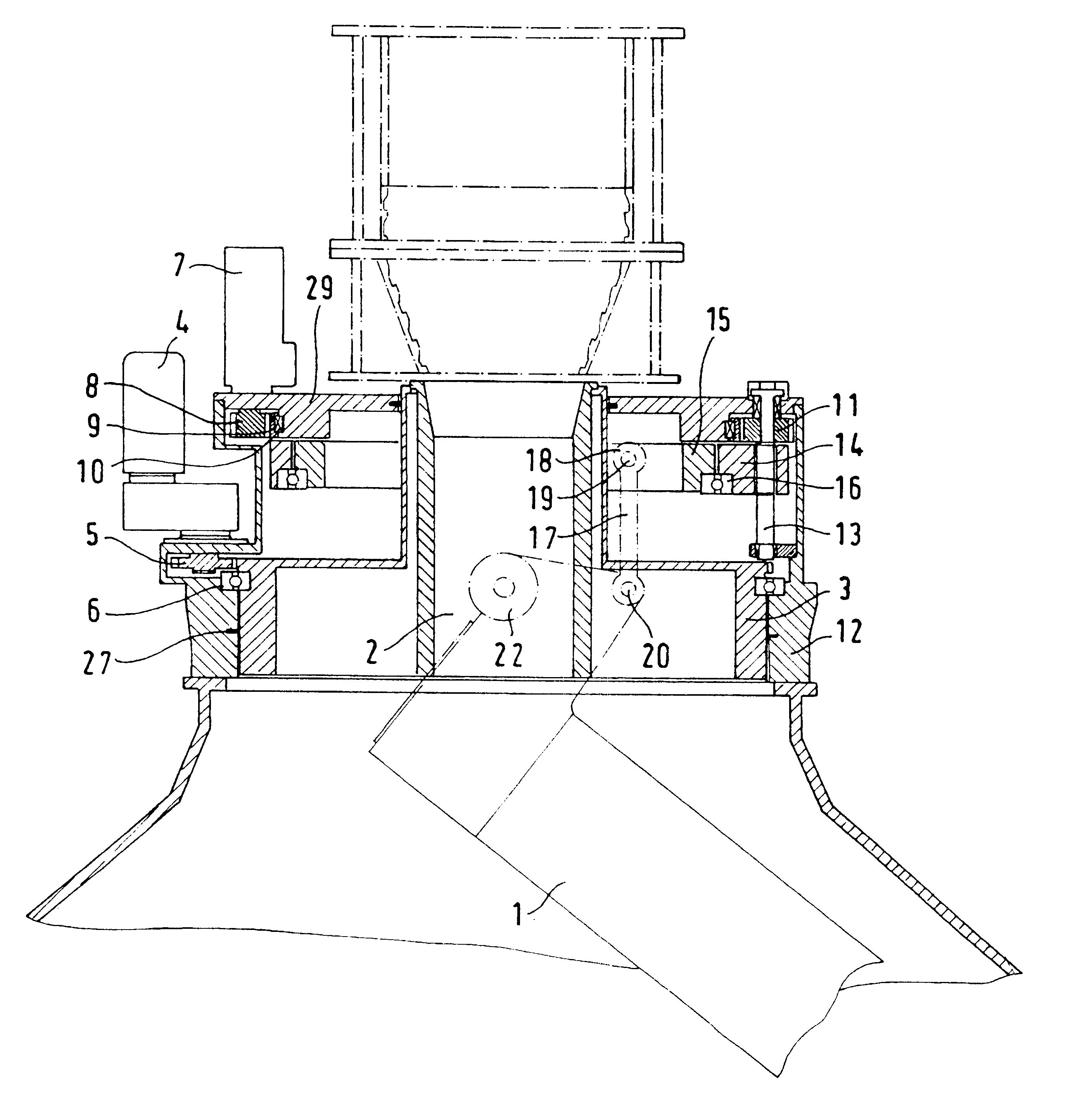

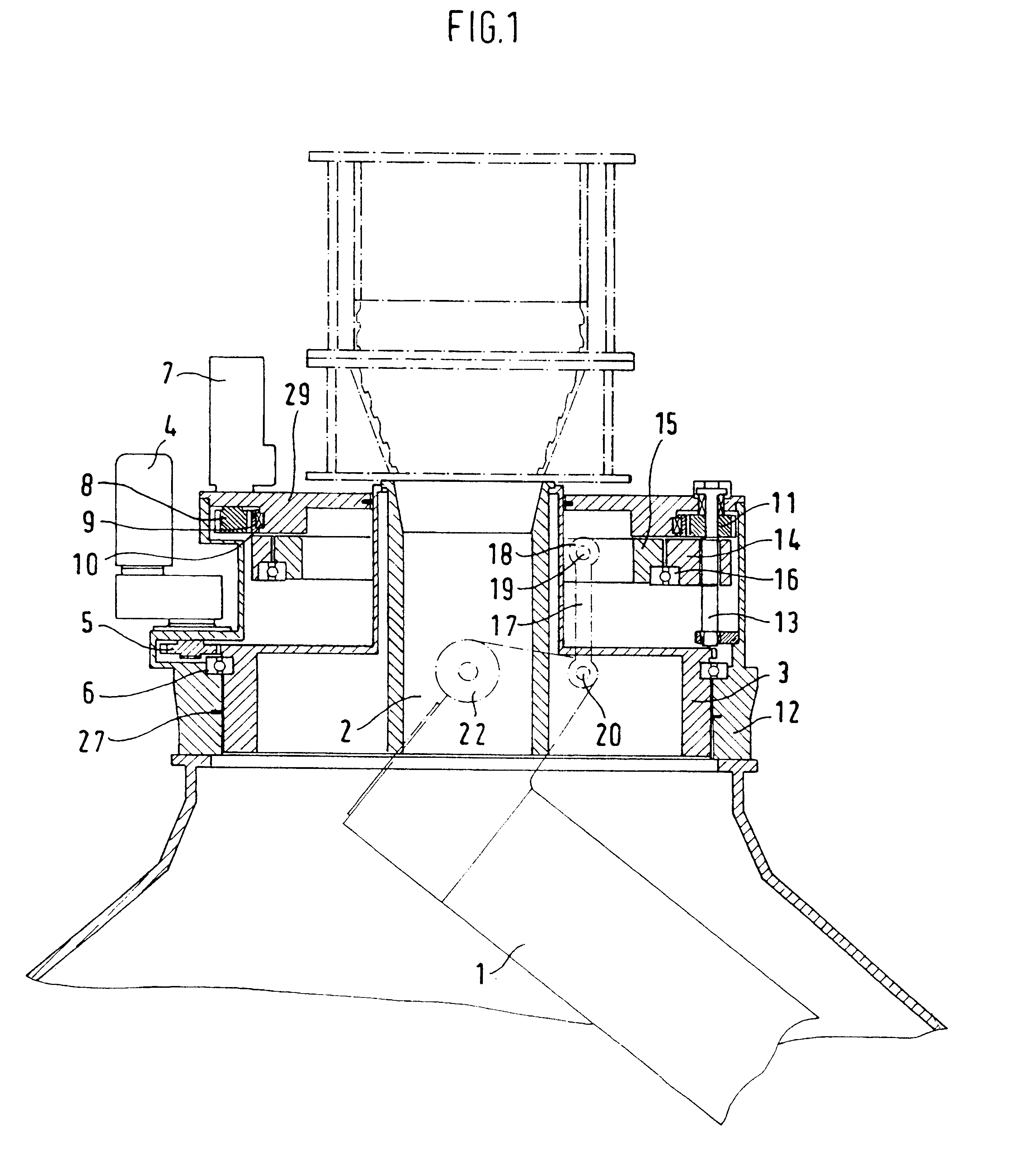

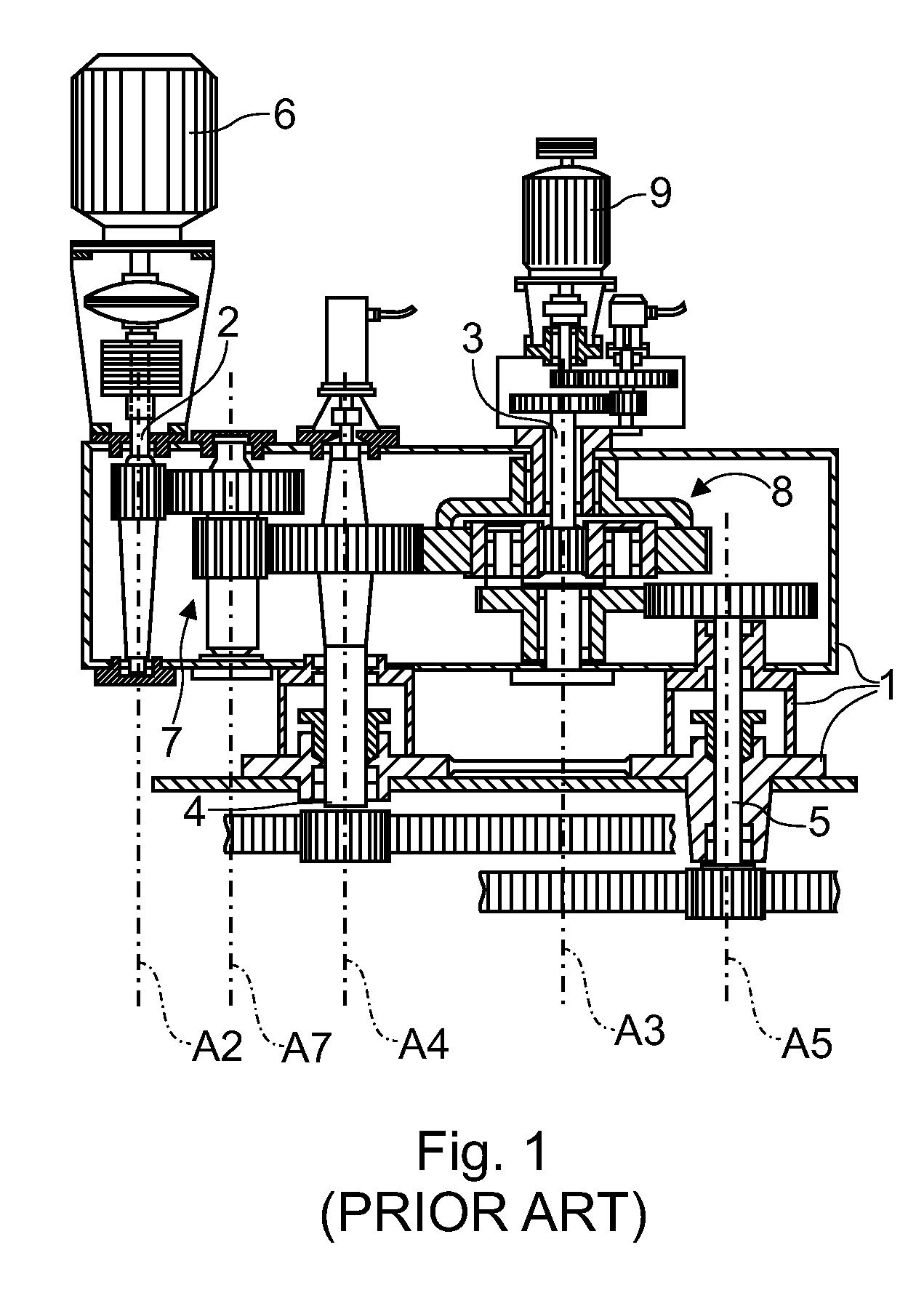

Bell and hopper for shaft furnaces

InactiveUS6540958B1Overcome disadvantagesCanting-free driveConveyorsBell-and-hopper arrangementWear resistantGear wheel

In order to configure a bell and hopper for shaft furnaces, in particular, blast furnaces, comprising a charging bin with a feed tube, a rotating chute carrier with rotary drive, a swiveling chute in the interior of the furnace with drive means arranged external to a housing, in a less failure-prone and a wear resistant way, the drive means for the swivel movement of the chute are to comprise: at least one motor (7) which drives by a respective pinion (8) a crown gear (9), wherein the crown gear (9) engages the spindle gear wheels (11) of at least two spindles (13) distributed about the periphery of the bell and hopper external to the rotating chute carrier (3) for generating a lifting and lowering movement of the spindles, as well as means (14, 15, 17, 21) for transmitting this vertical movement of the spindles onto the tilting shafts (22), which penetrate the inner wall (24) of the chute carrier (3) and from which the chute can be suspended, for generating a swivel and tilting movement of the chute.

Owner:PAUL WURTH SA

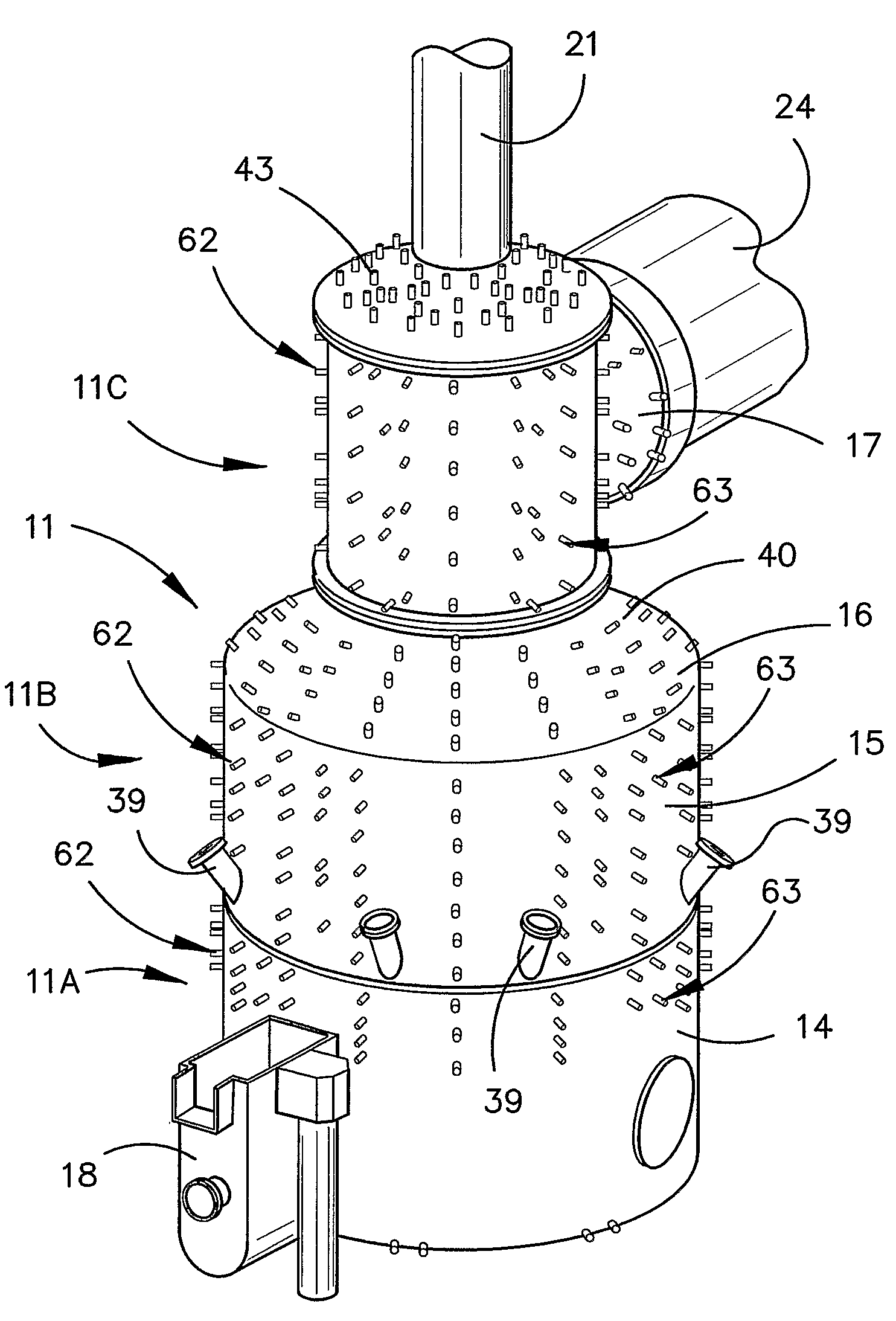

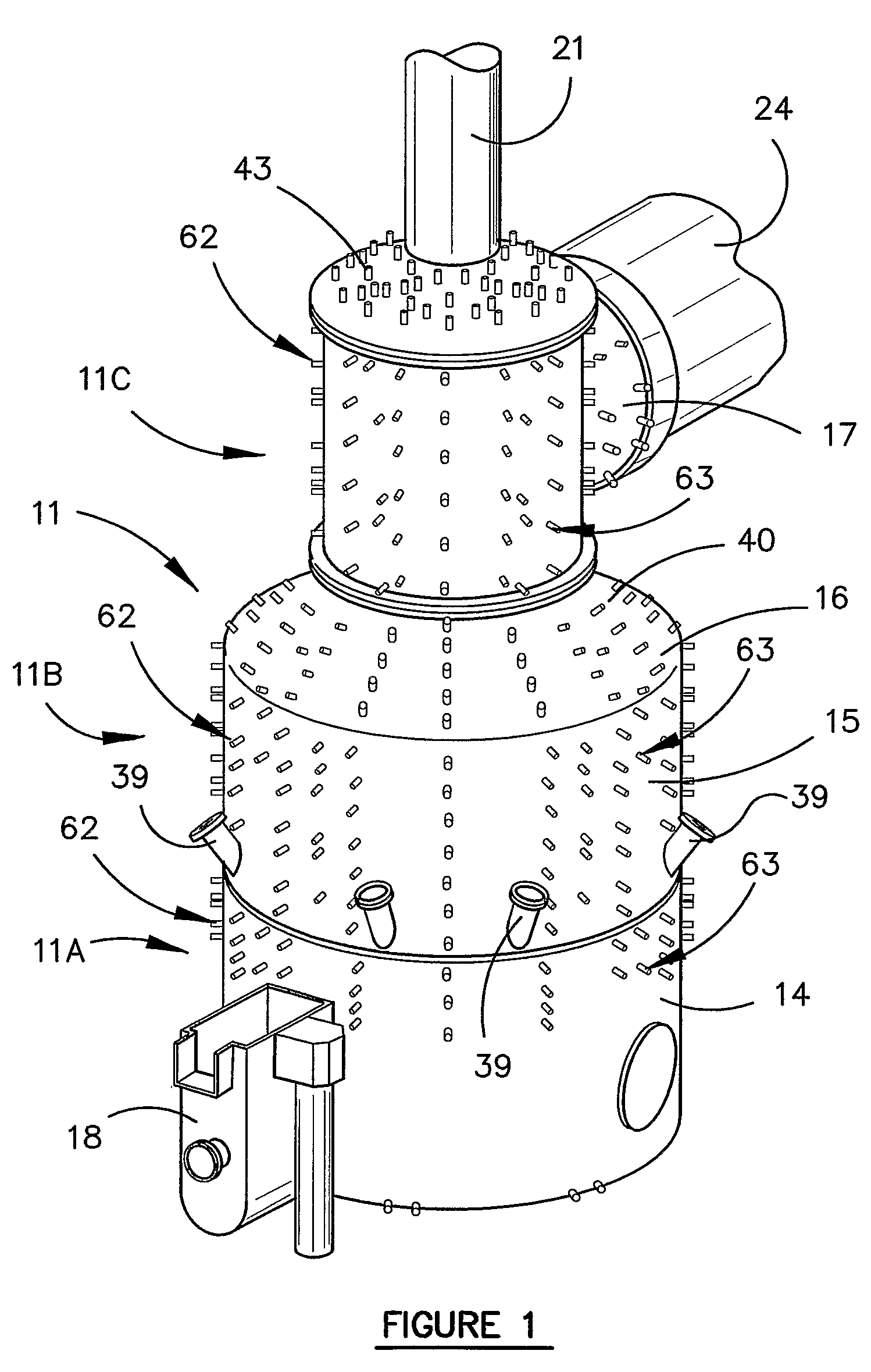

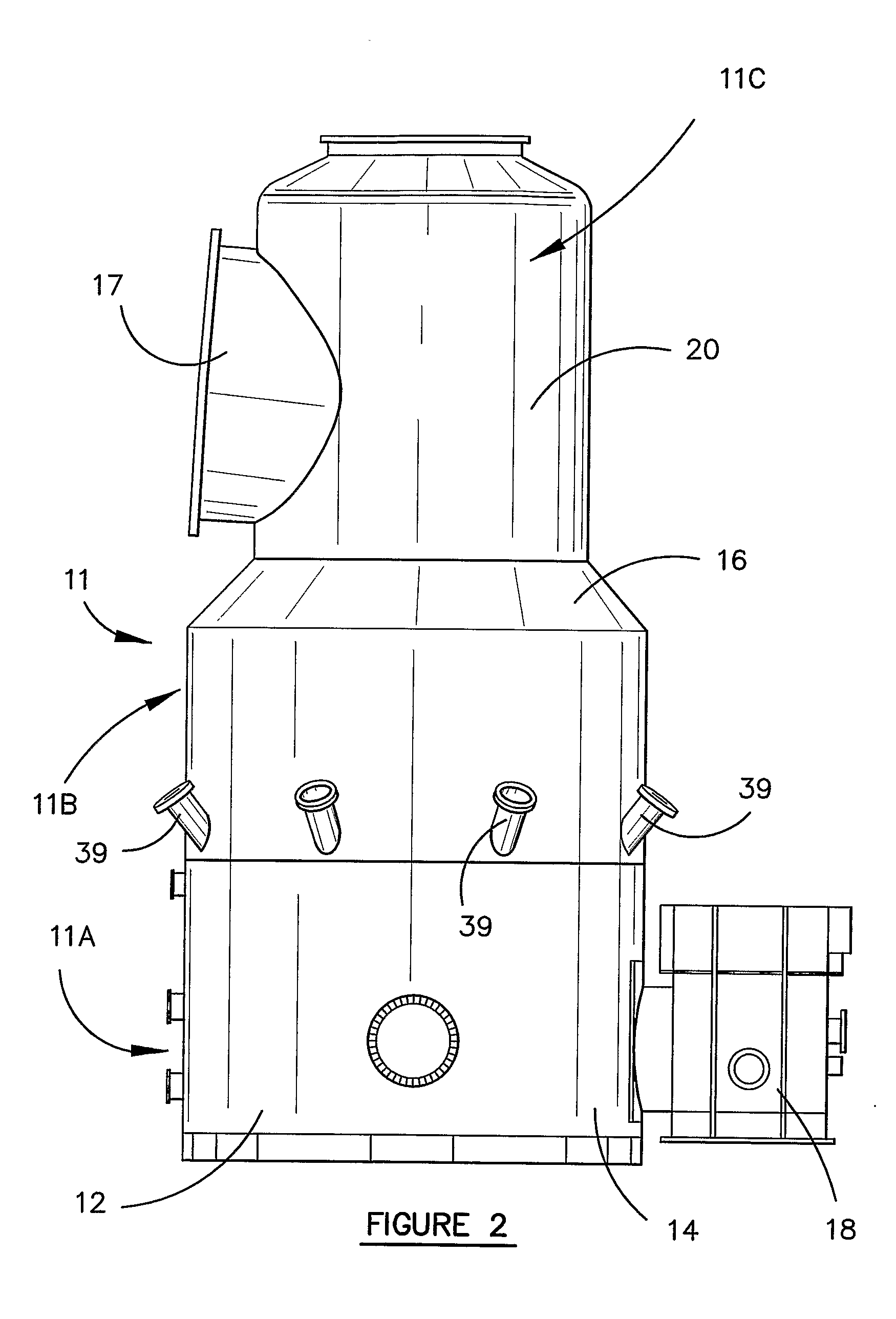

Direct Smelting Plant

Method of constructing and installing a direct smelting unit comprising a smelting vessel (11). The vessel is prefabricated off site in three modules (11A, 11B, 11C) which are then transported to the installation site where they are hoisted by a crane and deposited sequentially on top of one another and joined together by welding to form a unitary vessel. The vessel modules are prefabricated so as to be internally lined with water cooling panels connected to water inlet and outlet connectors (62) on the exterior of the circumferential wall sections of those modules. A vessel access tower is formed in modules brought together to envelop the tower and carrying water supply and return piping which is connected to the water inlet and outlet connectors (62) of the cooling panels.

Owner:TECH RESOURCES PTY LTD

Method and apparatus for heating a slurry to a predetermined temperature

InactiveUS6945775B2Accurately maintain temperatureEasy to controlFurnace componentsStorage heatersSlurryEngineering

The temperature of a metallurgical slurry in a heater vessel is accurately controlled by heating a first portion of the slurry in the heater vessel by contact with a heating medium such as steam, and by adding to the heater vessel controlled portions of a slurry at lower temperature. The lower temperature slurry may be added to the heater vessel in an intermittent or continuous manner, with addition of the lower temperature slurry being regulated by a valve, the operation of which is controlled by a control device which receives temperature information from one or more temperature sensors.

Owner:HATCH LTD

Method and apparatus for producing molten iron

InactiveUS20050151307A1Low costQuality improvementBlast furnace detailsExhaust gas handlingShaft furnaceIron ore

A system for producing molten iron from iron ores, including a direct reduction shaft furnace, a melting zone in a melting furnace having a coke bed in its lower portion and a charging and preheating chamber in its upper portion, and at least one reducing gas generation zone in communication with said melting zone.

Owner:HYLSA SA DE CV

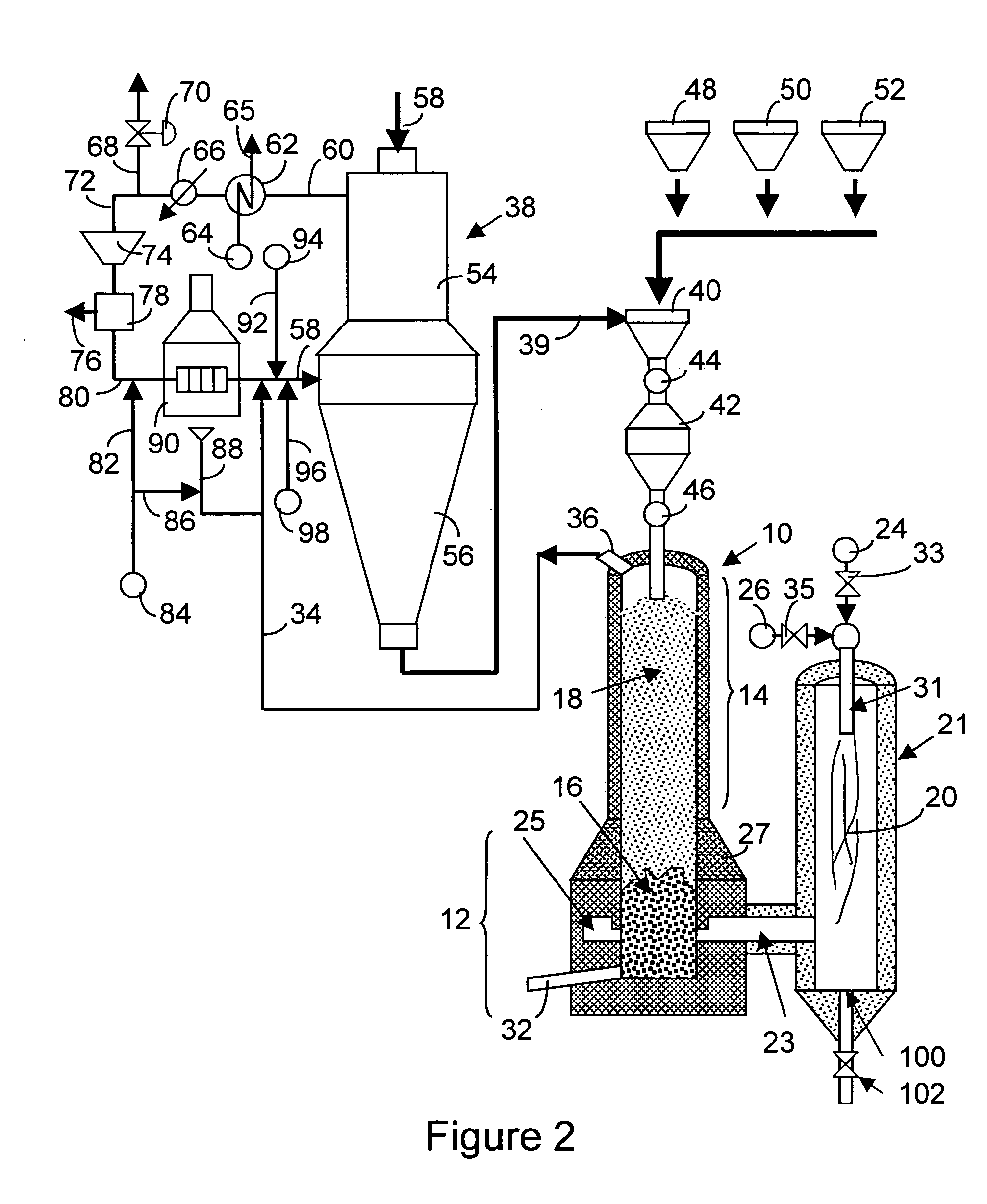

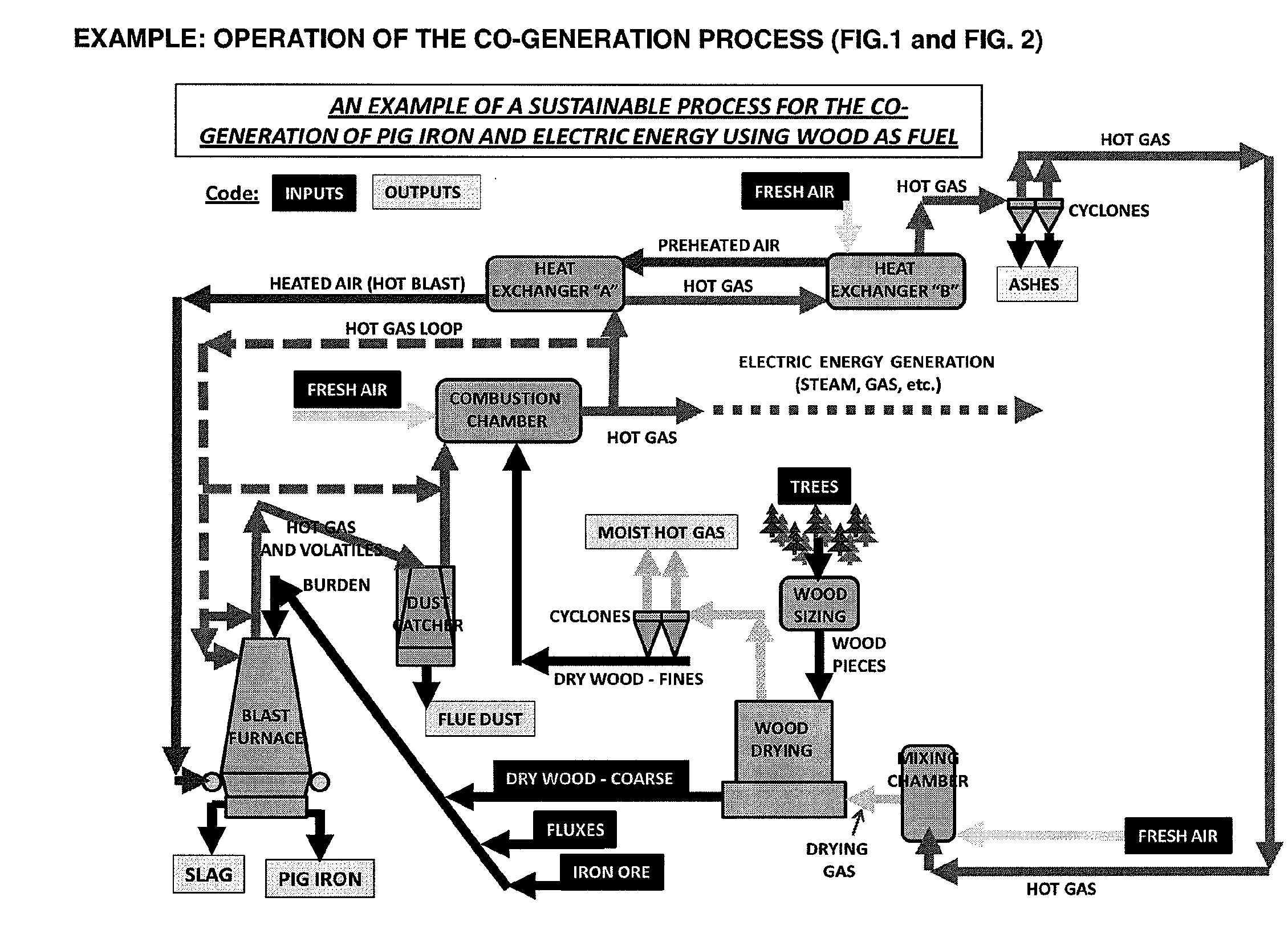

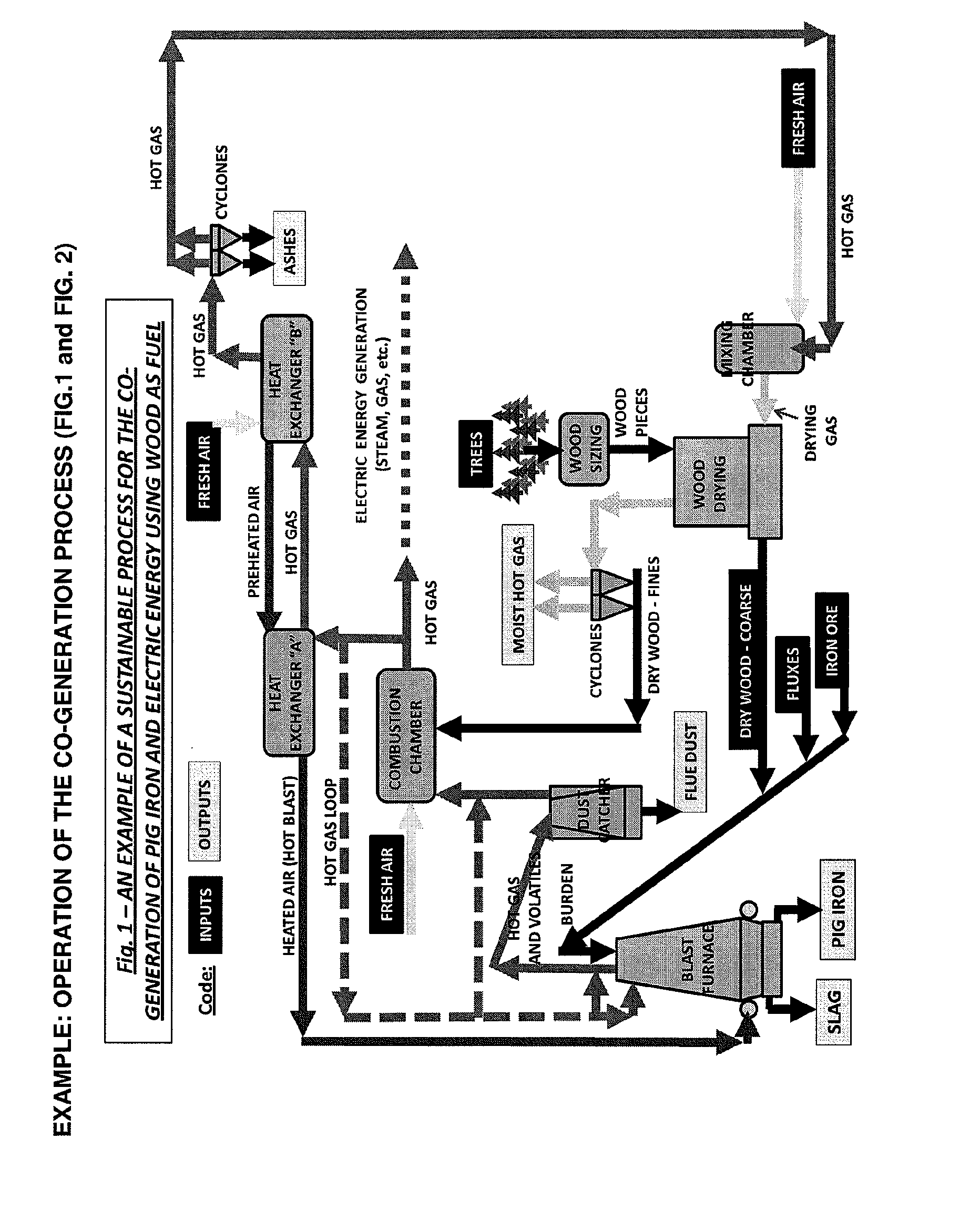

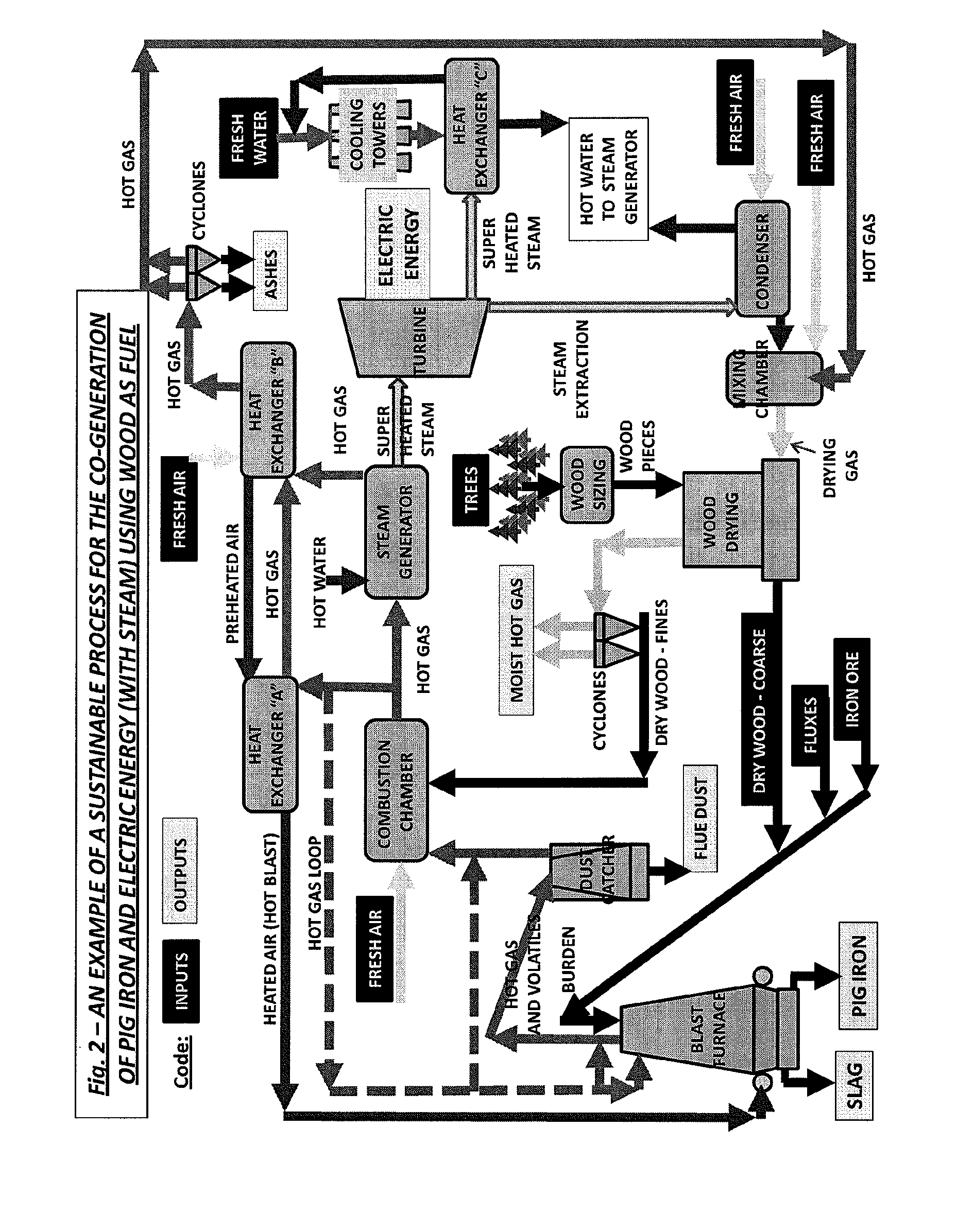

Sustainable process for the co-generation of pig iron and electric energy using wood as fuel

InactiveUS20140306386A1Optimizes charcoal production efficiency charcoalImprove material yieldWaste based fuelBlast furnace detailsEngineeringSustainable process

An integrated and sustainable process is presented for the co-generation of pig iron and electric energy in a blast furnace installation in which dried wood replaces charcoal as the fuel, as the reducing and as the carburizing agent. Furthermore, this application incorporates the process—until now independent—of transforming wood into coal, inside the blast furnace.

Owner:ACTIVE LAND INT CORP

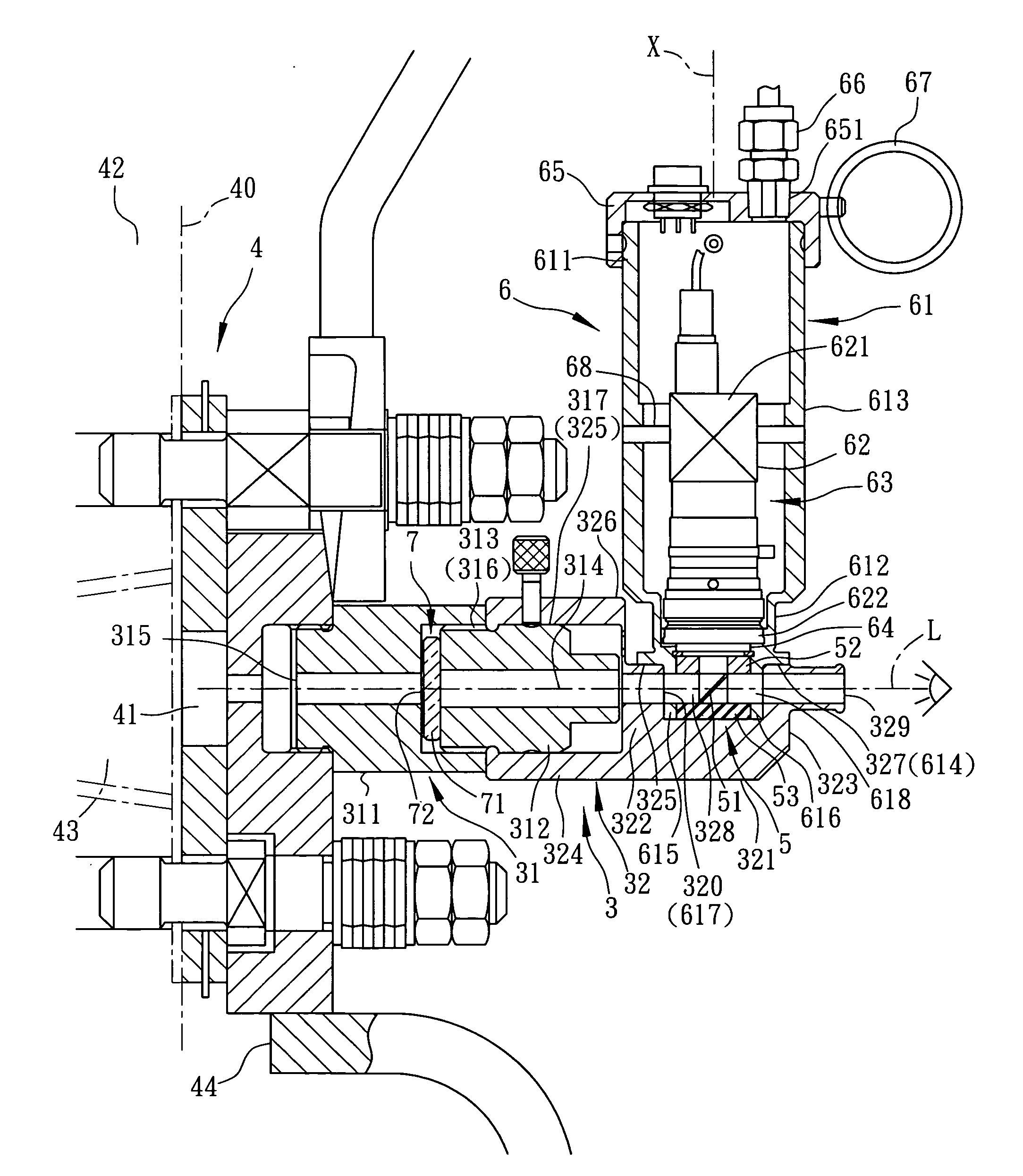

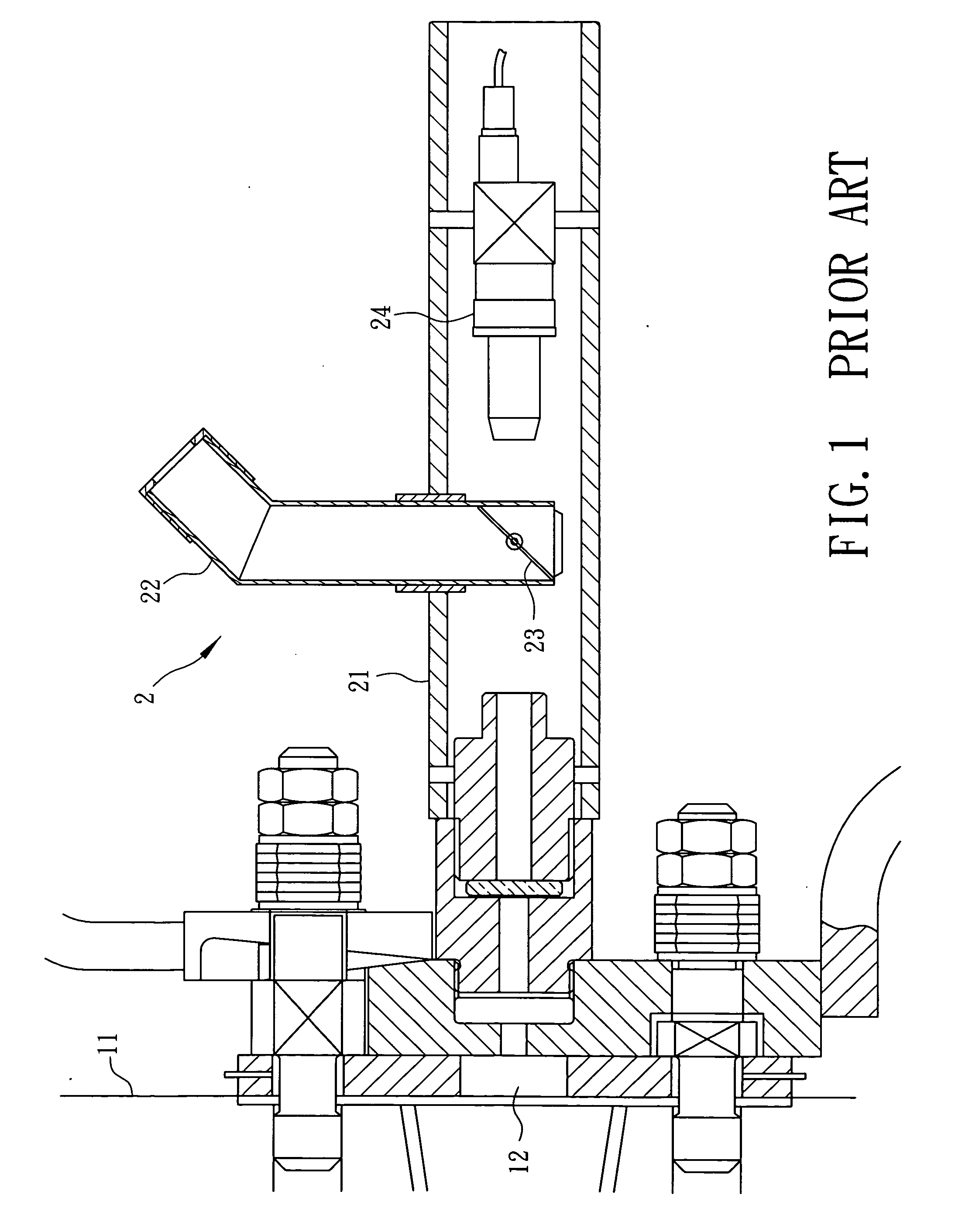

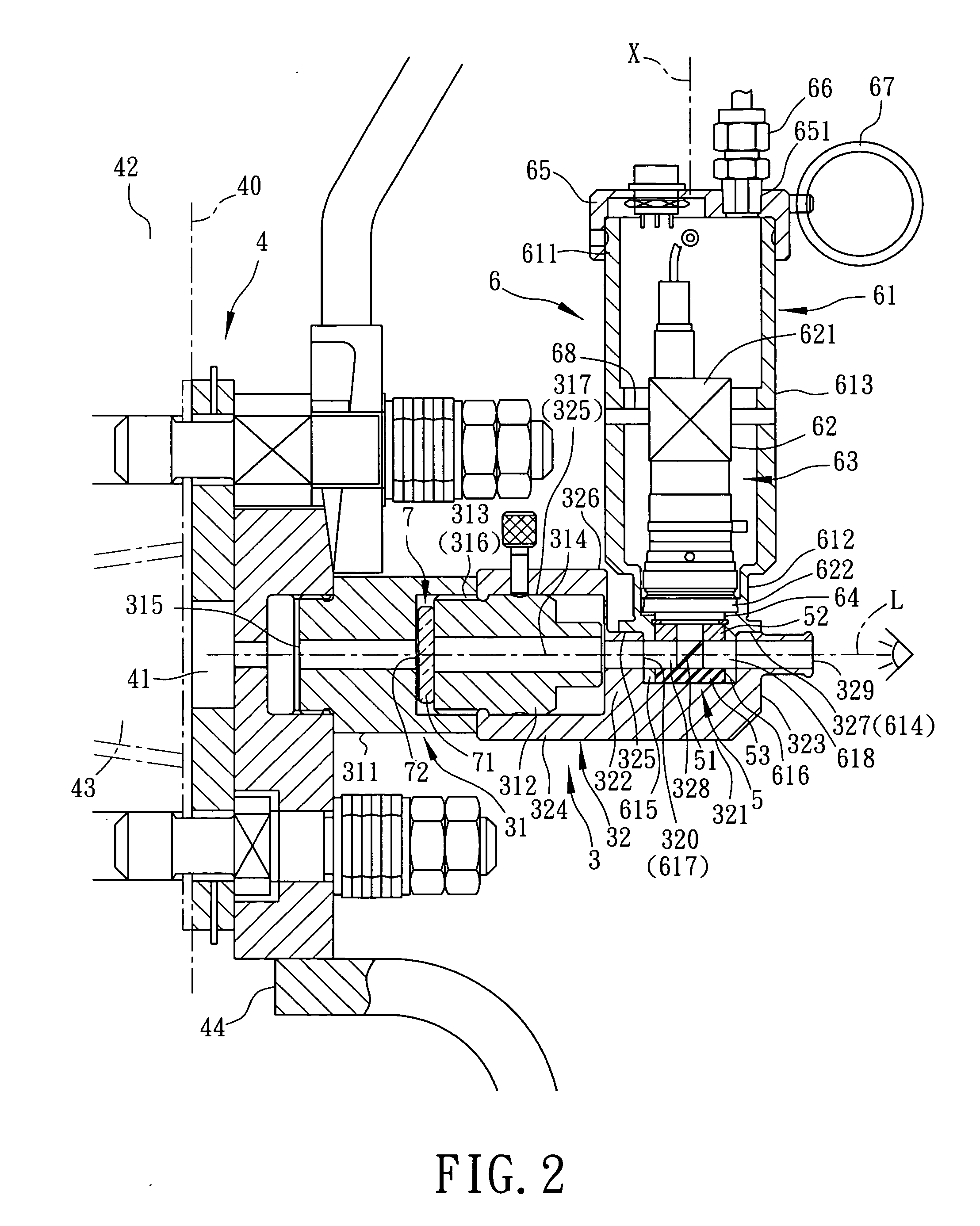

Apparatus for observing interior of a blast furnace system

An apparatus for observing the interior of a blast furnace system includes a visible light guiding unit which defines a light path along a viewing axis that is radial to an upright axis of a furnace wall body of a blast furnace and which is adapted to be secured to a furnace blowpipe to permit the light path to be in visual communication with a tuyere, a beam splitter which is disposed in an accommodation space in the tubular mount to split a beam of light propagating along the light path into a horizontal component so that the operator can observe furnace condition through a peeping hole, and a vertical component, and a video camera system which includes an elongate casing connected to the tubular mount, and a video camera disposed in a cooling chamber of the casing to capture a light image from the vertical component of the light beam.

Owner:CHINA STEEL

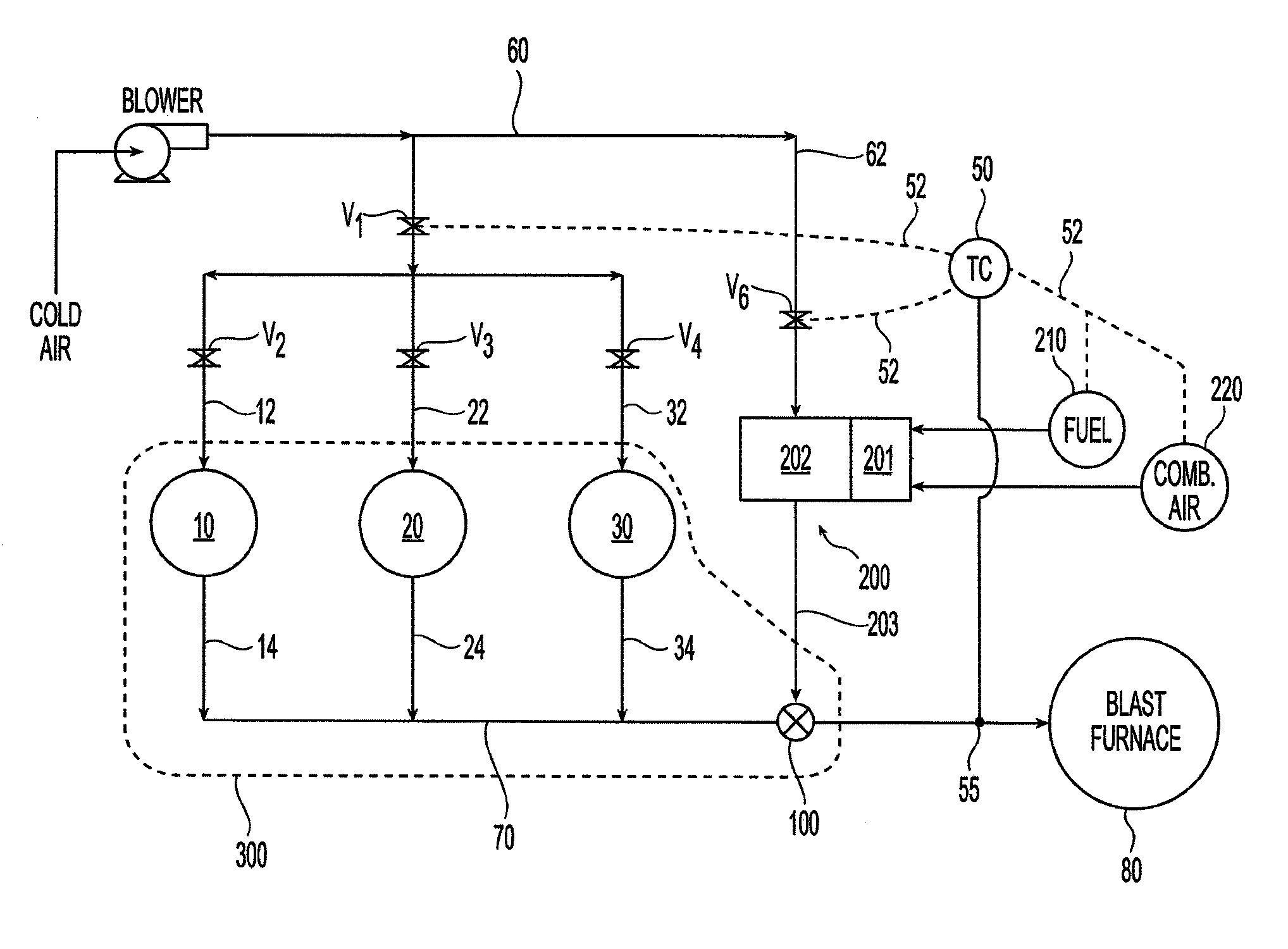

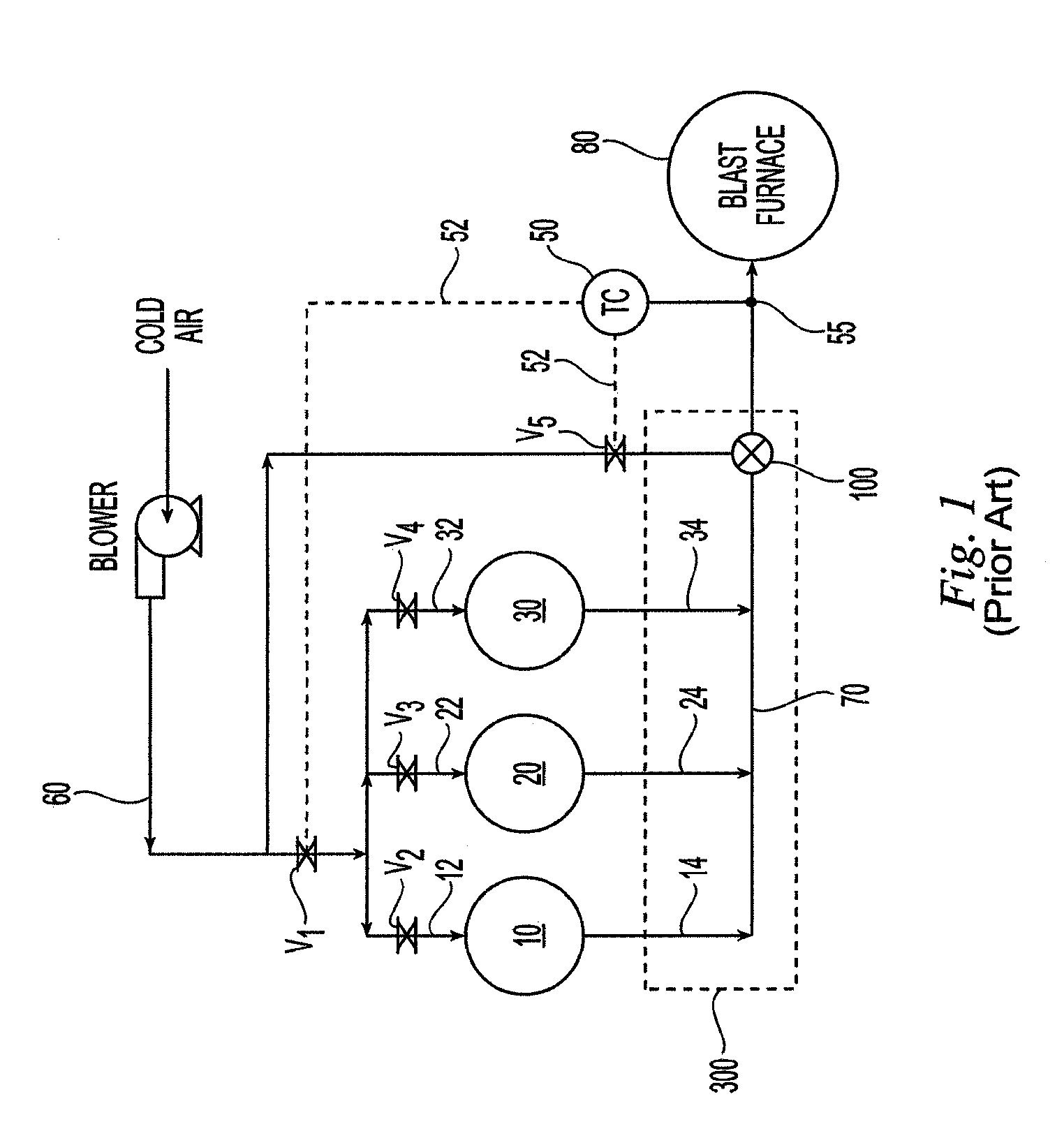

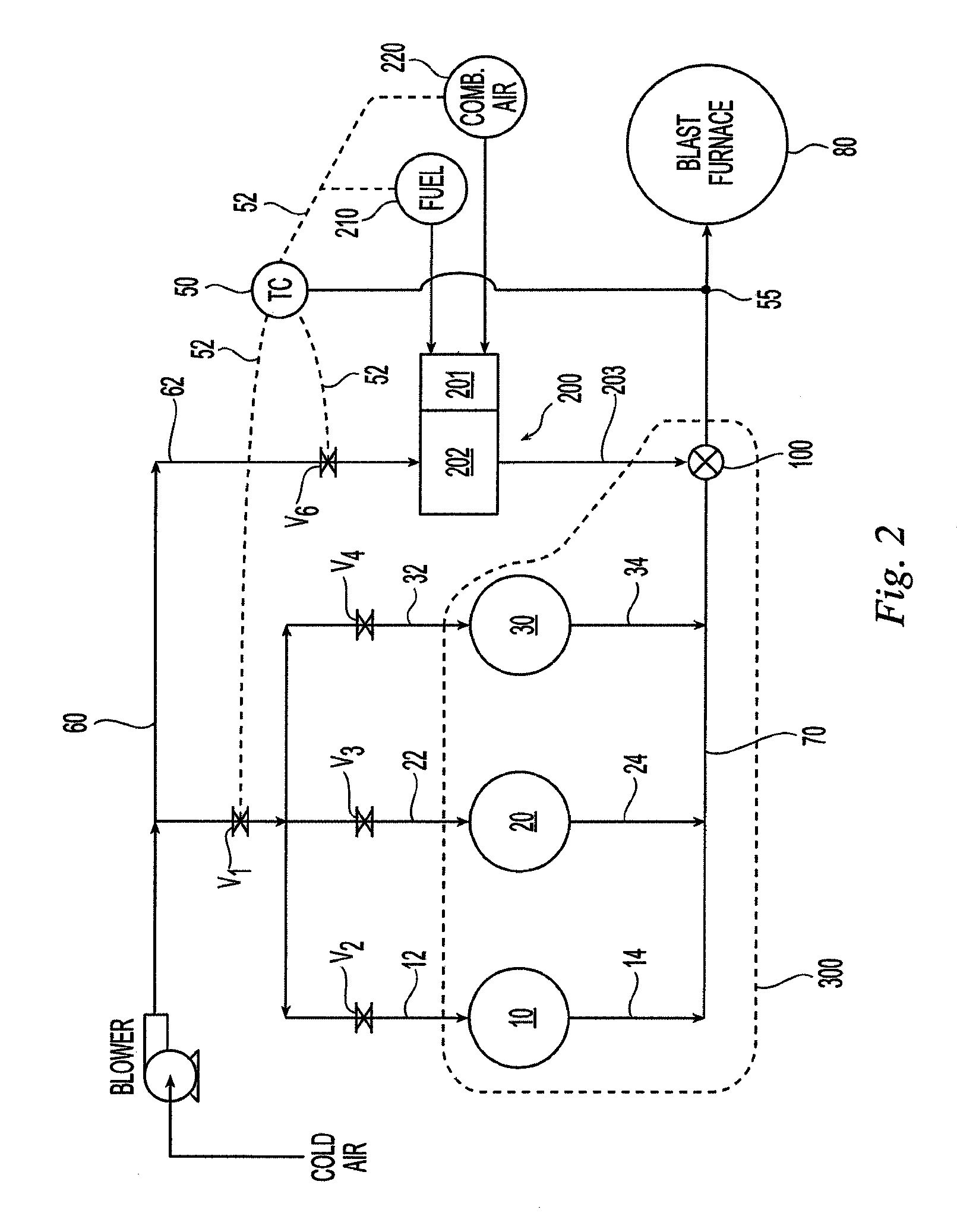

Preheating cold blast air of a blast furnace for tempering the hot blast temperature

InactiveUS7232542B2Extend your lifeLow costStorage heatersBlast furnace detailsCold blastBlast furnace

An improved blast furnace system for producing molten iron incorporating a preheater to heat the cold blast air used to temper the hot blast temperature is disclosed. The improved blast furnace system comprises a blast furnace, a hot blast main for conveying a supply of hot blast to the blast furnace, a plurality of stoves for heating a supply of cold blast and generating the hot blast, a cold blast main for conveying a supply of cold blast to the plurality of stoves, and at least one cold blast preheater for heating a portion of the cold blast, that has been diverted to the preheater, into heated air and the heated air is mixed with the hot blast to temper the hot blast temperature.

Owner:AKER KVAERNER METALS

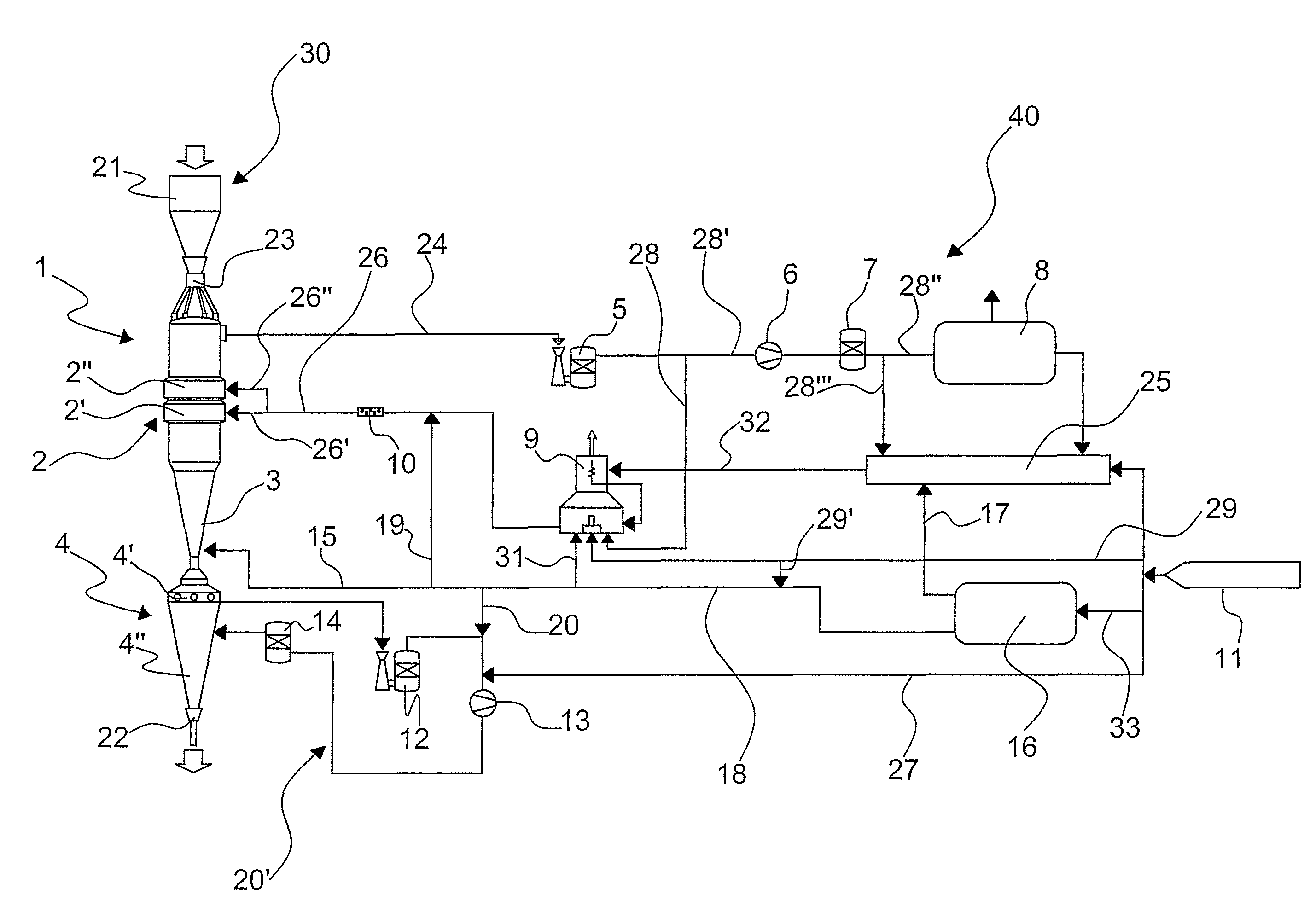

Reduction process and plant

ActiveUS7854786B2Prevent reoxidationSmall sizeTuyeresBell-and-hopper arrangementSyngasProcess engineering

Reduction process and relative plant for the production of metallic iron by means of the direct reduction of iron ore, in which a reduction shaft is connected to a source of reducing gas obtained from the gasification of coal. The process advantageously comprises a step in which a portion or all of the synthesis gas entering the plant circuit is processed to separate the methane from the rest of the components of said synthesis gas. The advantageous management of the extracted methane enables the entire reduction process to be optimized, making the efficiency of the process independent of the methane content in the original synthesis gas and making it possible to control the carbon content of the product more accurately and more easily.

Owner:DANIELI & C OFF MEC SPA

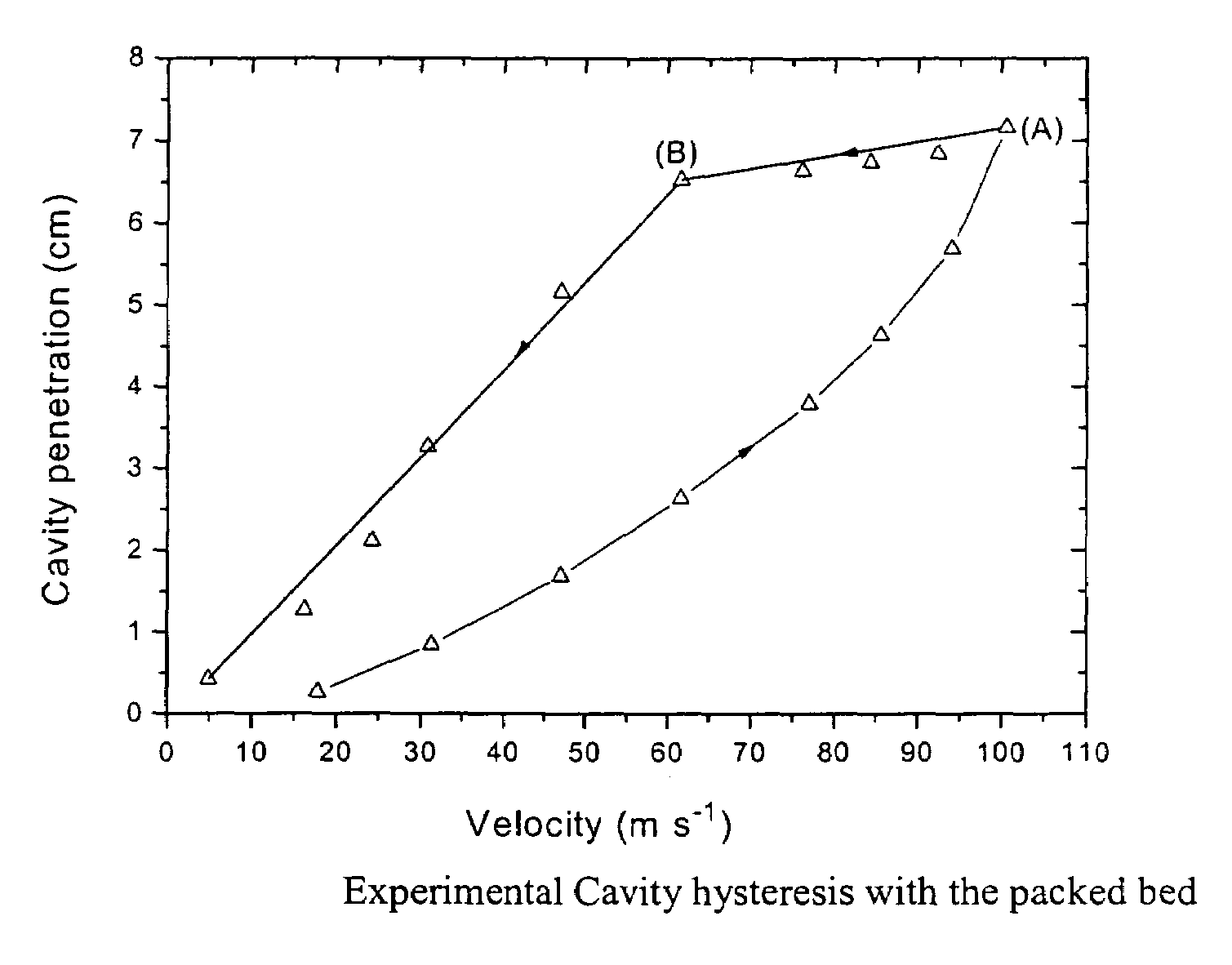

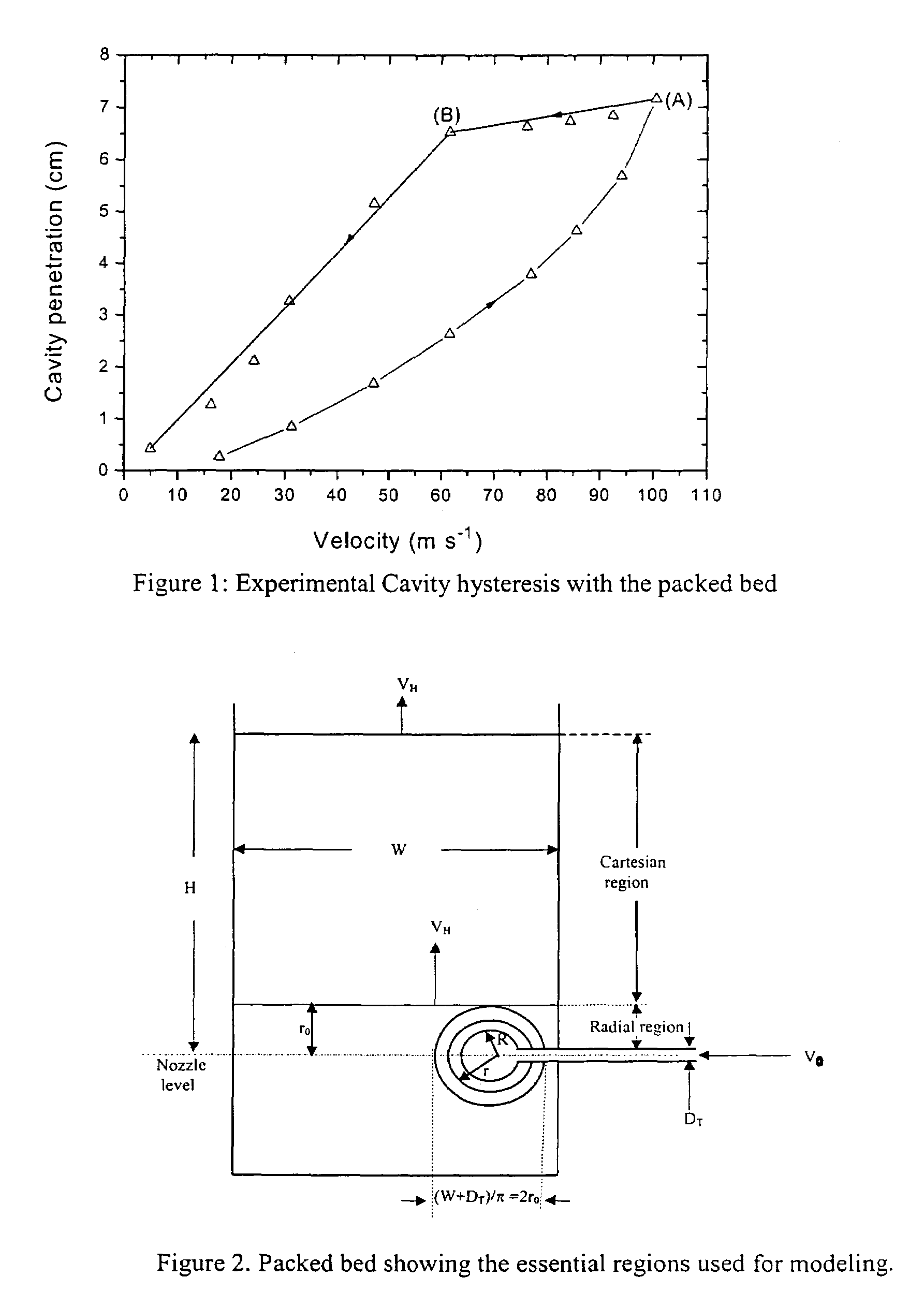

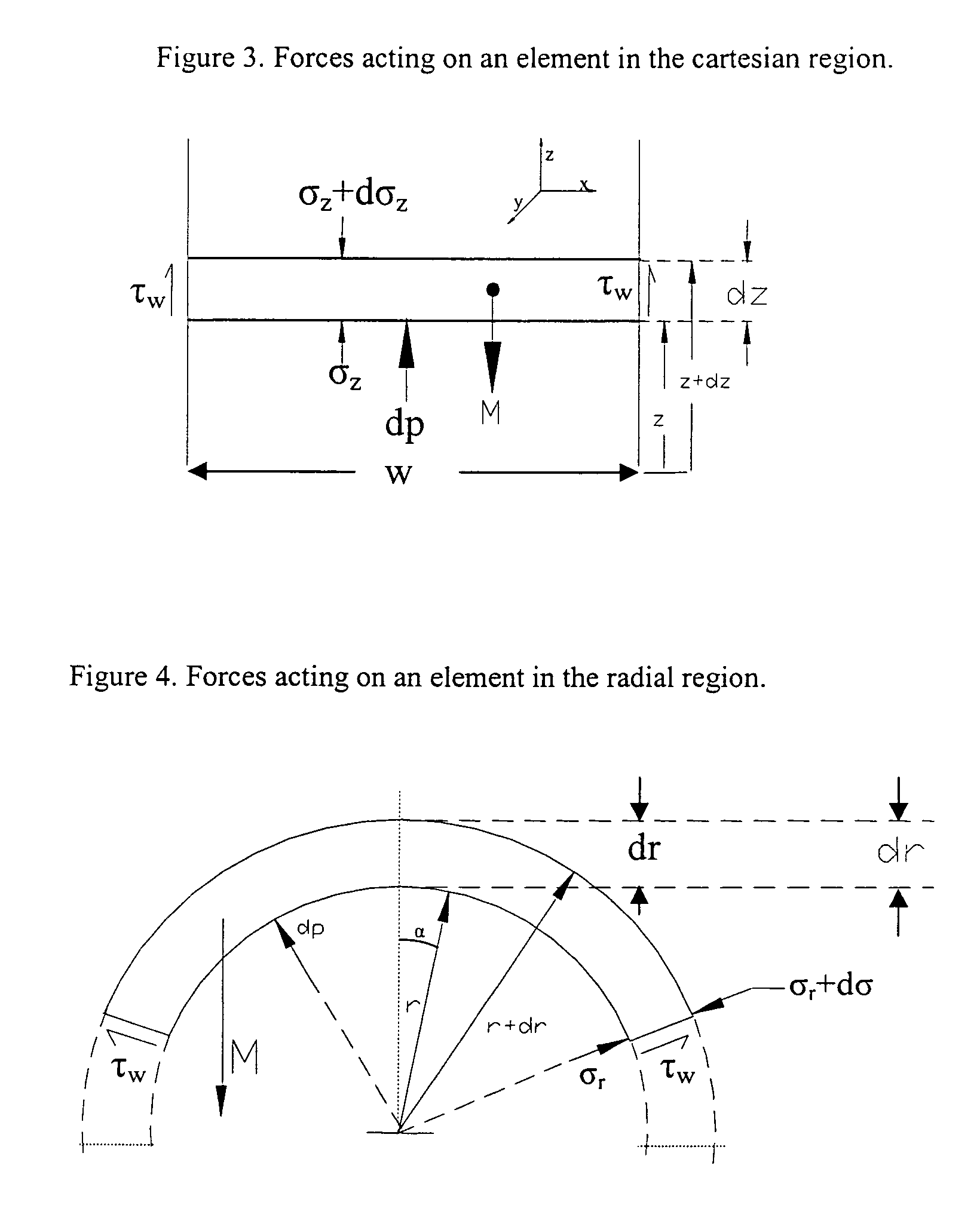

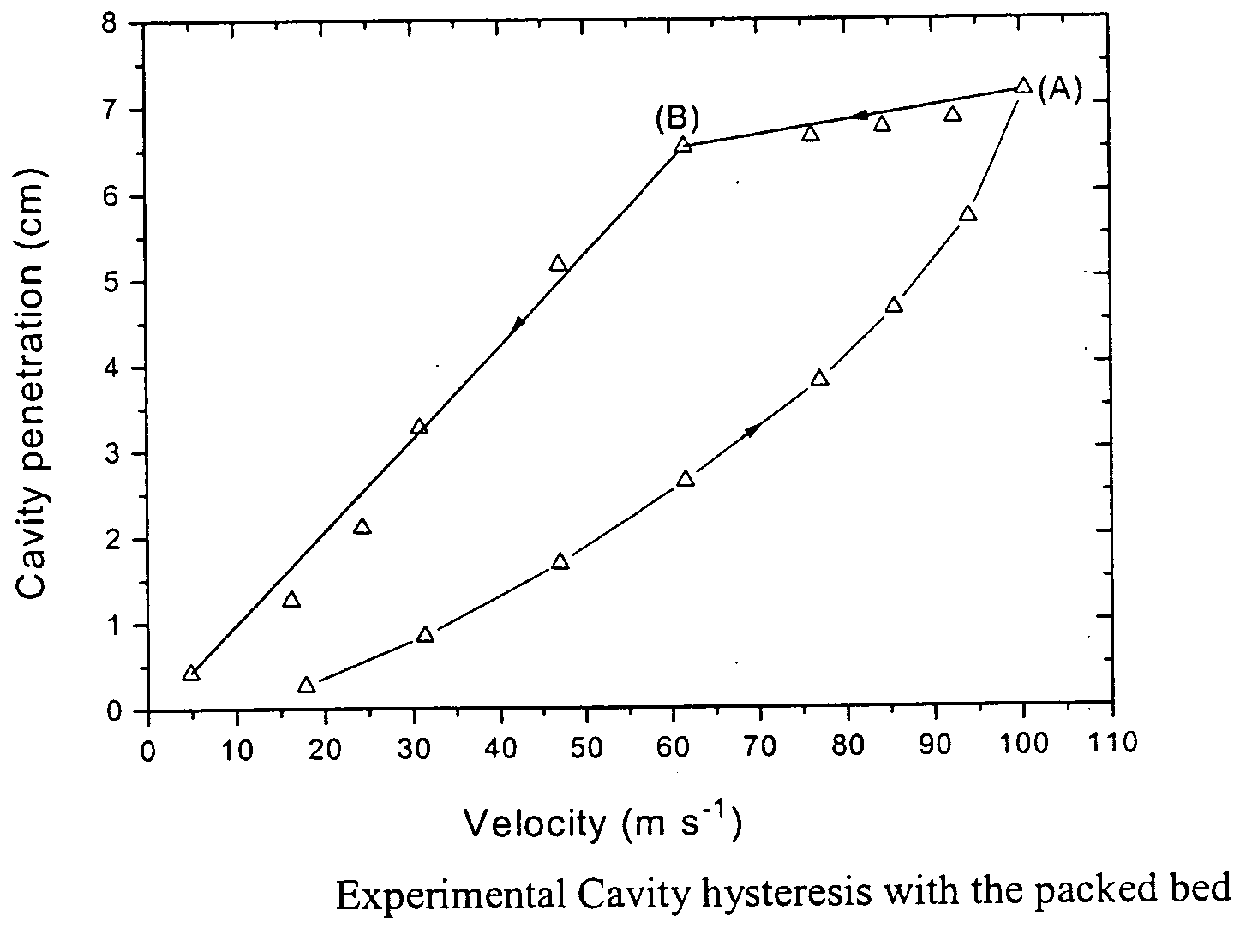

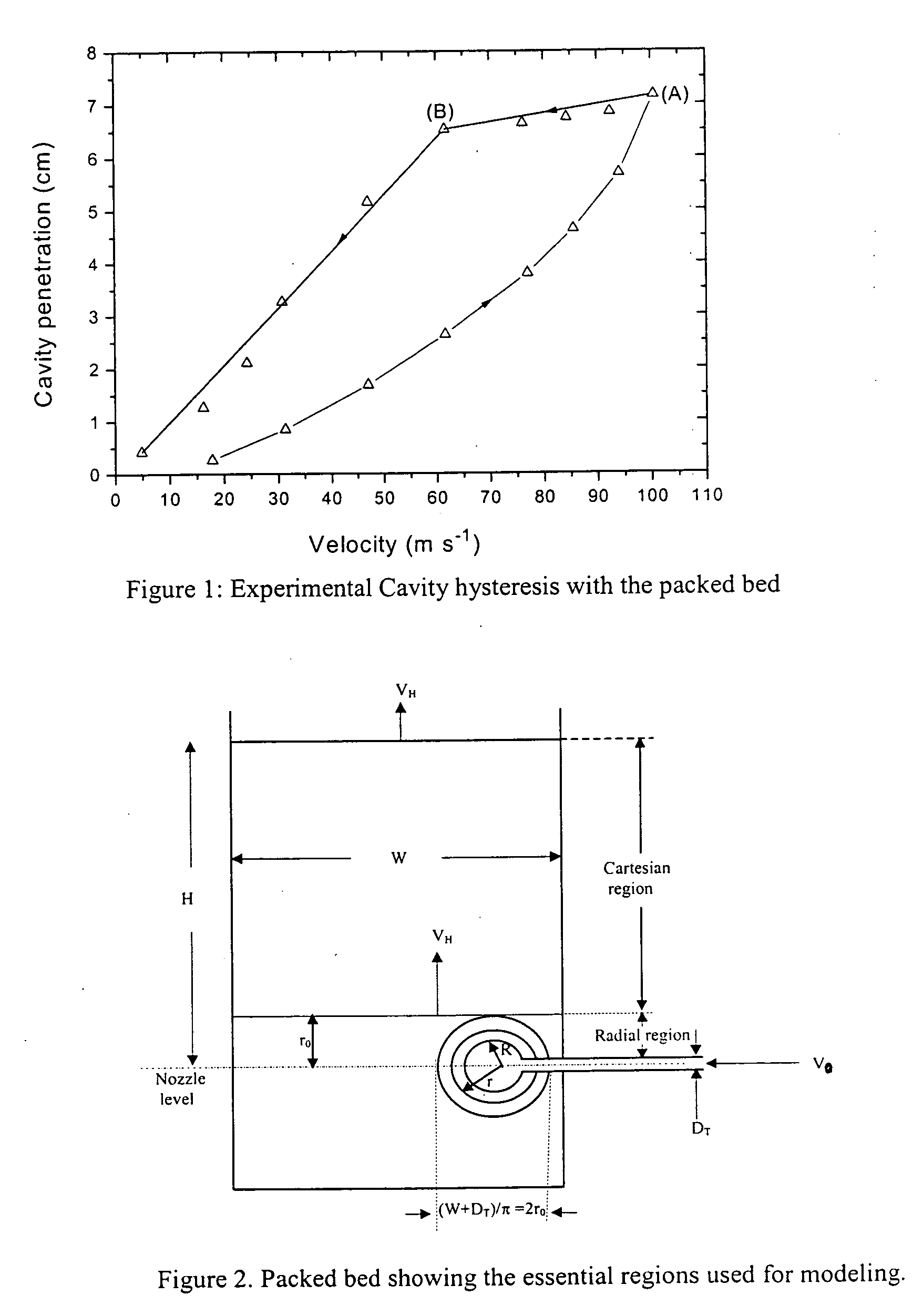

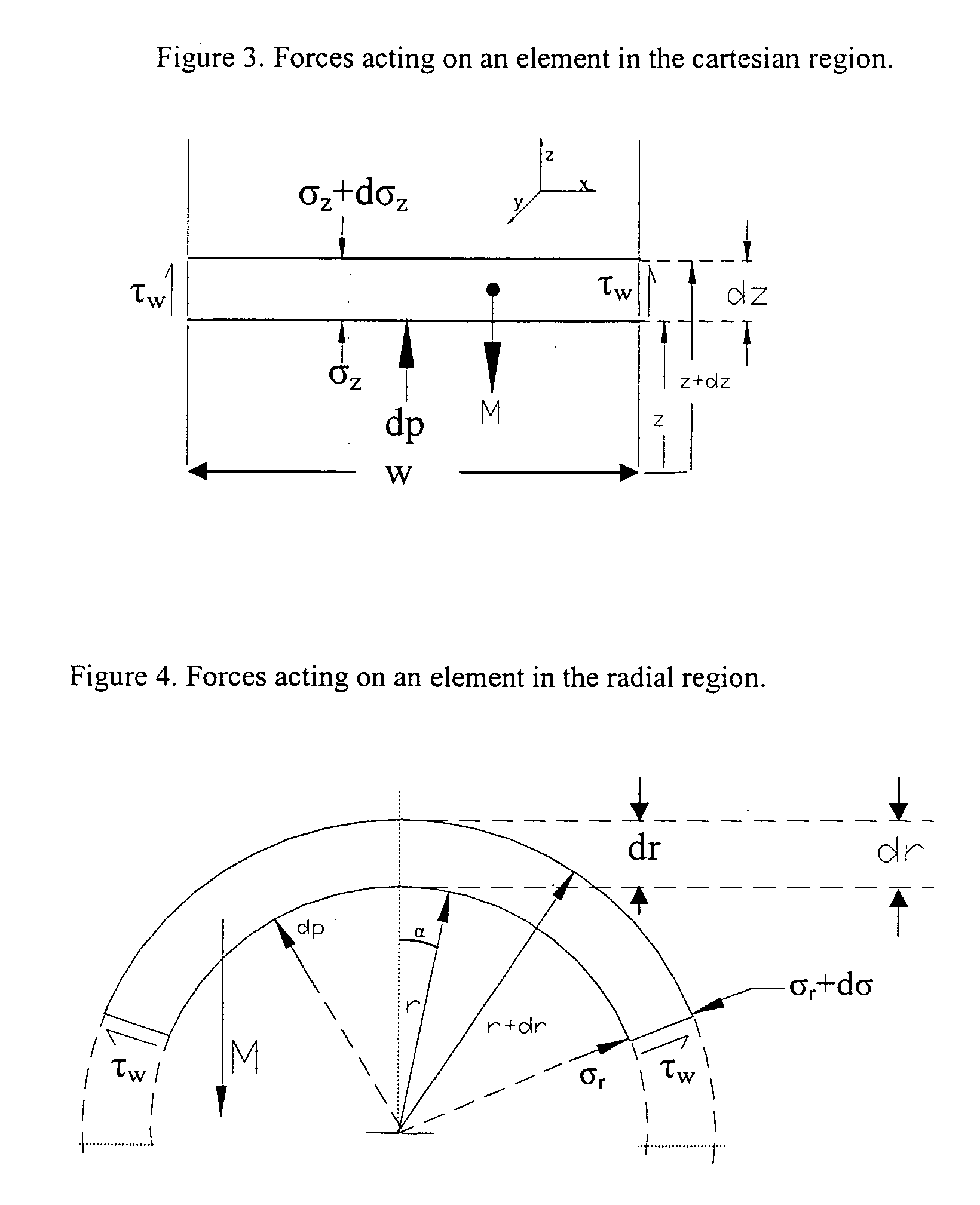

Prediction of cavity size in the packed bed systems using new correlations and mathematical model

It has been reported in the literature that raceway measurement made during the decreasing gas velocity is relevant to operating blast furnaces. However, no raceway correlation is available either for decreasing or increasing gas velocity which is developed based on a systematic study and none of the available correlation take care of frictional properties of the material. Therefore, a systematic experimental study has been carried out on raceway hysteresis. Based on experimental data and using dimensional analysis, two raceway correlations, one each for increasing and decreasing gas velocity, have been developed. Also, in the present study the effect of stresses has been considered along with pressure and bed weight terms mathematically. These three forces are expressed in mathematical form and solved analytically for one-dimensional case, using a force balance approach. Based on the force balance approach a general equation has been obtained to predict the size of the cavity in each case, i.e., for increasing and decreasing velocity. Results of these correlations and model have been compared with the data obtained from literature on cold and hot models and plant data along with some experimental data. An excellent agreement has been found between the predicted (using correlations and model) and experimental values. The proposed theory is applicable to any packed bed systems. It has been shown that hysteresis mechanism in the packed beds can be described reasonably taking into consideration the reversal of sign in frictional forces in increasing and decreasing velocity cases.

Owner:COUNCIL OF SCI & IND RES

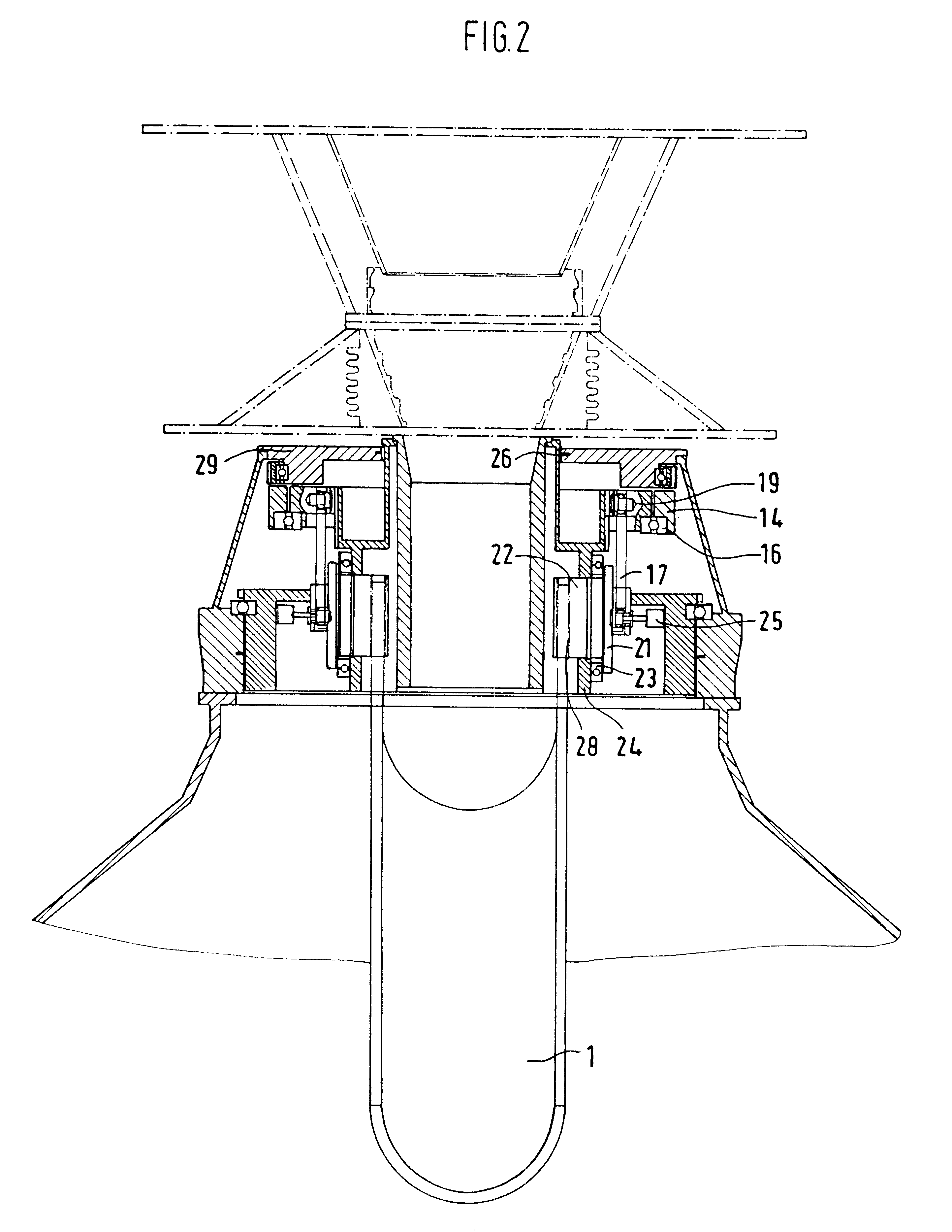

Furnace head or furnace throat seal

InactiveUS6948930B2Reliable data transfer is facilitatedIncrease resistanceBell-and-hopper arrangementBlast furnace detailsThroatEngineering

A blast furnace head (11) including a material loading device comprising rotary chute (14) driven in rotation about a first, vertical axis of rotation (16), and a loading chute (15) at the outlet of same, driven in rotation about a second, vertical axis of rotation (17) laterally offset relative to the first axis of rotation (16). The gears (20, 21) assigned to both of the chutes (14, 15) are arranged within a sealing chamber (22). Within this sealing chamber (22), a means (28) is arranged for supplying integrated measuring devices (29 or 30), lubrication points or similar maintenance recipients, with these supply means (28) being drivable by one of the gears (20, 21) assigned to the two chutes, in particular by the gear (20) assigned to the rotary chute (14).

Owner:Z & J TECH

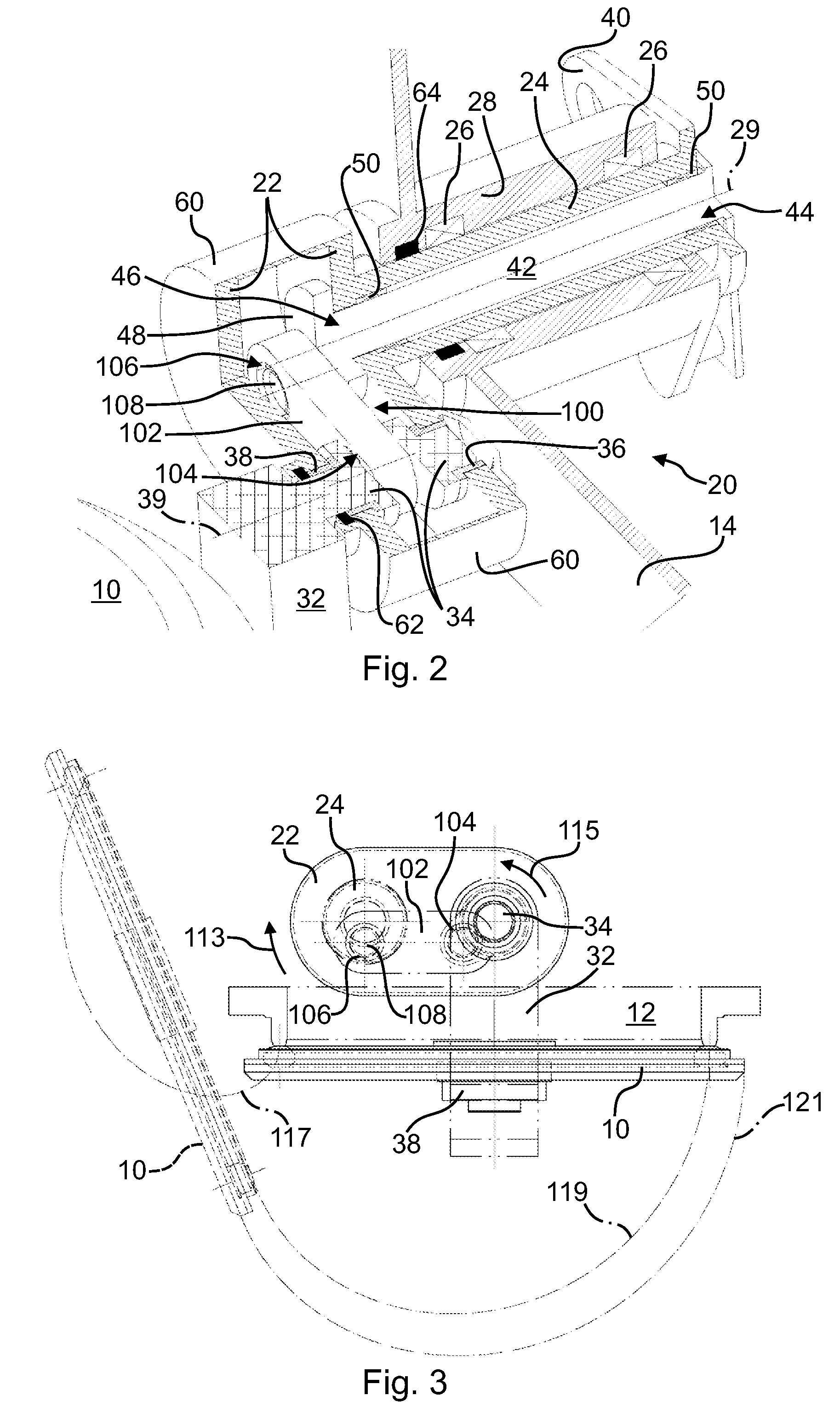

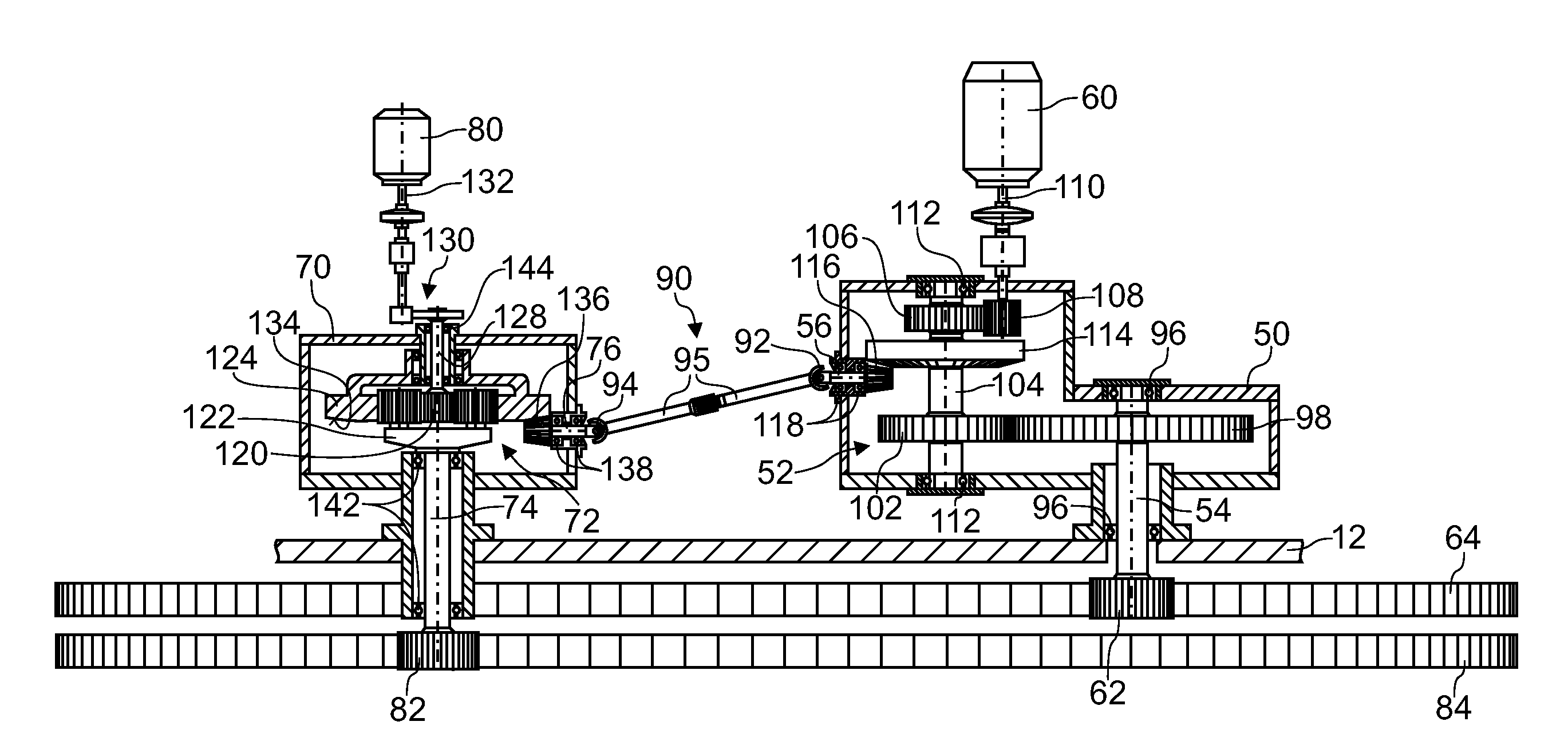

Device for distributing charge material into a shaft furnace

ActiveUS8920710B2Increased riskManufacturing precision less stringentMovable measuring chambersGearingRotation velocityEngineering

A shaft furnace charge material distribution device includes a main housing, a distribution chute, a suspension rotor and an adjustment rotor, which are rotatable about a vertical axis. The chute is suspended to the suspension rotor to rotate therewith for circumferential distribution of charge material and is adjustable in orientation for radial distribution of charge material. A differential gear interconnects the suspension rotor and adjustment rotor and is configured to transmit to the adjustment rotor the same speed of rotation that is imparted to the suspension rotor by a main rotation drive unless an adjustment drive imparts differential rotation to the adjustment rotor. The device includes two gear casings arranged on the main housing and a shaft arrangement. The first gear encloses a gear mechanism connecting the main rotation drive to one output shaft. The second gear casing encloses the differential gear connecting the adjustment drive to another output shaft.

Owner:PAUL WURTH SA

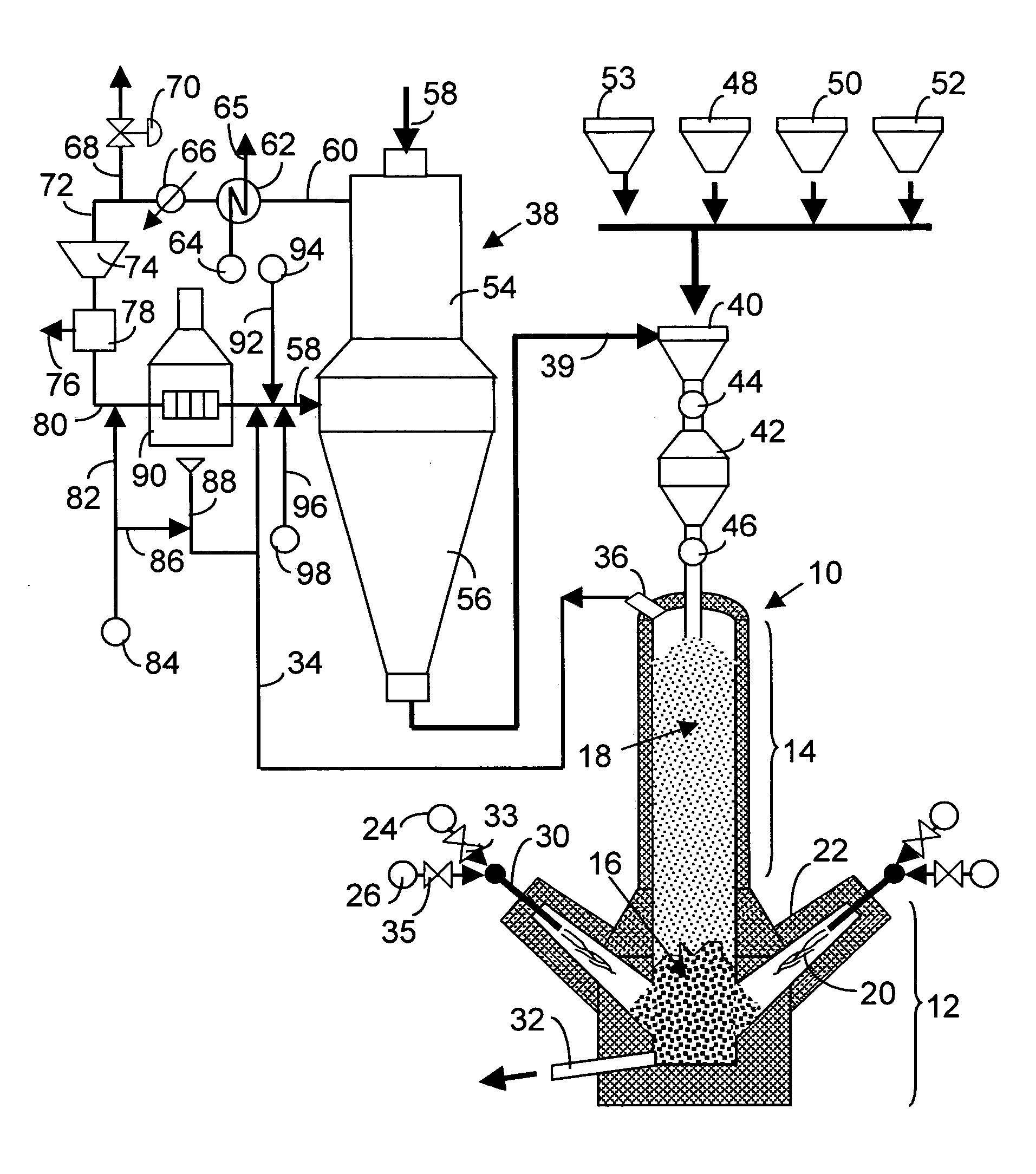

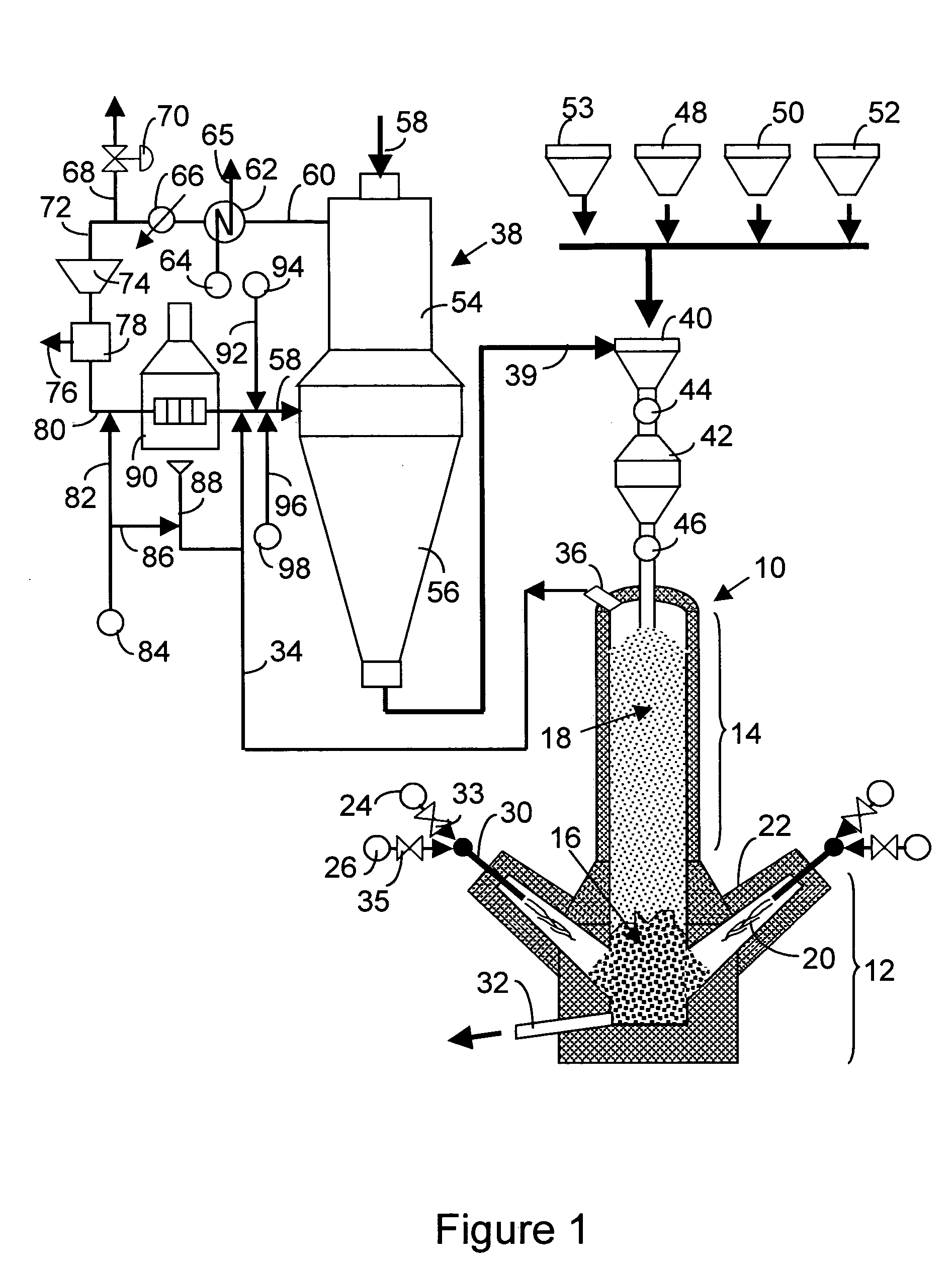

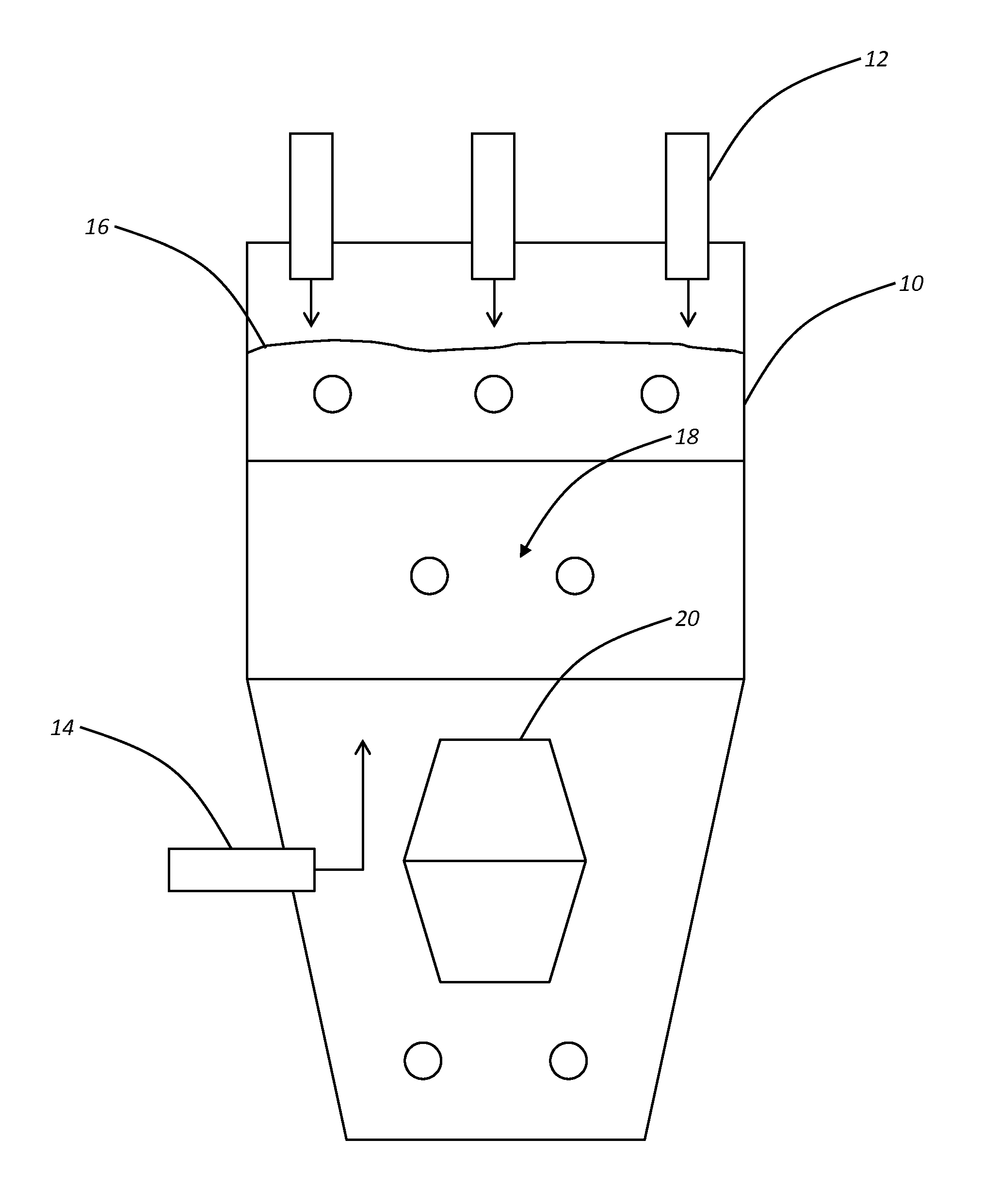

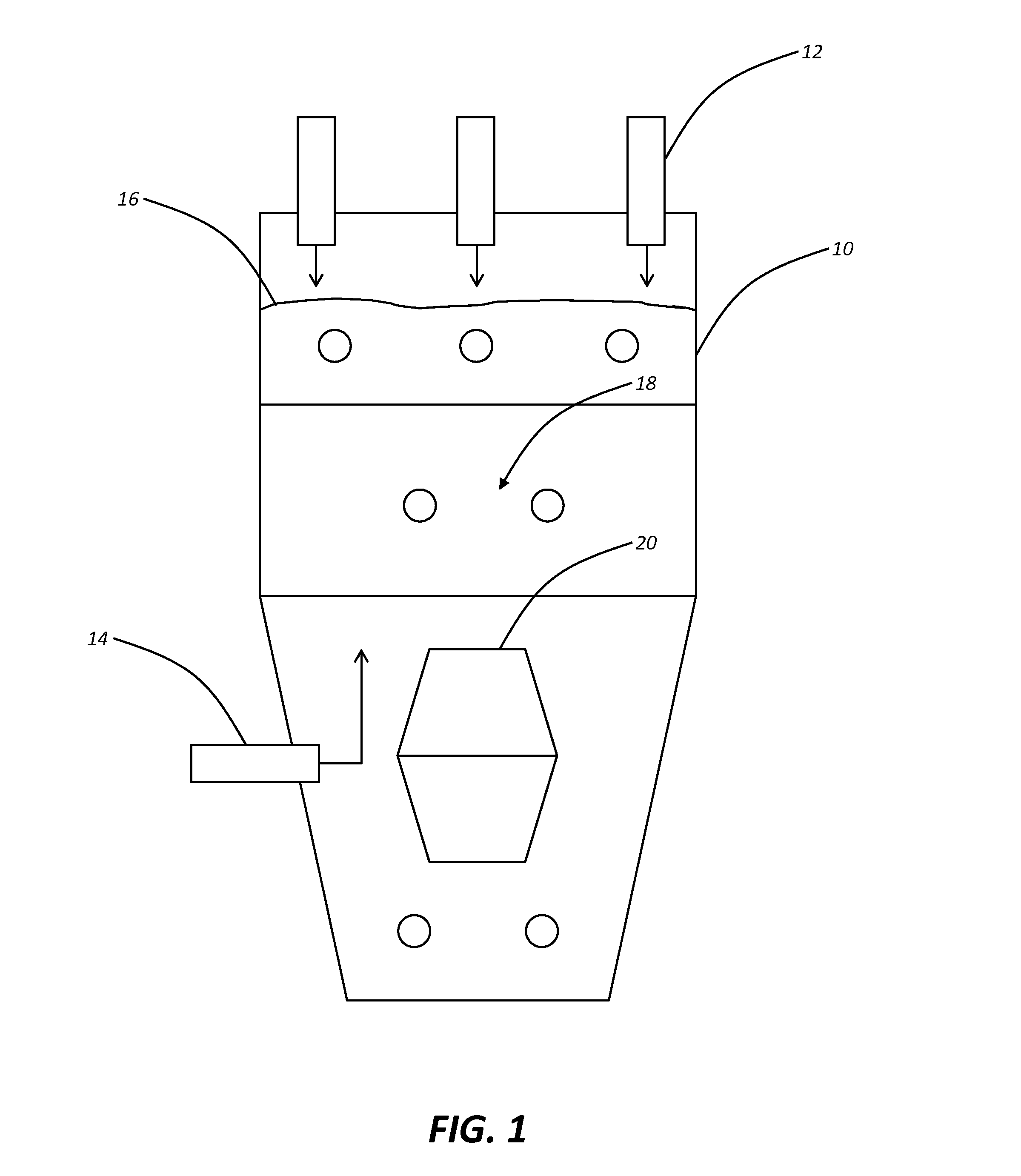

Devices and methods for enhancing burden uniformity in a combination reforming/reducing shaft furnace

ActiveUS20140091502A1Wide applicabilityCharge manipulationBlast furnace detailsEngineeringShaft furnace

The present invention provides a combination reforming / reducing shaft furnace for the production of direct reduced iron that utilizes one or more burden uniformity enhancers, such as one or more rotating / reciprocating mixing shafts, one or more stationary flow aids, one or more wall structures / variations, one or more agitators, or the like for ensuring that reforming and reducing in the shaft furnace take place evenly across the width of and throughout the depth of the burden in the shaft furnace.

Owner:MIDREX TECH INC

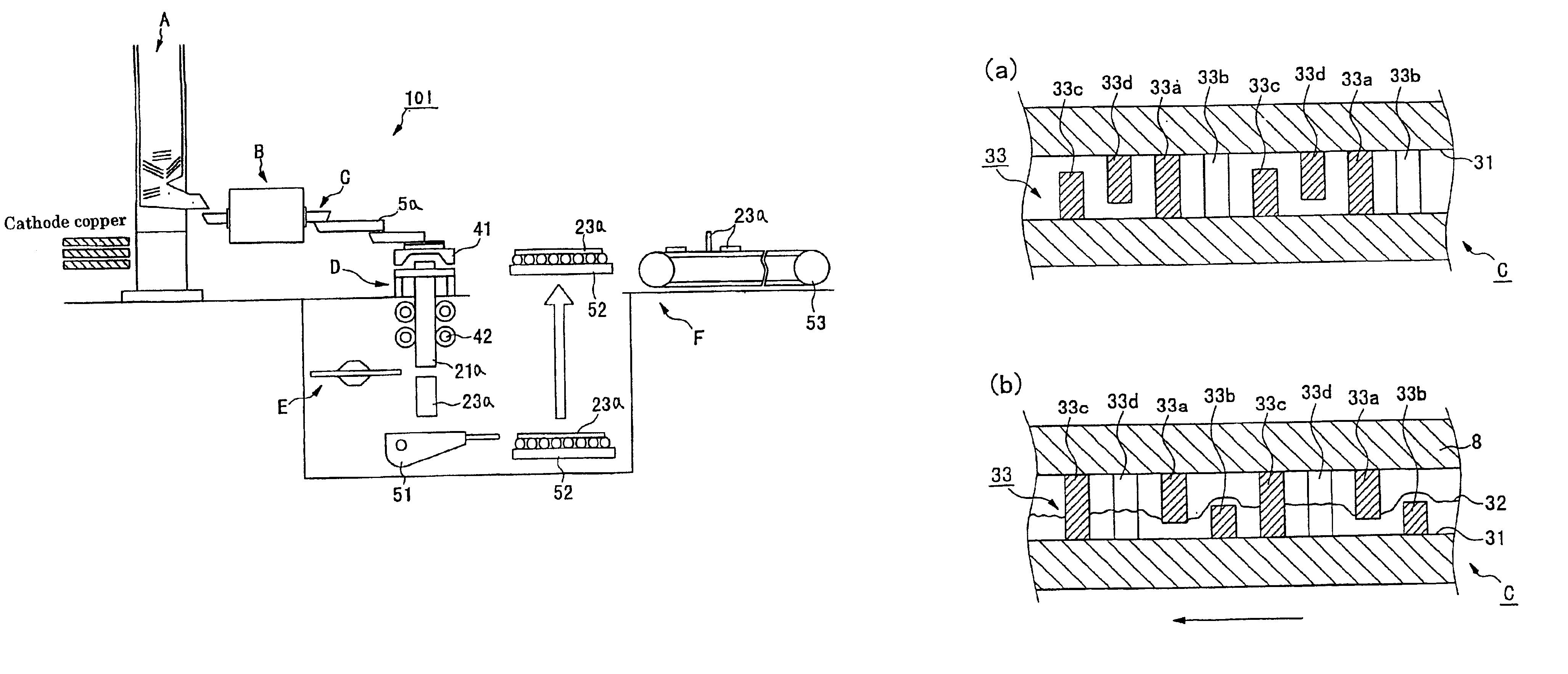

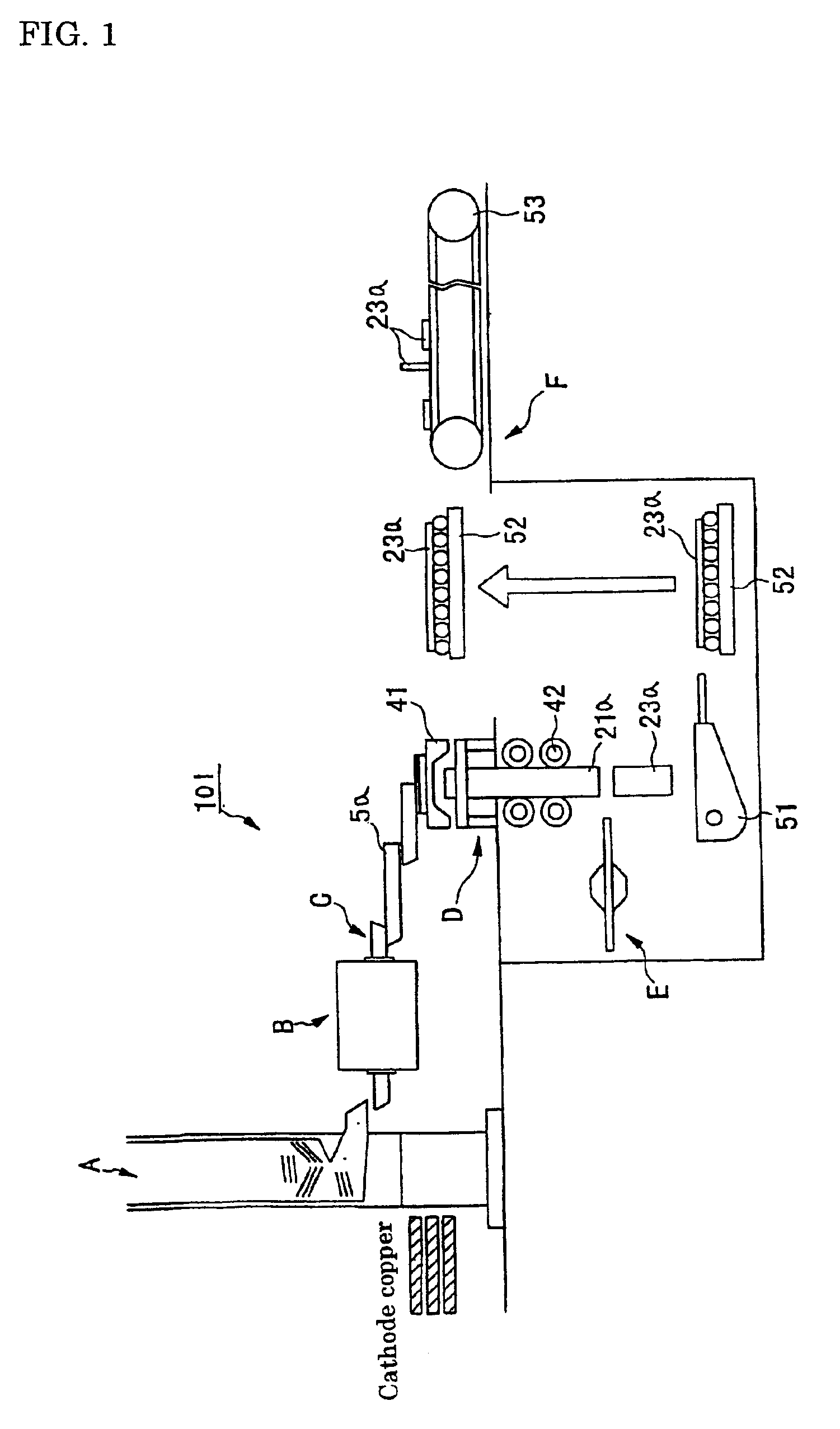

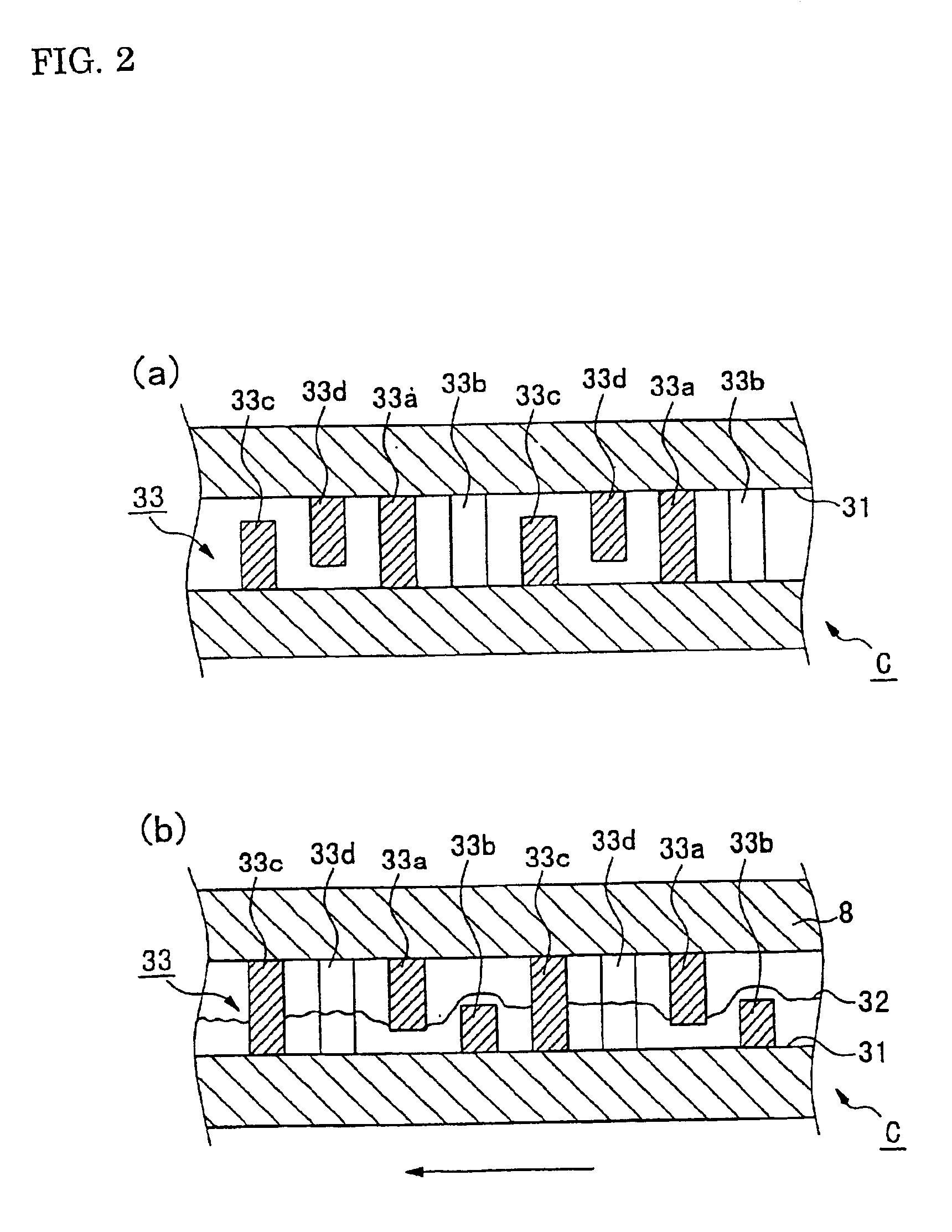

Method for manufacturing low-oxygen copper

InactiveUS6944930B2Improve degassing efficiencyGreat opportunityMetal rolling stand detailsBlast furnace detailsDegasserCombustion

A method for manufacturing a low-oxygen copper wire is provided, in which a dehydrogenating treatment can be performed without requiring a long moving distance of molten copper, and the generation of holes in solidification is suppressed, whereby high quality low-oxygen copper wire can be obtained having superior surface quality. The method for continuously manufacturing ingots of low-oxygen copper from molten copper includes a step of performing combustion in a reducing atmosphere in a melting furnace so as to produce molten copper; a step of sealing the molten copper in a non-oxidizing atmosphere in a casting trough; a step of transferring the molten copper to a turn-dish by using the casting trough; a degassing step of passing the molten copper through a degasser provided in the casting trough so as to dehydrogenate the molten copper; a step of continuously feeding the molten copper to a continuous casting machine so as to continuously produce cast copper; and a step of cutting the cast copper into a predetermined length.

Owner:MITSUBISHI MATERIALS CORP

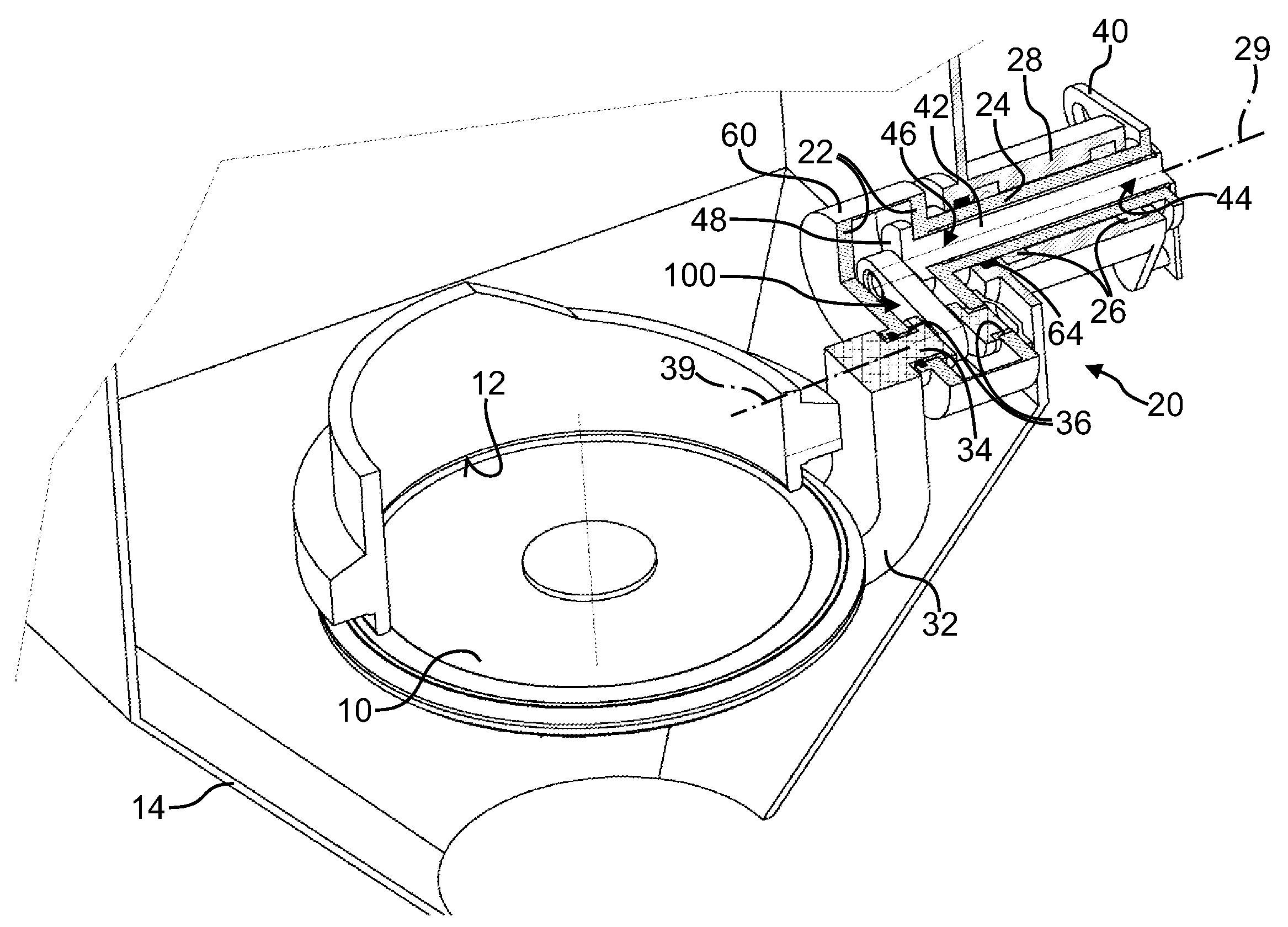

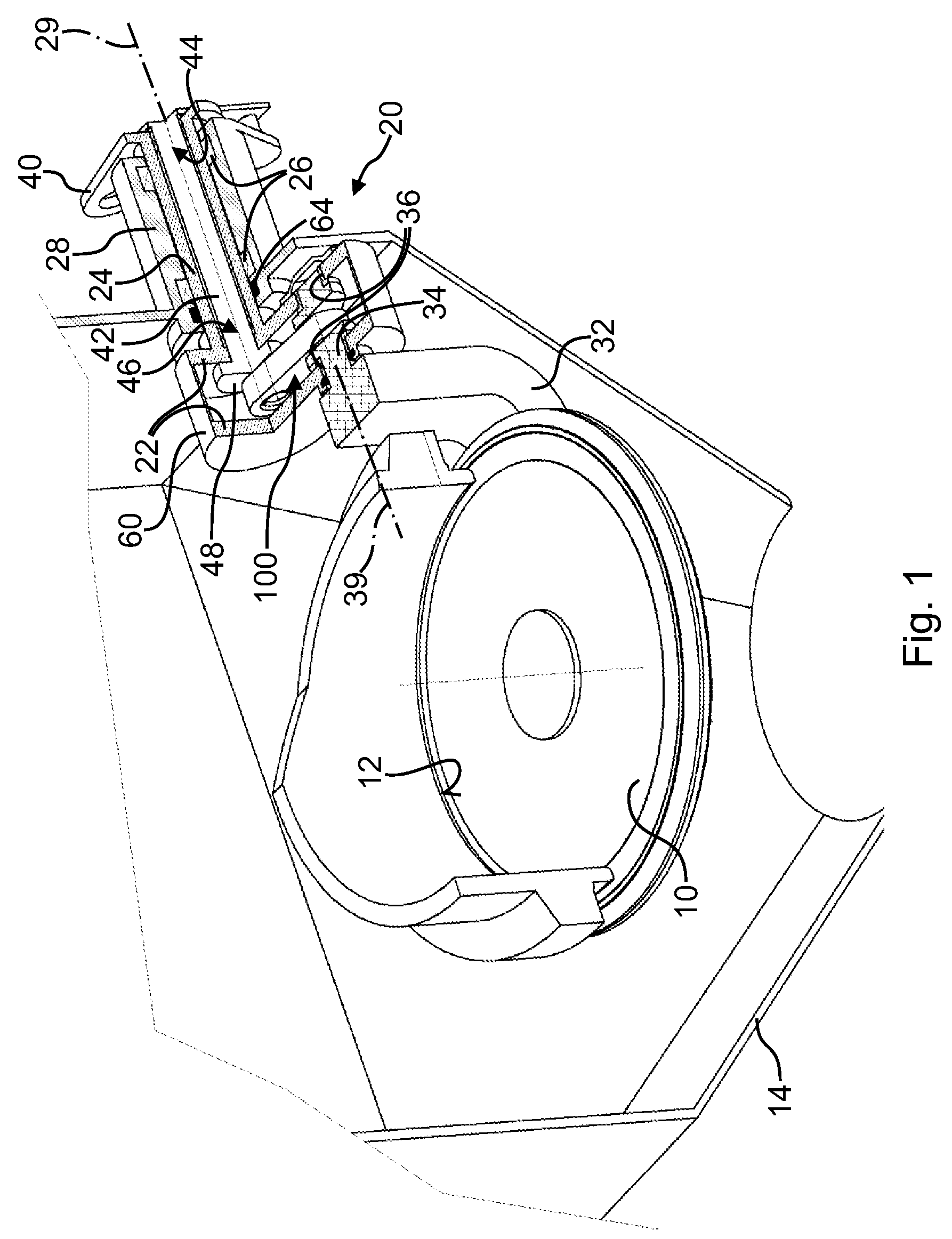

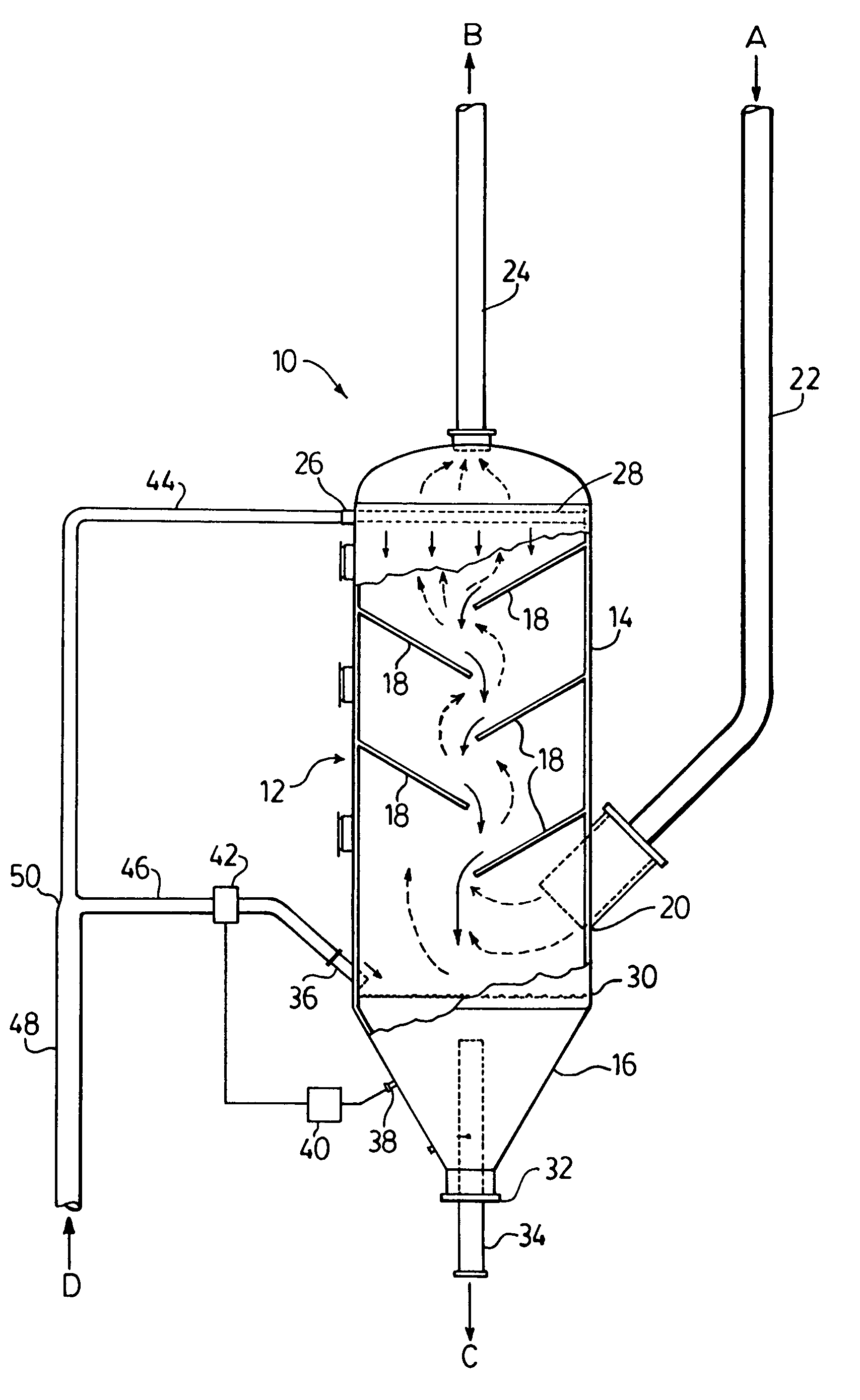

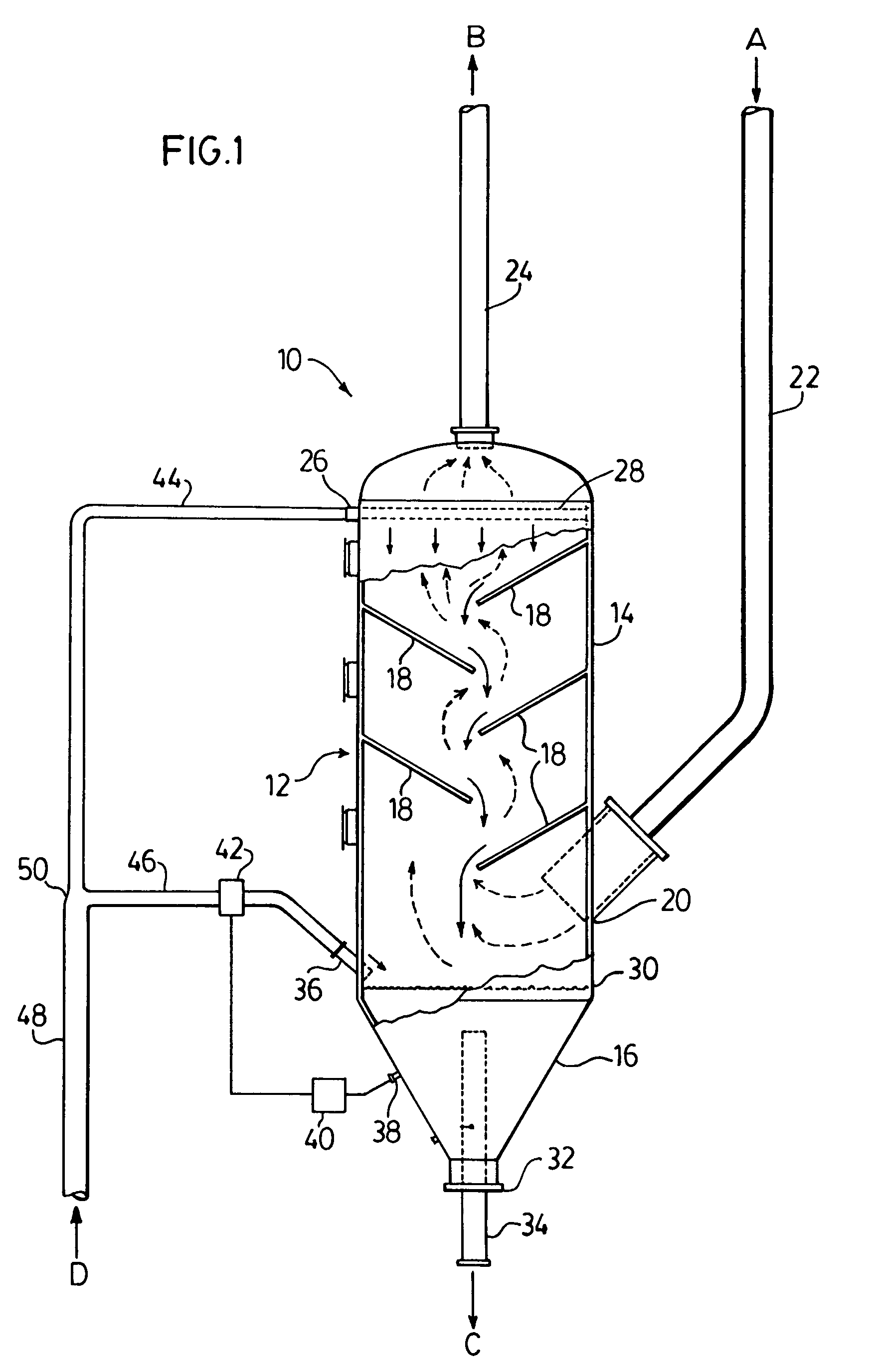

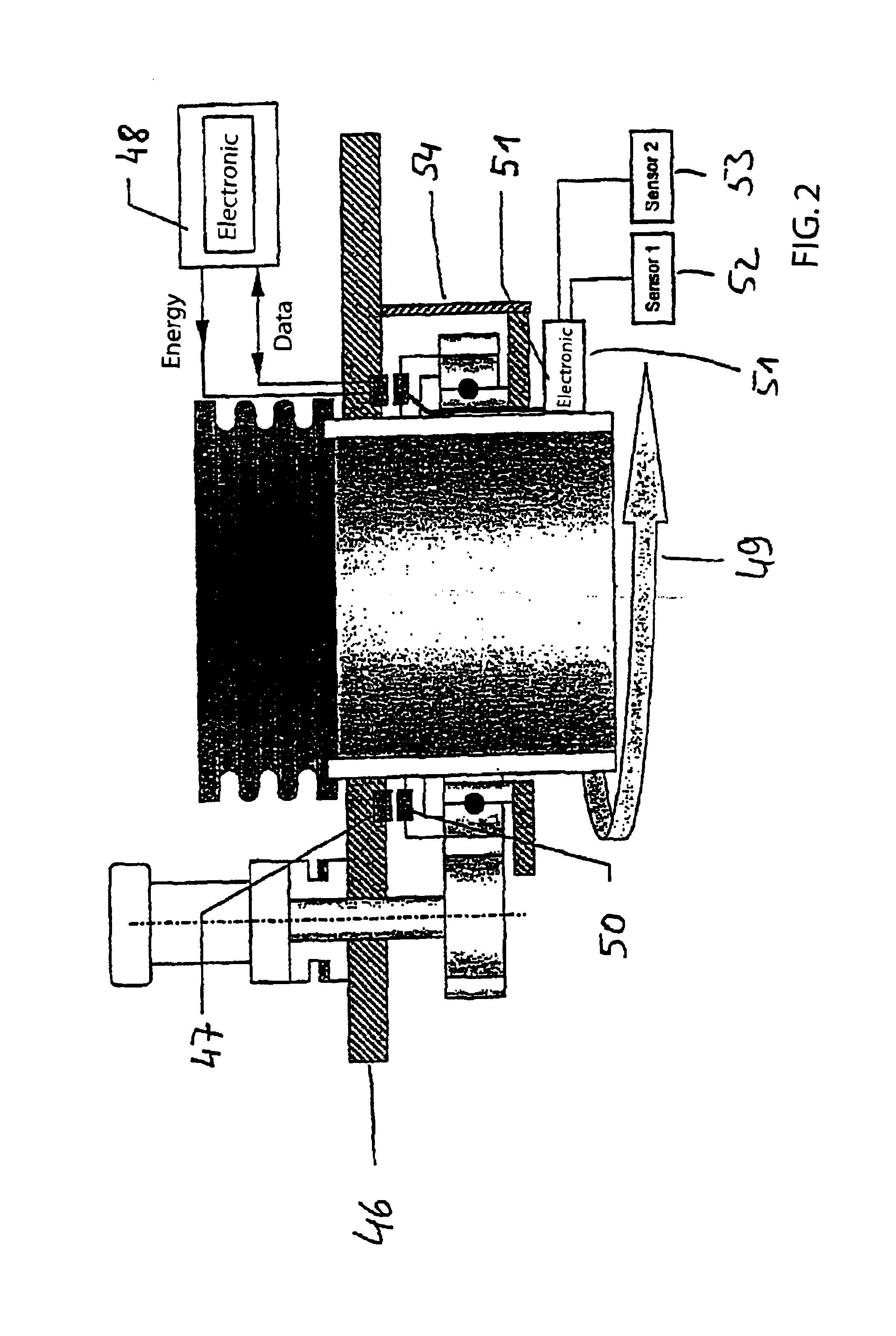

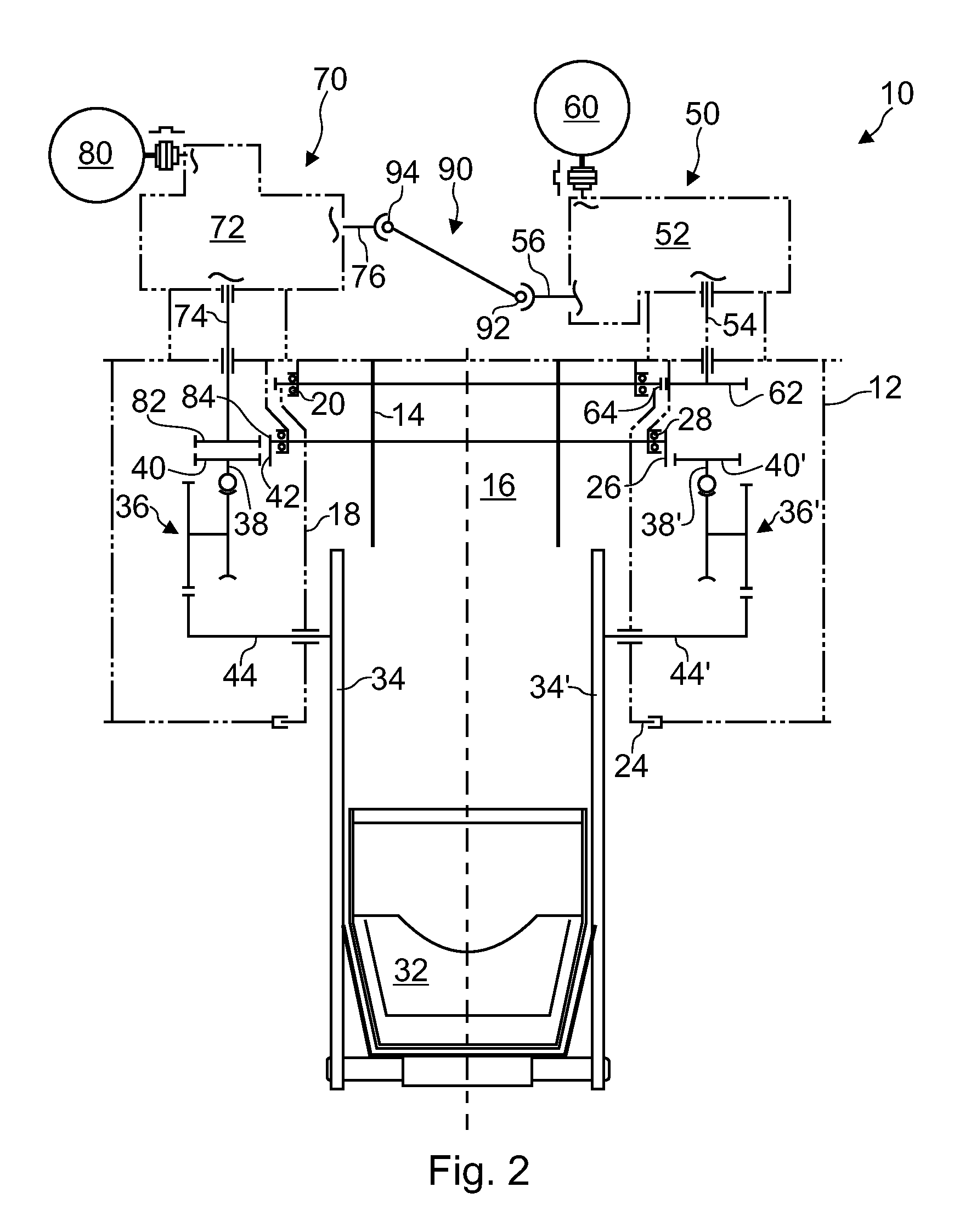

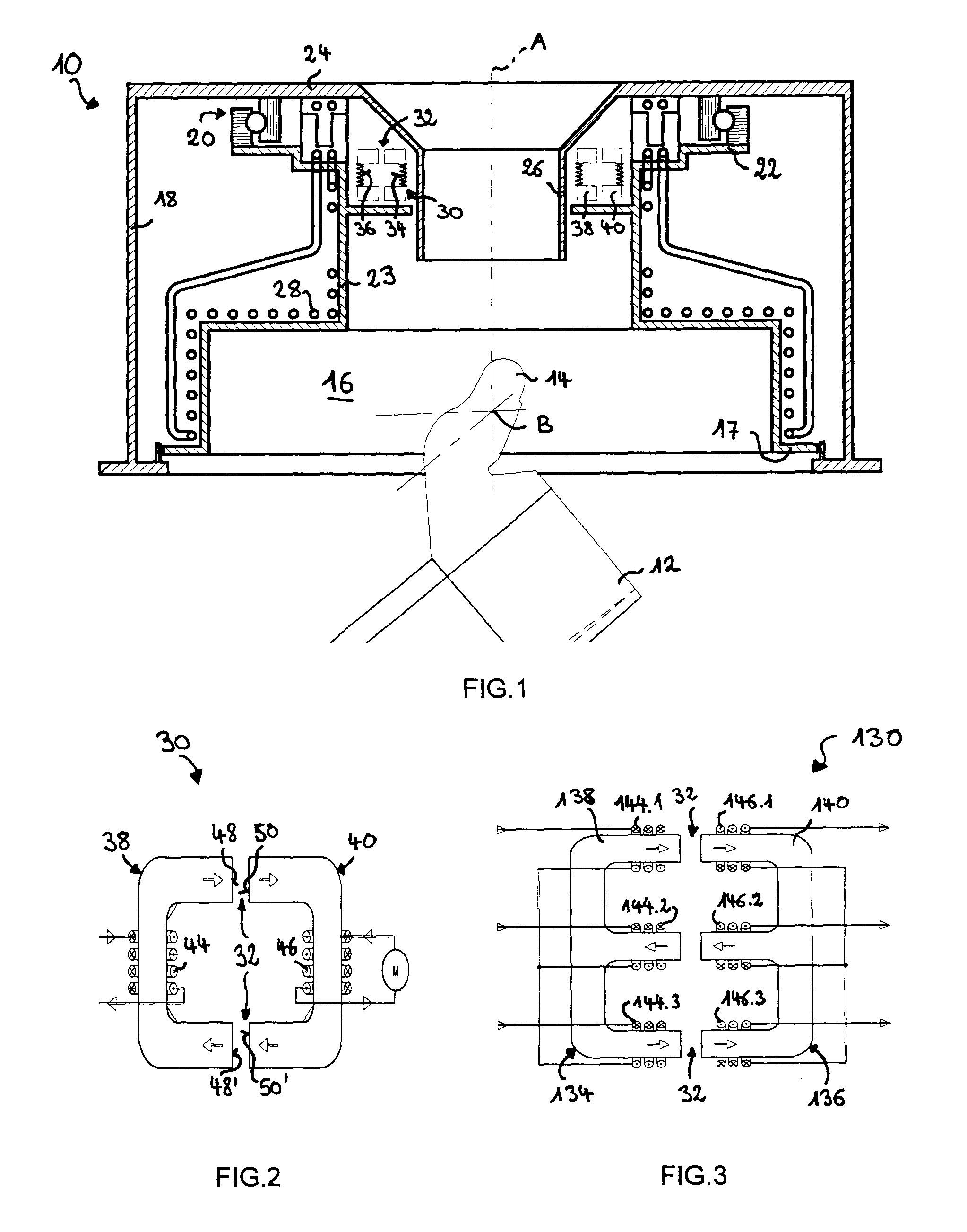

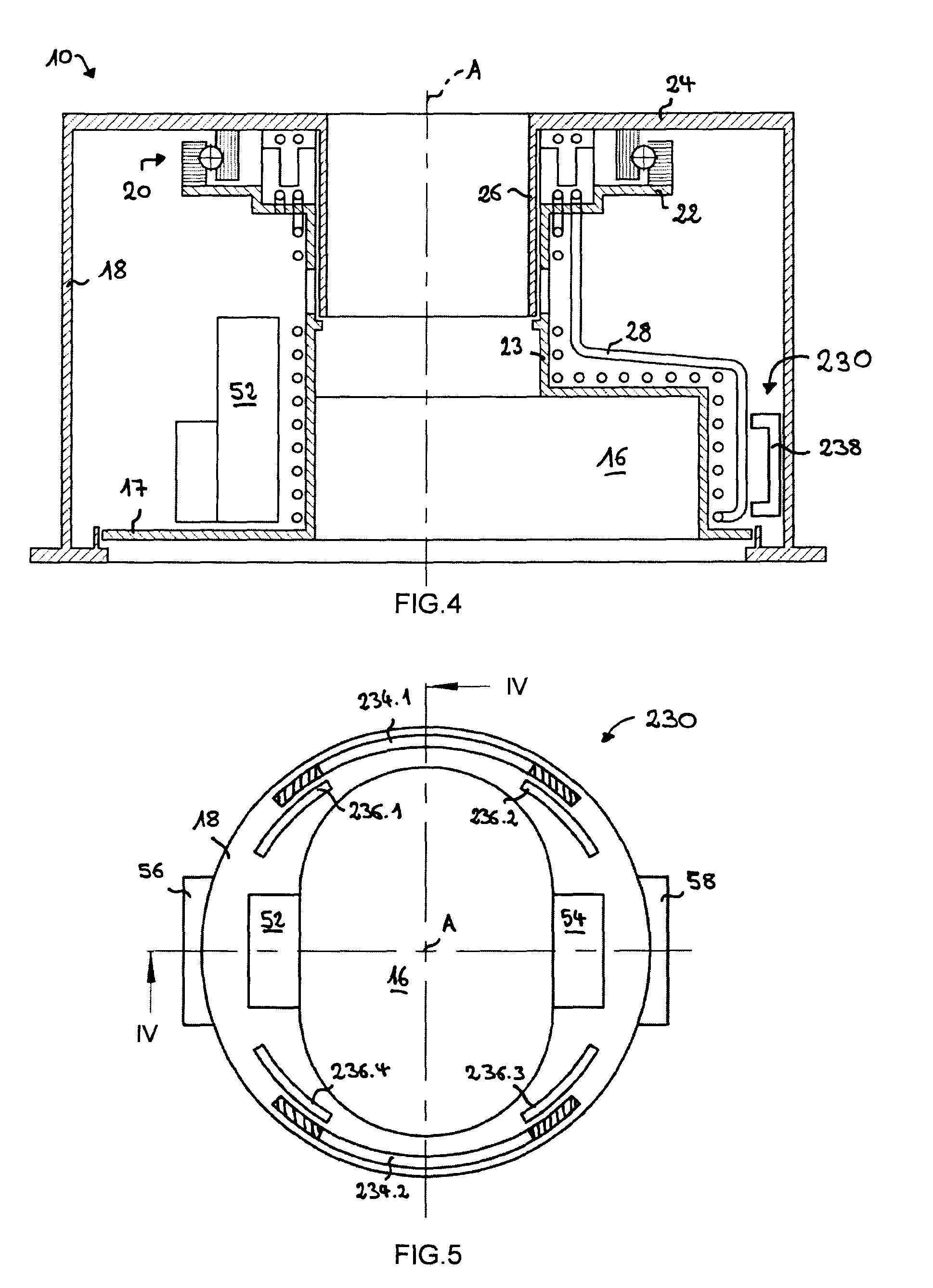

Rotary charging device for a shaft furnace

InactiveUS20100028106A1Maintenance-friendly and reliableWear is especially pronouncedConveyorsBell-and-hopper arrangementElectricityInductor

A rotary charging device (10) for a shaft furnace commonly comprises a rotary distribution means (12) for distributing charge material on a charging surface in the shaft furnace. A rotatable structure supports (16) the rotary distribution means and a stationary support (18) rotatably supports the rotatable structure. According to the invention, the charging device (10) is equipped with an inductive coupling device (30) including a stationary inductor (34) fixed to the stationary support and a rotary inductor (36) fixed to the rotatable structure. The stationary inductor (34) and the rotary inductor (36) are separated by a radial gap and configured as rotary transformer for achieving contact-less electric energy transfer from the stationary support (18) to the rotatable structure (16) by means of magnetic coupling trough the radial gap for powering an electric load arranged on the rotatable structure (16) and connected to said rotary inductor (36).

Owner:PAUL WURTH SA

Pre-treatment process for feed material for direct reduction process

ActiveUS7175690B2Reduce generationImprove productivityBlast furnace detailsExhaust gas handlingPretreatment methodReducing atmosphere

A pretreatment process for solid lump feed material for a gas and pellet / lump-based direct reduction process, comprising preheating feed material to a temperature of from about 200 C to about 500 C, without reduction, in a non-reducing atmosphere prior to charging the feed material to gas-based direct reduction furnace, thereby minimizing the formation of fines within the furnace.

Owner:TINTO RIO

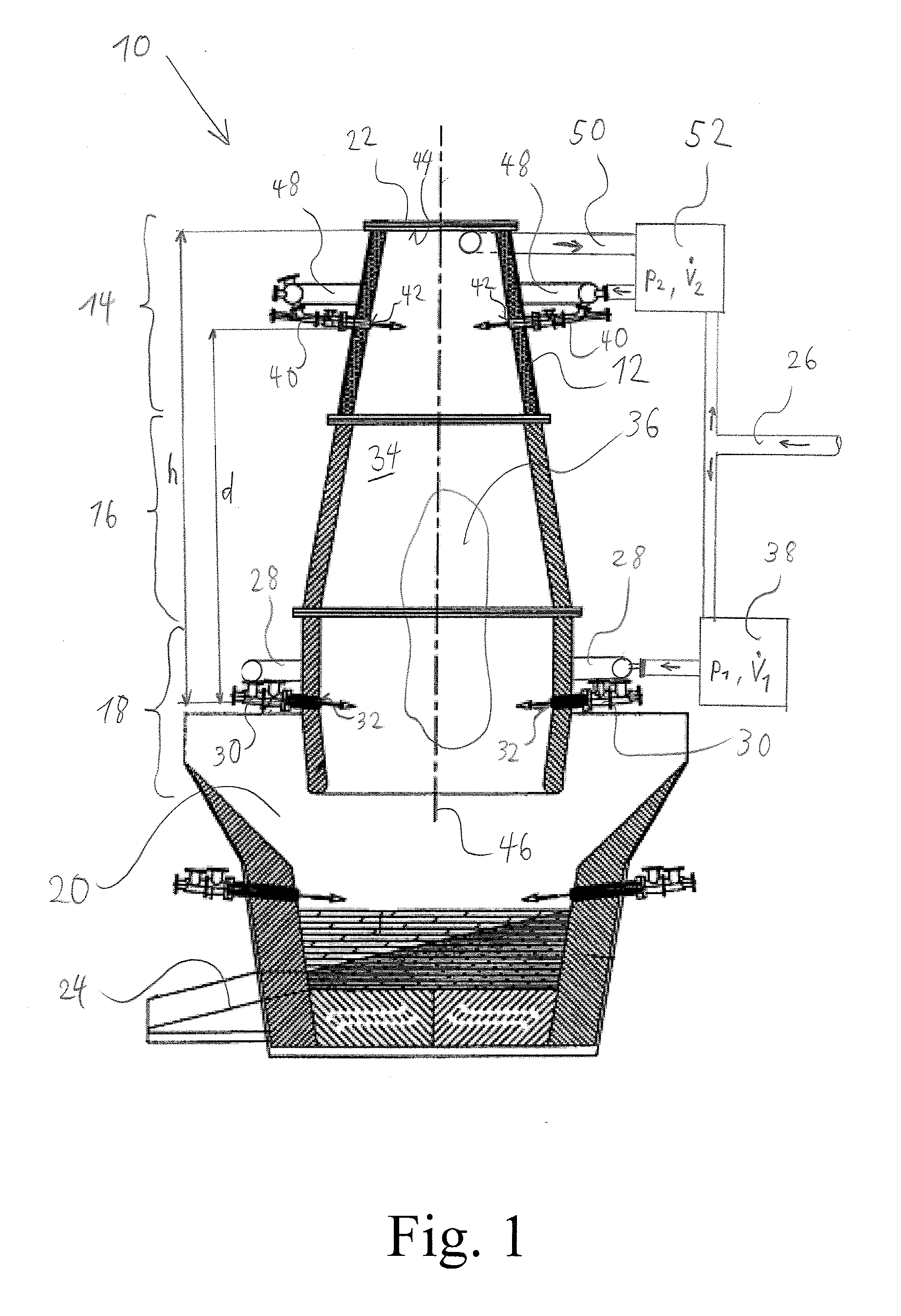

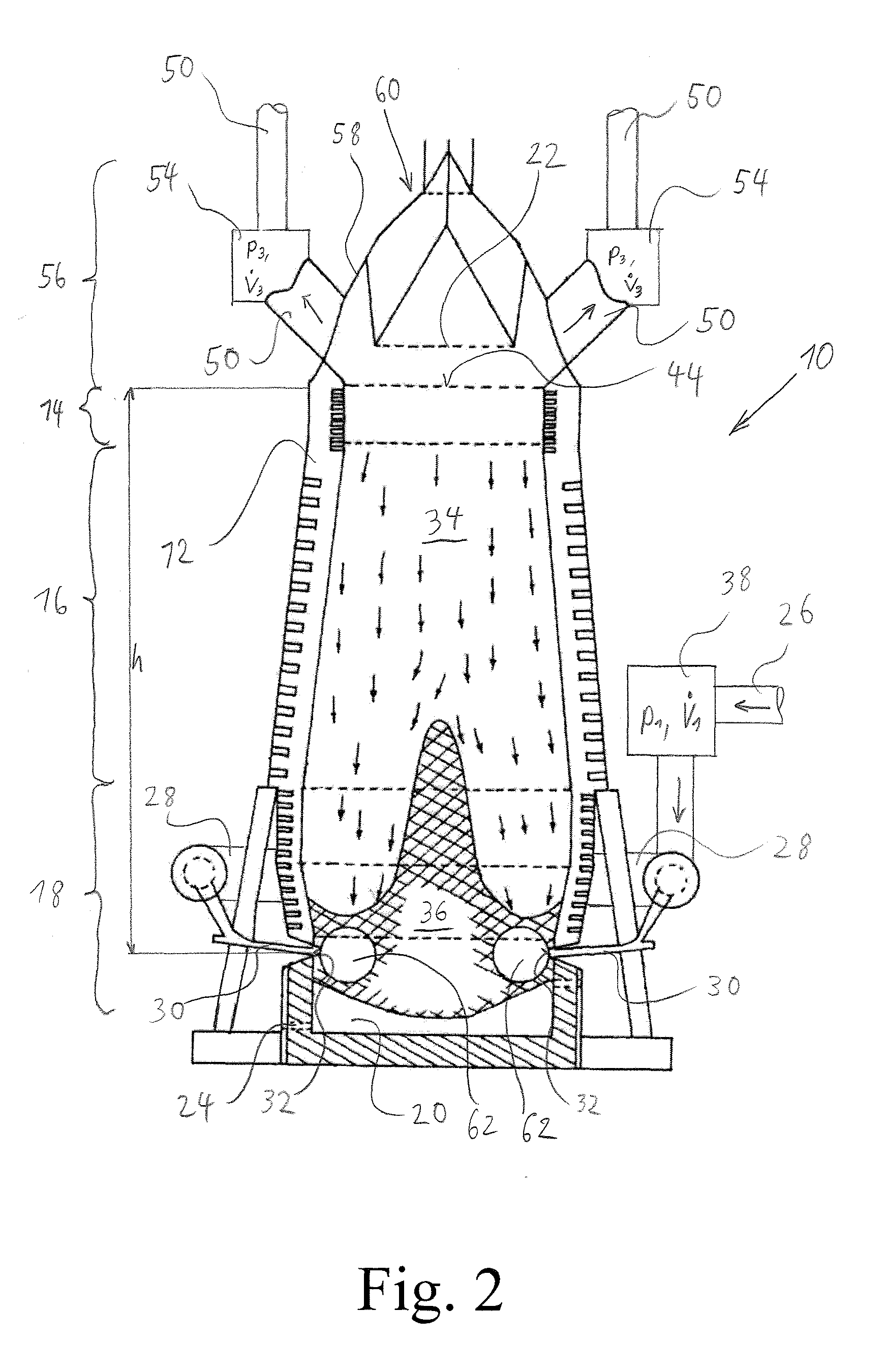

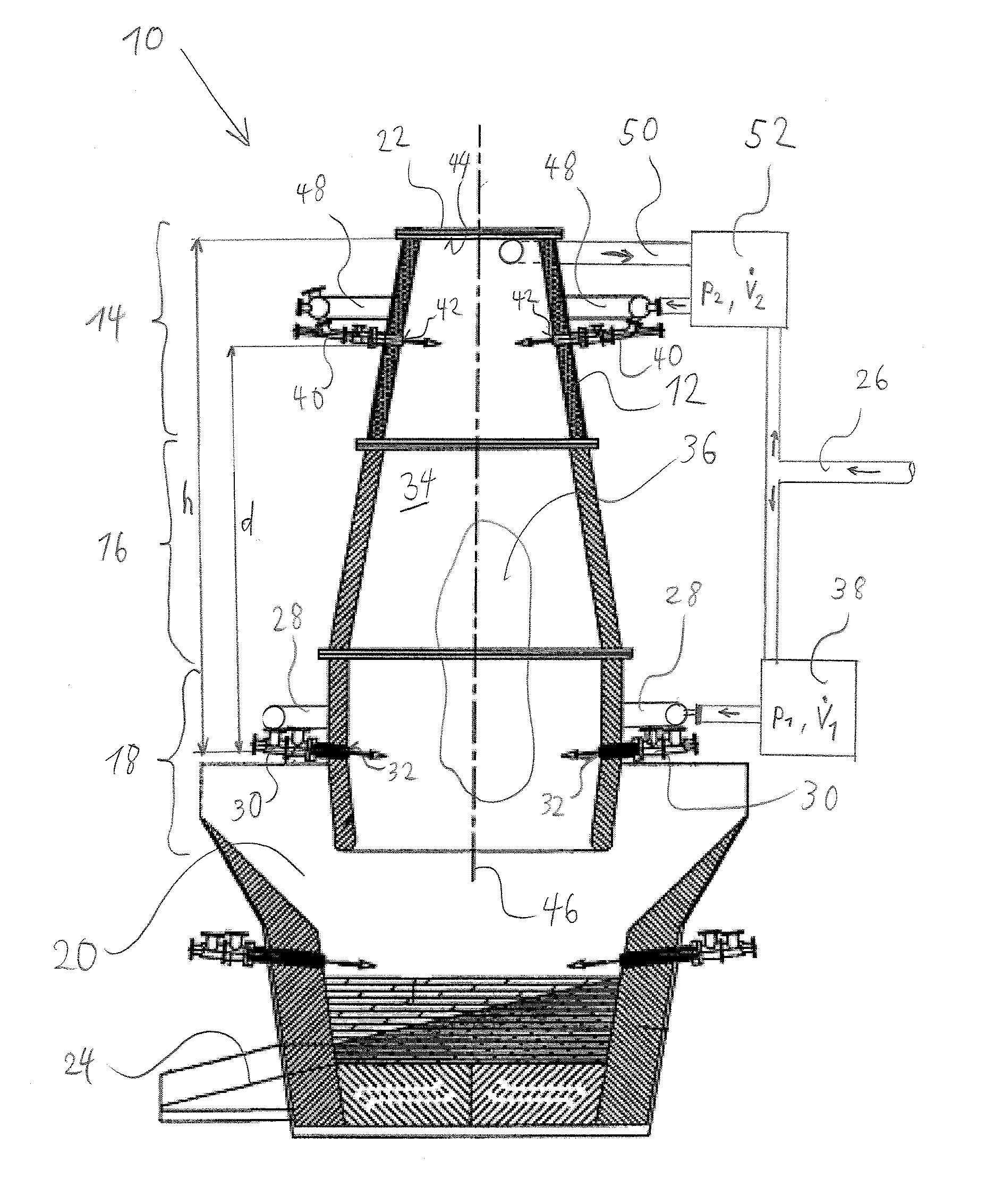

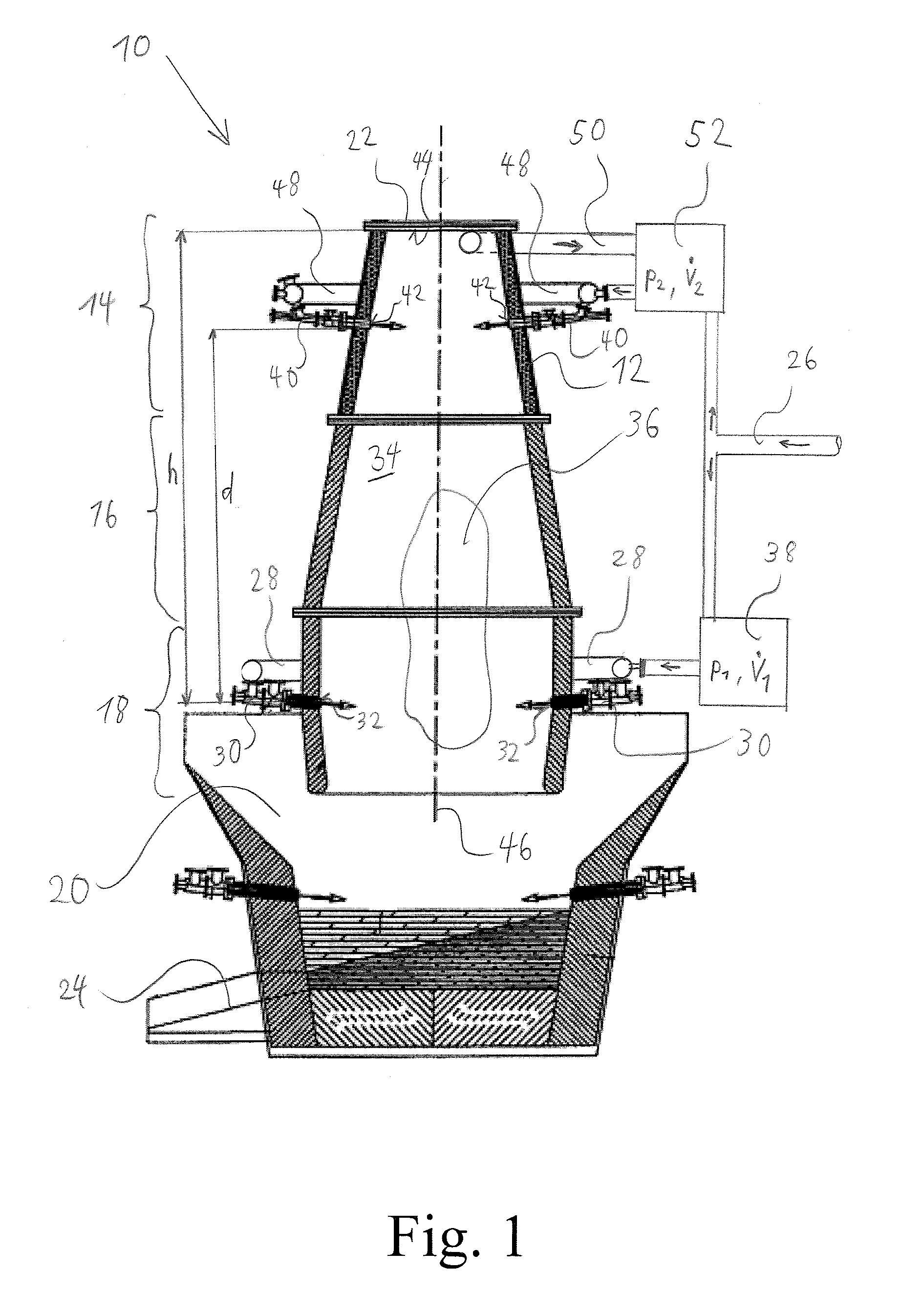

Method for operating a shaft furnace, and shaft furnance operable by that method

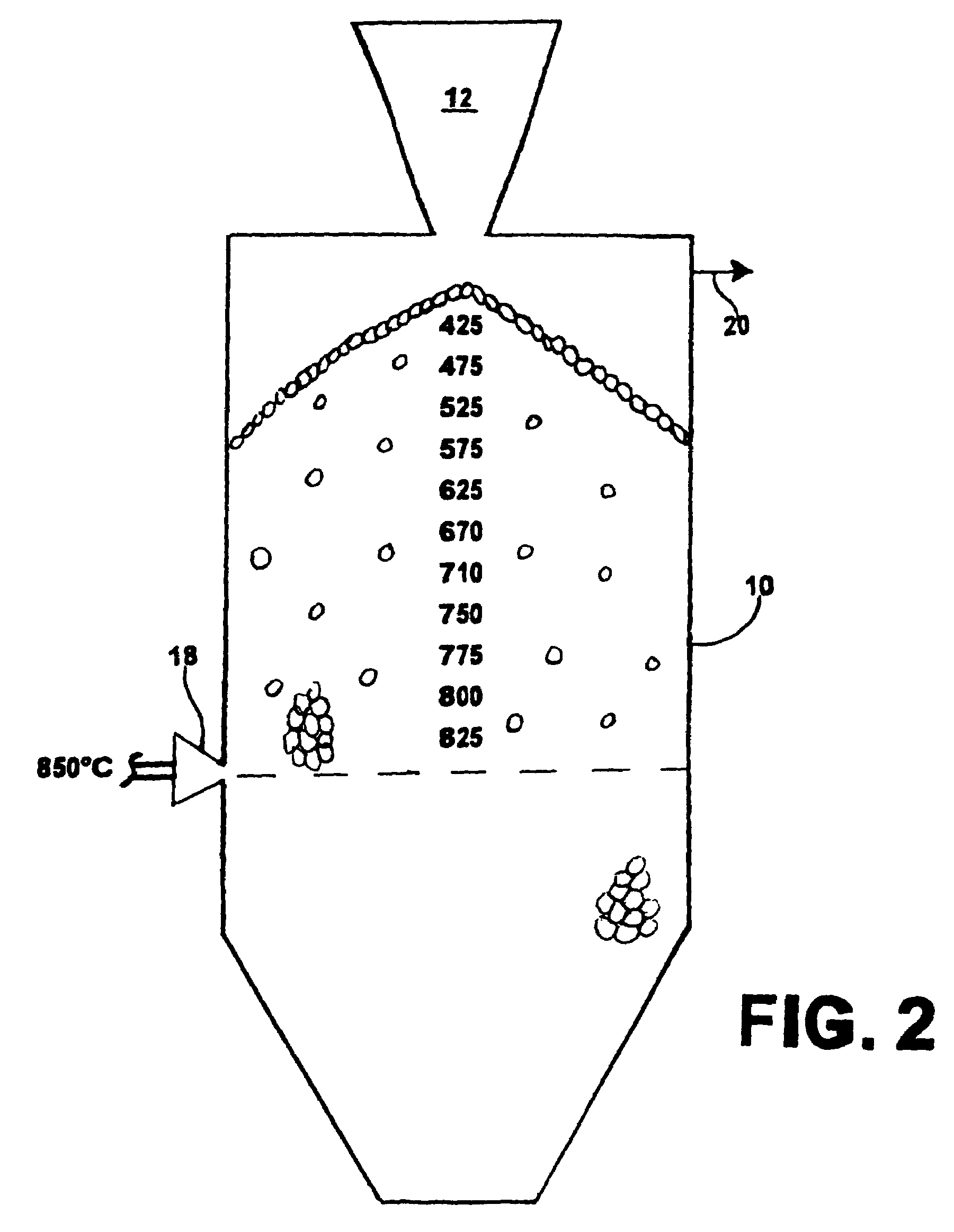

ActiveUS8173064B2Increased turbulenceEasy to breatheTuyeresBlast furnace detailsShaft furnaceAtmosphere

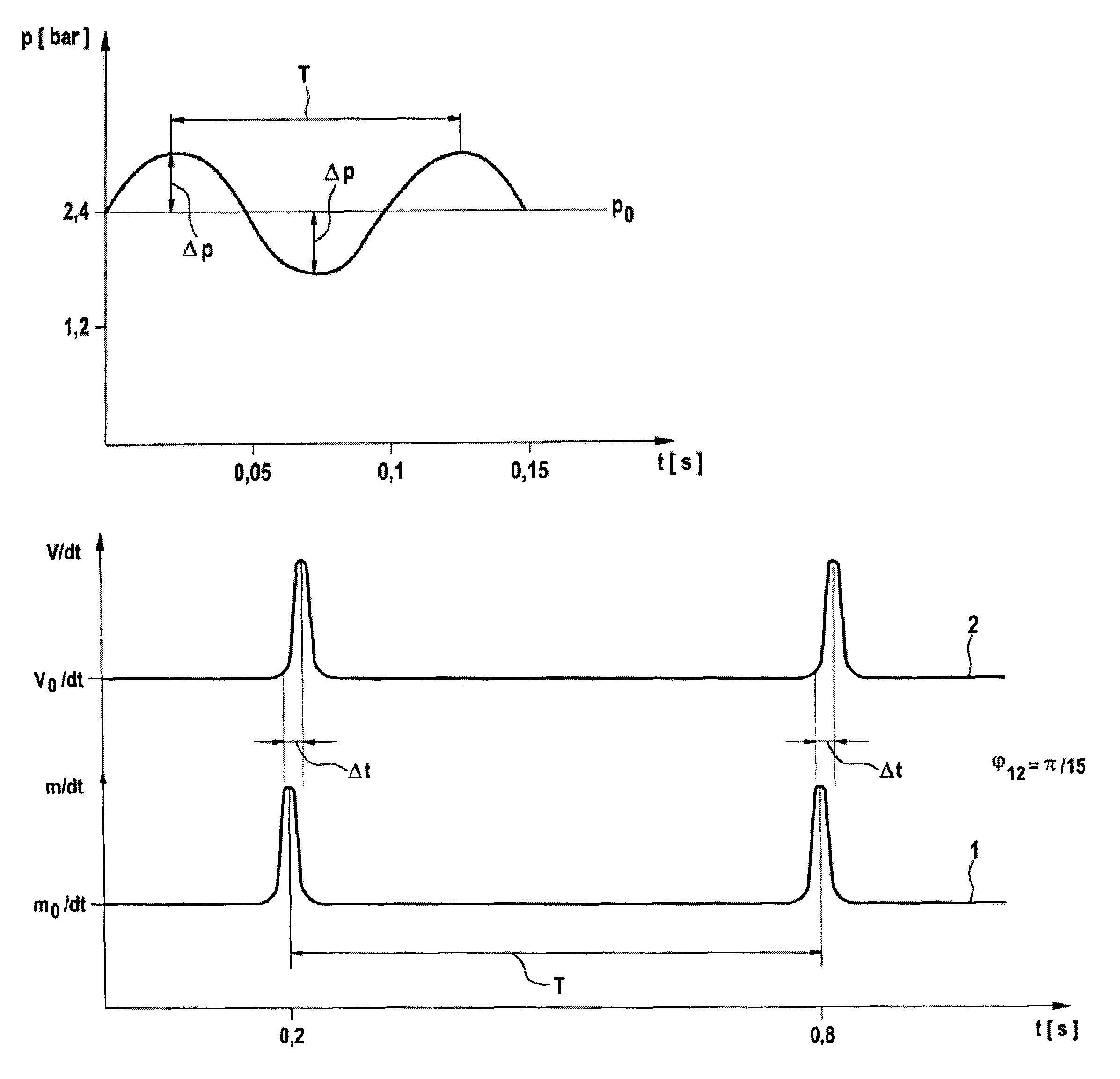

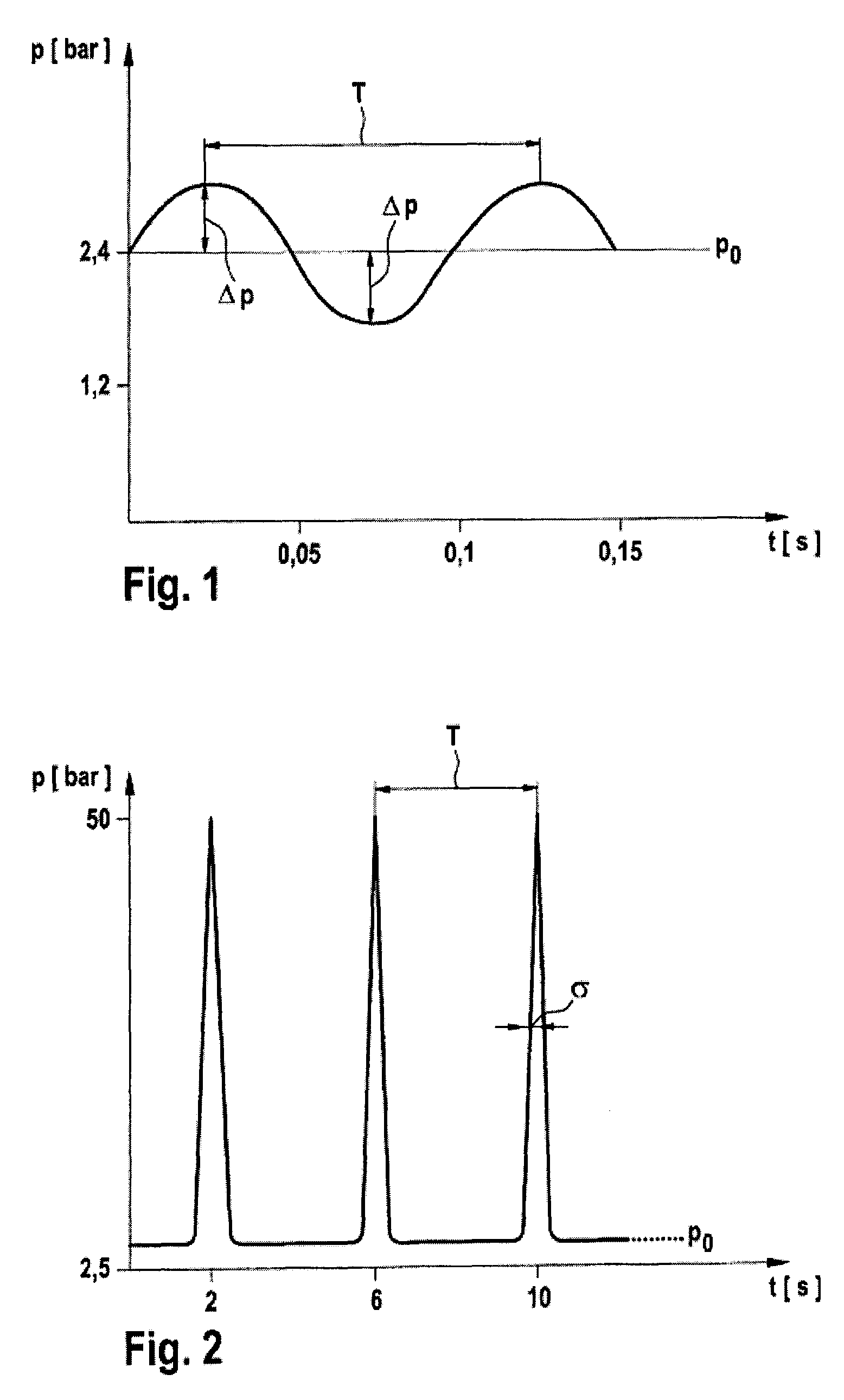

Method for operating a shaft furnace, whereby an upper section of the shaft furnace is charged with raw materials which due to gravity descend inside the furnace while the atmosphere prevailing within the shaft furnace causes part of the raw materials to melt and / or to be reduced, and in a lower section of the shaft furnace a process gas is injected so as to at least partly modify the atmosphere prevailing in the shaft furnace. The pressure and / or volume flow of the injected process gas is dynamically modulated within a time span of 40 s. Also, a shaft furnace operable by said method, thus achieving improved through-gassing.

Owner:THYSSENKRUPP AT PROTEC GMBH

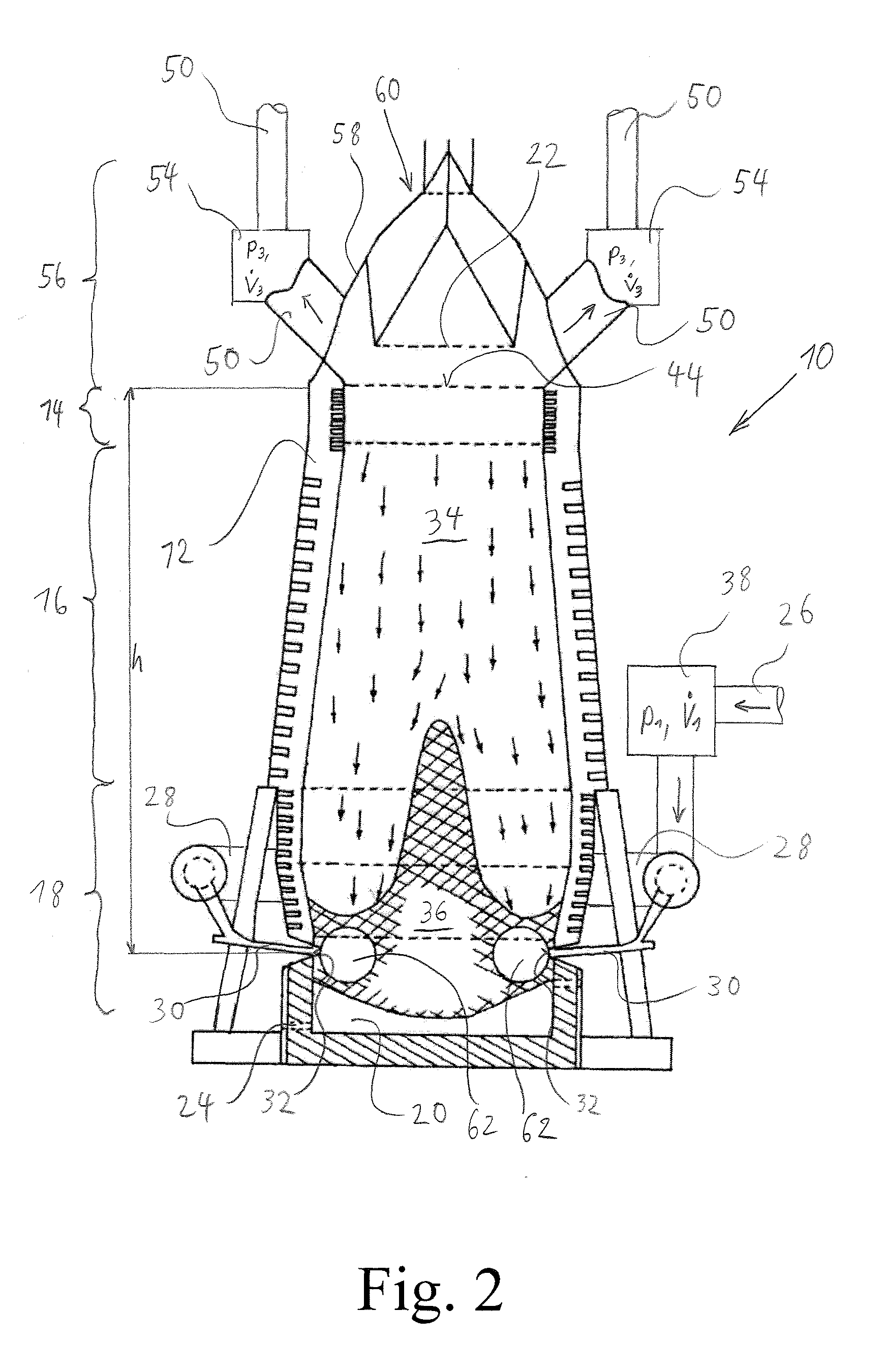

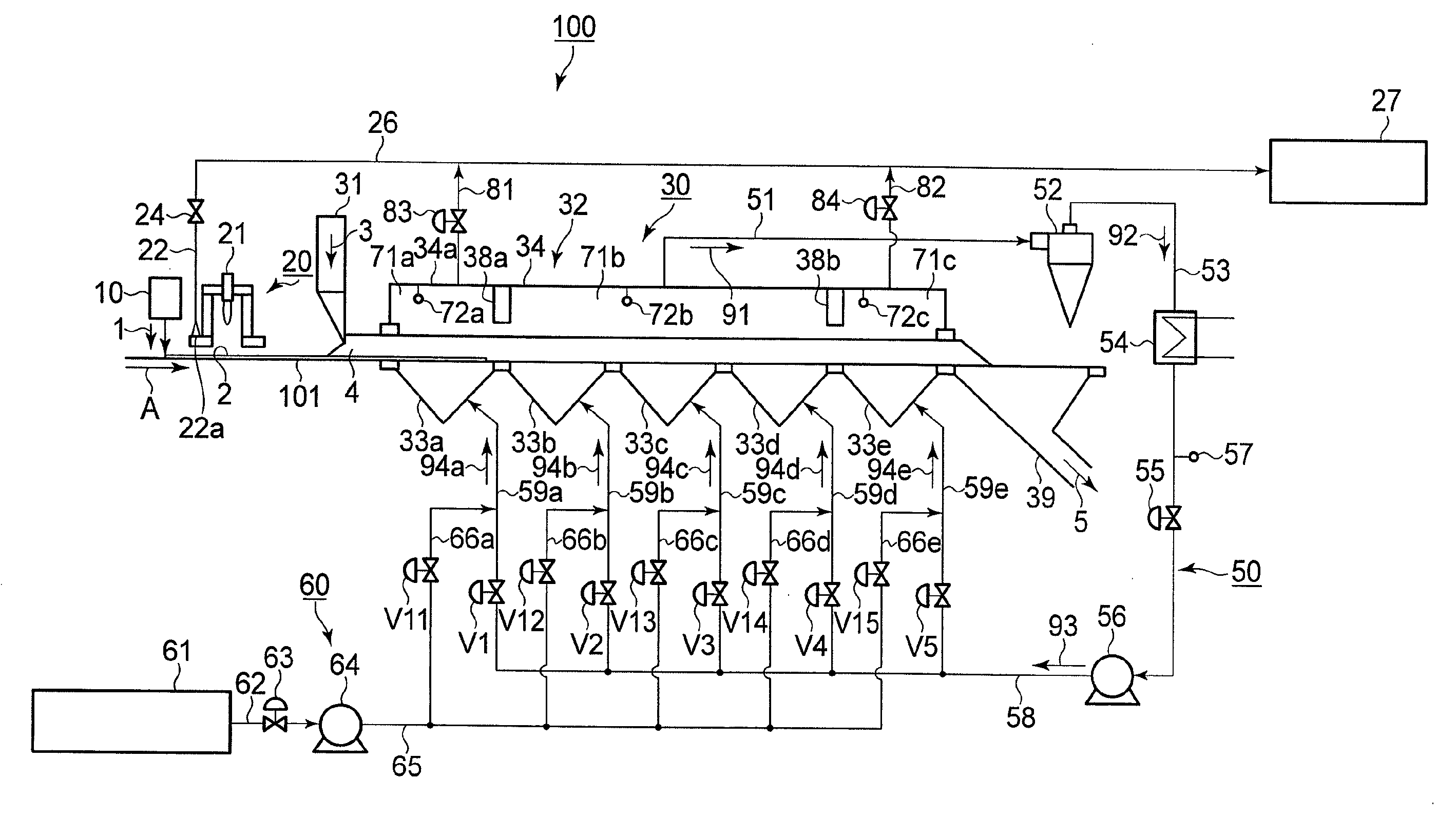

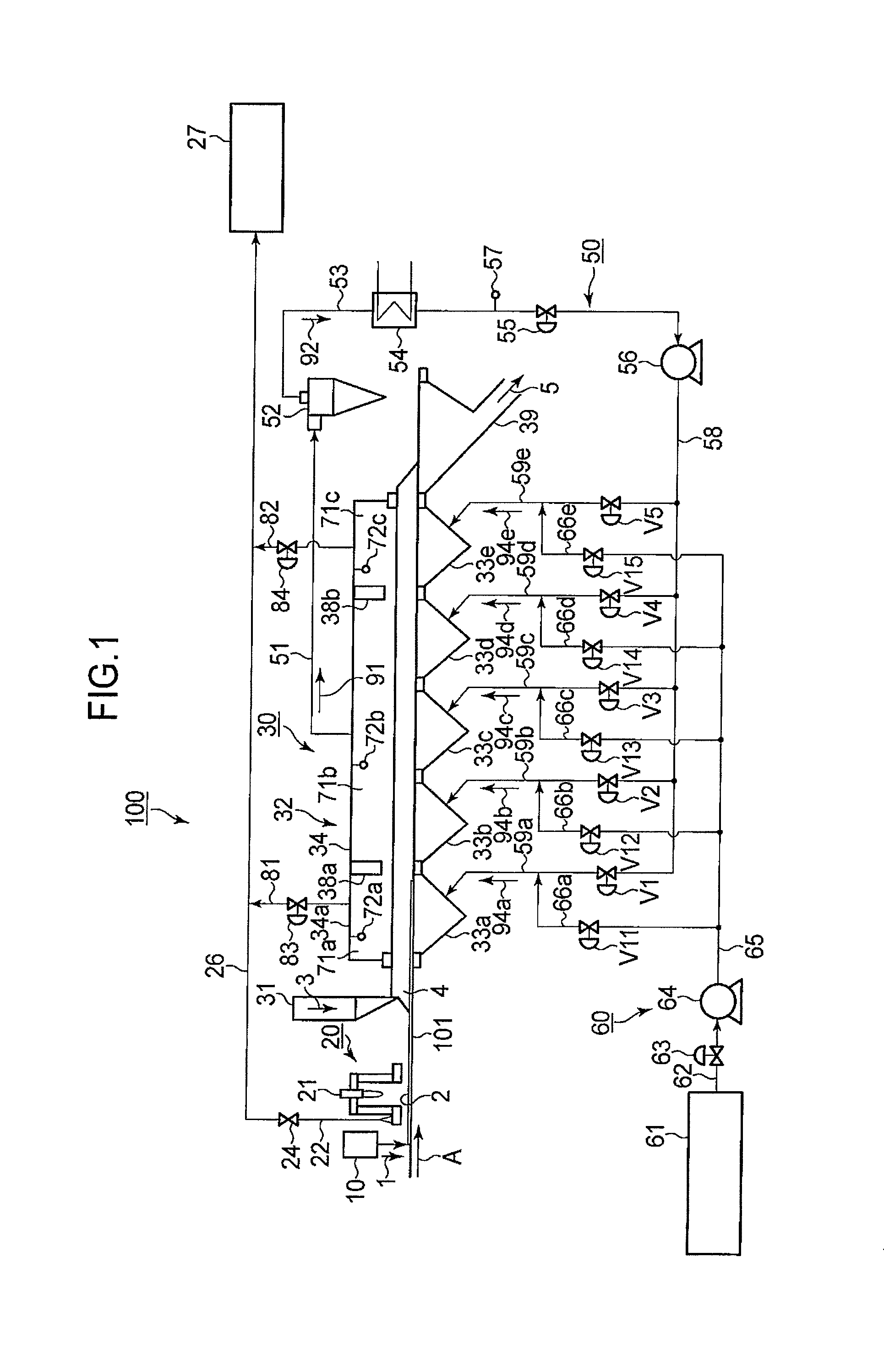

Shaft furnace and method for operating a furnace

ActiveUS20100251855A1Improve efficiencyMore materialSpeech analysisTuyeresShaft furnaceIndustrial engineering

The invention relates to a method for operating a shaft furnace (10). According to said method, an upper region (14) of the shaft furnace (10) is charged with raw materials which sink in the shaft furnace (10) under the influence of gravity. Part of the raw materials is melted and / or at least partially reduced by the action of the atmosphere inside the shaft furnace (10). A treatment gas is introduced in a lower region (18) of the shaft furnace (10) by means of at least one lower admission opening (32), said treatment gas at least partially influencing the atmosphere inside the shaft furnace (10). The introduction of the lower treatment gas is dynamically modulated such that, during the modulation, the operating variables, that is pressure p1 and / or volume flow (I), are varied at least temporarily over a time span of ≦40 s, especially ≦20 s, preferably ≦5 s and especially preferably ≦1 s. According to the invention, an addition gas is introduced via at least one addition opening (42) at a distance from the lower admission opening (32), the operating variables of the gas, that is pressure p2 and / or volume flow (II), being at least temporarily varied, and / or a shaft furnace gas is derived by means of a shaft furnace gas line (50) connected to the inside (34) of the shaft furnace (10), for removing gaseous reaction products, the operating variables of the shaft furnace gas, that is pressure p3 and / or volume flow (III), being at least temporarily varied. The variation of the operating variables of the addition gas and / or the shaft furnace gas is carried out according to the invention in such a way that the pressure p1 and / or the volume flow (I) inside (34) the shaft furnace (10) is at least partially increased.

Owner:THYSSENKRUPP AT PROTEC GMBH

Shaft furnace and method for operating a furnace

ActiveUS8309016B2Improve efficiencyImprove shaft efficiencySpeech analysisTuyeresShaft furnaceAtmosphere

The present invention relates to a shaft furnace as well as a method for operating a shaft furnace. For example, the present invention relates to methods for operating a shaft furnace which include charging an upper region of the shaft furnace with raw materials; the raw materials sink in the shaft furnace under the influence of gravity and a part of the raw materials is smelted an / or at least partially reduced under the effect of the atmosphere prevailing within the shaft furnace. The methods further comprise admitting an addition gas via at least one addition opening spaced from a lower admission opening and / or discharging a shaft furnace gas via a shaft furnace gas line to provide discharge of gaseous reaction products from the interior of the shaft furnace.

Owner:THYSSENKRUPP AT PROTEC GMBH

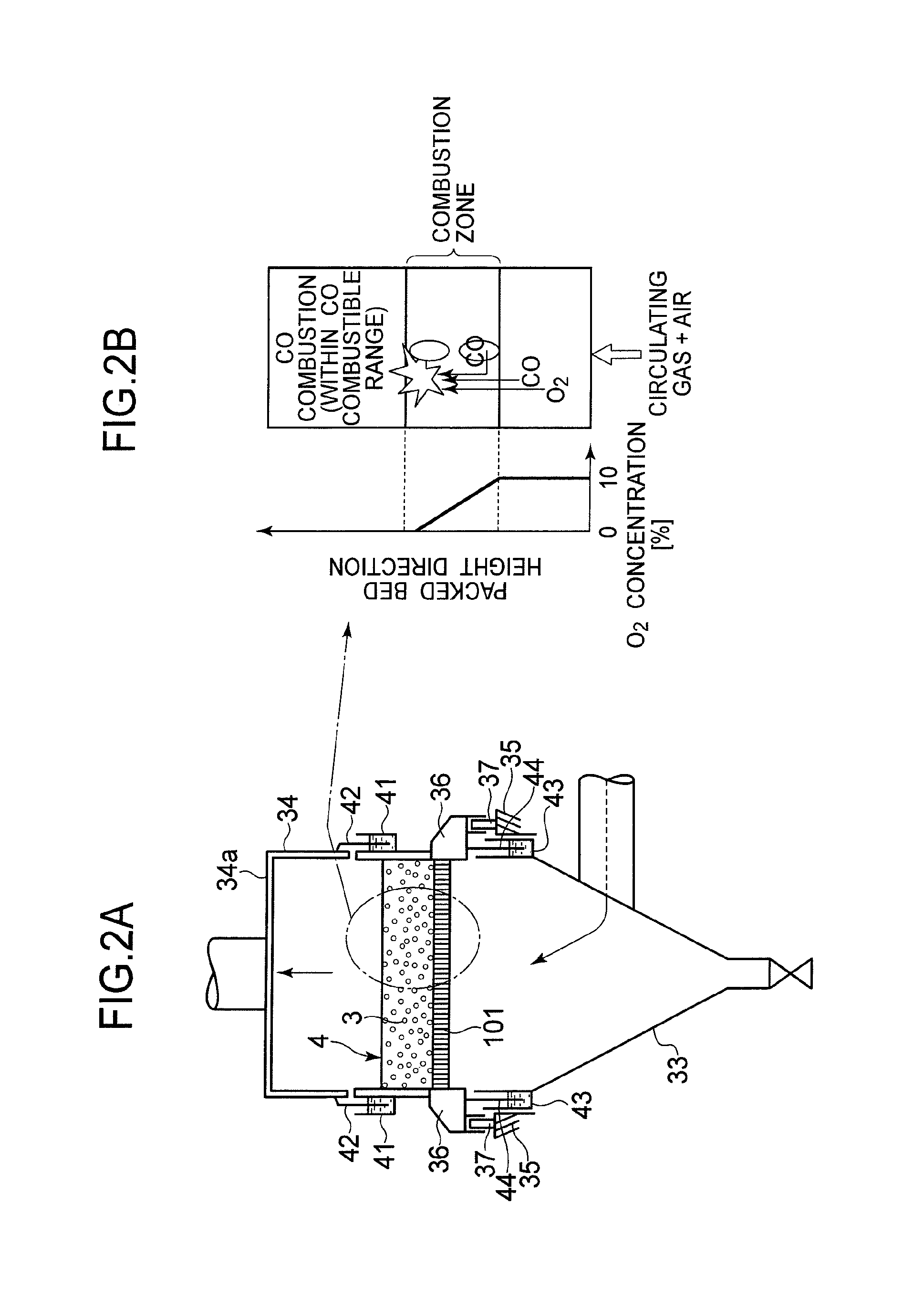

Partially-reduced iron producing method and partially-reduced iron producing apparatus

InactiveUS8961650B2Reduce processHigh degree of metallizationTuyeresBell-and-hopper arrangementDevice formMetallurgy

A reduction furnace includes a pellet material supplying device forming on a grate an ignition carbon material layer having a predetermined height; an ignition device; and an exhaust gas circulation device supplying an oxygen-containing gas comprising circulated exhaust gas mixed with air, to a packed bed of the pellets heated by a combustion heat of the ignition carbon material layer. A partially-reduced iron is produced by thermally reducing the pellets through a combustion region for the ignition carbon material layer and a heating region, the combustion region formed upstream in a travelling direction of the grate by supplying a gas having a high oxygen concentration, the heating region formed downstream of the combustion region by supplying a gas having a low oxygen concentration.

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

Prediction of cavity size in the packed bed systems using new correlations and mathematical model

It has been reported in the literature that raceway measurement made during the decreasing gas velocity is relevant to operating blast furnaces. However, no raceway correlation is available either for decreasing or increasing gas velocity which is developed based on a systematic study and none of the available correlation take care of frictional properties of the material. Therefore, a systematic experimental study has been carried out on raceway hysteresis. Based on experimental data and using dimensional analysis, two raceway correlations, one each for increasing and decreasing gas velocity, have been developed. Also, in the present study the effect of stresses has been considered along with pressure and bed weight terms mathematically. These three forces are expressed in mathematical form and solved analytically for one-dimensional case, using a force balance approach. Based on the force balance approach a general equation has been obtained to predict the size of the cavity in each case, i.e., for increasing and decreasing velocity. Results of these correlations and model have been compared with the data obtained from literature on cold and hot models and plant data along with some experimental data. An excellent agreement has been found between the predicted (using correlations and model) and experimental values. The proposed theory is applicable to any packed bed systems. It has been shown that hysteresis mechanism in the packed beds can be described reasonably taking into consideration the reversal of sign in frictional forces in increasing and decreasing velocity cases.

Owner:COUNCIL OF SCI & IND RES

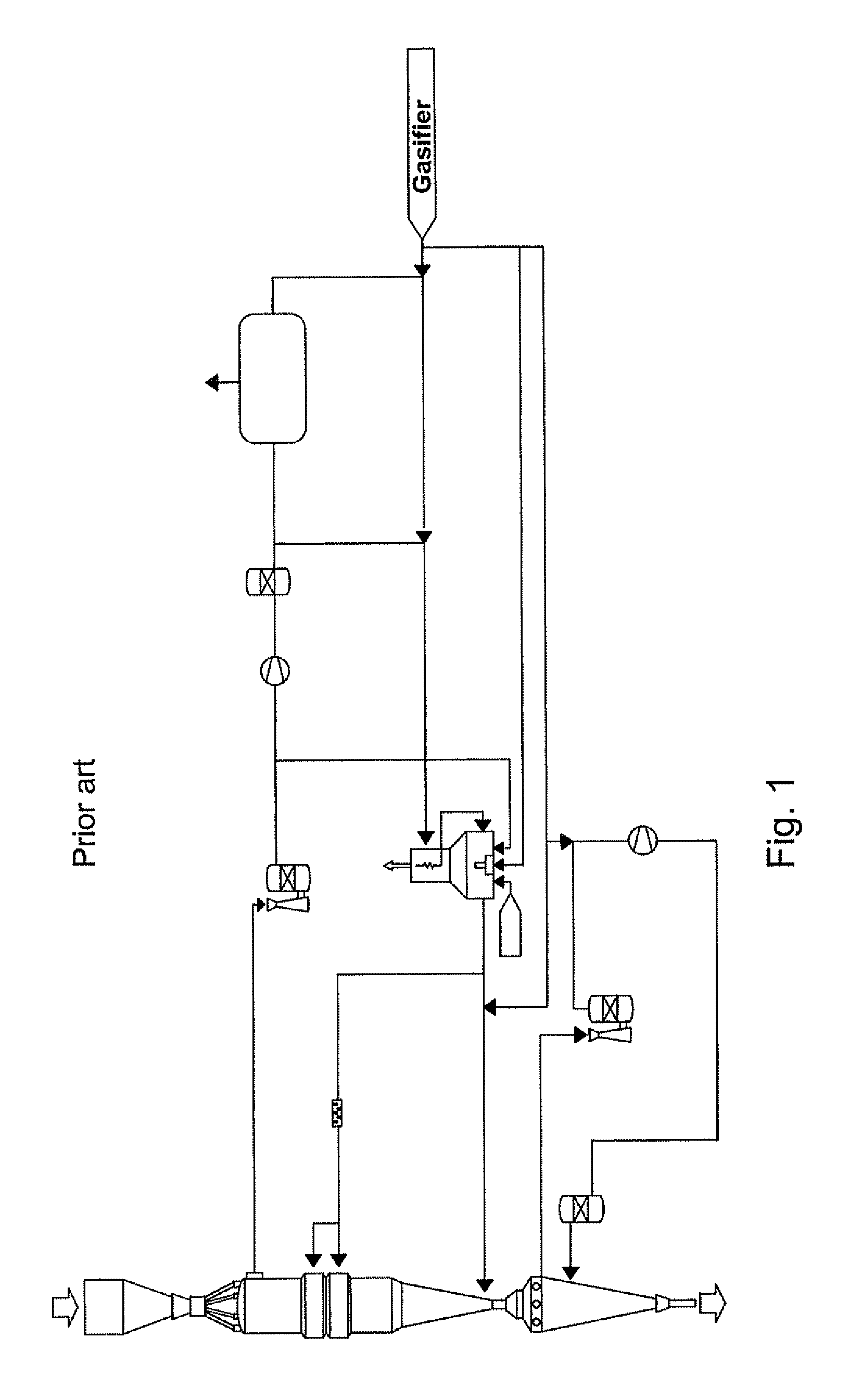

Method for operating a blast furnace and blast furnace installation

InactiveUS8545597B2Increase the amount of gasReduce the amount of solutionDirect heating destructive distillationBiofuelsCyclic processProduct gas

A method for operating a blast furnace and a corresponding blast furnace, the method including recovering top gas from the blast furnace, submitting at least a portion of the top gas to a recycling process, and feeding the recycled top gas back into the blast furnace, where the recycling process includes feeding the recovered top gas to a reformer unit, feeding volatile carbon containing material to the reformer unit, proceeding to flash gasification of the volatile carbon containing material in the reformer unit, at a temperature between 1100 and 1300° C., and thereby producing devolatized carbonaceous material and synthesis gas, and allowing the devolatized carbonaceous material and synthesis gas to react with the recovered top gas.

Owner:PAUL WURTH SA

Eddy-free high velocity cooler

A cooling system comprises serpentine cooling fluid passages cast into a work piece with carefully controlled turning radii and profiles. Individual interdigitated baffles are contoured in the plane of coolant flow to have walls that thicken and then round off at their distal ends. The outside radii at these turns is similarly rounded and controlled such that the coolant flow will not be swirled into eddies.

Owner:MACRAE ALLAN J

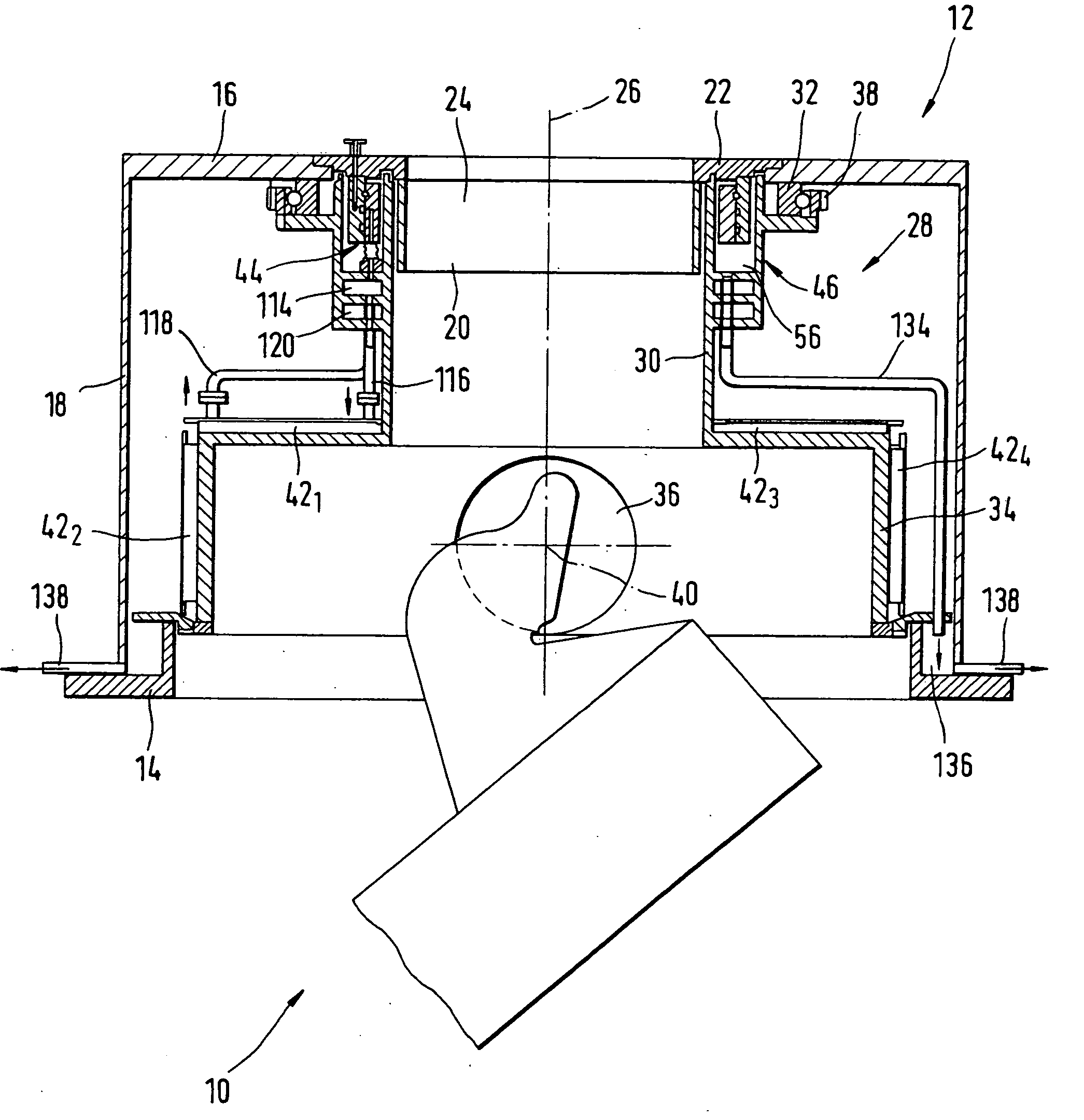

Device for loading a shaft furnace

A loading device for a shaft furnace comprises a chute supported by a suspension rotor (28) in a fixed housing. The rotor (28) is fitted with a cooling circuit, supplied with liquid coolant via a rotating annular joint (44). The latter comprises a fixed ring (60) and a rotating ring (62), and is fitted in an annular leak collecting tank (46) formed by the suspension rotor (28). Fixed ring (60) is supported by the housing (12). Rotating ring (62) is supported entirely by fixed ring (60) via a bearing (64). Selective coupling means (65, 66) connect the rotating ring (62) to the suspension rotor (28) in such a way as to transmit a rotary moment of rotor (28) to rotating ring (62) selectively, while at the same time preventing other forces from rotor (28) being transmitted to rotating ring (62).

Owner:PAUL WURTH SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com