Titanium ore cold briquetting for protecting blast furnace and its production method

A technology for blast furnace protection and production methods, which is applied in the field of iron and steel metallurgy, and can solve problems such as binder formulations and poor production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

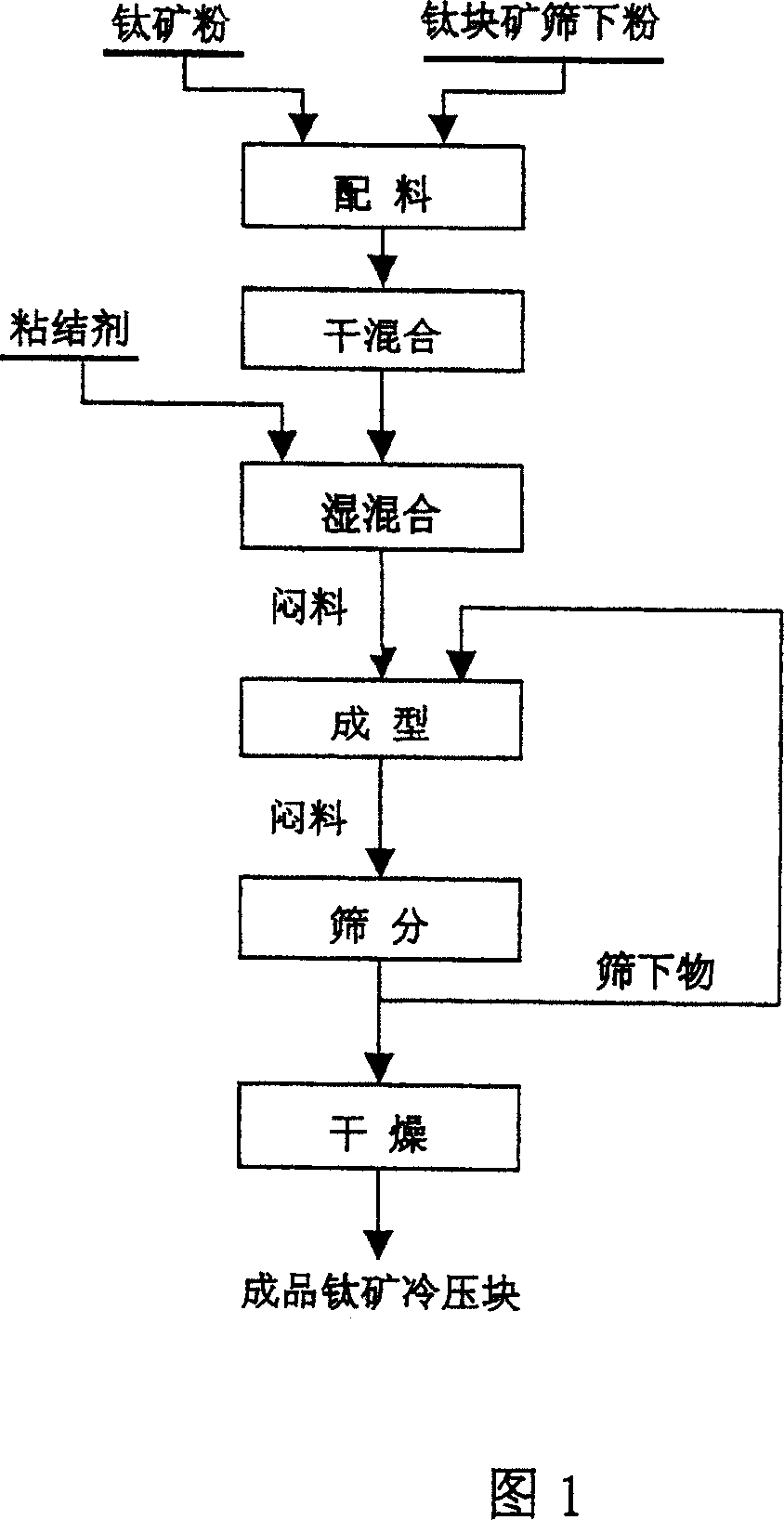

Method used

Image

Examples

Embodiment 1

[0017] Baosteel cooperates with Shanghai Aobao Industry and Trade Co., Ltd., adopts the briquetting production equipment and site of Shanghai Aobao Industry and Trade Co., Ltd., and uses Chengde ilmenite concentrate and Canadian titanium lump ore under-sieve powder in Baosteel stockyard as test raw materials. Using the above-mentioned composite binder 1 as the binder, a titanium-containing briquette numbered "Obao Titanium Ball 0762.2" was trial-produced, and its main properties are as follows:

[0018] TiO 2 28.7%, TFe 33.1%;

[0019] JIS drum strength is 75.7%, which is close to Baosteel sinter strength;

[0020] RDI (Japanese corporate standard) is 24.3%, which is better than the RDI index of Baosteel sintered ore, and is also better than the titanium-containing briquette of a plant that Baosteel blast furnace tried from October to December 1999. Its RDI is 45.0%:

[0021] The pulverization rate index after reduction at 900°C is 30.3%, which is significantly better than ...

Embodiment 2

[0024] Baosteel's No. 2 blast furnace started to use Opal titanium-containing briquettes produced by the invention to replace Panxi titanium lump ore. Its chemical composition and metallurgical performance indicators are shown in Table 1 and Table 2 below.

[0025] Table 1 The chemical composition of opal titanium-containing briquettes, %

[0026] Variety

[0027] Table 2 Metallurgical performance indicators of opal titanium-containing briquettes, %

[0028] Variety

[0029] After Baosteel's No. 2 blast furnace was used, the molten iron production level of the blast furnace was moderate, at 8800t / d; the air permeability index was 2.4-2.5; the furnace temperature was maintained at a high level, at 1505-1510°C. The practice of blast furnace production during this period shows that the process of titanium being reduced into molten iron is normal, indicating that titanium is effectively utilized in the furnace; compared with titanium lump ore, titanium briqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com