Strengthening process of mechanical part

A technology of mechanical parts and mechanical processing, which is applied in the field of mechanical parts strengthening technology, can solve the problems of energy waste and cumbersome process, and achieve the effect of reducing energy loss, simplifying steps, and improving wear resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

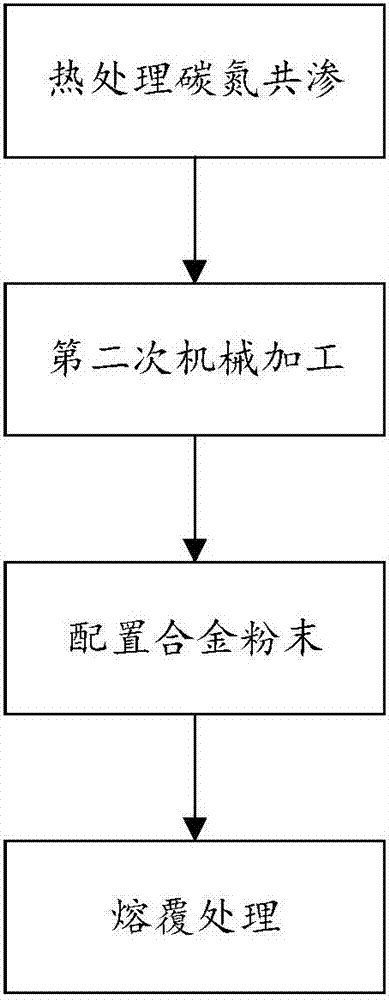

[0021] Combine below figure 1 The present invention will be described in detail.

[0022] Such as figure 1 As shown, the embodiment of the present application discloses a mechanical accessory strengthening process, which is characterized in that it includes the following steps:

[0023] Step 1: Heat treatment carbonitriding, put the machined parts into the carburizing furnace, increase the temperature of the carburizing furnace to 850-870°C, and keep it for 8-10 hours;

[0024] Step 2: the second mechanical processing, keeping the temperature of the second mechanical processing at 540-560°C;

[0025] Step 3: configuring alloy powder, the composition of which is 50-60% nickel, 10-20% chromium, and 20-30% iron;

[0026] Step 4: Cladding treatment, the surface of the mechanical parts is clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com