Halogen-free resin composition and resin-coated copper foil and copper-clad plate prepared from same

A resin composition and resin coating technology, applied in the directions of layered products, metal layered products, chemical instruments and methods, etc., can solve the problems of low thermal decomposition temperature, poor alkali resistance, poor heat resistance of resin-coated copper foil, etc. Achieve the effect of excellent alkali resistance, good heat resistance, and excellent tracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

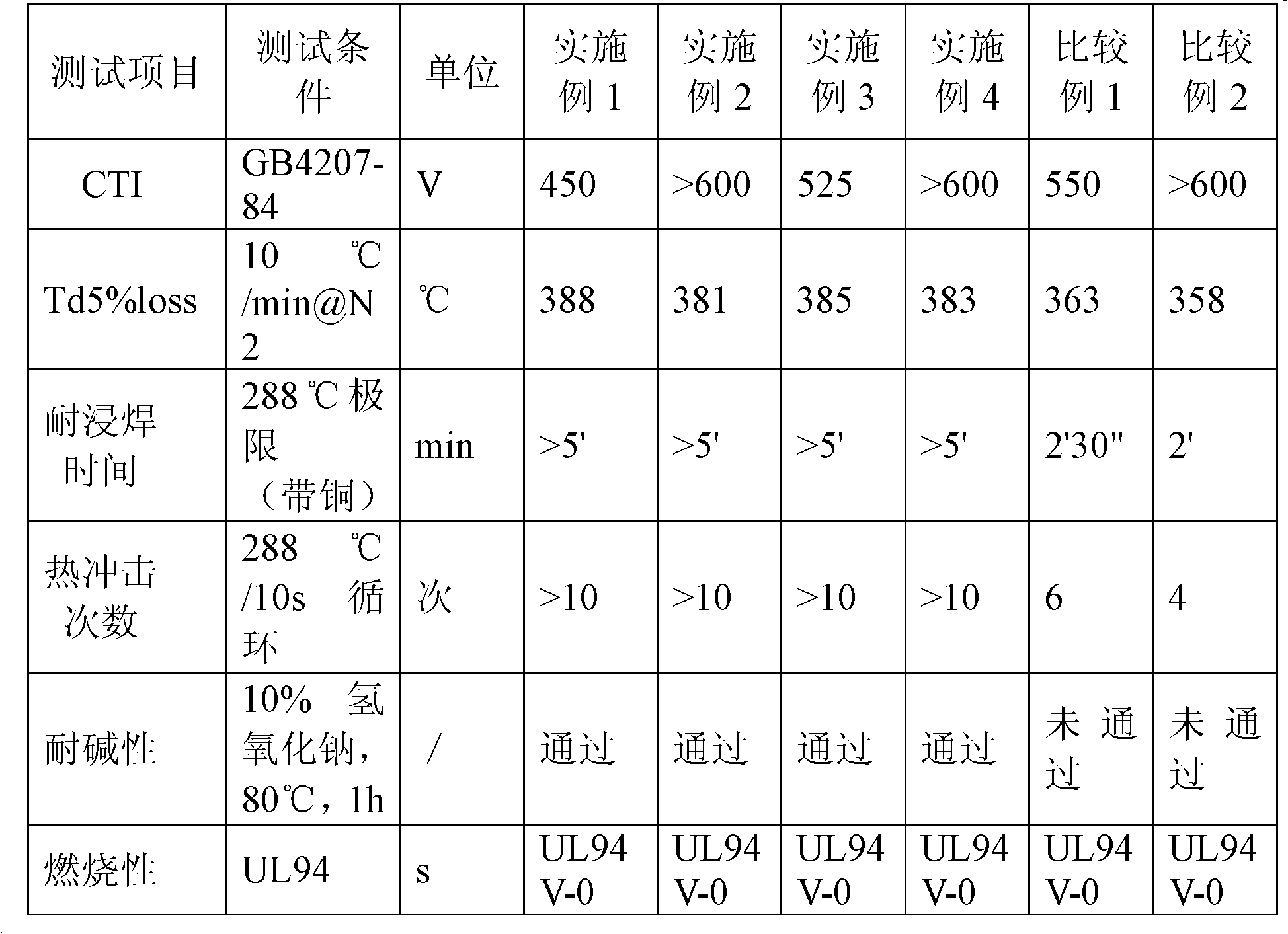

[0021] The total weight part is based on 100 parts, and the halogen-free resin composition includes: 30 parts of phosphorus-containing epoxy resin, 15 parts of bisphenol A epoxy resin, 8.5 parts of novolac epoxy resin, 10 parts of phenoxy resin, 35 parts of barium sulfate filler part, 1.5 parts of dicyandiamide. Add appropriate amount of accelerator and solvent to the composition to form glue, stir the above glue for 1 hour, and after 20 minutes of high-speed shearing by filler dispersing equipment, apply the dispersed glue on the coating machine On the electrolytic copper foil, bake it in an oven at 155 degrees for 6 minutes to obtain a resin-coated copper foil. Take 8 sheets of FR-4 adhesive sheets (model: S1155) and stack them up, and cover the top and bottom with a resin-coated copper foil prepared above, and laminate them in a laminator at 190 degrees for 90 minutes to obtain a copper-clad laminate. The detection performance is shown in Table 1.

Embodiment 2

[0023] The total weight part is based on 100 parts, and the halogen-free resin composition includes: 20 parts of phosphorus-containing epoxy resin, 5 parts of bisphenol A epoxy resin, 5 parts of novolac epoxy resin, 19.5 parts of phenoxy resin, 50 parts of barium sulfate filler part, 0.5 part of dicyandiamide. Add appropriate amount of accelerator and solvent to the composition to form glue, stir the above glue for 1 hour, and after 20 minutes of high-speed shearing by filler dispersing equipment, apply the dispersed glue on the coating machine On the electrolytic copper foil, bake it in an oven at 155 degrees for 6 minutes to obtain a resin-coated copper foil. Take 8 sheets of FR-4 adhesive sheets (model: S1155) and stack them up, and cover the top and bottom with a resin-coated copper foil prepared above, and laminate them in a laminator at 190 degrees for 90 minutes to obtain a copper-clad laminate. The detection performance is shown in Table 1.

Embodiment 3

[0025] The total weight part is based on 100 parts, and the halogen-free resin composition includes: 25 parts of phosphorus-containing epoxy resin, 9 parts of bisphenol A epoxy resin, 10 parts of novolac epoxy resin, 15 parts of phenoxy resin, 40 parts of barium sulfate filler part, 1 part of dicyandiamide. Add appropriate amount of accelerator and solvent to the composition to form glue, stir the above glue for 1 hour, and after 20 minutes of high-speed shearing by filler dispersing equipment, apply the dispersed glue on the coating machine On the electrolytic copper foil, bake it in an oven at 155 degrees for 6 minutes to obtain a resin-coated copper foil. Take 8 sheets of FR-4 adhesive sheets (model: S1155) and stack them up, and cover the top and bottom with a resin-coated copper foil prepared above, and laminate them in a laminator at 190 degrees for 90 minutes to obtain a copper-clad laminate. The detection performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com