Vacuum insulator coating capable of increasing flashover voltage and method of preparation thereof

A technology of vacuum insulation and flashover along the surface, which is applied to organic insulators, insulators, plastic/resin/wax insulators, etc., and can solve the problem of lack of data on the vacuum surface of insulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: concrete preparation process comprises the following steps:

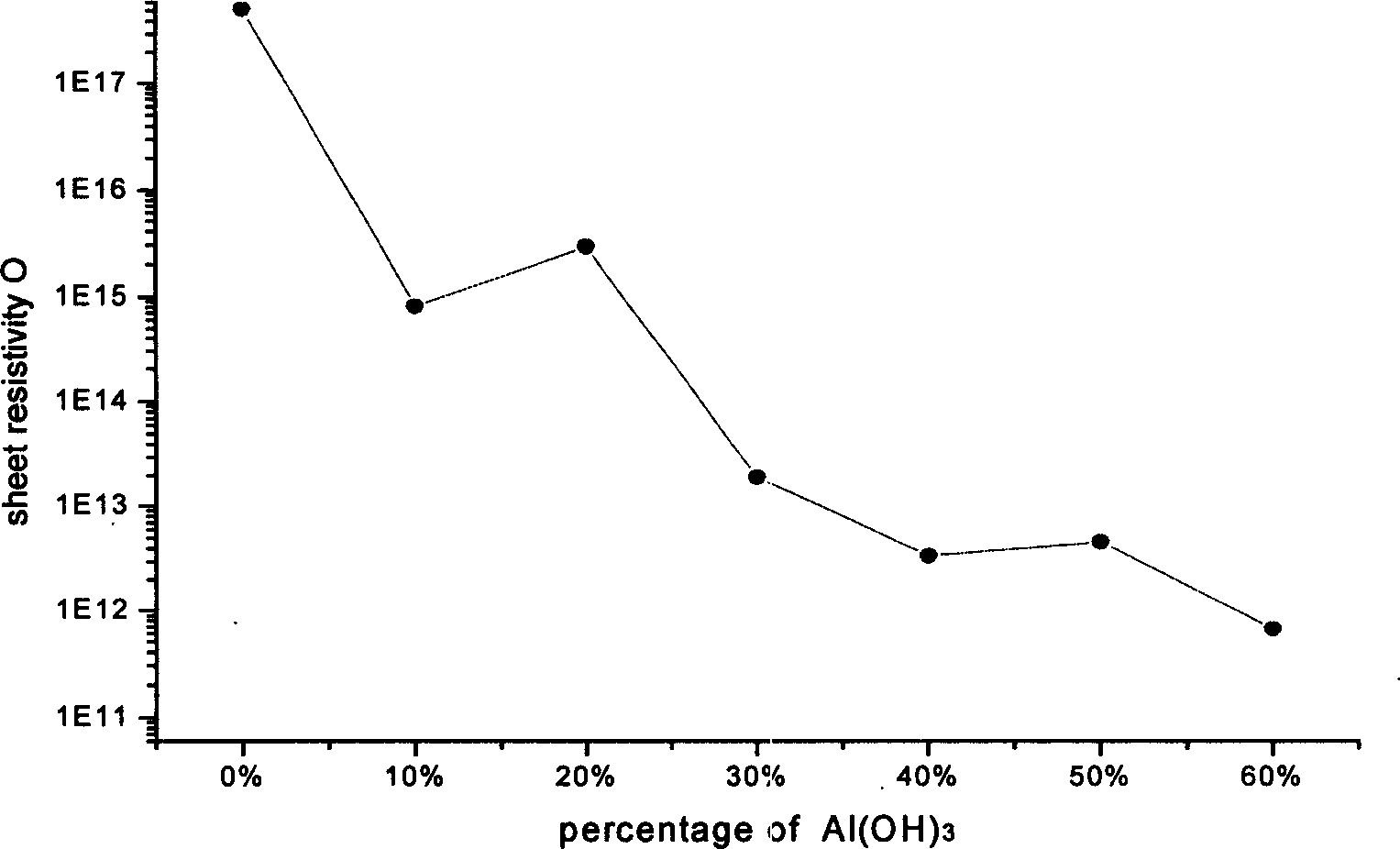

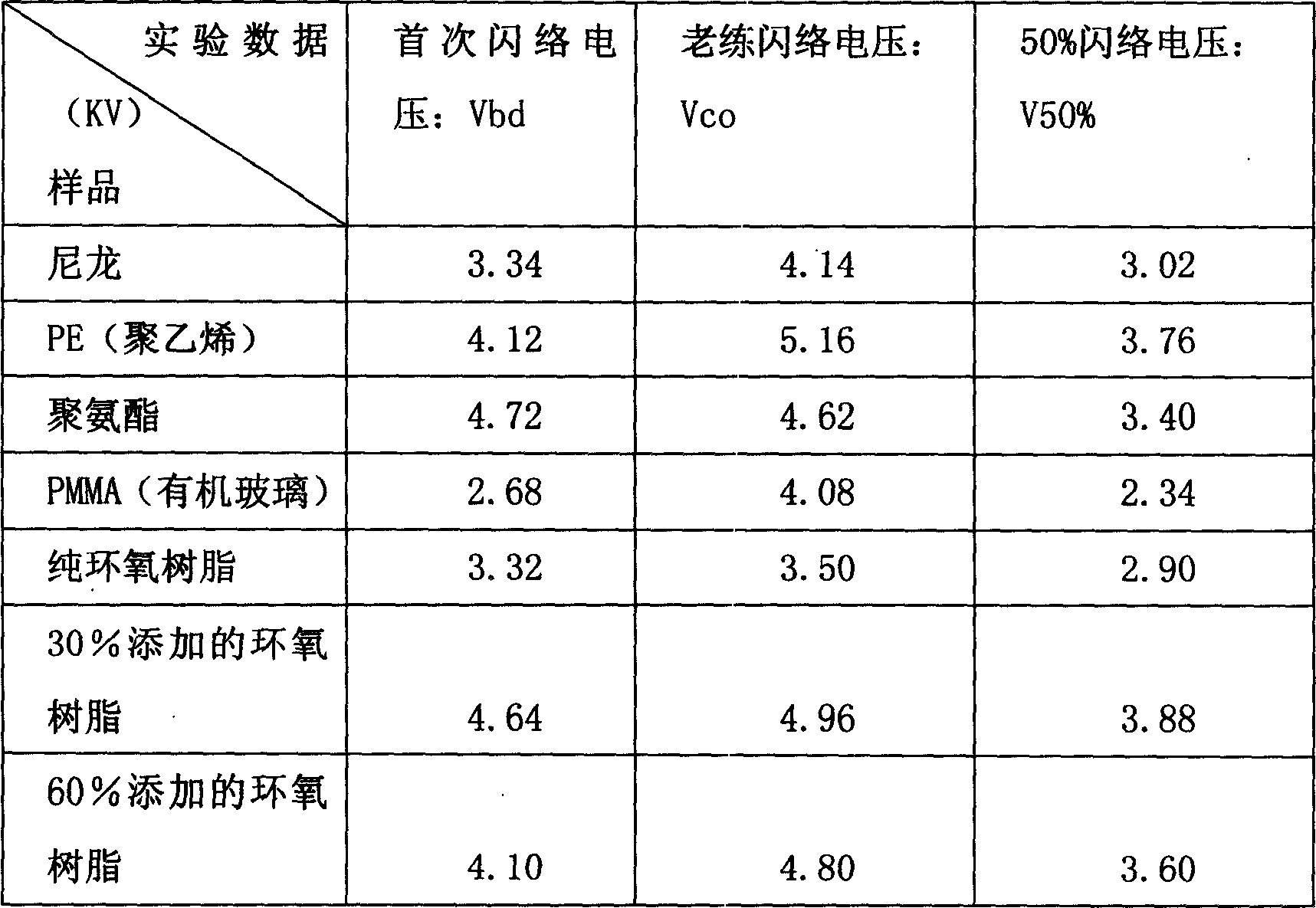

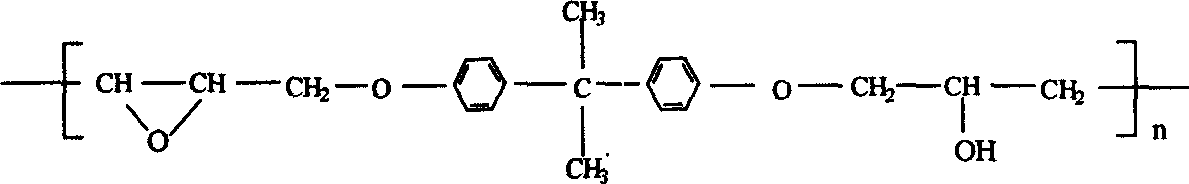

[0040] 1. Mix epoxy resin, aluminum hydroxide powder, modified synthetic amine curing agent, and butyl glycidyl ether diluent according to the mass percentage of 66%: 20%: 13%: 0%.

[0041] 2. Put the epoxy resin weighed according to the proportion, the modified synthetic amine curing agent and the butyl glycidyl ether diluent into the oven and heat it at 50°C for 20 minutes, then put it into the vacuum drying oven -0.001 Under Mpa (vacuum tightness 100), vacuumize 30 minutes, remove moisture and air bubble in the raw material;

[0042] 3. Mix the epoxy resin with the modified synthetic amine curing agent, while stirring, slowly add aluminum hydroxide powder and butyl glycidyl ether diluent until the mixture is complete; stir with an electric mixer for 30 minutes, then put it in the oven Heat at 50°C for 20 minutes. Vacuum again at -0.001Mpa (vacuum degree 100) for 30 minutes, then remove and ...

Embodiment 2

[0046] 1. Mix epoxy resin, aluminum hydroxide powder, modified synthetic amine curing agent, and butyl glycidyl ether diluent according to the mass percentage of 50%: 30%: 15%: 5%.

[0047] 2. Put the epoxy resin weighed according to the proportion, the modified synthetic amine curing agent and the butyl glycidyl ether diluent into the oven and heat it at 60°C for 20 minutes, then put it in a vacuum drying oven at - Vacuumize at 0.001Mpa (vacuum degree 100) for 60 minutes to remove moisture and air bubbles in the raw materials;

[0048] 3. Mix the epoxy resin with the modified synthetic amine curing agent, and slowly add aluminum hydroxide powder and butyl glycidyl ether diluent while stirring until complete; stir with an electric mixer for 50 minutes, then put it in the oven for 60 °C for 20 minutes. Vacuum again at -0.001Mpa (vacuum degree 100) for 60 minutes, then remove and remove the air bubbles floating on the surface;

[0049] 4. Cast the raw material without air bubb...

Embodiment 3

[0052] 1. Mixing epoxy resin, aluminum hydroxide powder, modified synthetic amine curing agent, and butyl glycidyl ether diluent according to the mass percentage of 20%: 60%: 13.3%: 6.6%.

[0053] 2. Put the epoxy resin weighed according to the proportion, the modified synthetic amine curing agent and the butyl glycidyl ether diluent into the oven and heat it at 60°C for 20 minutes, then put it in a vacuum drying oven at - Vacuumize at 0.001Mpa (vacuum degree 100) for 60 minutes to remove moisture and air bubbles in the raw materials;

[0054] 3. Mix the epoxy resin with the modified synthetic amine curing agent, and slowly add aluminum hydroxide powder and butyl glycidyl ether diluent while stirring until complete; stir with an electric mixer for 60 minutes, then put it in an oven for 60 minutes °C for 20 minutes. Vacuum again at -0.001Mpa (vacuum degree 100) for 60 minutes, then remove and remove the air bubbles floating on the surface;

[0055] 4. Repeat step 3 once, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com