Prepreg for improving electric leakage-resisting tracking index and drilling processing properties and application thereof

A technology of anti-tracking and prepreg, which is applied in applications, other household appliances, electronic equipment, etc., can solve the problems of insufficient toughness and easy microcracks of printed circuit boards, and achieve excellent anti-tracking characteristics, good drilling Improvement of hole processing performance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

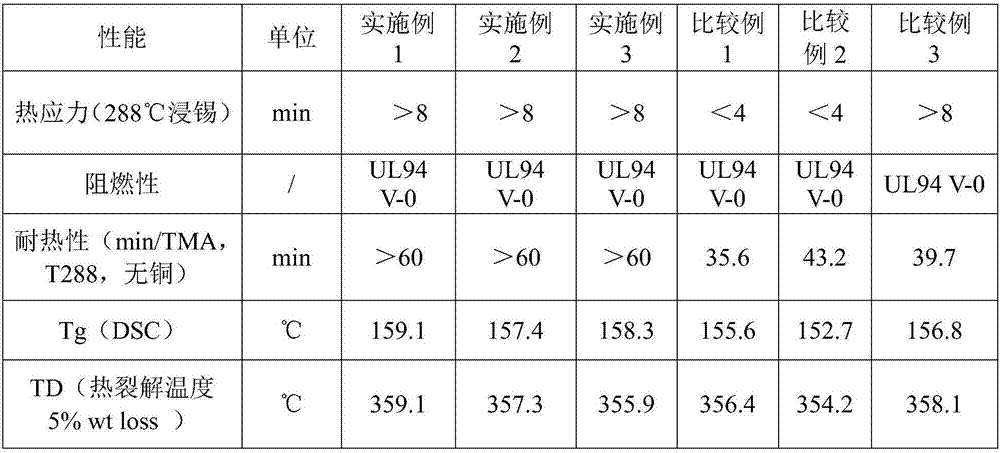

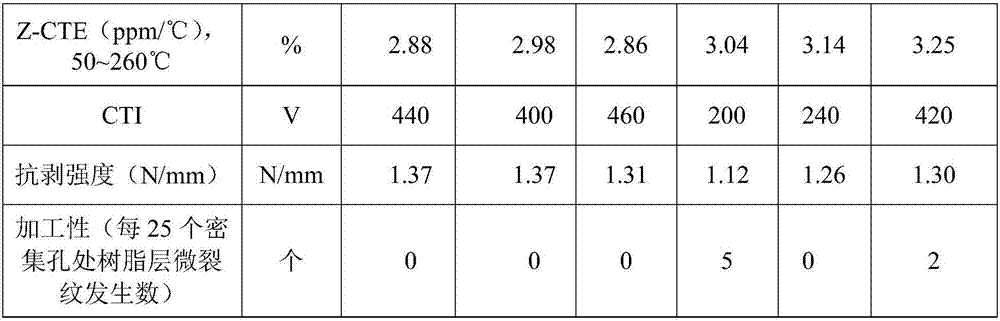

[0034] An adhesive suitable for improving the drilling performance of medium Tg lead-free printed circuit boards. Oxygen resin, phenolic resin curing agent, imidazole accelerator, amine curing agent, silane, inorganic filler, barium sulfate, organic solvent and toughening agent, etc., as shown in Table 1.

[0035] Table 1

[0036] material name

Example 1

Example 2

Example 3

Comparative example 1

Comparative example 2

Comparative example 3

Novolac epoxy resin

12

10

11

12

10

13

Isocyanate Modified Epoxy Resin

10

10

9

10

10

8

High Brominated Epoxy Resin

5

4

4

5

4

6

Bisphenol A Brominated Epoxy Resin

26

29

30

26

29

25

Phenolic resin curing agent

18

17

17

18

17

18

imidazole accelerator

0.02

0.02

0.02

0.02

0.02

0.02

Amine curing agent

0.18

0.17

0.17 ...

Embodiment 4

[0061] Prepregs with improved tracking resistance index and drilling processing performance, control the glue line speed to 6m / min, circulate the adhesive to the glue machine, and apply the adhesive evenly on the glass after pre-dipping and main dipping On the fiber cloth; the glass fiber cloth coated with the adhesive is baked in a 100°C oven to volatilize the solvent, and the adhesive is initially reacted and solidified to obtain a prepreg.

[0062] Control of the physical parameters of the prepreg: gelation time: 250 seconds; resin content: 40% (referring to the mass percentage of the resin component in the prepreg); resin fluidity: 20%; volatile matter: 0.29%.

[0063] Adhesives are prepared by the following methods:

[0064] (1) Prepare materials according to the raw materials of the following components and parts by weight:

[0065] Novolac epoxy resin 5, isocyanate modified epoxy resin 5, high brominated epoxy resin 2, bisphenol A type brominated epoxy resin 5, phenoli...

Embodiment 5

[0071] Prepregs with improved tracking resistance index and drilling processing performance, control the glue line speed to 10m / min, circulate the adhesive to the glue machine, and apply the adhesive evenly on the glass after pre-dipping and main dipping On the fiber cloth; the glass fiber cloth coated with the adhesive is baked in a 200°C oven to volatilize the solvent, and the adhesive is initially reacted and solidified to obtain a prepreg.

[0072] Control of the physical parameters of the prepreg: gelation time: 300 seconds; resin content: 60% (referring to the mass percentage of the resin component in the prepreg); resin fluidity: 30%; volatile matter: 0.35%.

[0073] Adhesives are prepared by the following methods:

[0074] (1) Prepare materials according to the raw materials of the following components and parts by weight:

[0075] Novolak type epoxy resin 20, isocyanate modified epoxy resin 20, high bromine epoxy resin 15, bisphenol A type brominated epoxy resin 25, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com