Patents

Literature

50results about How to "To achieve the effect of toughening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

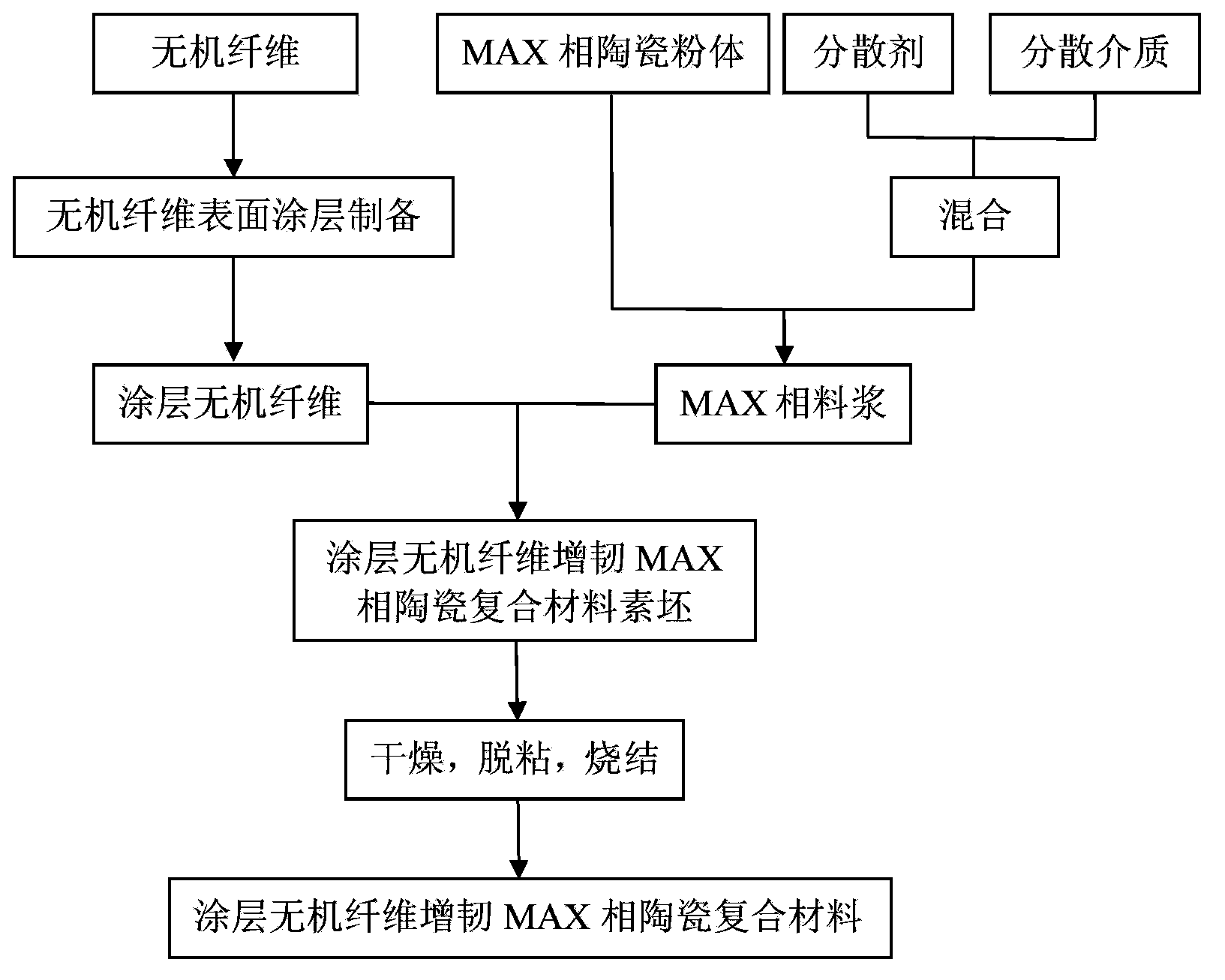

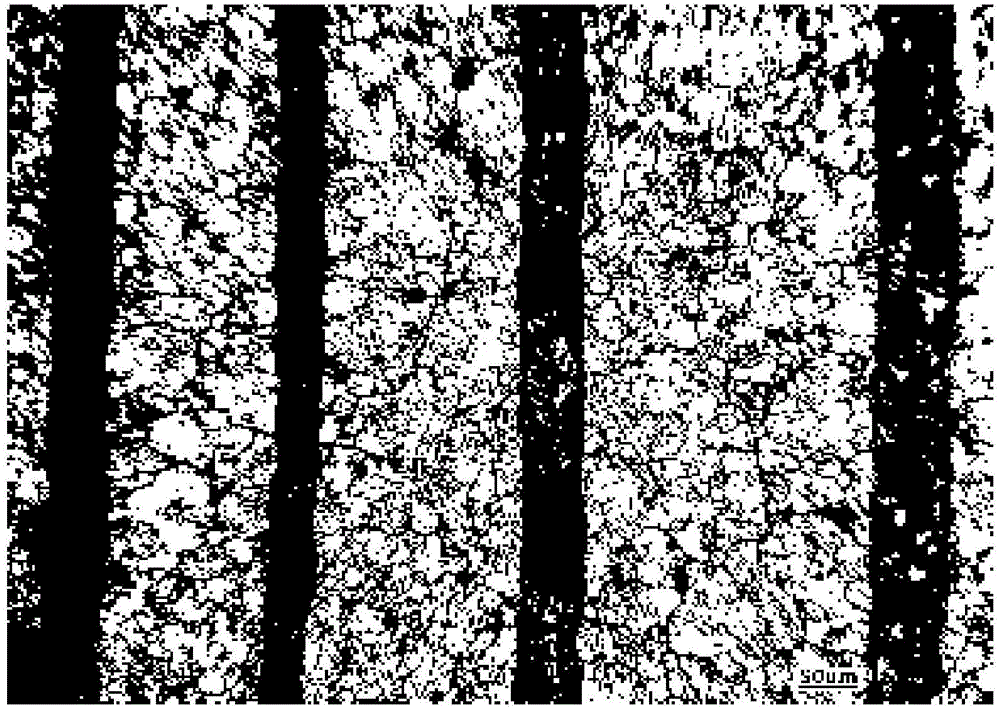

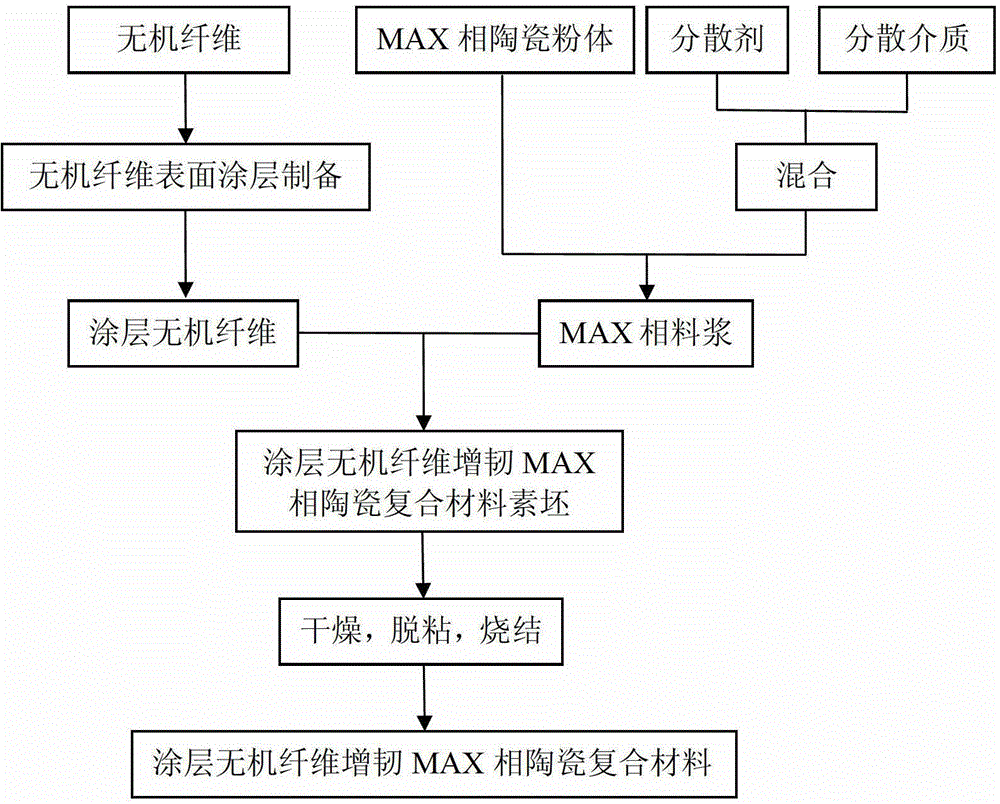

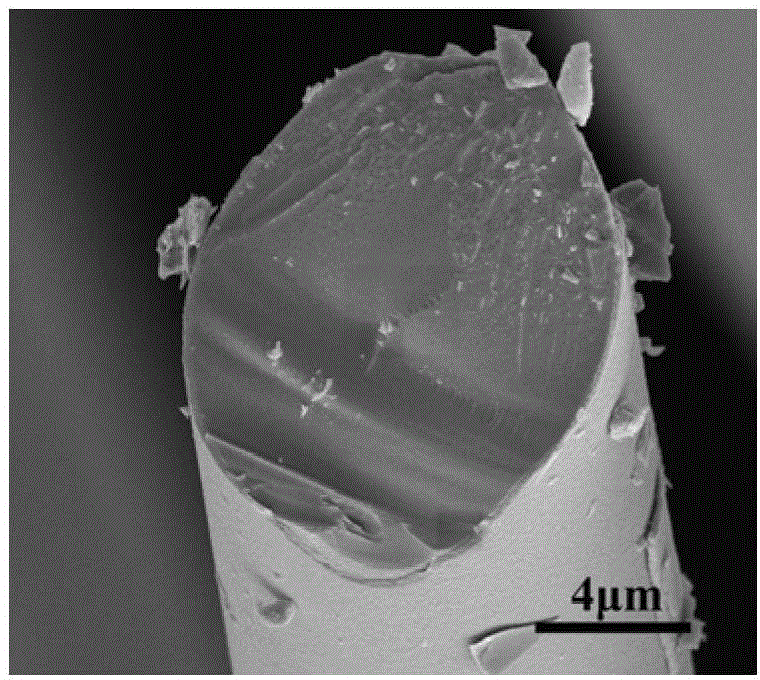

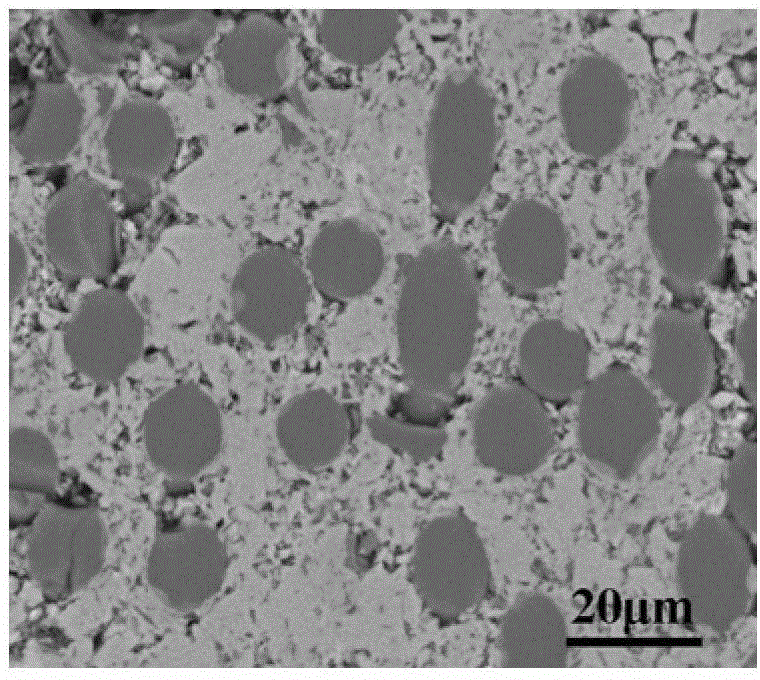

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High wear resistance surfacing alloy material containing multiphase metal ceramics

ActiveCN101879670AImprove performanceInhibit growthWelding/cutting media/materialsSoldering mediaHigh carbonRare earth

The invention relates to a high wear resistance surfacing alloy material containing multiphase metal ceramics and belongs to the technical field of the material. The high wear resistance surfacing alloy material comprises the following ingredients in percentage by weight: 25 to 50 percent of ferrochrome, 1 to 10 percent of ferrotitanium, 1 to 10 percent of ferrovanadium, 0.1 to 5 percent of rare earth material, 1 to 7 percent of ferroboron, 0.4 to 8 percent of ferromolybdenum, 0.5 to 5 percent of aluminium powder, 0.4 to 7 percent of ferronickel, 0.1 to 10 percent of powder material, 8 to 15 percent of sodium potassium silicate, 0.1 to 5 percent of carbon black and the balance of ferrum, wherein the granularity is between 70 and 140 meshes. When the high wear resistance surfacing alloy material containing the multiphase metal ceramics of the invention is adopted to carry out carbon arc surfacing or plasma surfacing, the operation method is simple and the cost is low. Compared with a manual wear-resistance surfacing electrode, the high wear resistance surfacing alloy material is easy to obtain a surfacing layer with high carbon content, high hardness and high wear resistance and has the advantages of firm combination of hard phases and a matrix, high performance of resisting abrasive wear and wide application range.

Owner:LIAONING TECHNICAL UNIVERSITY +1

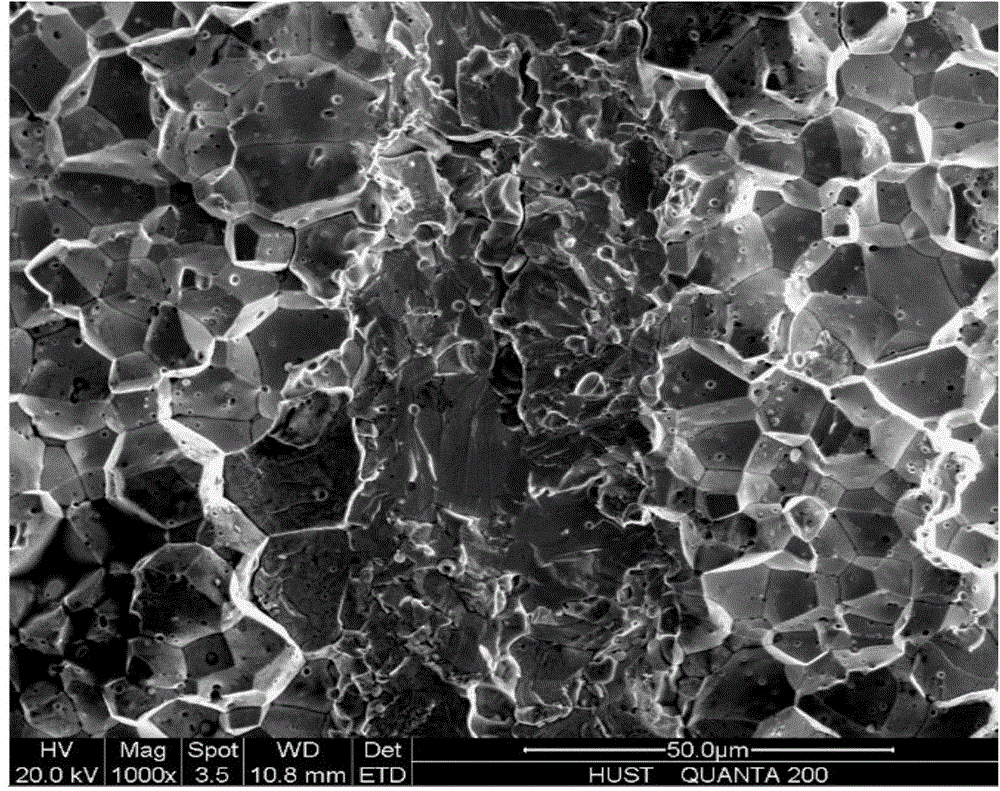

Layered toughening tungsten and preparation method thereof

The invention discloses layered toughening tungsten and a preparation method thereof and belongs to the field of structural materials. The layered toughening tungsten comprises a tungsten layer and a toughening layer which are mutually cascaded mutually; the toughening layer comprises a metal tantalum sheet. The preparation method for the layered toughening tungsten comprises the following steps of S1 mechanically grinding the tungsten powder under protection of inert gases; S2 alternately stacking the tungsten powder and the metal tantalum sheet to obtain a sintering body; S3 performing spark plasma sintering on the sintering body under the protection of the inert gases, wherein the sintering process is divided into three stages, heat preservation is performed at the first stage under the condition that the temperature is from 600 DEG C to 800 DEG C and the pressure is from 5KN to 10 KN; heat preservation is performed at the second stage under the condition that the temperature is from 1100 DEG C to 1300 DEG C and the pressure is from 12 KN to 20 KN; heat preservation is performed under the condition that the temperature is from 1600 DEG C to 1800 DEG C and the pressure is from 30 KN to 35 KN. Compared with pure tungsten, the layered tungsten prepared by the preparation method improves the toughness by 50%.

Owner:HUAZHONG UNIV OF SCI & TECH

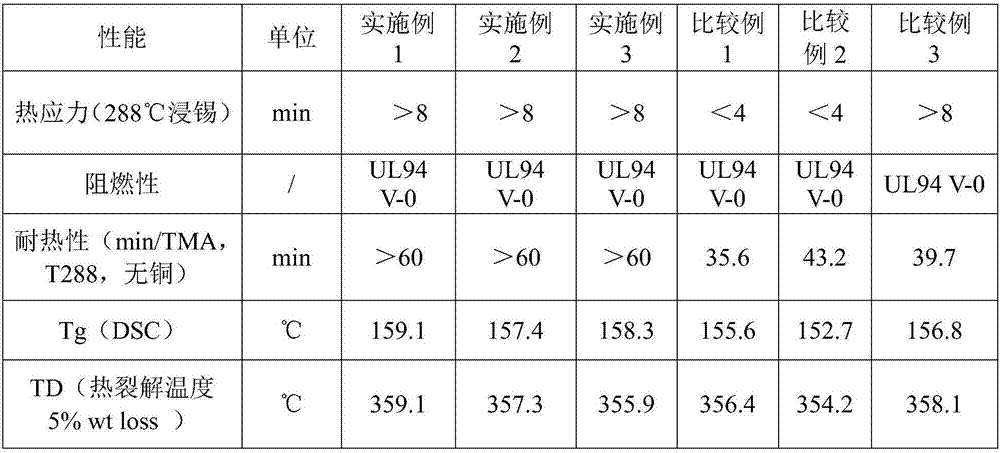

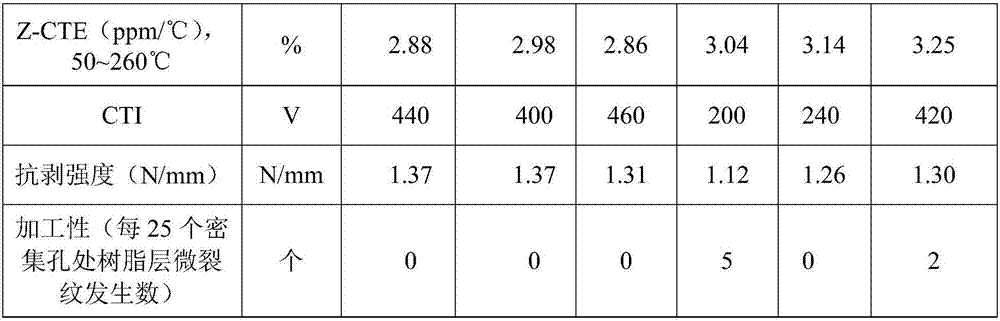

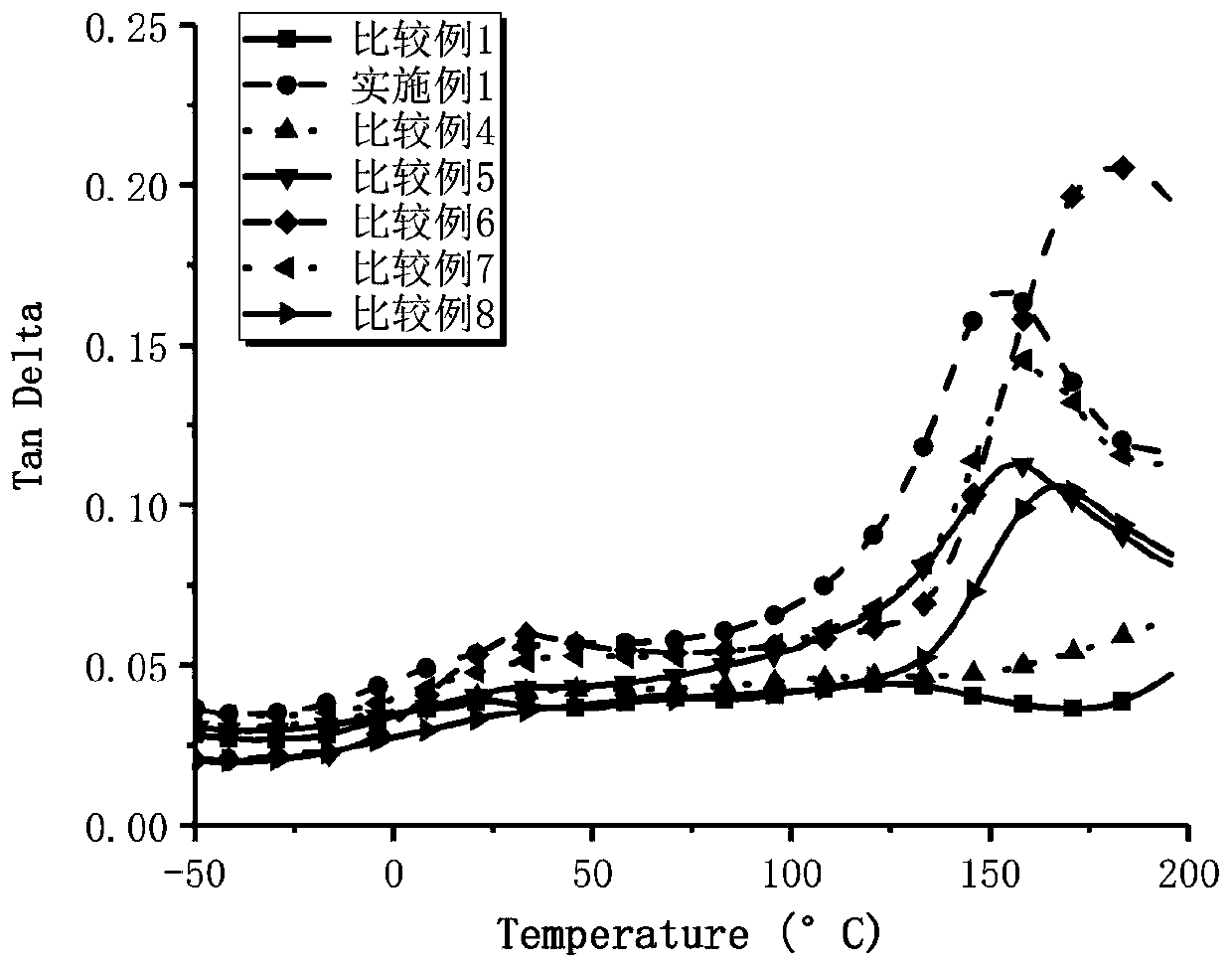

Prepreg for improving electric leakage-resisting tracking index and drilling processing properties and application thereof

InactiveCN107298831AReduce conductivityEasy to processLaminationLamination apparatusGlass fiberCopper foil

The invention relates to a prepreg for improving electric leakage-resisting tracking index and drilling processing properties and an application thereof. The prepreg is prepared according to the method which comprises the following steps: controlling a coating linear velocity at 6-15m / min, circularly loading an adhesive onto a gluing machine, uniformly coating a glass fiber cloth with the adhesive by presoaking and primarily soaking, baking the glass fiber cloth coated with the adhesive in a drying box at 100 DEG C-250 DEG C, evaporating the solvent, preliminarily reacting and curing the adhesive, thereby acquiring the prepreg. Compared with the prior art, the invention not only can promote the electric leakage-resisting tracking index of a Tg unleaded coated copper foil plate, but also can obviously improve the drilling processing properties of a sandwich plate prepared from the prepreg.

Owner:NANYA NEW MATERIAL TECH CO LTD

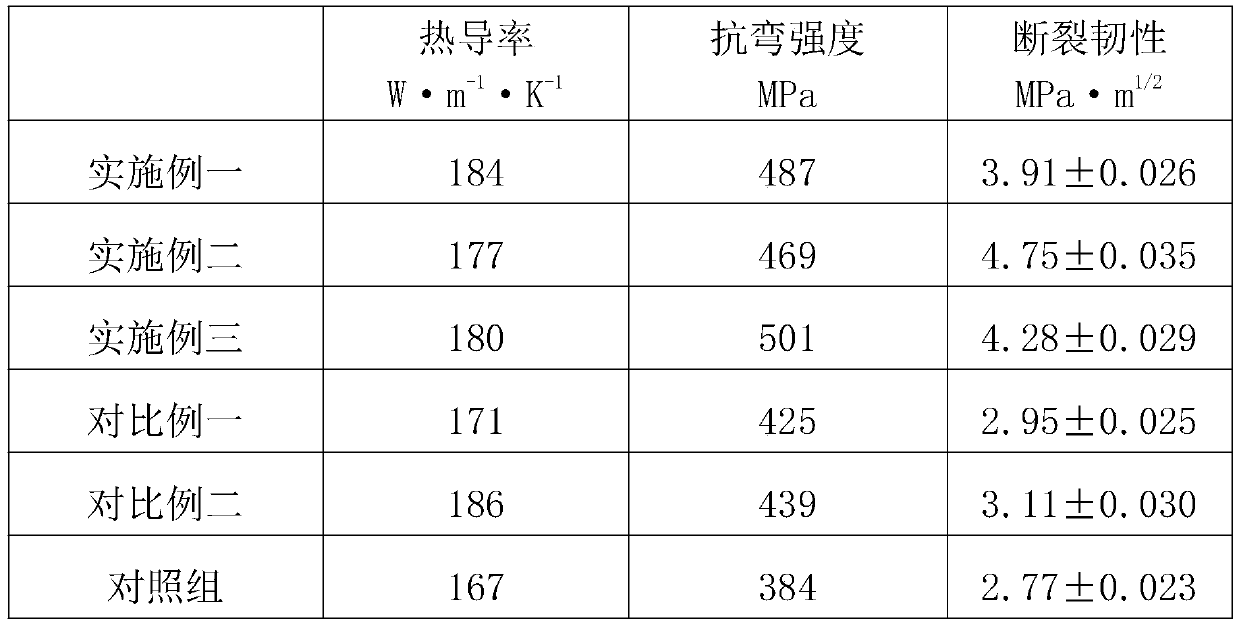

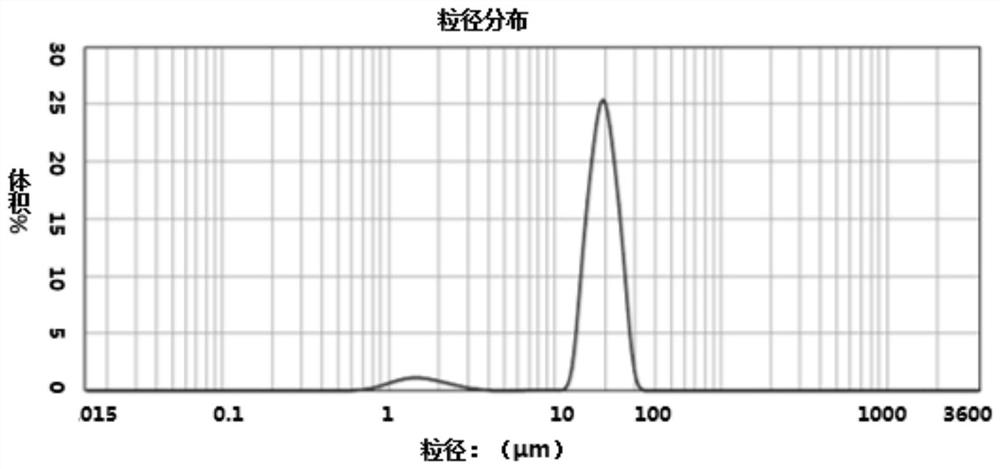

Particle dispersion toughened aluminum nitride ceramic substrate and preparation method thereof

The invention relates to the technical field of preparation of aluminum nitride ceramic substrates, provides a particle dispersion toughened aluminum nitride ceramic substrate and a preparation methodthereof, and solves the problem that an aluminum nitride ceramic has insufficient fracture toughness and cannot satisfy high requirements for material performance in the application field in the prior art. The aluminum nitride ceramic is prepared from the following raw material components: 75-90 parts of aluminum nitride powder, 3-6 parts of a sintering auxiliary agent, 2-4 parts of hafnium carbide, 3-5 parts of zirconium oxide, 0.5-1 part of aluminum oxide, 5-10 parts of polyimide, 1-3 parts of bis(2-ethylhexyl) phthalate, and 4-8 parts of an antifoaming agent. The method provided by the invention adopts a composite toughening manner to modify an aluminum nitride ceramic substrate, and the fracture toughness of the ceramic substrate is obviously superior to that of an aluminum nitride ceramic substrate prepared by single toughening modification.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

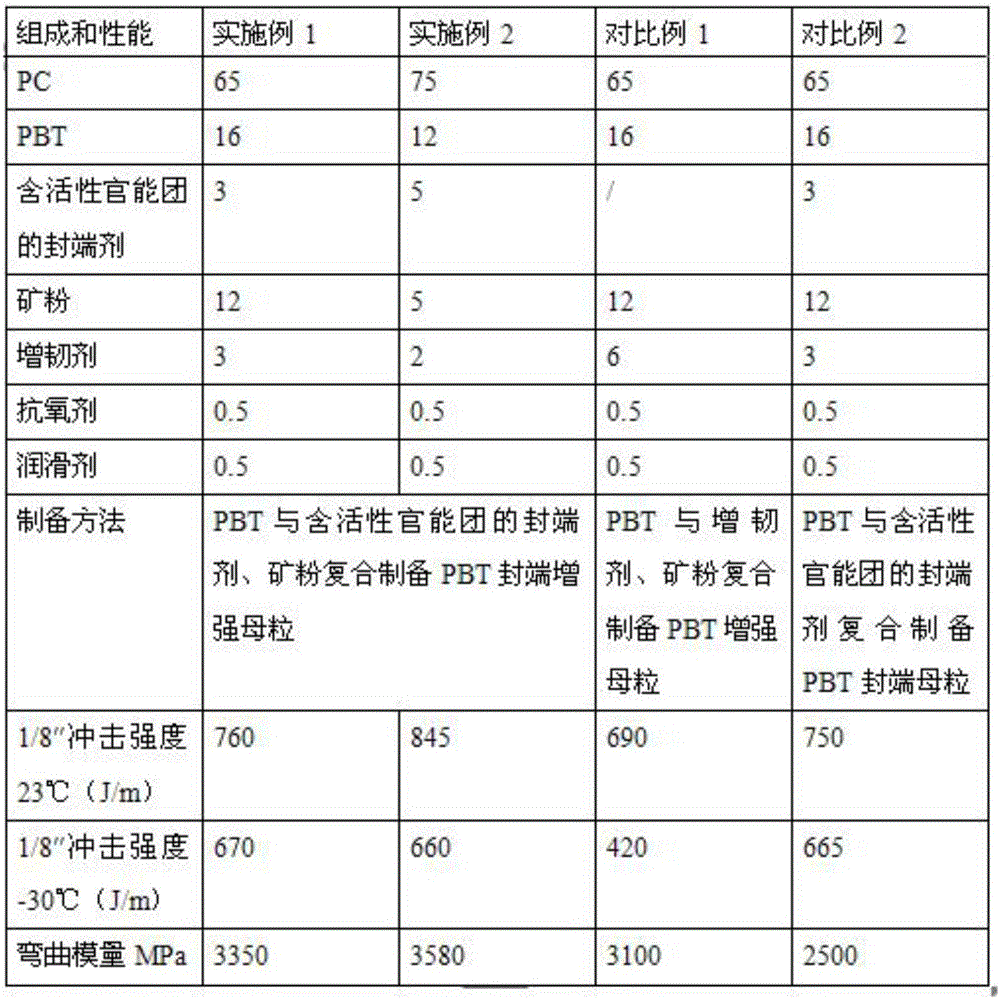

High-toughness and high-rigidity PC/PBT (polycarbonate/polybutylene terephthalate) alloy material and method for preparing same

InactiveCN106280375ATo achieve the effect of tougheningInhibition of exchange reactionsPolyethylene terephthalateAntioxidant

The invention relates to a high-toughness and high-rigidity PC / PBT (polycarbonate / polybutylene terephthalate) alloy material and a method for preparing the same. The alloy material comprises, by weight, 35-85 parts of PC resin, 10-45 parts of PBT resin, 1-5 parts of end-capping agents with active functional groups, 0.1-1 part of antioxidants, 0-5 parts of toughening agents, 0.1-1 part of lubricants and 5-15 parts of mineral powder. The method includes steps of (1), melting, blending, extruding and granulating the PBT resin, the end-capping agents with the active functional groups and the mineral powder by the aid of a double-screw extruder to prepare PBT end-capping strengthening master batch; (2), premixing, melting, blending and granulating the PBT end-capping strengthening master batch and other components to obtain PC / PBT alloy. The high-toughness and high-rigidity PC / PBT alloy material and the method have the advantages that the PC / PBT alloy is high in toughness and rigidity, and the toughness and the rigidity of the material can be balanced.

Owner:上海聚威新材料股份有限公司

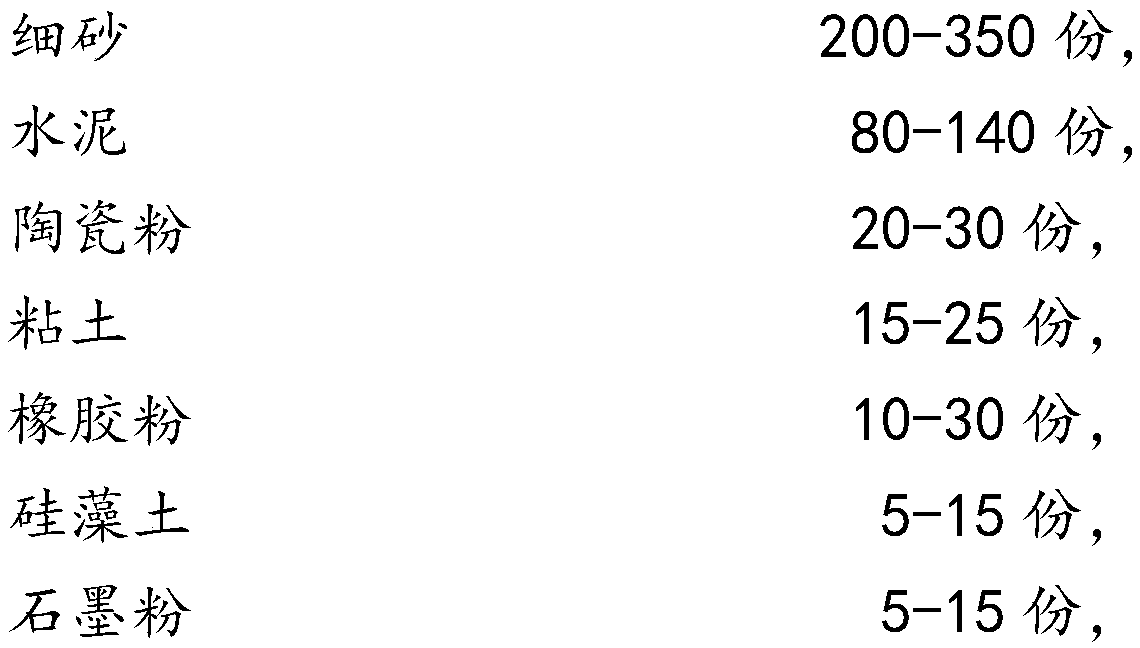

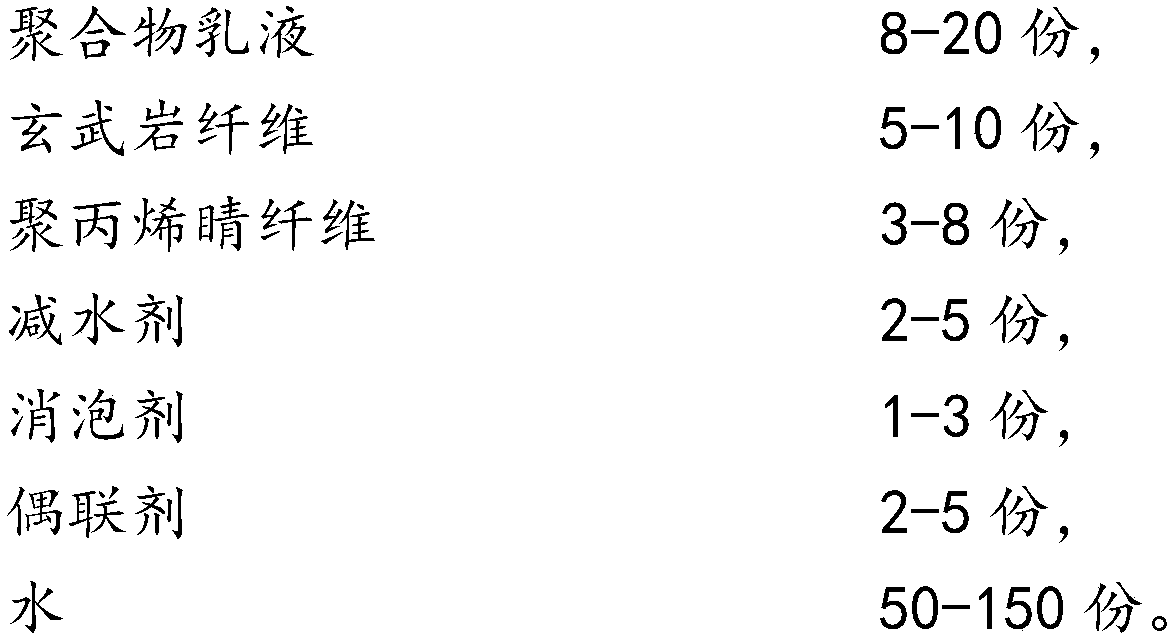

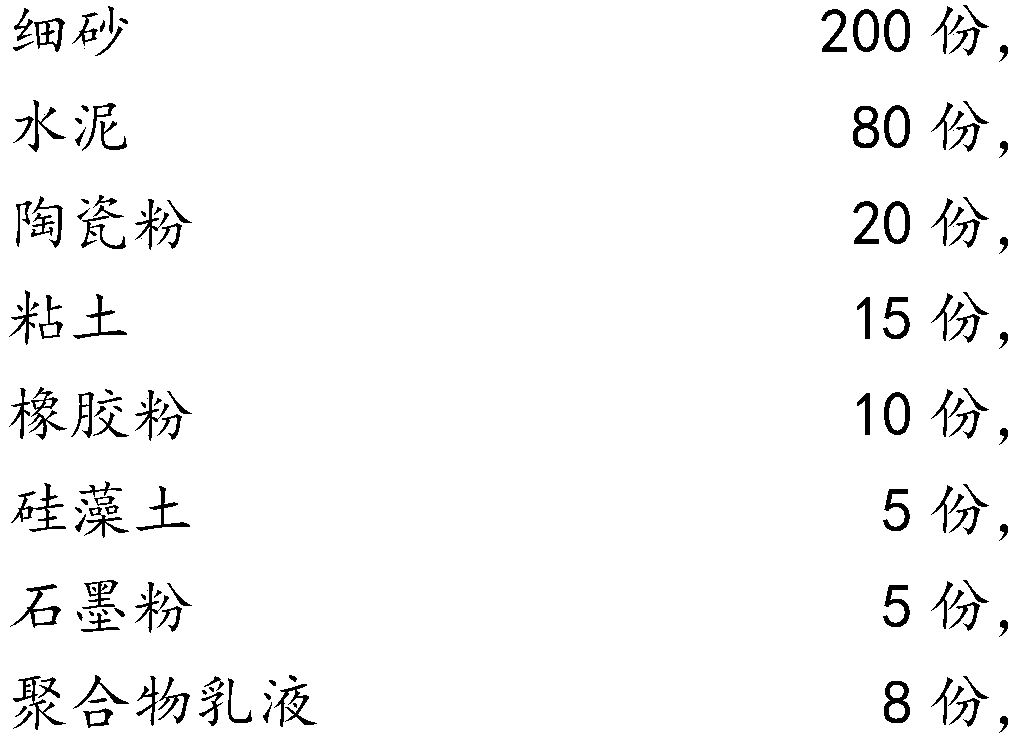

Polymer cement-based modified mortar

The invention discloses polymer cement-based modified mortar. The polymer cement-based modified mortar comprises the following raw materials in parts by mass: 200 to 350 parts of fine sand, 80 to 140parts of cement, 20 to 30 parts of ceramic powder, 15 to 25 parts of clay, 10 to 30 parts of rubber powder, 5 to 15 parts of diatomite, 5 to 15 parts of graphite powder, 8 to 20 parts of polymer emulsion, 5 to 10 parts of basalt fiber, 3 to 8 parts of polyacrylonitrile fiber, 2 to 5 parts of a water-reducing agent, 1 to 3 parts of a defoaming agent, 2 to 5 parts of a coupling agent and 50 to 150 parts of water. The polymer cement-based modified mortar has advantages of high structural strength, high waterproofness, high toughness, high bending strength, high volume stability, high durability,high freezing resistance, high early strength and good use effect, and is not liable to crack.

Owner:SUZHOU BIZUNION ARCHITECTURAL ENG CO LTD

High-toughness ceramic and its preparation method and application

ActiveCN107599536AImprove toughnessIncreased resistance to impact damage such as drop damageLaminationLamination apparatusWhiskersToughness

The invention discloses a high-toughness ceramic and its preparation method and application. The high-toughness ceramic comprises a plurality of ceramic layers and a plurality of fiber layers sandwiched between the ceramic layers. The fiber layers are zirconia fiber layers or alumina fiber layers. The fibers in the fiber layers comprise long fibers and short fibers. The short fibers comprise chopped fibers and whiskers. The preparation method comprises preparing flexible ceramic casting sheets through a tape casting method, overlaying the ceramic casting sheets and the fiber layers, carrying out pressing molding to obtain a sample blank, carrying out isostatic pressing treatment on the sample blank, and carrying out degreasing and sintering to obtain high-performance ceramic. The high-performance ceramic is used for a housing of an electronic product. Through use of the ceramic fibers between the ceramics, ceramic toughness can be significantly improved and resistance to impact damagesuch as drop damage is improved.

Owner:GUANGDONG XINXIU NEW MATERIAL CO LTD

Method for toughening thermosetting resin by using collagen fibers and modified thermosetting resin

The invention relates to the technical field of biomass material toughening modified thermosetting resin, in particular to a method for toughening thermosetting resin by collagen fibers and modified thermosetting resin. The method for toughening the thermosetting resin by using the collagen fibers comprises the following steps: uniformly mixing a thermosetting resin prepolymer with the skin collagen fibers, and carrying out curing reaction. The collagen fibers are used for toughening and modifying the thermosetting resin, so that the toughening effect is achieved, and meanwhile, the modulus ofthe thermosetting resin can be improved. Moreover, as a renewable natural fiber, the collagen fiber is wide in source and low in price, and compared with an existing toughening method, the cost of the collagen fiber is lower.

Owner:SICHUAN UNIV

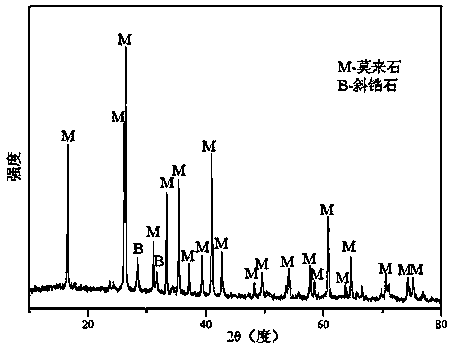

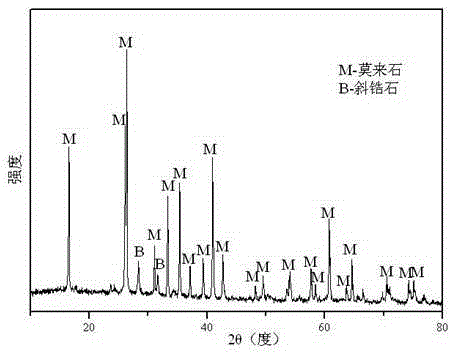

Zirconium-containing mullite composite phase material and preparation method thereof

The invention relates to a zirconium-containing mullite composite phase material and a preparation method thereof. The invention adopts the technical scheme that the preparation method comprises the following steps: firstly, mixing waste molding sand and alumina as raw materials, further adding water which accounts for 40-50wt% of the raw materials and polyving alcohol which accounts for 2-4wt% of water, performing spray granulation and mechanical pressing on the ball-milled slurry, keeping the temperature of formed blanks for 3-5 hours at 1600-1700 DEG C, and naturally cooling, so as to obtain the zirconium-containing mullite composite phase material, wherein the mass ratio of Al2O3 to SiO2 in the raw materials is (2.6-2.8):1. The content of Al2O3 in the waste molding sand is 30-55wt%, the content of SiO2 in the waste molding sand is 35-60wt%, the content of ZrO2 in the in the waste molding sand is greater than or equal to 4.5wt%, and the particle size of the waste molding sand is less than or equal to 0.089mm. The preparation method has the characteristics that the production cost is low, the environment pollution is small and the industrialization production is easy. The zirconium-containing mullite composite phase material prepared by using the method is relatively low in thermal expansion coefficient and good thermal shock resistance and is wide in application range.

Owner:WUHAN UNIV OF SCI & TECH

High-toughness waterproof base plate and preparation method thereof

ActiveCN111993713AImprove film formationSolve the disadvantages of being difficult to volatilize and form a filmSynthetic resin layered productsConstructions elementsElastomerSodium bicarbonate

The invention discloses a high-toughness waterproof base plate which comprises a glass magnesium plate base material layer, a toughening layer and a waterproof coating layer coating the surface of thetoughening layer, wherein the toughening layer is adhered to the surface of the magnesium plate base material layer through an adhesive; the toughening layer is made of a high-toughness polystyrene composite material; sequentially adding sodium bicarbonate and sodium oleate into a three-neck flask filled with deionized water, and carrying out stirring at a constant speed of 100-120 r / min until the particles are completely dispersed; and then adding styrene and divinyl benzene, carrying out heating in a water bath at 55-60 DEG C, carrying out stirring for 2 hours at a rotating speed of 240 r / min, and demulsifying, washing and drying the prepared particles to prepare particles for filling. The invention further discloses a preparation method of the high-toughness waterproof base plate. Thebutadiene rubber can be used as an elastomer to be blended to endow the finally prepared polystyrene with excellent toughness, so that the prepared polystyrene composite material has excellent toughness, and the effect of toughening the floor is achieved.

Owner:ANHUI YANGZI FLOORING

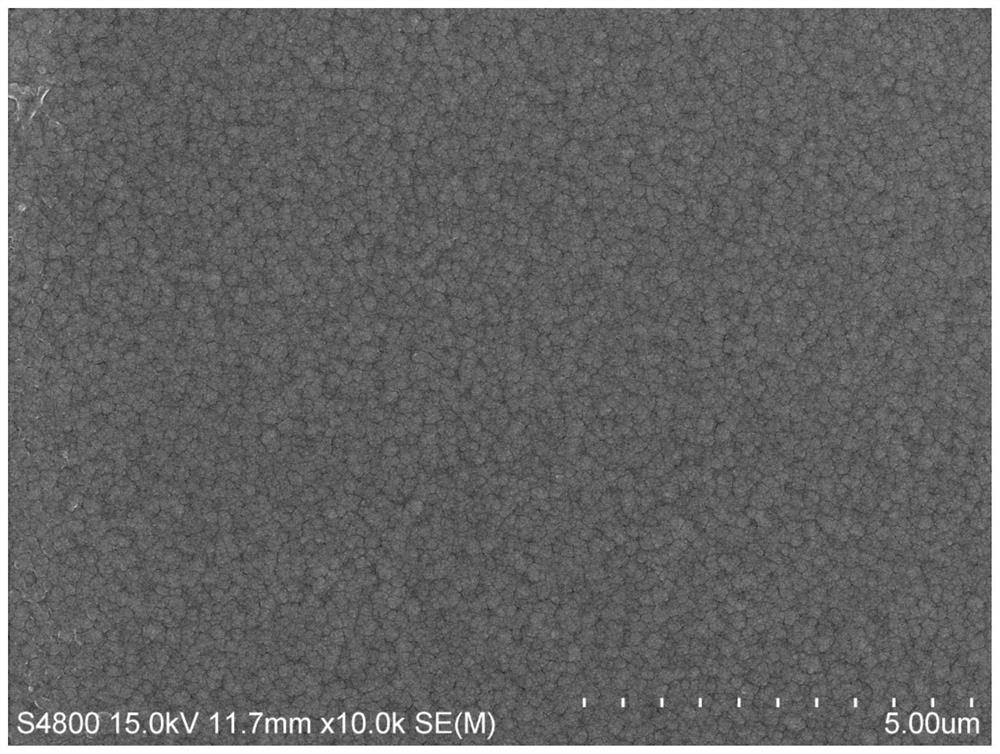

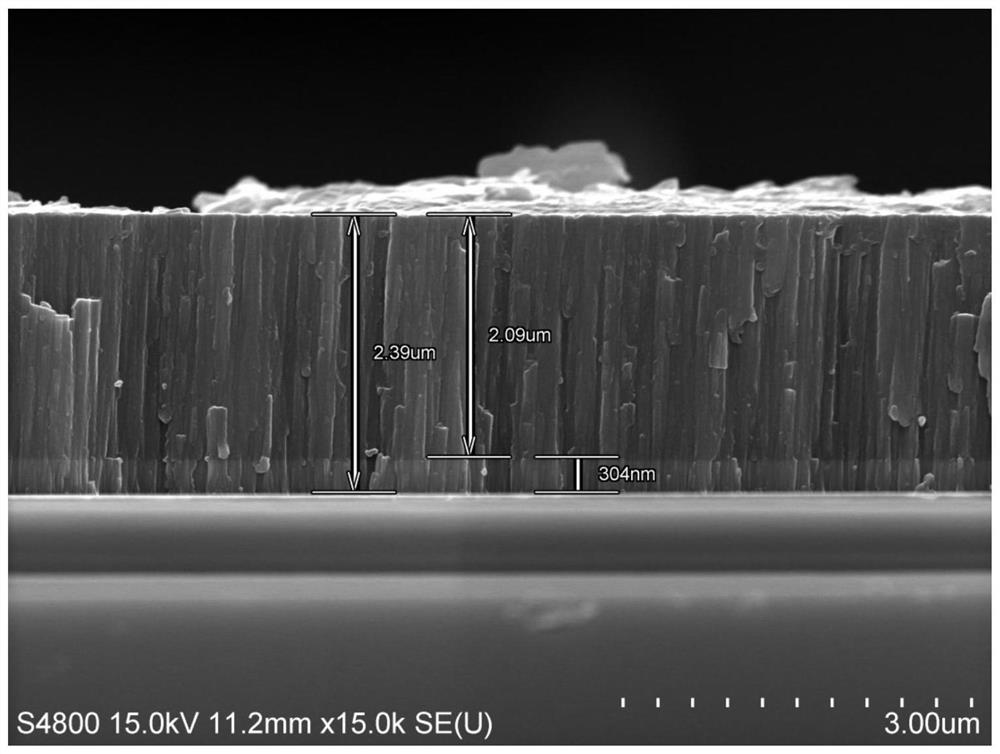

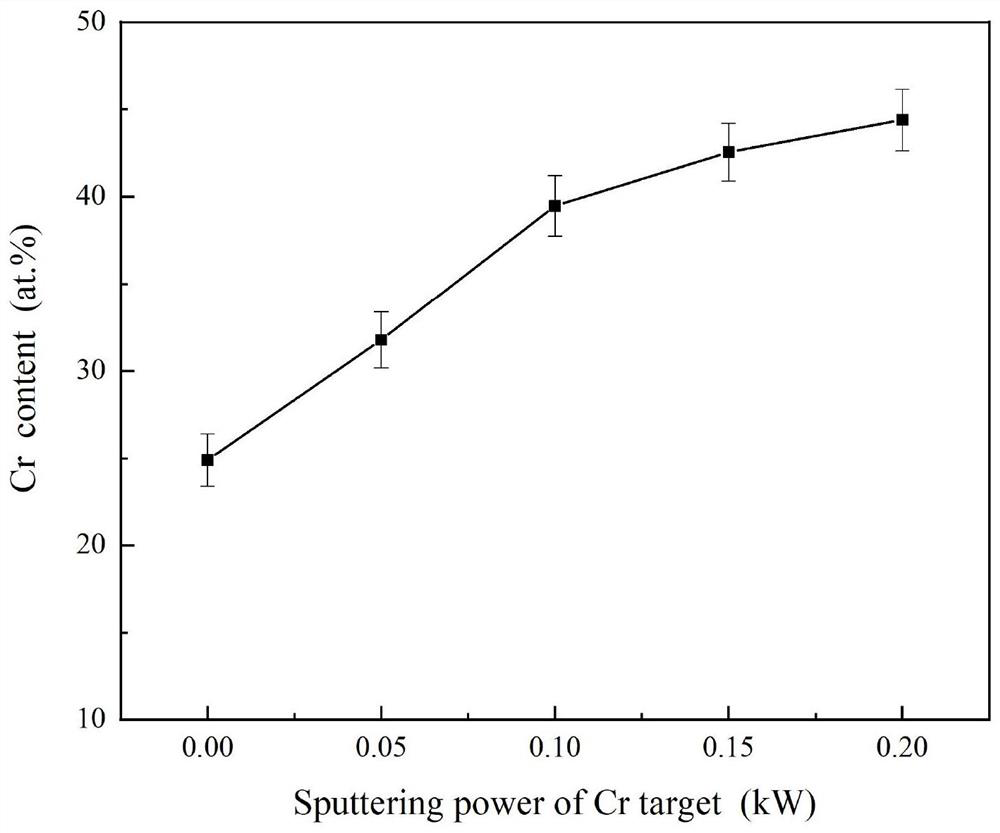

Preparation process of CrB2-Cr coating with high Cr content

ActiveCN112410728AIncrease ionization rateAchieve resilienceVacuum evaporation coatingSputtering coatingArgon atmosphereHeat stability

The invention discloses a preparation process of a CrB2-Cr coating with high Cr content, and belongs to the technical field of coating preparation. The CrB2-Cr nano composite coating is prepared on ametal or hard alloy matrix by adopting a high-power pulse and pulse direct-current composite magnetron sputtering technology. In order to better control the content of Cr in the coating, a CrB2 targetand two metal Cr targets are selected and used as target materials at the same time, a metal Cr transition layer is deposited after glow discharge cleaning and ion bombardment cleaning are conductedon the surface of a base material, finally, the Cr targets and the CrB2 target are started at the same time, the CrB2-Cr coating is deposited, and the coating process is conducted in the argon atmosphere all the time. The process is simple and good in repeatability; and the Cr element content in the prepared CrB2-Cr coating is remarkably increased, the coating has high hardness, a high melting point and excellent high-temperature thermal stability and corrosion resistance, the toughness of the coating is also improved to a certain extent, and the coating is compact in structure and high in binding force with the matrix.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

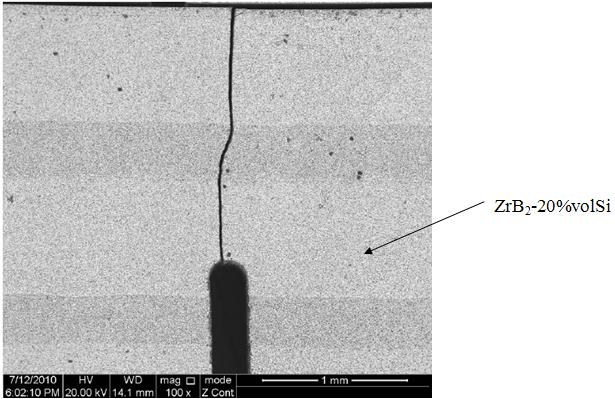

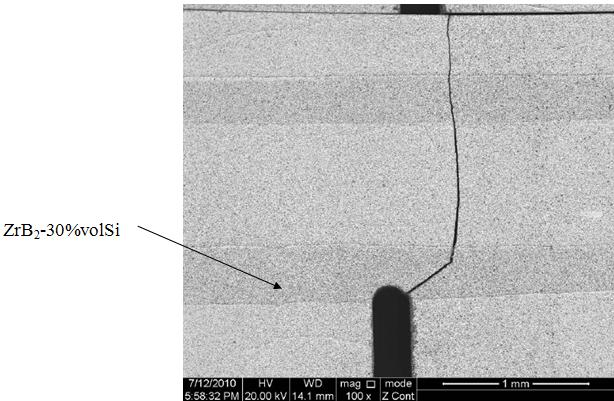

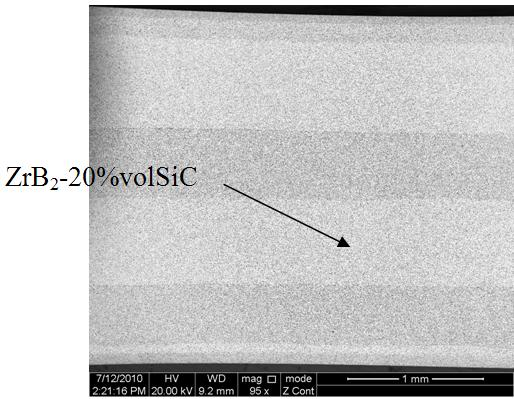

Preparation method for matricial ultra-temperature ceramic composite material of zirconium boride-silicon carbide

InactiveCN101891480AIntrinsic properties are not changedExpansion drive increasesBorideCeramic composite

The invention provides a preparation method for matricial ultra-temperature ceramic composite material of zirconium boride-silicon carbide, which relates to a preparation method of a composite material. The invention solves the problems of easy frangibility and low strength of the existing zirconium boride-silicon carbide based composite material. The preparation method comprises the following steps: respectively preparing ZrB2-20%volSiC powders and ZrB2-30%volSiC powders; symmetrically and alternatively laminating the ZrB2-20%volSiC powders and the ZrB2-30%volSiC powders into a graphite mould to obtain a green body; prepressing the green body; and maintaining pressure for 60 min under the condition of 190 DEG C and 30 MPa to obtain the composite material of the invention. Strength of the matricial ultra-temperature ceramic composite material of zirconium boride-silicon carbide in the invention is 1.57-2.36 times that of the zirconium boride-silicon carbide (ZrB2-20 parts of SiC) based composite material; and fracture toughness of the matricial ultra-temperature ceramic composite material of zirconium boride-silicon carbide in the invention can be increased by 17%-46% compared with that of the zirconium boride-silicon carbide (ZrB2-20 parts of SiC) based composite material.

Owner:HARBIN INST OF TECH

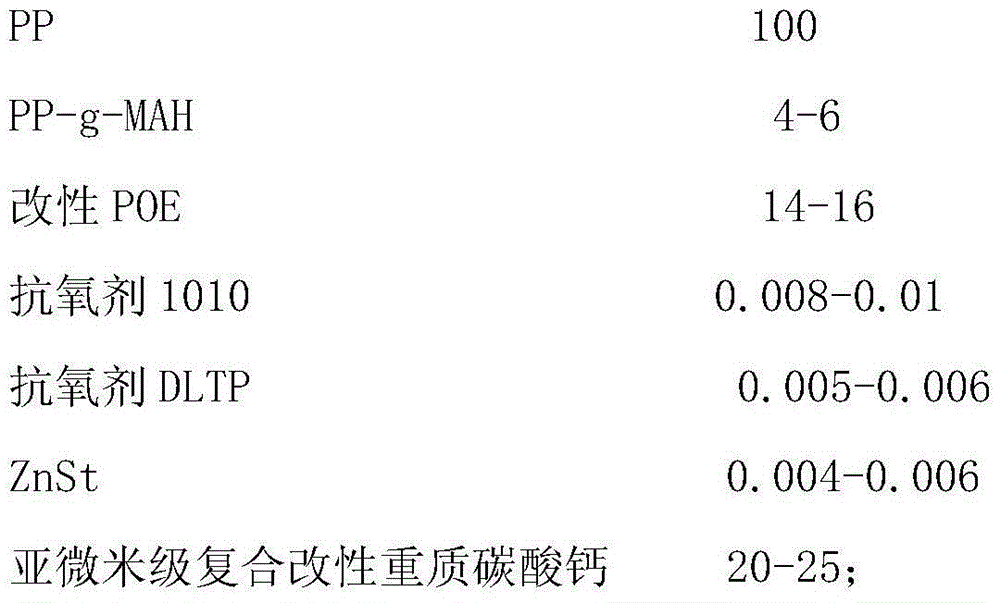

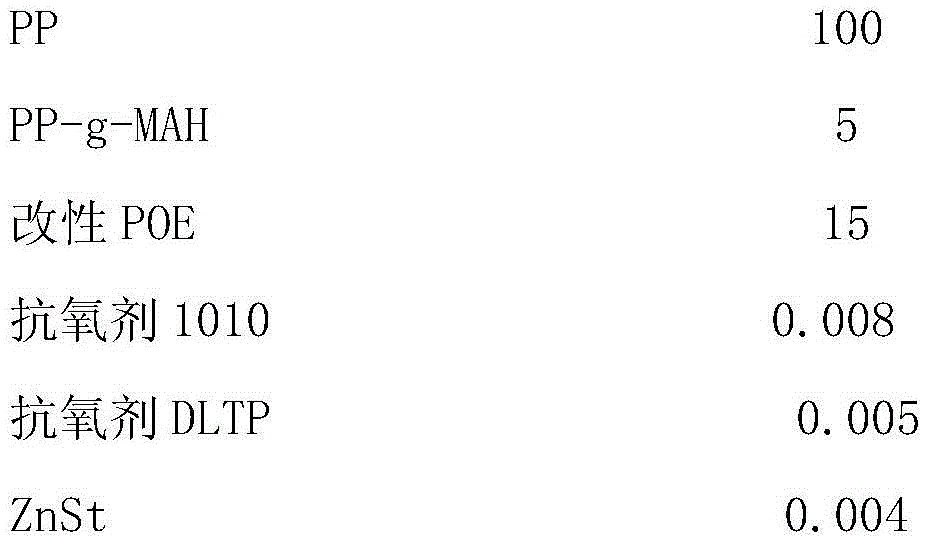

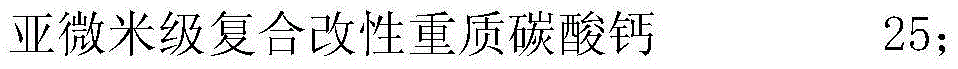

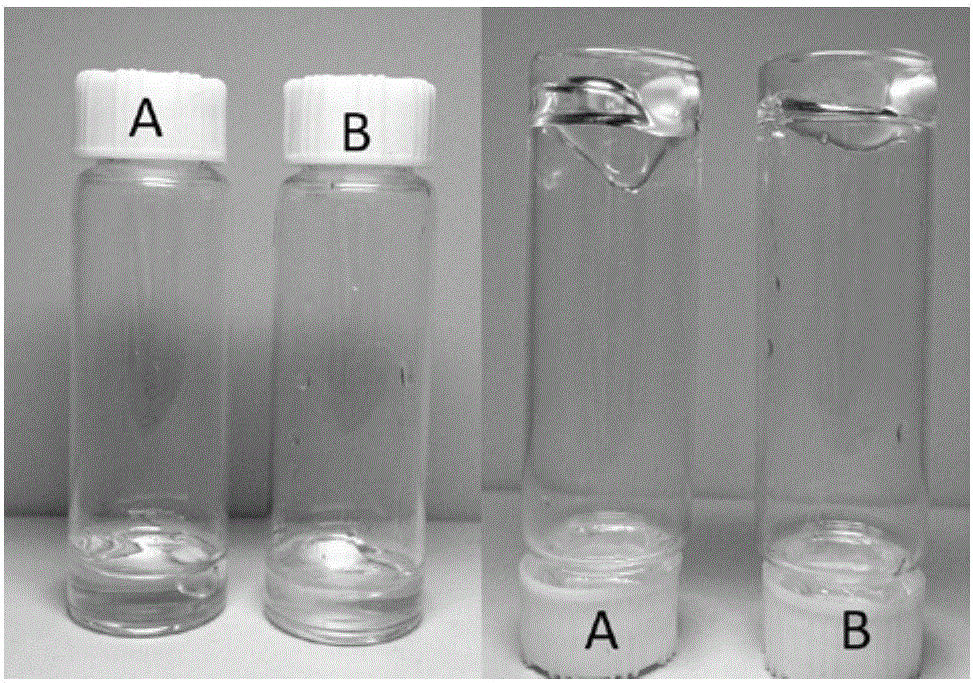

Super-strength and super-toughness polypropylene modified resin and its preparation technology

The invention discloses a super-strength and super-toughness polypropylene modified resin. The resin is characterized in that the resin is prepared by using the following raw materials, by weight, 100 parts of PP, 4-6 parts of PP-g-MAH, 14-16 parts of modified POE, 0.008-0.01 parts of an antioxidant 1010, 0.005-0.006 parts of an antioxidant DLTP, 0.004-0.006 parts of ZnSt, and 20-25 parts of submicron composite modified heavy calcium carbonate; and in the above formula system, the modified POE has a better compatibility with a PP matrix than EPDM (ethylene-propylene diene monomer) and SBS (styrene butadiene elastomer) as a polyolefin thermoplastic elastomer. The addition of the PP-g-MAH (PP grafted maleic anhydride) further enhances the compatibility with the PP matrix, so the toughness of the obtained blend is greatly improved.

Owner:芜湖同达新材料科技有限公司

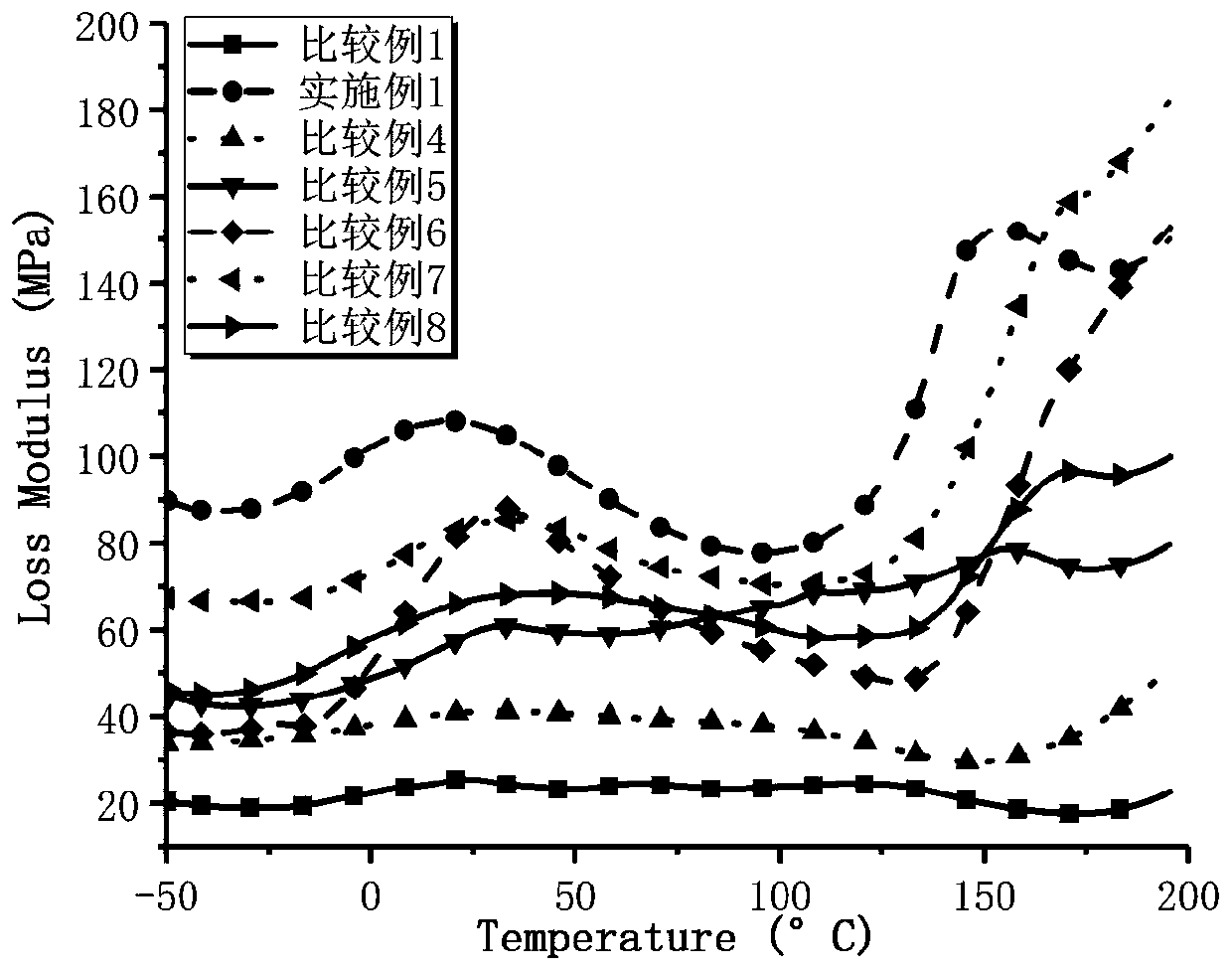

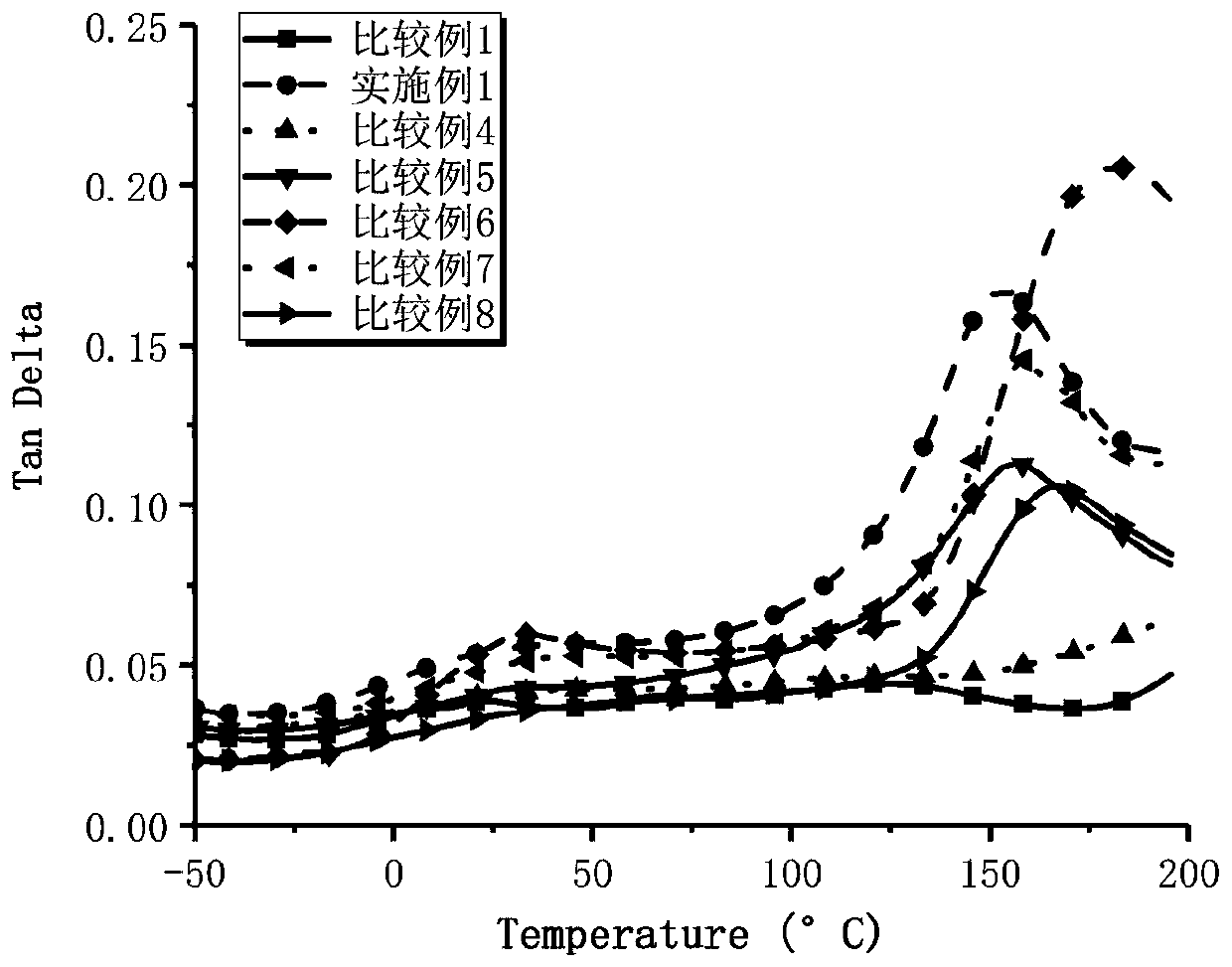

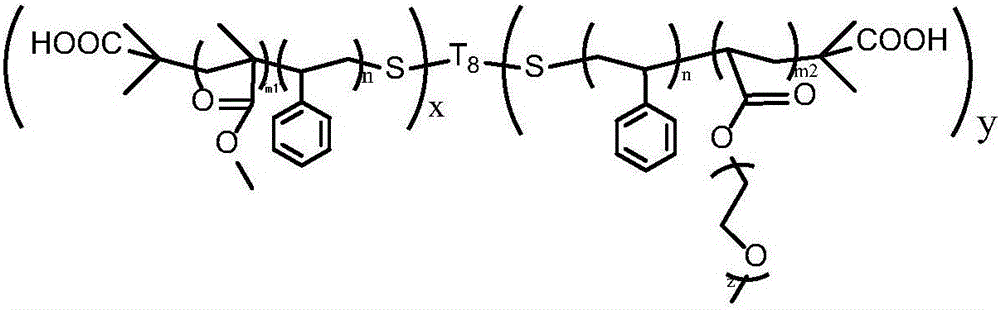

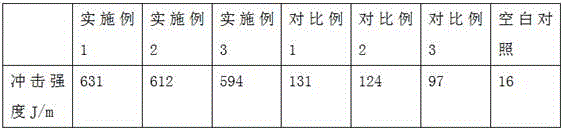

Epoxy toughening agent containing cage type silsesquioxane star block copolymer, and preparation method and application thereof

The invention belongs to the technical field of preparation of toughening agents, and discloses an epoxy toughening agent containing a cage type silsesquioxane star block copolymer, and a preparation method and application thereof. The toughening agent comprises four components: (1) a linear block copolymer P (MMA-b-St); (2) a linear block copolymer P (PEGMEA-b-St); (3) a cage type silsesquioxane T8 star-shaped copolymer M-T8-P, wherein x is not smaller than 1 and is not greater than 7, y is not smaller than 1 and is not greater than 7, and z is not smaller than 6 and is not greater than 9; and (4) a cage type silsesquioxane T10 star-shaped copolymer M-T10-P, wherein x is not smaller than 1 and is not greater than 9, y is not smaller than 1 and is not greater than 9, z is not smaller than 6 and is not greater than 9, m1 is not smaller than 10 and is not greater than 80, n is not smaller than 1 and is not greater than 10, and m2 is not smaller than 10 and is not greater than 40. The toughening agent is a reactive toughening agent and generates multiple reactions in the toughening of epoxy resin to realize a toughening effect; and the proportions of compatible and incompatible chain segments in the polymer are adjusted to keep the transmissivity while ensuring the toughening effect.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Polystyrene sheet and preparation method thereof

The invention belongs to the field of polystyrene sheets and particularly relates to a polystyrene sheet and a preparation method thereof. The polystyrene sheet comprises the following materials in parts by weight: 85-90 parts of polystyrene, 7-9 parts of black master batches, 7-9 parts of a filling agent, 6-8 parts of a toughening agent, 0.5-1 part of a dispersing agent and 0.1 part of an antistatic agent, wherein the toughening agent is a mixture of ABS (Acrylonitrile Butadiene Styrene), SBS (Styrene Butadiene Styrene) and talcum powder according to the weight ratio of 4:3:1. The particle size of the talcum powder is 50-100nm. Compared with the traditional polystyrene sheet, the polystyrene sheet obtained by adopting a formula of the invention is better in property, has the excellent properties of easy stacking, good light transmittance and high toughness, and has the advantages that the application range of the polystyrene sheet is expanded and more application requirements for customers can be better met.

Owner:宁德聚能动力电源系统技术有限公司

Flexible yellowing-resistant photosensitive resin used for 3D printing and preparation method thereof

InactiveCN110272521AImprove performanceLow viscosityAdditive manufacturing apparatusMechanical propertyBisphenol

The invention provides flexible yellowing-resistant photosensitive resin used for 3D printing. The flexible yellowing-resistant photosensitive resin comprises the following raw materials in parts by weight: 10 to 50 parts of liquid-state hydrogenated bisphenol A epoxy resin, 10 to 50 parts of alicyclic epoxy resin, 10 to 40 parts of an acrylate monomer, 1 to 7 parts of a radical initiator and 1 to 7 parts of a cationic photoinitiator. By implementation of a technical scheme of the invention, hydrogenated bisphenol A epoxy resin is introduced into a photosensitive resin system, so the effect of toughening is realized, and the technical problems of large brittleness and poor mechanical properties of a conventional 3D-printed material are effectively solved; meanwhile, hydrogenated epoxy is used, so yellowing resistance of a 3D-printed material can be effectively improved.

Owner:络合高新材料(上海)有限公司

Submicron crystalline ceramic coating for hard alloy and preparation method

InactiveCN104446397AImprove thermal stabilityImprove thermal shock resistanceCeramic coatingThermal expansion

The invention provides a submicron crystalline ceramic coating for a hard alloy and a preparation method. The components of the submicron crystalline ceramic coating comprise Al2O3, ZrO2, TiO2, and SiO2. The preparation method comprises the following steps: respectively weighing powder materials, mixing the powder materials, heating to smelt the mixture, carrying out water quenching on the mixture to obtain non-crystalline ceramic, and ball-milling to obtain non-crystalline ceramic powder; adding Co powder into the non-crystalline ceramic powder, adding a solvent, and wet-milling to obtain coating slurry; coating the surface of the hard alloy with the coating slurry, drying the hard alloy, and sintering the hard alloy in a vacuum environment to obtain the submicron crystalline ceramic coating for the hard alloy. According to the invention, problems that the sintering temperature of SAZ ceramic coating is high, and the thermal expansion coefficient is not matched with the hard alloy are solved, the prepared coating has the advantages of high-temperature resistance and corrosion resistance, the preparation method is simple, the production cost of the hard alloy coating can be greatly reduced, such failure problems as oxidation, corrosion and attrition of hard alloy components under actual working conditions are solved to a certain extent, and the service lives of hard alloy materials and devices are prolonged.

Owner:CENT SOUTH UNIV

Novel environment-friendly plastic and preparation method thereof

The invention provides a novel environment-friendly plastic and a preparation method thereof. The novel environment-friendly plastic is prepared from the following components: polyvinyl chloride, polypropylene, kaolin, graphene, modified calcium carbonate, straws, rice chaff, crylic acid, gamma-aminopropyl trimethoxy silane, fatty alcohol polyoxyethylene lauryl ether sulfate sodium, sodium dodecylbenzene sulfonate, diallyl phthalate, quadrol, m-xylene, toughening agent, anti-wear agent, defoaming agent and deionized water. The environment-friendly plastic prepared according to the invention has high strength, is environment-friendly and harmless, is recyclable and has a better application prospect; the preparation process is free from secondary pollution; the production is clean and civilized; the process flow for preparation is short and the efficiency is high; the straws and rice chaff in the raw materials have the benefits of energy saving and environmental protection.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

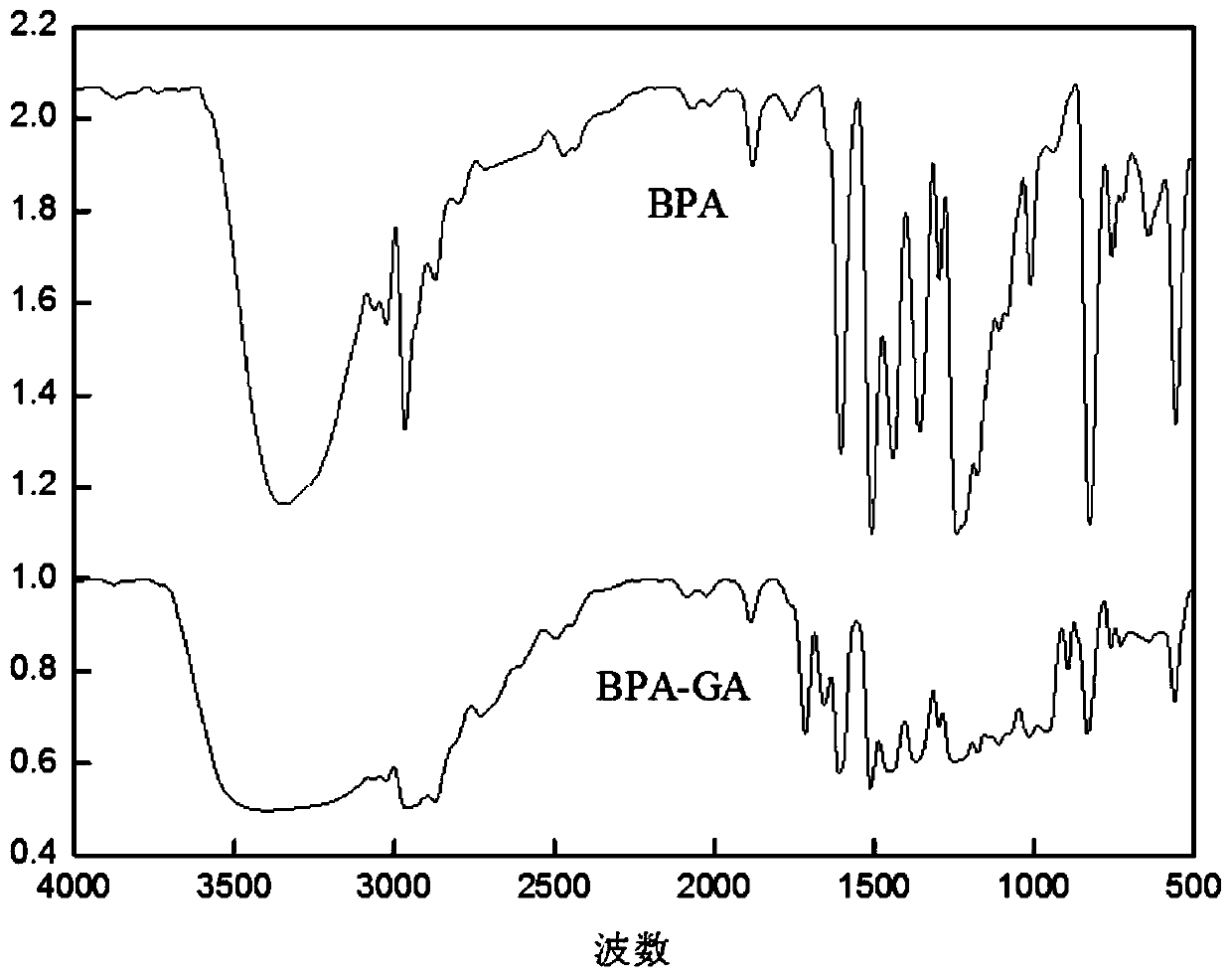

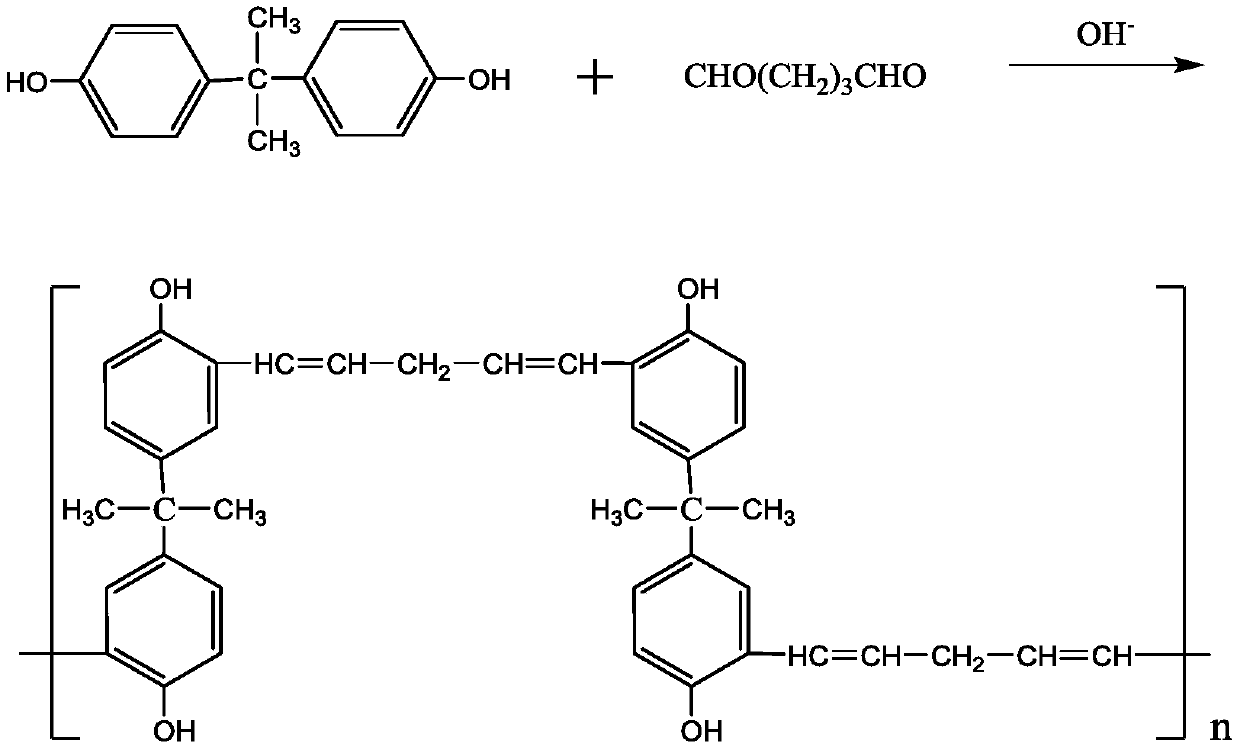

BPA-GA (bisphenol A-glutaraldehyde) phenol-formaldehyde resin and preparation method thereof

The invention provides BPA-GA (bisphenol A-glutaraldehyde) phenol-formaldehyde resin and a preparation method thereof. The method comprises the following steps: step 1, BPA and GA in the mass ratio of11.4:(5.0-5.4) are mixed with a NaOH solution, and a mixed system A is obtained; step 2, the mixed system A is subjected to a reaction at 90-100 DEG C for 5.8-6.2 h, and a mixed system B is obtained;and step 3, products in the mixed system B are separated and dried, and the BPA-GA phenol-formaldehyde resin is obtained. GA is grafted to the BPA phenolic hydroxyl ortho-position, a longer methylenechain segment is introduced, a flexible chain segment of the BPA phenolic hydroxyl ortho-position is extended, so that the phenol-formaldehyde resin achieves the toughening effect, and the treatmentprocess is simple; and furthermore, the application range of the phenol-formaldehyde resin in the chemical industry is expanded, and the phenol-formaldehyde resin has higher application value in multiple fields such as composite materials, molded plastics, coatings, epoxy molded plastics for chip packaging, epoxy intermediates and curing agents.

Owner:SHAANXI UNIV OF SCI & TECH

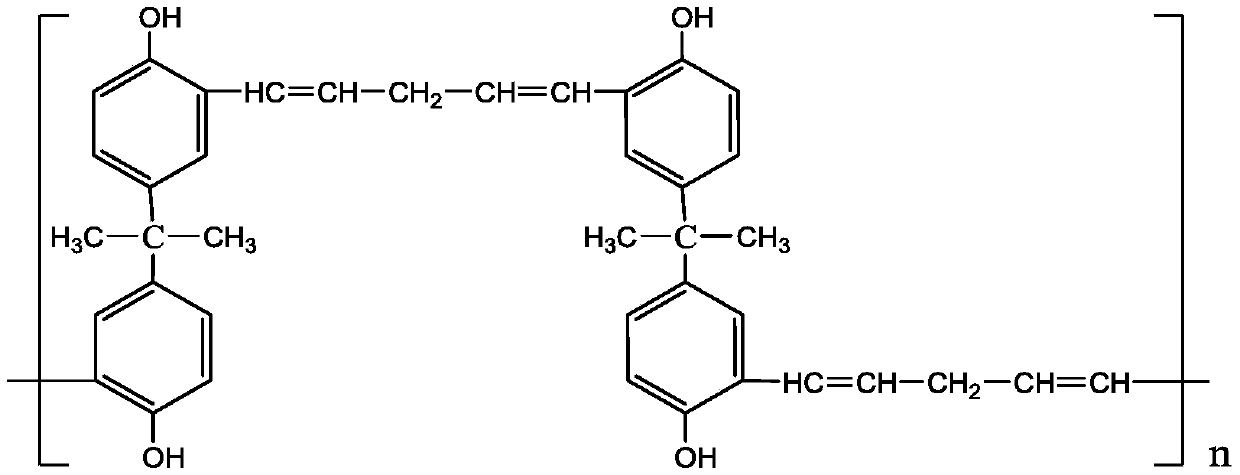

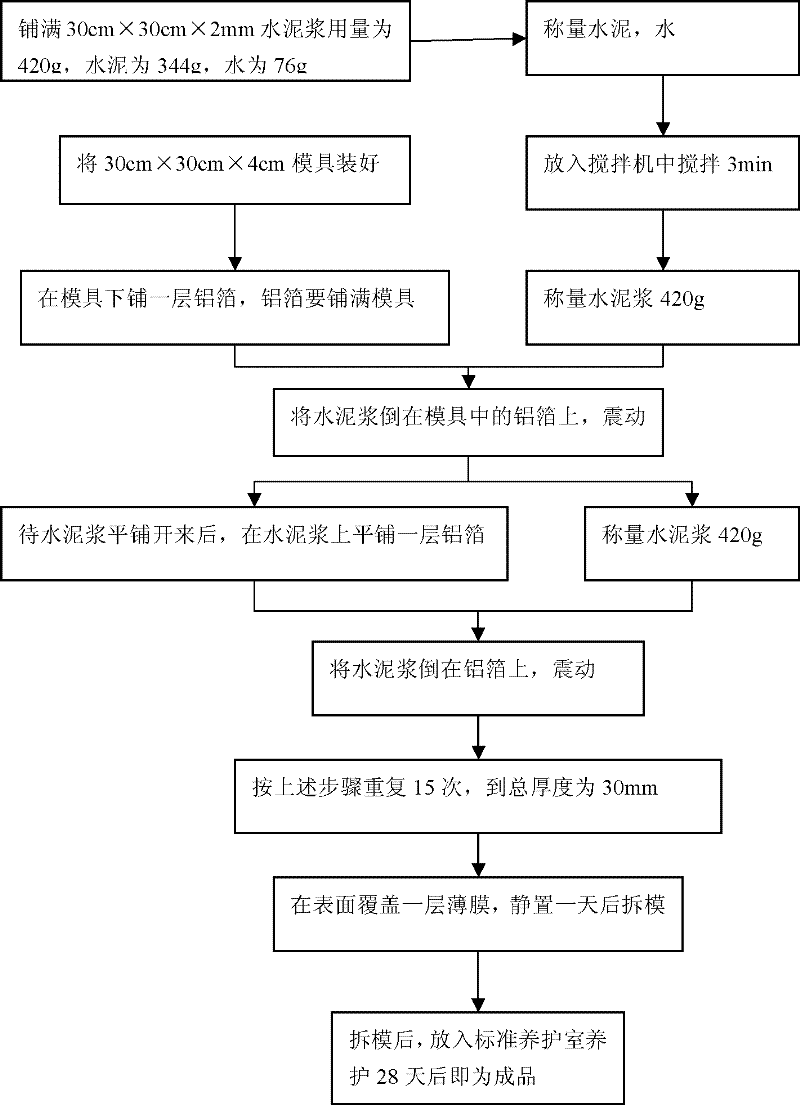

Layered cement-based composite material and its preparation method

InactiveCN102336037AImprove toughnessTo achieve the effect of tougheningLaminationLamination apparatusCement slurryUltimate tensile strength

The invention provides a layered cement-based composite material, which is composed of a cement slurry layer and a weak interlayer which are sequentially laminated, the strength of the weak interlayer is lower than that of the cement slurry layer. The invention also discloses a preparation method which comprises the following steps: taking a die, laying one layer of weak interlayer in die, pouring the self-leveling cement slurry onto the weak interlayer, vibrating and flattening, then repeating the step 1 for at least 10 times, standing for one day and then removing the die, then performing a standard maintenance. The invention also provides another preparation method which comprises the following steps: paving a material of the weak interlayer on a vibration table, placing the die around the material of the weak interlayer, pouring the cement slurry into the die, fully vibrating on the vibration table, scrapping the redundant cement slurry from the die to obtain a single layer composite material by using a doctor blade method, removing the die after initial setting period of the cement slurry, cutting the single layer composite material into small blocks of material with same size, stacking the small blocks of composite material, wherein the stacking frequency is greater than 10 times, then placing the stacked small blocks of composite material on the vibration table for 5 minutes and performing the standard maintenance finally.

Owner:SOUTHEAST UNIV

A kind of zirconium-containing mullite composite phase material and preparation method thereof

Owner:WUHAN UNIV OF SCI & TECH

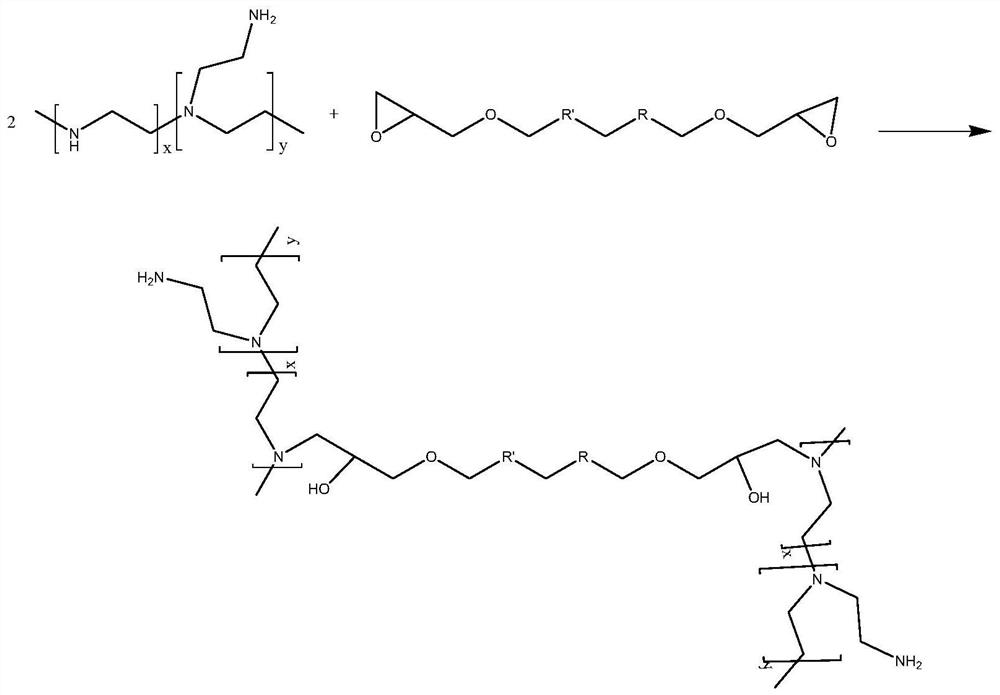

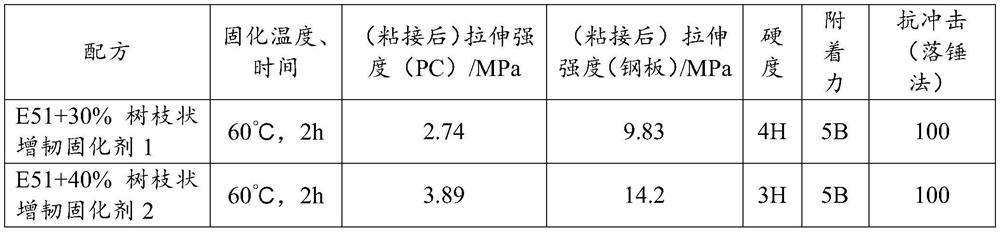

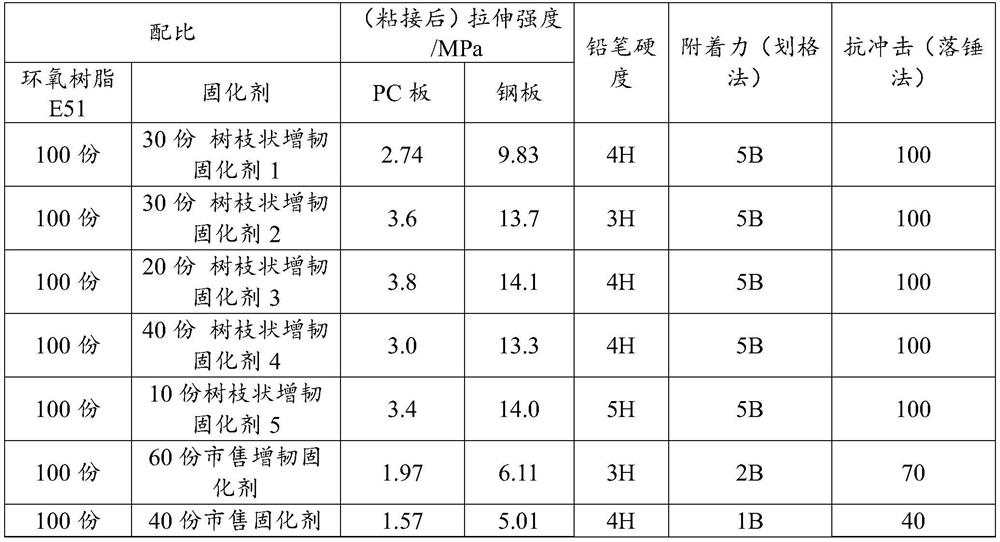

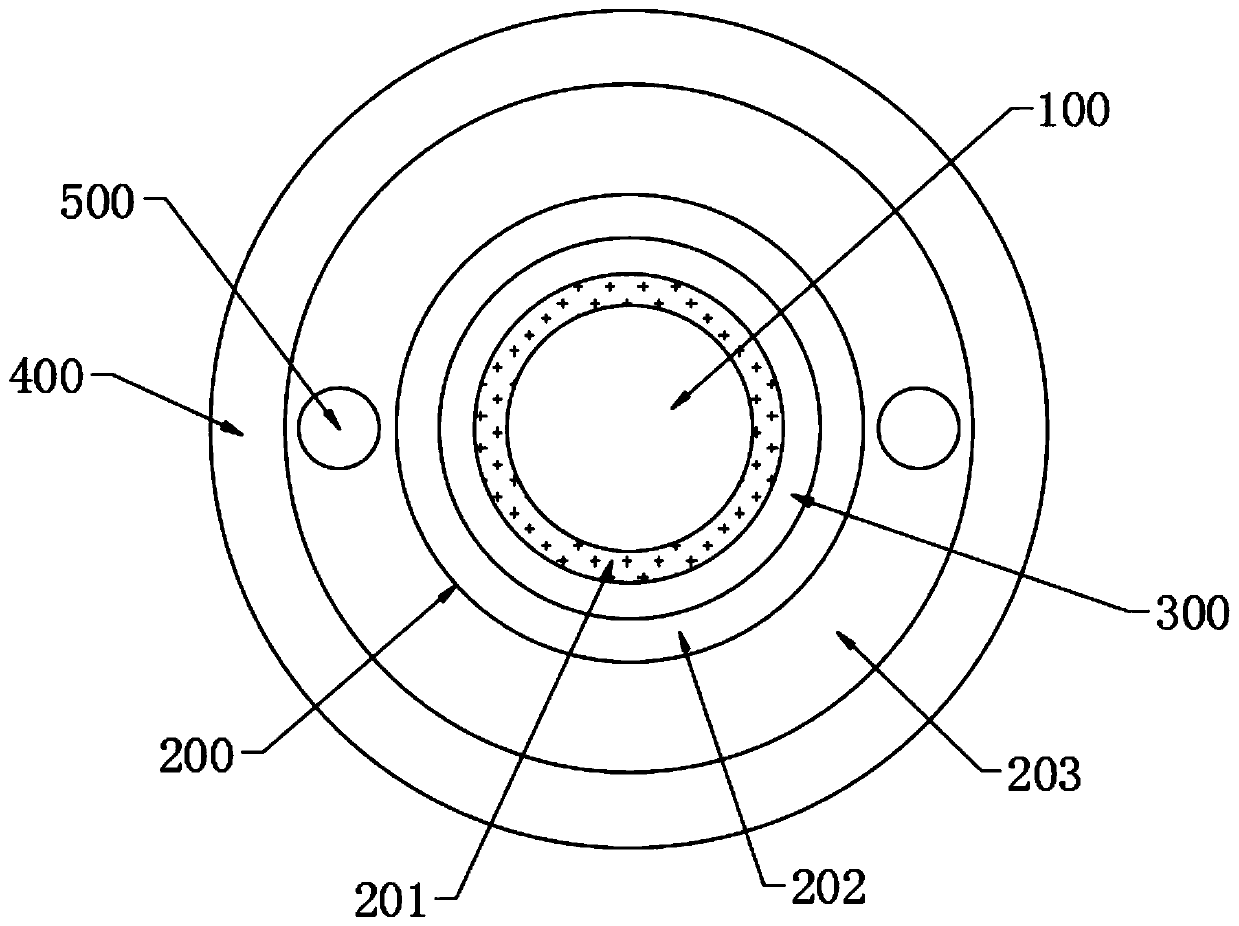

Dendritic toughening curing agent as well as preparation method and application thereof

The invention discloses a dendritic toughening curing agent as well as a preparation method and application thereof, and belongs to the field of curing agents. According to the technical scheme, an epoxy-terminated monomer containing a flexible long chain reacts with a polyethylene polyamine monomer at a certain temperature to generate the amino-terminated dendritic toughening curing agent. The agent is applied to epoxy resin curing and toughening, can be used to solve the problems that the existing epoxy resin curing agent cannot have both toughening and curing properties and the preparation method is complicated, and has the characteristics of excellent curing property, capability of remarkably improving the resin toughness, simple preparation method and easiness in industrial production.

Owner:WEIHAI CY DENDRIMER TECH

Preparation method of controlled-release type urea formaldehyde foamed plastic deacidification agent

InactiveCN103170288BGood slow releaseThe phenomenon of warping, deformation and even cracking disappearsMicroballoon preparationMicrocapsule preparationBristleDecomposition

The invention discloses a preparation method of a controlled-release type urea formaldehyde foamed plastic deacidification agent, and relates to a preparation method of the deacidification agent. The method comprises the following steps of: firstly loading an alkaline substance on a carrier with a cellular structure, causing a macromolecule aqueous solution capable of having crosslinking reaction to form a wrapping layer on the surface of the carrier, feeding the resulting carrier into a crosslinking agent solution to cause the macromolecular substance to have crosslinking reaction to form a gel, encapsulating the carrier, and at last carrying out the steps of filtering, separating, drying and the like to obtain the controlled-release type urea formaldehyde foamed plastic deacidification agent. The deacidification agent can effectively solve the problems of the decomposition of a urea formaldehyde resin caused by the acid residue in the urea formaldehyde foamed plastic and the corrosion of an alkaline cement. In addition, the carrier with the cellular structure simultaneously has strengthening and toughening functions, so that the foamed plastic added with the deacidification agent is higher in strength, better in toughness, and improved in the hard while bristle defect and easy crack defect.

Owner:重庆阁林环保科技有限公司

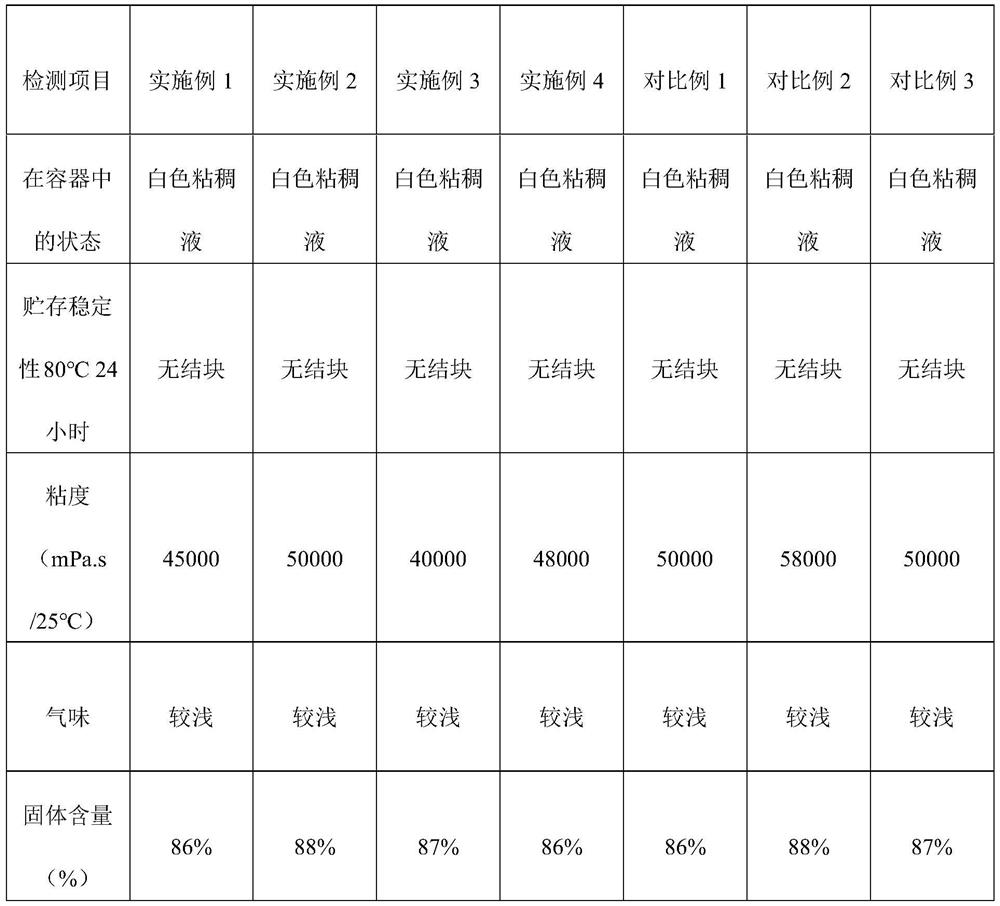

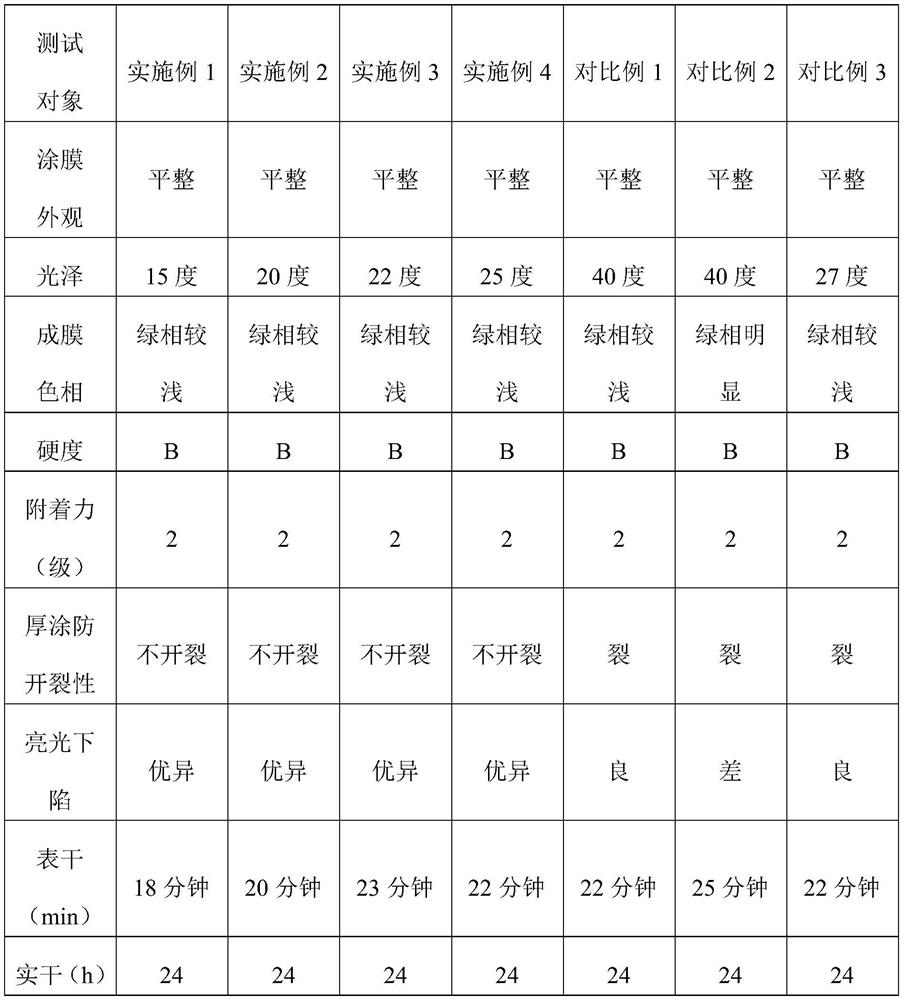

Unsaturated polyester resin coating and preparation method thereof

InactiveCN112341913AIncrease the number ofAvoid crackingPolyester coatingsPolymer scienceAcrylic resin

The invention relates to an unsaturated polyester resin coating and a preparation method thereof. The unsaturated polyester resin coating is mainly prepared from a component A, a component B, a component C and a component D in a mass ratio of 100: (25-50): (0.8-2.5): (1-2.5), wherein the component A is prepared from the following raw materials: 20%-50% of air-dried unsaturated polyester resin, 2%-15% of thermoplastic acrylic resin, 0.1%-1% of a polyphosphate polymer, 20%-65% of filler, 0.1%-4% of an auxiliary agent and 1%-5% of styrene; the component B comprises the following raw materials inpercentage: 10%-50% of a diluting monomer and 50%-90% of a solvent; the component C is a curing accelerator; and the component D is an initiator. A paint film obtained from the unsaturated polyester resin coating is high in hardness, strong in adhesive force, relatively high in glossiness, high in drying speed, excellent in thick coating anti-cracking property, good in light sinking property and excellent in comprehensive performance, and has a wide application prospect.

Owner:SHANGHAI CARPOLY PAINT

Building material and preparation method thereof

InactiveCN109180106AGood environmental characteristicsStrong environmental protectionFiberPolyvinyl alcohol

The invention discloses a building material. The building material comprises, by weight, 5-25 parts of triethanolamine, 6-18 parts of silicon oxide, 6-18 parts of heavy calcium carbonate, 2-18 parts of polyvinyl alcohol, 3-13 parts of expanded perlite, 3-15 parts of sodium silicate, 1-17 parts of deionized water, 3-15 parts of Portland cement, 4-18 parts of glass beads, 4-18 parts of fly ash, 4-18parts of polyacrylonitrile fiber, 4-18 parts of modified epoxy resin, 3-13 parts of 2-hydroxy-4-methoxybenzophenone, 6-18 parts of heptyl 4-hydroxybenzoate, 3-17 parts of sulfonated melamine-formaldehyde resin and 3-13 parts of brominated bisphenol A epoxy resin. The building material has the advantages of good fracture resistance, good ultraviolet radiation resistance and long service life.

Owner:孙浩

Nylon 66 modified plastic and preparation method thereof

The invention discloses a nylon 66 modified plastic. The nylon 66 modified plastic comprises the following components in percentage by weight: 52-77% of nylon 66 resin, 9-18% of nylon 6 resin, 1.2-1.8% of a toughening agent, 0.5-1.2% of a coupling agent, 5-17% of a fire retardant, 0.5-1.2% of an antioxygen and 5-10% of a filling agent, wherein the sum is 100%. The nylon 66 modified plastic disclosed by the invention has the following technological effects; the nylon 66 modified plastic is reasonable in design; and the produced modified nylon 66 has low water absorptivity, good flame retardant property, friction resistance and anti-fatigue property and proper rigidity.

Owner:SUZHOU RONGCHANG COMPOUND MATERIAL

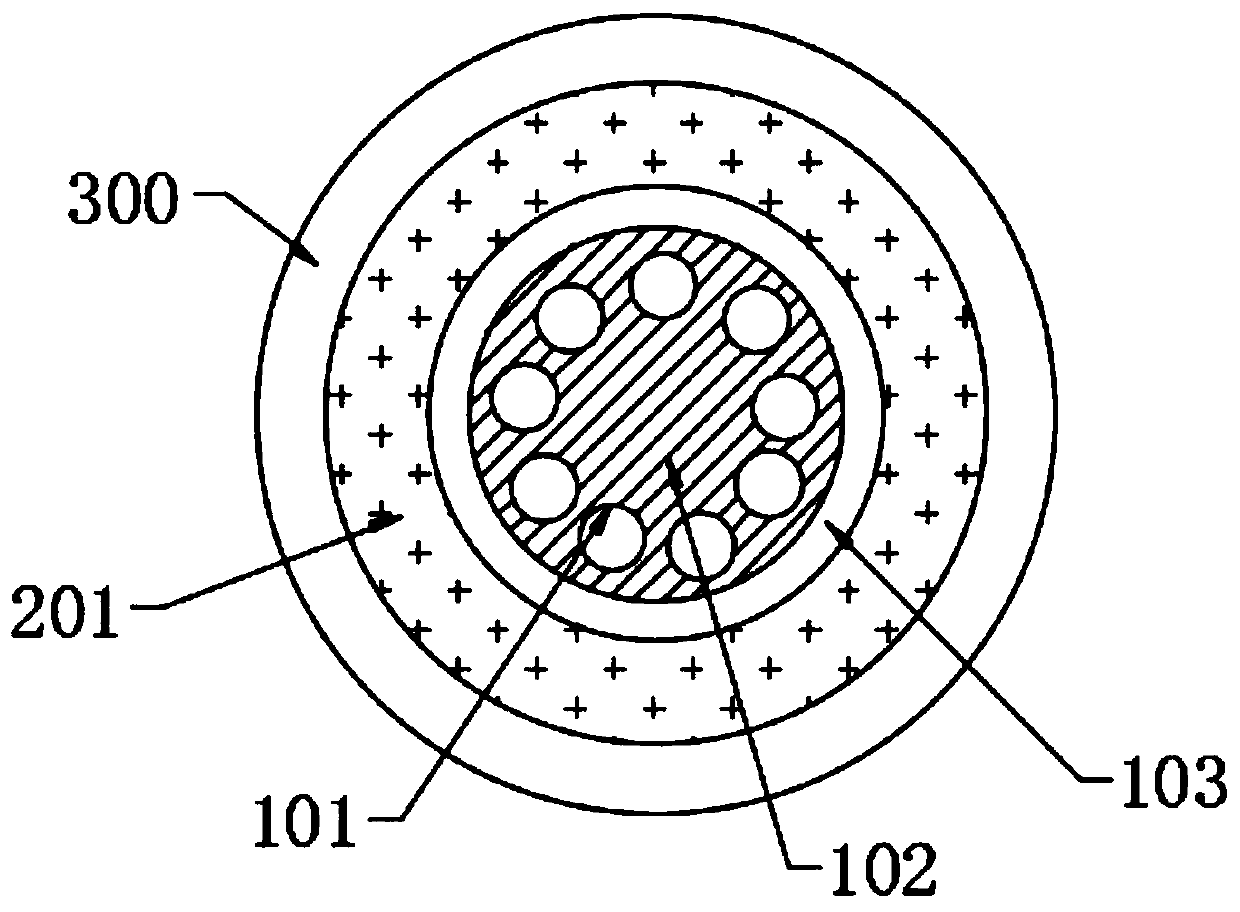

Flame-retardant composite optical cable

InactiveCN111007604APrevent crackingLow costFibre mechanical structuresFlame resistanceSilicon nitride

The invention discloses a flame-retardant composite optical cable. The optical cable comprises a cable core and an outer sheath. The cable core comprises optical fiber assemblies and a loose tube. Theloose tube sleeves the optical fiber assemblies. Fiber paste is filled between the loose tube and the optical fiber assemblies. A fireproof layer assembly is arranged outside the cable core, the fireproof layer assembly comprises a first fireproof layer, a second fireproof layer and a third fireproof layer, the first fireproof layer is annularly arranged outside the loose sleeve, an armor layer is arranged outside the first fireproof layer, and the armor layer is arranged in the outer wall of the first fireproof layer in a surrounding mode. According to the invention, a mica tape wraps the cable core to serve as the first fireproof layer; the optical cable can be effectively prevented from cracking, the insulation effect can be achieved, the manufacturing cost is low, the effect is dual-purpose, the second fireproof layer and the third fireproof layer are CNTS reinforced silicon nitride ceramic layers respectively, the mechanical property of the optical cable can be improved on the basis of improving the high temperature resistance, and the optical cable is simple in structure and convenient to use.

Owner:广州亚太线缆科技有限公司

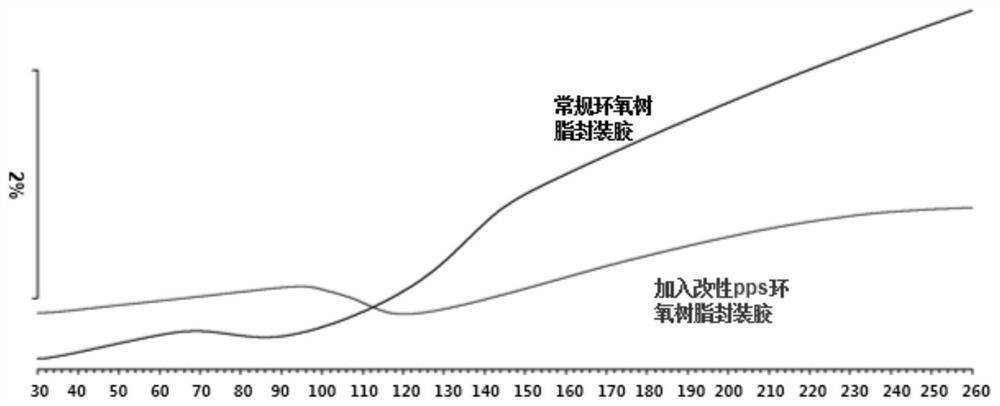

Modified polyphenylene sulfide light diffusion agent for LED epoxy packaging and preparation method thereof

ActiveCN112063334AHeat resistantHigh refractive indexMacromolecular adhesive additivesEpoxy resin adhesivesEpoxyMasterbatch

The invention discloses a modified polyphenylene sulfide light diffusion agent for LED epoxy packaging and a preparation method thereof, the modified polyphenylene sulfide light diffusion agent is prepared from polyphenylene sulfide masterbatch with a glass transition temperature of 70-130 DEG C and a melting point of 220-300 DEG C and special epoxy resin in a nitrogen environment, and the ratio of the polyphenylene sulfide masterbatch to the special epoxy resin is 10: 0.5-10: 12. The modified polyphenylene sulfide light diffusion agent has the advantages of high refractive index, excellent temperature resistance and excellent ultraviolet resistance, can be easily dispersed in LED epoxy packaging adhesive, can greatly improve the toughness of the epoxy packaging adhesive, achieves the toughening effect, can make the LED epoxy packaging adhesive have excellent optical characteristics, and achieves the effect of high light extraction efficiency.

Owner:JIANGSU AISEN SEMICON MATERIAL CO LTD

Coated inorganic fiber toughened max phase ceramic composite material, its preparation method and application

ActiveCN103910532BAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com