Layered cement-based composite material and its preparation method

A composite material, cement-based technology, applied in chemical instruments and methods, hydraulic material layered products, lamination, etc., can solve the problems of large fossil energy consumption and difficult dispersion of the matrix.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

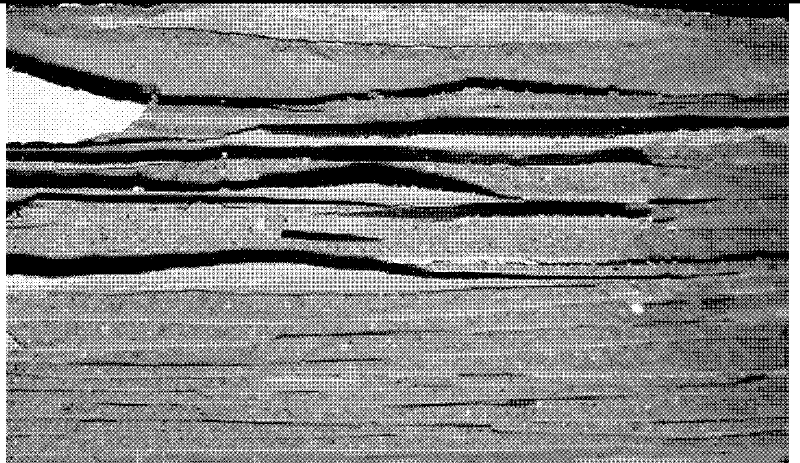

[0017] A layered cement-based composite material. The layered cement-based composite material is composed of a cement paste layer 1 and a weak interlayer 2, and the strength of the weak interlayer 2 is lower than that of the cement paste layer 1. In this implementation In the example, the cement slurry layer 1 used is a self-leveling cement slurry layer; the weak interlayer 2 is aluminum foil, paper, foam concrete or high water-binder ratio cement slurry; the total layer of the layered cement-based composite material Count at least 20 layers.

Embodiment 2

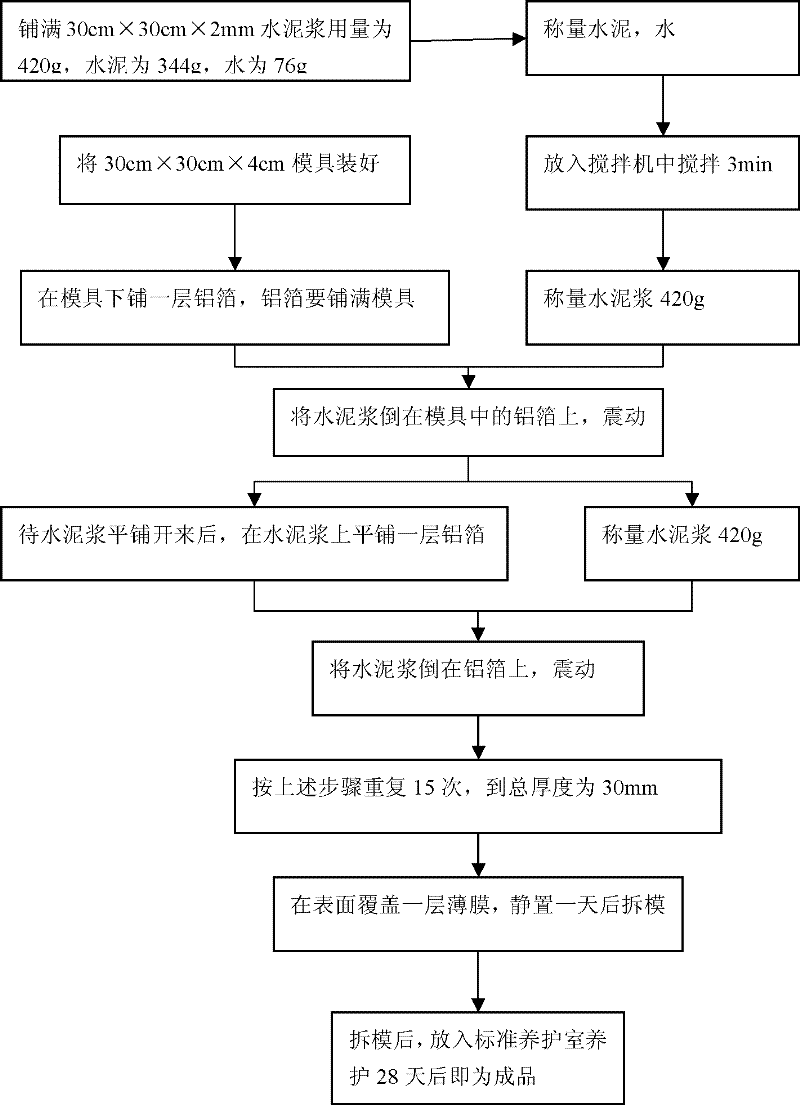

[0019] A method for preparing a layered cement-based composite material, comprising the following steps:

[0020] Step 1 Take a mold, lay a layer of weak interlayer material in the mold, pour the self-leveling cement slurry on the weak interlayer, vibrate and make it flat,

[0021] Step 2 After repeating step 1 at least 10 times, remove the mold after standing for 1 day, and then carry out standard maintenance.

Embodiment 3

[0023] A method for preparing layered cement-based composite materials, laying weak interlayer materials on a vibrating table, placing molds around the weak interlayer materials, pouring cement slurry into the mould, vibrating and flattening on the vibrating table, and using the scraper method , scrape off the excess cement slurry in the mold to obtain a single-layer composite material, remove the mold after the cement slurry reaches the initial setting, then cut the single-layer composite material into small pieces of the same size, and compound the small pieces The materials are stacked, after that, the stacked small pieces of composite materials are placed on a vibrating table to vibrate for about 5 minutes, after standing for 24 hours, the formwork is removed, and finally, put into the curing room for standard curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com