Preparation process of CrB2-Cr coating with high Cr content

A preparation process and coating technology, which is applied in the field of preparation of CrB2-Cr coatings with high Cr content, can solve problems such as poor bonding force between coatings and substrates, limited ablation resistance, and decreased thermal shock performance, so as to improve the resistance Corrosion performance, crack tip energy consumption, and the effect of large elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

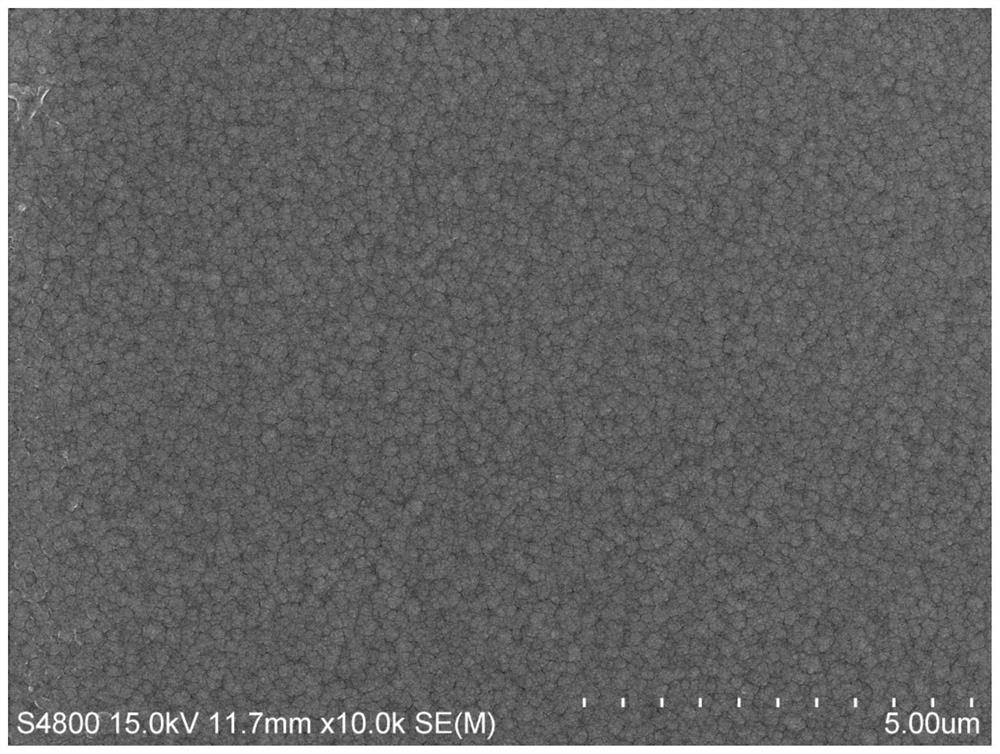

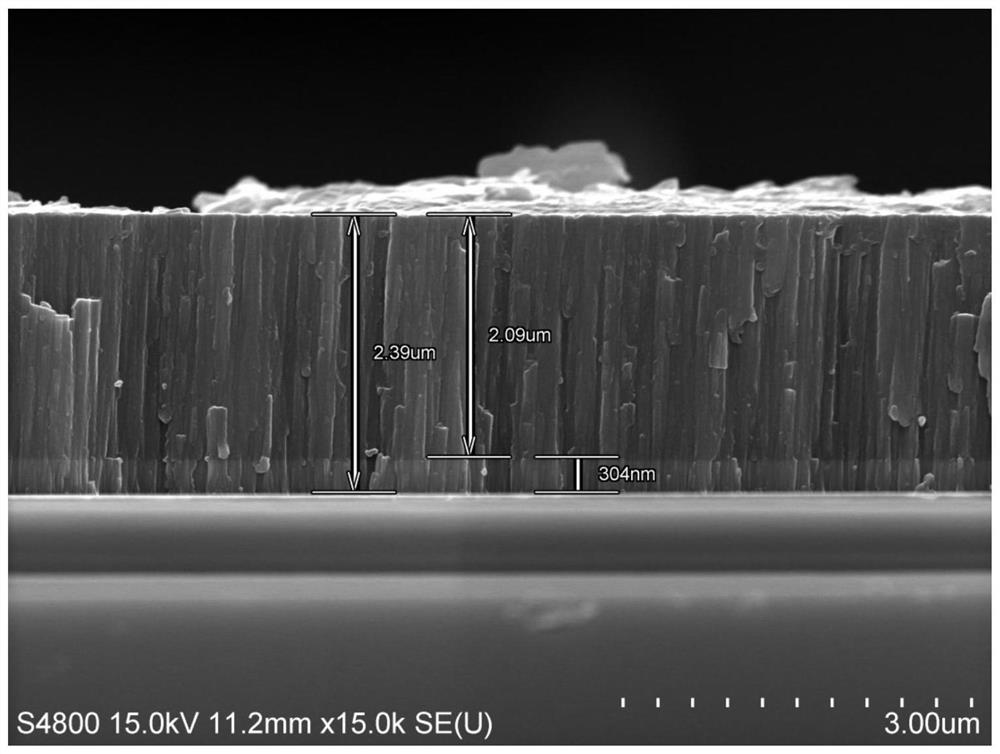

[0034] This embodiment is to deposit CrB on a mirror-polished single crystal Si sheet ((100) orientation) 2 -Cr coating. A total of three targets, CrB 2 One target and two Cr targets (Cr target I and Cr target II). First fix the Si sheet on the rotating frame in the vacuum chamber, connect the Cr target Ⅰ to the high-power pulse magnetron sputtering power supply, connect the Cr target Ⅱ to the pulsed DC power supply, and connect the CrB target to the pulsed DC power supply. 2 The target is connected to a high-power pulsed magnetron sputtering power supply.

[0035] Before putting the substrate into the vacuum chamber, it was ultrasonically cleaned in acetone and alcohol solutions for 20 minutes respectively, then dried with high-purity nitrogen, and then fixed on the rotating rack in the vacuum chamber facing the target. The coating process is carried out on a V-TECH AS610 high-power pulse and pulse DC composite magnetron sputtering coating machine, and the cathode target i...

Embodiment 2

[0042] This embodiment is to deposit CrB on the mirror polished AISI 304 stainless steel substrate (Cr-18.5, Ni-9.4, Mn-0.8, Si-0.4, P-0.1, Fe remainder, all are weight percentages) 2 -Cr coating. The substrate was first ground and polished by metallographic sandpaper, then ultrasonically cleaned with acetone and alcohol respectively, dried and fixed on the sample holder in the vacuum chamber facing the target. The coating deposition process and deposition parameters are the same as in Example 1.

[0043] Measurement of CrB deposited on stainless steel substrates by the continuum stiffness method using a nanoindenter 2 -Nanohardness of Cr coating, test results see Figure 5 , the coating hardness range is 15.9-19.9GPa, and the average value measured at 18 points is 17.6GPa, and the coating hardness is relatively high. The bonding strength between the coating and the substrate is tested by the scratch method. The tip radius of the diamond scratch head is 200μm, the normal lo...

Embodiment 3

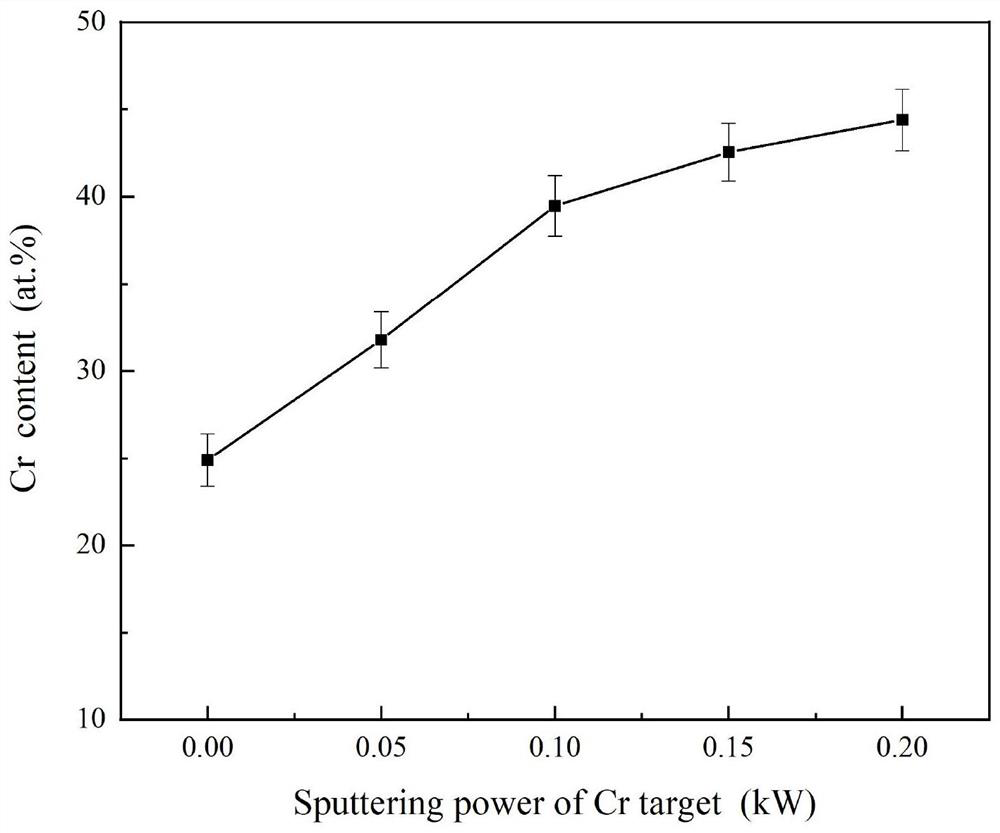

[0045] The difference from Example 1 is that the sputtering power of the Cr target II is adjusted to 0kW, 0.05kW, 0.1kW, 0.15kW, and 0.2kW, and the other processes are the same as in Example 1.

[0046] The XRD diffraction pattern of prepared each coating is as follows Figure 7 Shown, Cr content is respectively 25.0at.%, 31.8at.%, 39.5at.%, 42.5at.% and 44.4at.% ( image 3 ). It can be seen that when the sputtering power of Cr target II > 0.05kW, that is, with the increase of Cr content in the coating, the CrB 2 Diffraction peaks gradually disappear, Cr 2 The B diffraction peak gradually strengthens, and the Cr in the coating 2 Phase B is dominant, accompanied by a small amount of amorphous phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com