Epoxy toughening agent containing cage type silsesquioxane star block copolymer, and preparation method and application thereof

A technology of block polymers and siloxane-based stars, which is applied in the field of epoxy tougheners containing cage-shaped silsesquioxane-based star-shaped block polymers and its preparation, can solve the problem of affecting and toughening rings Oxygen resin transparency and other issues to achieve the effect of maintaining light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

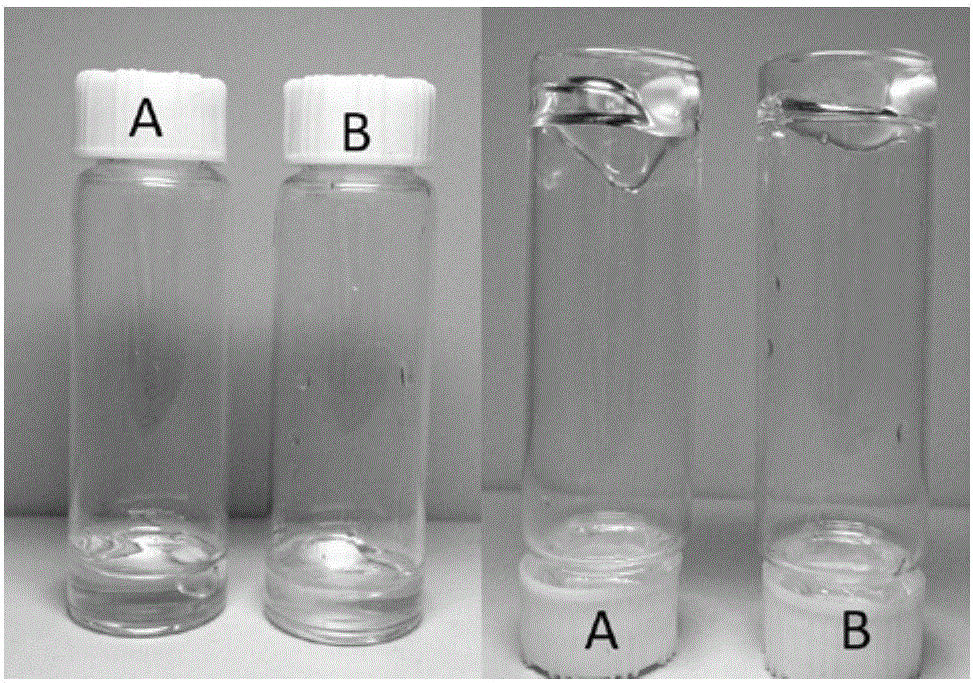

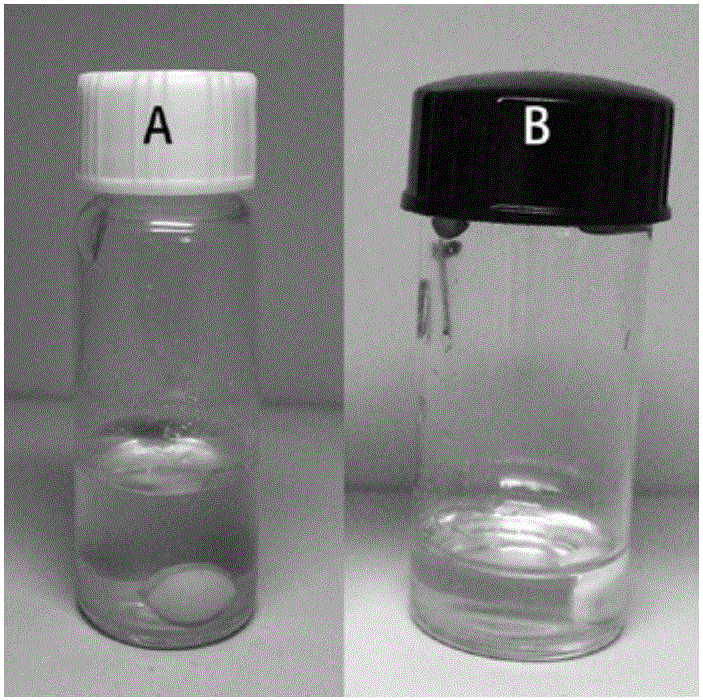

[0061] Example 1: Preparation and Application of an Epoxy Toughener Containing Cage Silsesquioxane Star Block Polymer

[0062] (1) Synthesis of each component:

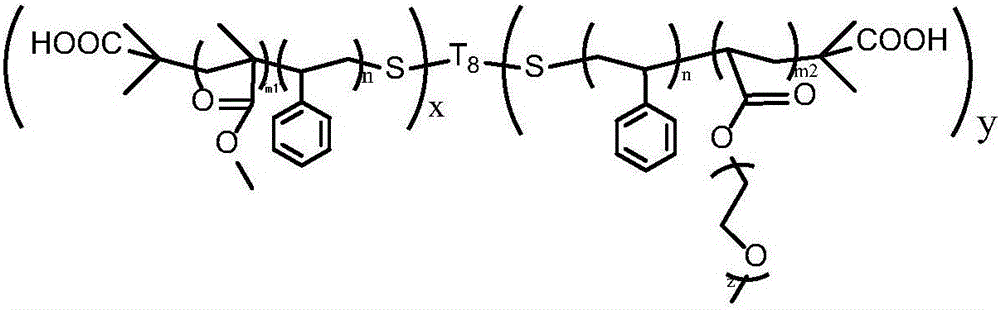

[0063] Methyl methacrylate was prepared into a chain by RAFT polymerization, under standard living polymerization conditions, the reaction temperature was 70° C., and the reaction time was 3 h. Then block styrene under the same conditions, and the reaction time is 1h to obtain P(MMA-b-St); its molecular weight is 6000.

[0064] Methoxypolyethylene glycol acrylate was prepared into chains by RAFT polymerization, under standard living polymerization conditions, the reaction temperature was 70° C., and the reaction time was 3 h. Then block styrene under the same conditions, and the reaction time is 1h to obtain P(PEGMEA-b-St); its molecular weight is 9000.

[0065] P(MMA-b-St) and P(PEGMEA-b-St) were desulfurized under the action of n-hexylamine to form thiol-terminated polymers (P(MMA-b-St)-SH, P(PEGMEA-b -St)-SH). ...

Embodiment 2

[0070] Example 2: Preparation and Application of an Epoxy Toughener Containing Cage Silsesquioxane Star Block Polymer

[0071] (1) Synthesis of each component:

[0072] Methyl methacrylate was prepared into chains by RAFT polymerization, under standard living polymerization conditions, the reaction temperature was 70°C, and the reaction time was 4h. Then block styrene under the same conditions, and the reaction time is 1h to obtain P(MMA-b-St); its molecular weight is 7000.

[0073] The methoxypolyethylene glycol acrylate was prepared into chains by RAFT polymerization, under standard living polymerization conditions, the reaction temperature was 70° C., and the reaction time was 4 hours. Then block styrene under the same conditions, and the reaction time is 1h to obtain P(PEGMEA-b-St); its molecular weight is 11,000.

[0074] P(MMA-b-St) and P(PEGMEA-b-St) were desulfurized under the action of n-hexylamine to form thiol-terminated polymers (P(MMA-b-St)-SH, P(PEGMEA-b -St)-...

Embodiment 3

[0079] Example 3: Preparation and Application of an Epoxy Toughener Containing Cage Silsesquioxane Star Block Polymer

[0080] (1) Synthesis of each component:

[0081]Methyl methacrylate was prepared into chains by RAFT polymerization, under standard living polymerization conditions, the reaction temperature was 70°C, and the reaction time was 5 hours. Then block styrene under the same conditions, and the reaction time is 1h to obtain P(MMA-b-St); its molecular weight is 8000.

[0082] The methoxypolyethylene glycol acrylate was prepared into chains by RAFT polymerization, under standard living polymerization conditions, the reaction temperature was 70° C., and the reaction time was 5 h. Then block styrene under the same conditions, and the reaction time is 1h to obtain P(PEGMEA-b-St); its molecular weight is 12,000.

[0083] P(MMA-b-St) and P(PEGMEA-b-St) were desulfurized under the action of n-hexylamine to form thiol-terminated polymers (P(MMA-b-St)-SH, P(PEGMEA-b -St)-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| translucency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com