High-toughness ceramic and its preparation method and application

A high-toughness, ceramic technology, applied in the direction of ceramic layered products, chemical instruments and methods, lamination devices, etc., can solve the problems of high processing cost, poor drop resistance, hard ceramics, etc., to ensure the effect of ceramics, increase Wear-resistant, increase the effect of impact damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

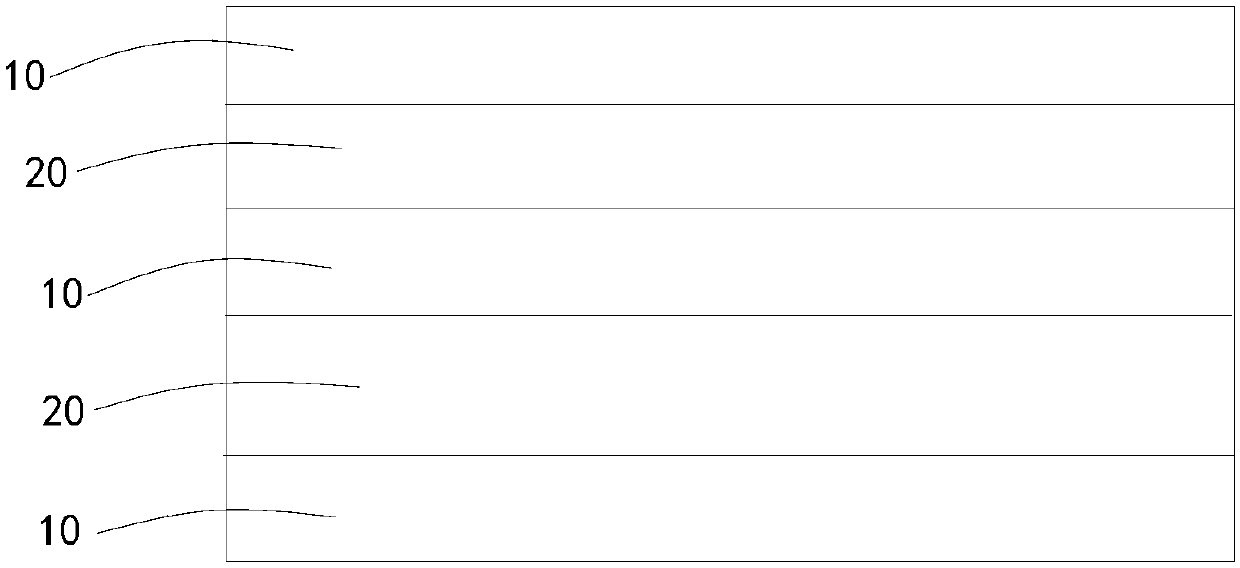

[0048] Please refer to figure 1 , the high-toughness ceramics of the present invention include three layers of ceramic layers 10 and two layers of fiber layers 20, the fiber layers 20 are interposed between the ceramic layers 10, wherein the fiber layers 20 are long fiber layers of zirconia.

[0049] The high-toughness ceramics described in this embodiment are used as the casing of the mobile phone to form a ceramic casing. The total thickness of the ceramic casing is 0.5 mm, and the thickness of the ceramic layer 10 and the fiber layer 20 are both 0.1 mm.

[0050] The method for preparing above-mentioned high-performance ceramics is:

[0051]The soft ceramic casting sheet is prepared by casting method. Specifically, different ratios of zirconia, alumina, solvent and binder are mixed and ball-milled to form the surface layer and the middle layer of casting slurry, and then passed through the flow casting method. The casting machine prepares the casting slurry into ceramic cas...

Embodiment 2

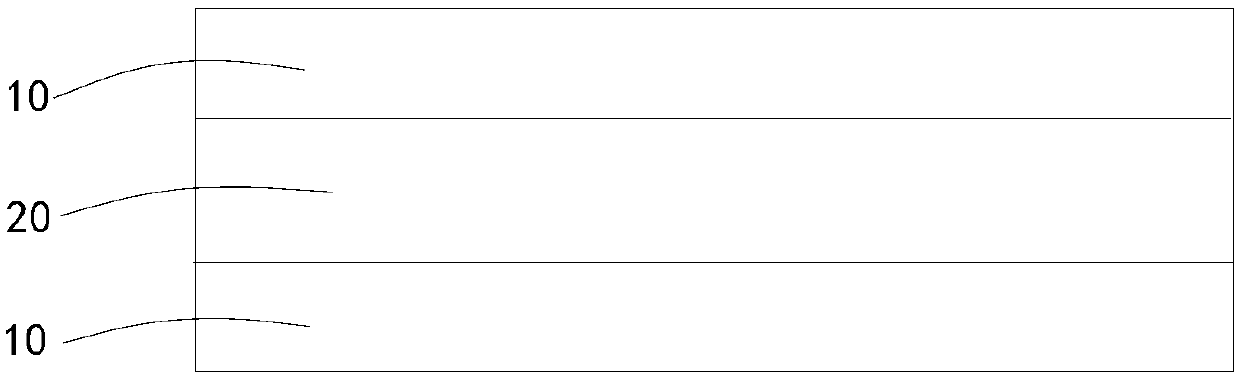

[0053] Please refer to figure 2 , the high-toughness ceramics of the present invention include two ceramic layers 10 and a fiber layer 20, the fiber layer 20 is interposed between the ceramic layers 10, wherein the fiber layer 20 is a short fiber layer of zirconia.

[0054] The high-toughness ceramic described in this embodiment is used as the shell of the mobile phone to form a ceramic shell. The total thickness of the ceramic shell is 0.5 mm, the thickness of the ceramic layer 10 is 0.2 mm, and the thickness of the fiber layer 20 is 0.1 mm.

[0055] The method for preparing above-mentioned high-performance ceramics is:

[0056] The soft ceramic casting sheet is prepared by casting method. Specifically, different ratios of zirconia, alumina, solvent and binder are mixed and ball-milled to form the surface layer and the middle layer of casting slurry, and then passed through the flow casting method. The casting machine prepares the casting slurry into a ceramic casting sheet...

Embodiment 3

[0059] Please refer to figure 2 , the high-toughness ceramics of the present invention include two ceramic layers 10 and a fiber layer 20, the fiber layer 20 is sandwiched between the ceramic layers 10, wherein the fiber layer 20 is a long fiber layer of alumina.

[0060] The high-toughness ceramics described in this embodiment are used as the casing of the mobile phone to form a ceramic casing. The total thickness of the ceramic casing is 0.3 mm, and the thickness of the ceramic layer 10 and the fiber layer 20 are both 0.1 mm.

[0061] The method for preparing above-mentioned high-performance ceramics is:

[0062] The soft ceramic casting sheet is prepared by casting method. Specifically, different ratios of zirconia, alumina, solvent and binder are mixed and ball-milled to form the surface layer and the middle layer of casting slurry, and then passed through the flow casting method. The casting machine prepares the casting slurry into ceramic casting sheets; makes the long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com