Super-strength and super-toughness polypropylene modified resin and its preparation technology

A super-tough polypropylene and modified resin technology, applied in the field of polypropylene bars, can solve the problems of high molding shrinkage, poor low-temperature performance and aging resistance of homopolymers, restricting the development and application of polypropylene, and reduce stress. , the effect of low water absorption, excellent surface activity and processing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment the present invention is described in detail.

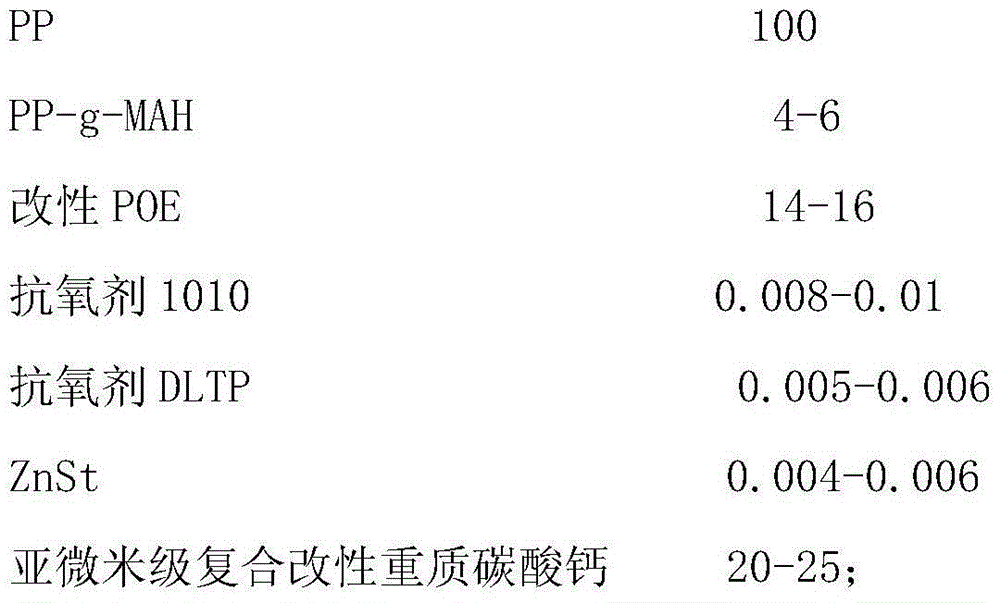

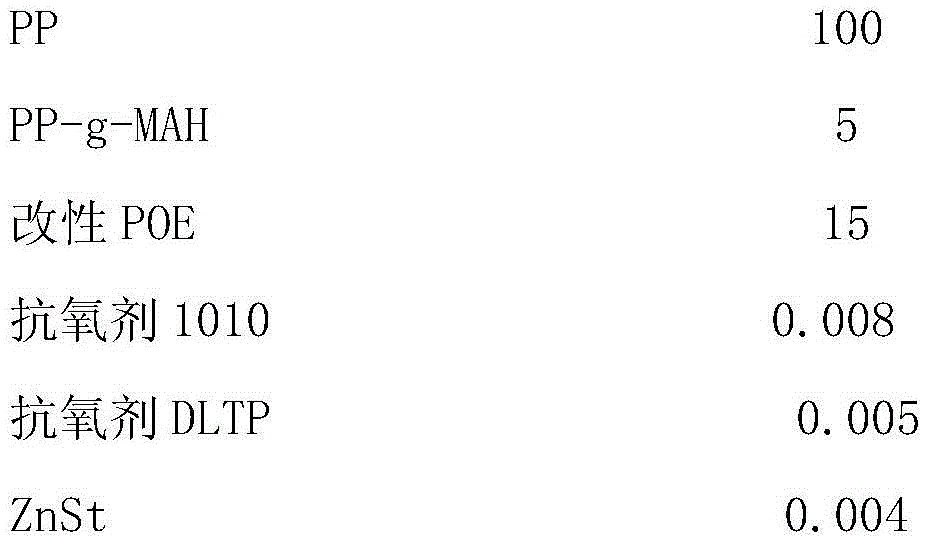

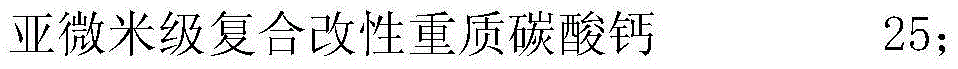

[0023] A kind of super strong super tough polypropylene modified resin, it is made by the raw material of following weight (kg):

[0024]

[0025]

[0026] The modified POE is prepared from the following weight (kg) raw materials: POE140, SBS8, white ointment 2, p-toluenesulfonyl hydrazide 2, tributyltin chloride 2, zinc oxide 4, microencapsulated red Phosphorus 1, di-n-nonyl phthalate 0.5, monoglyceride succinate 1.5, opal powder 5, lanolin 0.3, gum arabic powder 7, antioxidant 6260.8;

[0027] The preparation method of the modified POE is as follows: After mixing the raw materials, put them into the extruder for mixing, and control the temperature of the extruder at 150°C to obtain the extrudate;

[0028] The sub-micron compound modified heavy calcium carbonate is prepared from the following weight (KG) raw materials: heavy calcium carbonate 80, light calcium carbonate 13, carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com