Dendritic toughening curing agent as well as preparation method and application thereof

A curing agent and dendritic technology, applied in the field of preparation of dendritic toughening curing agent, can solve the problems of epoxy resin curing agent not having both toughening and curing dual properties, complicated preparation method and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

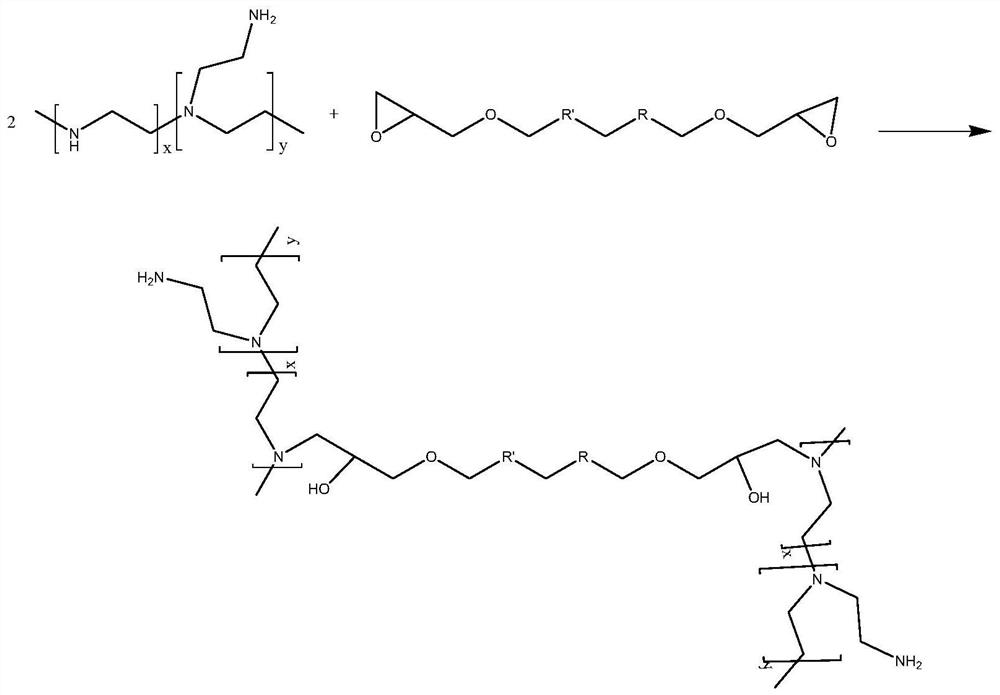

Method used

Image

Examples

Embodiment 1

[0033] Add ethylene glycol diglycidyl ether dropwise to diethylenetriamine, feed according to the molar ratio of the number of epoxy groups to diethylenetriamine 1:1, and react at 40 °C for 5 hours, then the terminal amino group can be obtained. The dendritic toughening curing agent 1.

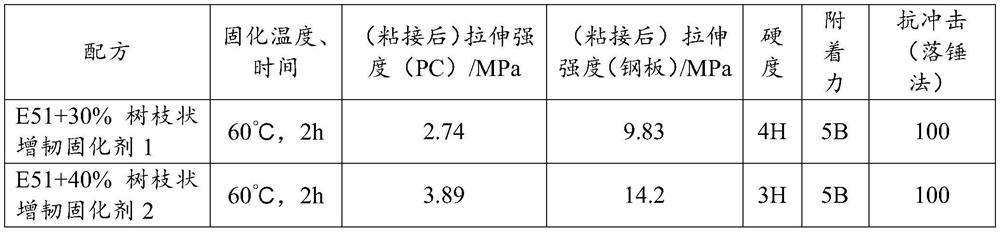

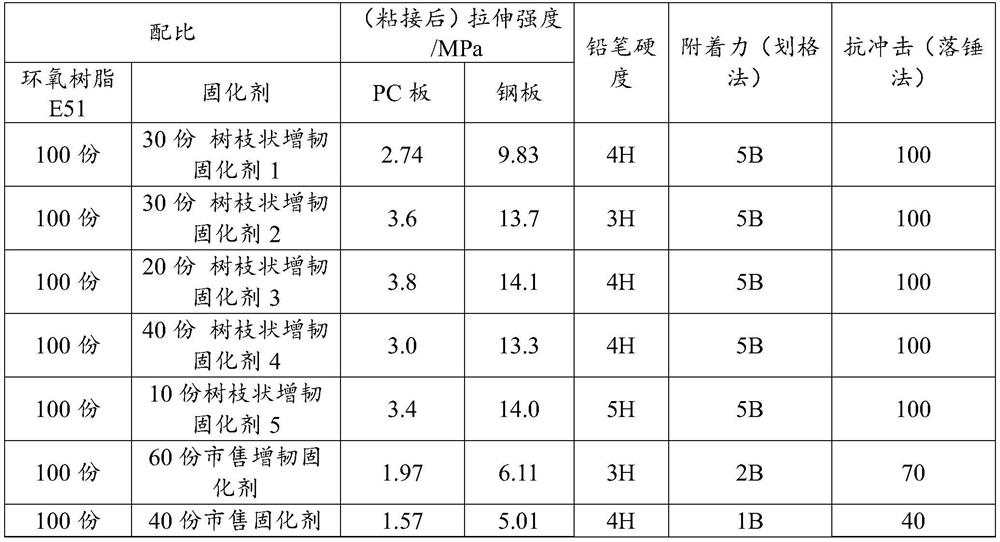

[0034] The above-mentioned dendritic toughening curing agent 1 was blended with epoxy resin, and its application performance was tested after curing at 60°C for 2 hours.

Embodiment 2

[0036] Add polyethylene glycol diglycidyl ether dropwise to triethylene tetramine, feed according to the molar ratio of the number of epoxy groups and triethylene tetraamine 1:1.5, and react at 60 ° C for 8 hours, then the terminal amine can be obtained. Based dendritic toughening curing agent 2.

[0037] The above-mentioned dendritic toughening curing agent 2 was blended with epoxy resin, and its application performance was tested after curing at 60°C for 2 hours.

Embodiment 3

[0039] Castor oil triglycidyl ether is added dropwise to tetraethylene pentamine, feeding according to the number of epoxy groups and tetraethylene pentamine molar ratio of 1:3, react at 40 ° C for 5 hours, and then the terminal amine group can be obtained. The dendritic toughening curing agent 3.

[0040] The above-mentioned dendritic toughening curing agent 3 was blended with epoxy resin, and its application performance was tested after curing at 60°C for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com