BPA-GA (bisphenol A-glutaraldehyde) phenol-formaldehyde resin and preparation method thereof

A BPA-GA and phenolic resin technology, applied in the field of BPA-GA phenolic resin and its preparation, can solve the problems of poor toughness of phenolic resin, restrict further application, etc., and achieve the effects of low production cost, low toxicity and widening application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

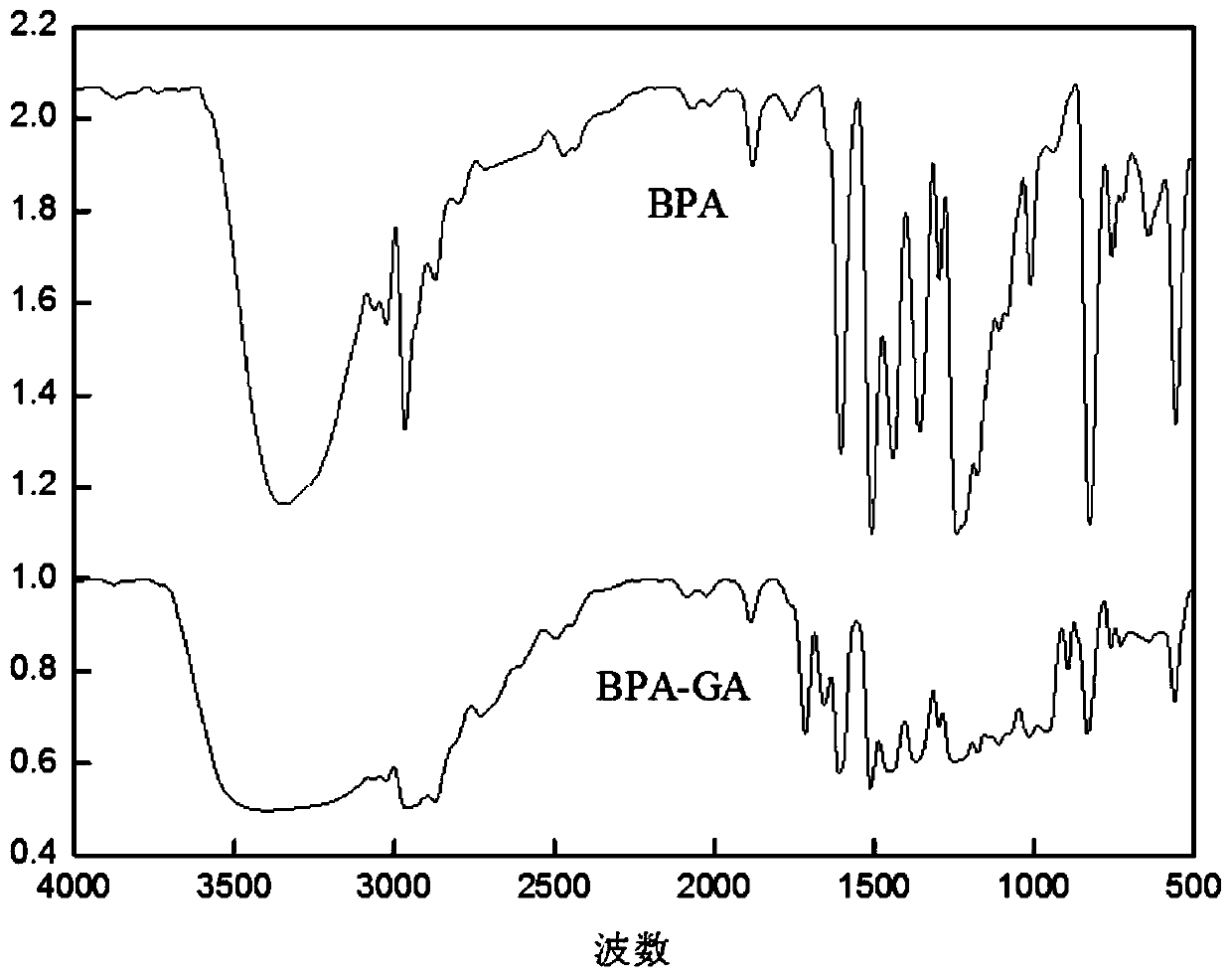

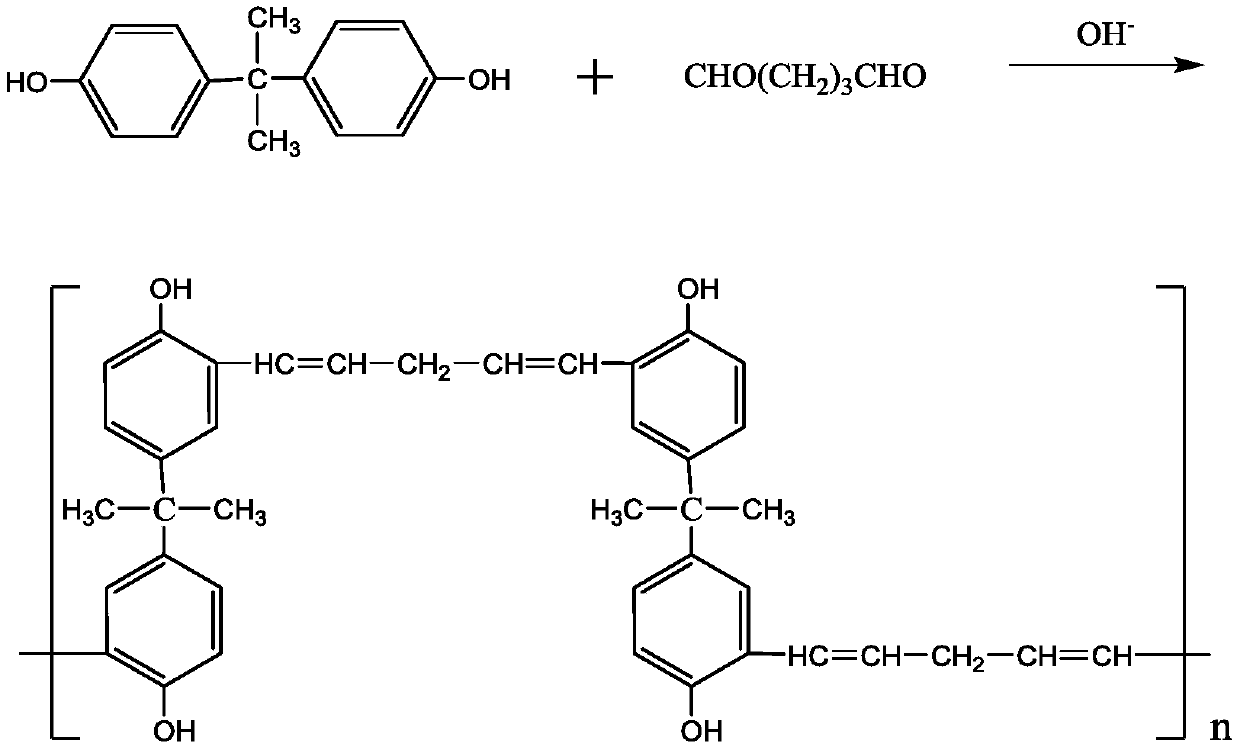

[0025] A kind of preparation method of BPA-GA phenolic resin of the present invention, wherein BPA is bisphenol A, and GA is glutaraldehyde, and the chemical reaction principle in the preparation process is as follows,

[0026]

[0027] Under alkaline conditions, bisphenol A undergoes polycondensation reaction with glutaraldehyde, the phenolic hydroxyl ortho position of bisphenol A undergoes electron transfer with glutaraldehyde, and the phenolic hydroxyl ortho position of bisphenol A undergoes hydroxymethylation to graft glutaraldehyde , to achieve the effect of flexible chain forging growth.

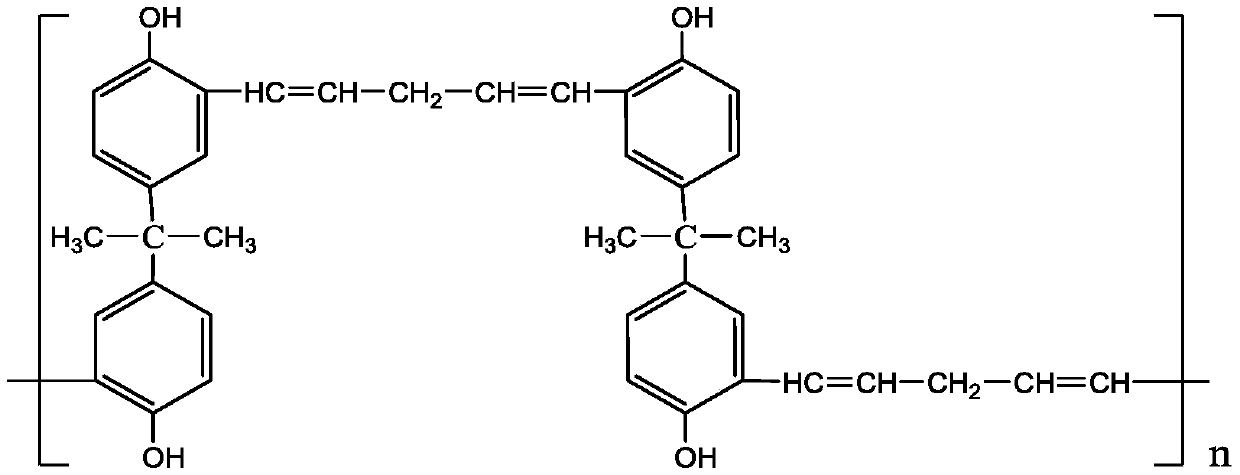

[0028] The chemical formula of this BPA-GA phenolic resin is:

[0029]

[0030] The relative molecular mass is 4000-5000.

Embodiment 1

[0032] A kind of preparation method of BPA-GA phenolic resin of the present invention specifically comprises the following steps,

[0033] Step 1, take 11.4g of bisphenol A and 25mL of n-butanol into a 250mL three-necked round-bottomed flask with a mechanical stirrer, stir and heat to 65°C for 20min, n-butanol is used as a solvent to dissolve the solid bisphenol A get a solution;

[0034] Step 2, stir the solution to make it clear and transparent, cool to room temperature, then add 20g of glutaraldehyde aqueous solution with a mass fraction of 25% and 0.25g of a 1% NaOH solution with a mass fraction, and then heat to 95°C to react Time 6h, NaOH is used as a catalyst to obtain a mixed system containing BPA-GA phenolic resin;

[0035] Step 3, the mixed system obtained in step 2 is subjected to vacuum distillation at 95° C. for 1 h to remove n-butanol, water and glutaraldehyde;

[0036] Step 4, the mixture obtained in step 3 was dissolved in acetone solvent to form a mixed solu...

Embodiment 2

[0041] A kind of preparation method of BPA-GA phenolic resin of the present invention comprises the following steps,

[0042] Step 1, take 11.4g of bisphenol A and 25mL of n-butanol into a 250mL three-necked round bottom flask with a mechanical stirrer, stir and heat to 60°C for 30min;

[0043] Step 2, when the reaction system is clear and transparent, cool to room temperature, then add 21.6g of a 25% glutaraldehyde aqueous solution and 0.35g of a 1% NaOH solution, and then heat to 90°C to react Time 5.8h, obtain the mixed system containing BPA-GA phenolic resin;

[0044] Step 3, the mixed system obtained in step 2 was subjected to vacuum distillation at 90° C. for 45 minutes to remove n-butanol, water and glutaraldehyde;

[0045] Step 4, the mixture obtained in step 3 was dissolved in acetone solvent to form a mixed solution, and dialyzed for 6 hours, specifically, the mixed solution was put into a dialysis bag with a molecular weight of 500, and the two ends were sealed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com