High-toughness and high-rigidity PC/PBT (polycarbonate/polybutylene terephthalate) alloy material and method for preparing same

An alloy material and high rigidity technology, which is applied in the field of high rigidity PC/PBT alloy material and its preparation, and high toughness, can solve the problems of unsatisfactory strength requirements, unstable alloy performance, decreased rigidity and thermal stability, etc., to achieve Improve rigidity, improve impact toughness, and evenly disperse the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

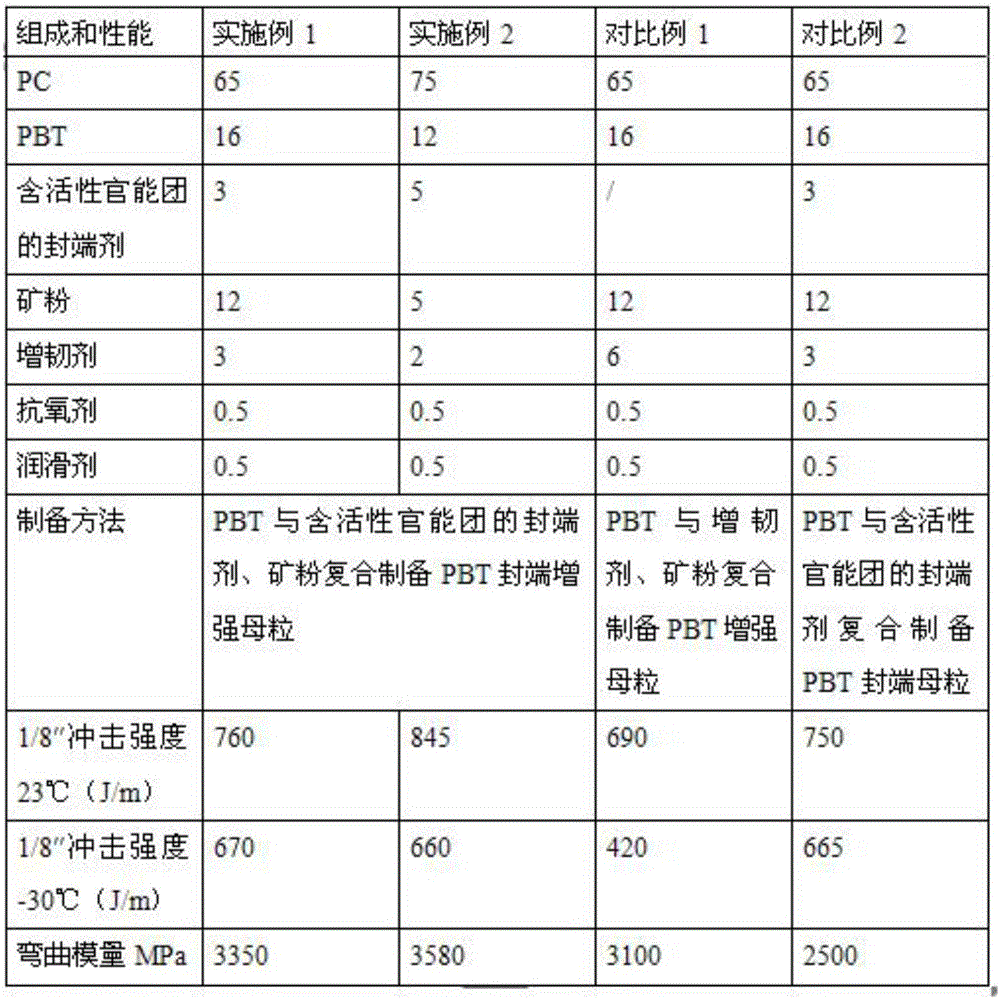

Embodiment 1

[0032] 1) Weigh the following raw material components by weight: PC resin: 65 parts; PBT resin: 16 parts; end-capping agent containing active functional groups: 3 parts; antioxidant: 0.5 parts; toughening agent: 3 parts; Agent: 0.5 parts; Talcum powder: 12 parts;

[0033] 2) First, PBT (viscosity 1.0) resin, MBS containing active functional groups (particle size is 200-300nm, wherein the grafted GMA content is 10%) end-capping agent and talcum powder (particle size 1.5 microns) are extruded by twin-screw Extrusion melt blending and extrusion granulation to prepare PBT end-capped reinforced masterbatch; the process settings of the twin-screw extruder are: the temperature of the conveying section is 180-200°C, the temperature of the plasticizing section is 210-230°C, and the temperature of the homogenization section 210-220°C; screw speed 280-550r / min;

[0034] 3) Then premix the PBT end-capped reinforcement masterbatch with other components (5-10 minutes), melt blend, and gran...

Embodiment 2

[0037] 1) Weigh the following raw material components by weight: PC resin: 75 parts; PBT resin: 12 parts; end-capping agent containing active functional groups: 5 parts; antioxidant: 0.5 parts; toughening agent: 2 parts; Agent: 0.5 parts; Talcum powder: 5 parts;

[0038] 2) First, PBT (viscosity 1.0) resin, E-MA-GMA (particle diameter of 200-300nm, wherein the grafted GMA content is 8%) containing active functional groups end-capping agent and diatomaceous earth (particle diameter of 10 microns ) through twin-screw extruder melt blending, extrusion and granulation to prepare PBT end-capped reinforced masterbatch; the process setting of twin-screw extruder is: the temperature of the conveying section is 180-200°C, and the temperature of the plasticizing section is 210-230°C , the homogenization section temperature is 210-220°C; the screw speed is 280-550r / min;

[0039] 3) Then premix the PBT end-capped reinforcement masterbatch with other components (5-10 minutes), melt blend,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com