Modified polyphenylene sulfide light diffusion agent for LED epoxy packaging and preparation method thereof

A technology of polyphenylene sulfide and light diffusing agent, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of difficult preparation process of diffusing powder, small possibility of stable mass production, etc., and achieve excellent optical Features, excellent UV resistance, high light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the first step, first add 50ml of NMP solution into a clean and dry three-necked flask, and pass nitrogen gas. In the second step, dissolve 2.5g of special epoxy resin E-1 in NMP organic solvent, heat to 60°C to help dissolve, and continue Stir for 1 hour; in the third step, evenly disperse 47.5g of PPS masterbatch in the mixed solution in the second step, then raise the temperature to 100°C and continue to stir for 4 to 6 hours, and cool down to room temperature naturally after the reaction is completed; finally, in the nitrogen protection environment Next, grind the dispersion liquid obtained in the third step in a ball mill for 10 minutes, repeat three times, and control the temperature below 60°C. After the product is washed with methanol or ethanol to remove the solvent, it is dried in a vacuum oven at 50°C under negative pressure to obtain a high Refractive index modified polyphenylene sulfide white powder p-1.

[0032] Take 3.5g p-1 and join in the commerciall...

Embodiment 2

[0034] In the first step, first add 50ml of NMP solution into a clean and dry three-necked flask, and pass nitrogen gas. In the second step, dissolve 8.33g of special epoxy resin E-2 in NMP organic solvent, heat to 60°C to help dissolve, and continue Stir for 1 hour; in the third step, evenly disperse 42.67g of PPS masterbatch in the mixed solution in the second step, then raise the temperature to 160°C and continue stirring for 4 to 6 hours, and cool down to room temperature naturally after the reaction; Next, grind the dispersion obtained in the third step in a ball mill for 10 minutes, repeat three times, and control the temperature below 60°C. After the product is washed with methanol or ethanol to remove the solvent, it is dried in a vacuum oven at 50°C under negative pressure to obtain a high Refractive index modified polyphenylene sulfide white powder p-2.

[0035] Take 3.0g p-2 and add it to the commercially available two-component encapsulant (agent A is a modified ep...

Embodiment 3

[0037] In the first step, first add 50ml of NMP solution into a clean and dry three-necked flask, and pass nitrogen gas. In the second step, dissolve 16.67g of special epoxy resin E-3 in NMP organic solvent, and heat it to 60°C to help dissolve it. Stir for 1 hour; in the third step, evenly disperse 33.33g of PPS masterbatch in the mixed solution in the second step, then raise the temperature to 80°C and continue stirring for 4 to 6 hours, and cool down to room temperature naturally after the reaction is completed; finally, under nitrogen protection environment Grind the dispersion in the third step for 10 minutes in a ball mill, repeat three times, and control the temperature below 60°C. After the product is washed with methanol or ethanol to remove the solvent, it is dried in a vacuum oven at 50°C under negative pressure to obtain a high refractive index. rate of modified polyphenylene sulfide white powder p-3.

[0038] Take 3.0g p-3 and add it to the commercially available ...

PUM

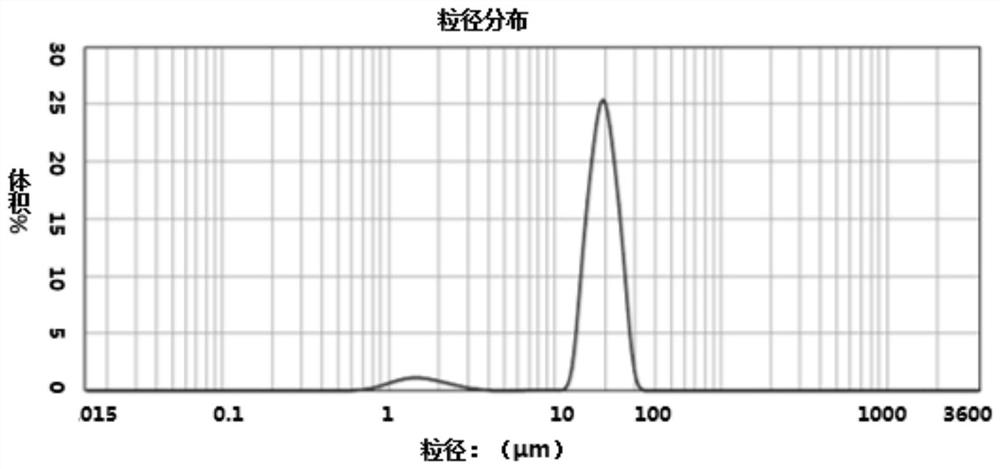

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com