Layered toughening tungsten and preparation method thereof

A toughening and layered technology, applied in the field of layered toughened tungsten and its preparation, and the first wall structure of fusion reactors, can solve the problems of tungsten irradiation embrittlement, rising tritium retention, and limited application of pure tungsten materials , to achieve the effect of increasing the expansion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

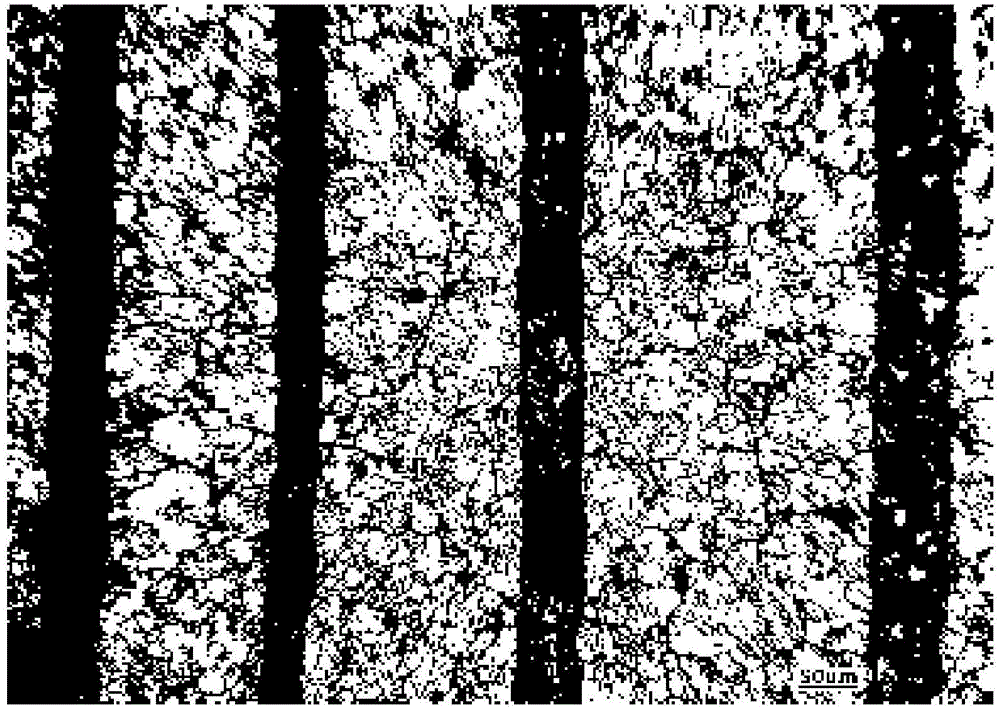

[0024] This embodiment is used to prepare layered toughened tungsten, which includes alternately stacked tungsten layers and toughening layers, the thickness of the tungsten layer is about 200 μm, the thickness of the toughening layer is 30 μm, and the metal tantalum sheet is 30 μm. Specific steps are as follows:

[0025] S1: The tungsten powder is mechanically ground under the protection of Ar gas to prepare the base tungsten powder.

[0026] During ball milling, dry milling was carried out first, and the dry milling time was 8 hours, and then anhydrous ethanol was added for wet milling, and the wet milling time was 5 hours. The ball-to-material ratio of the ball mill is 10:1, and the rotational speed of the ball mill tank is 300r / min.

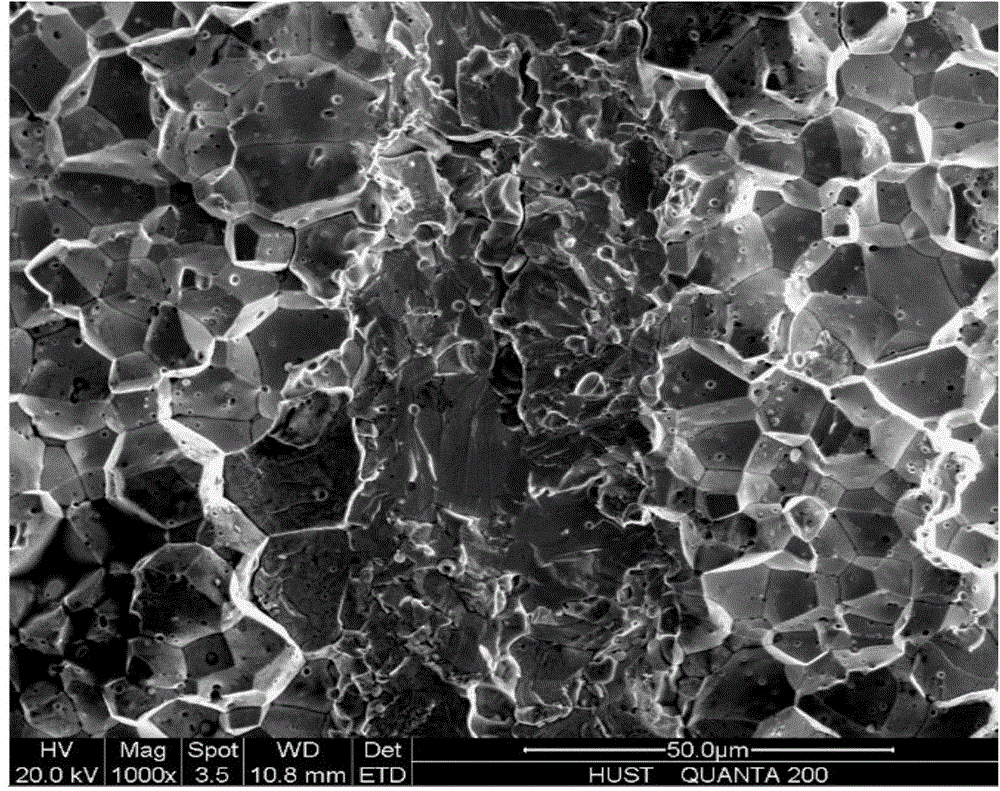

[0027] After ball milling, use a 400-mesh sieve to sieve to obtain matrix powder with a particle size of less than 40 μm. The use of finer particle size powder is beneficial to the sintering quality. After the tungsten powder is reduced by ...

Embodiment 2

[0033] This embodiment is used to prepare layered toughened tungsten, which includes alternately stacked tungsten layers and toughening layers, the thickness of the tungsten layer is 150 μm, and the thickness of the toughening layer is 30 μm. The toughening layer is a metal tantalum sheet of 30 μm. Specific steps are as follows:

[0034] S1: Mechanically grind tungsten powder under the protection of Ar gas to prepare tungsten powder.

[0035] During ball milling, dry milling was performed first, and the dry milling time was 10 hours, and then anhydrous ethanol was added for wet milling, and the wet milling time was 3 hours. The ball-to-material ratio of the ball mill is 15:1, and the rotational speed of the ball mill jar is 250r / min.

[0036] After ball milling, use a 400-mesh sieve to sieve to obtain tungsten powder with a particle size of less than 40 μm. The finer particle size powder is beneficial to the sintering quality. After the tungsten powder is reduced by hydroge...

Embodiment 3

[0040] This embodiment is used to prepare layered toughened tungsten, which includes alternately stacking tungsten layers and toughening layers, the thickness of the tungsten layer is 250 μm and the thickness of the toughening layer is 30 μm. The toughening layer is a metal tantalum sheet of 30 μm. Specific steps are as follows:

[0041]S1: The tungsten powder is mechanically ground by high-energy ball milling under the protection of Ar gas to prepare tungsten powder.

[0042] During ball milling, dry milling was carried out first, and the dry milling time was 5 hours, and then anhydrous ethanol was added for wet milling, and the wet milling time was 6 hours. The ball-to-material ratio of the ball mill is 8:1, and the rotational speed of the ball mill tank is 350r / min.

[0043] After ball milling, use a 400-mesh sieve to sieve to obtain tungsten powder with a particle size of less than 40 μm. The finer particle size powder is beneficial to the sintering quality. After the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com