A kind of layered toughened ods steel and preparation method thereof

A toughening and layered technology, applied in the field of steel structure materials, can solve the problems of limited application and poor toughness, and achieve the effects of excellent corrosion resistance, improved strength and elongation at break, and improved strength and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

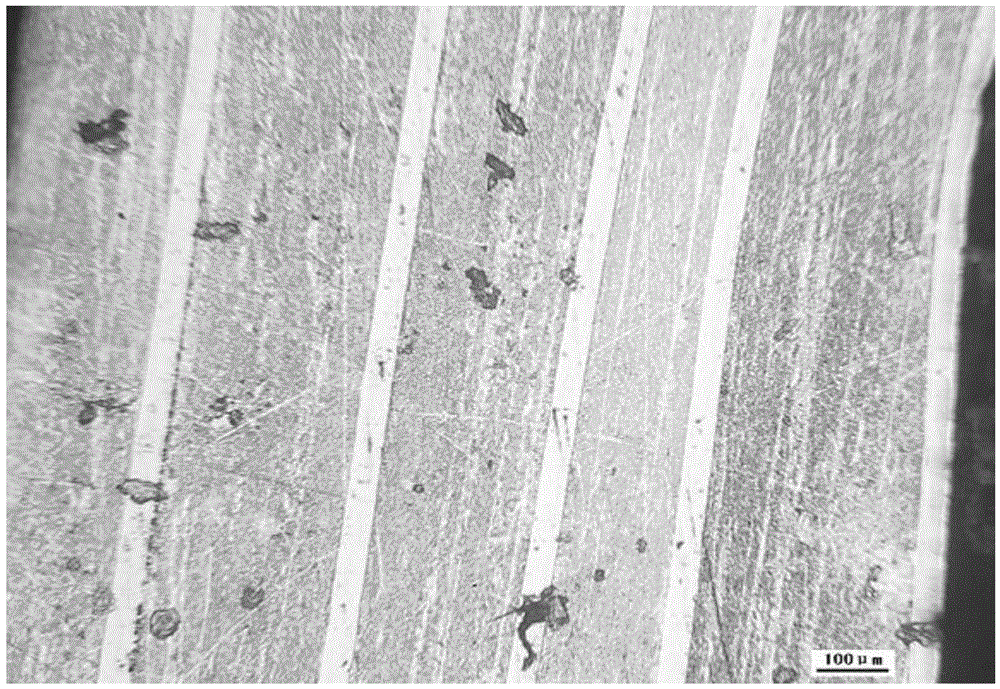

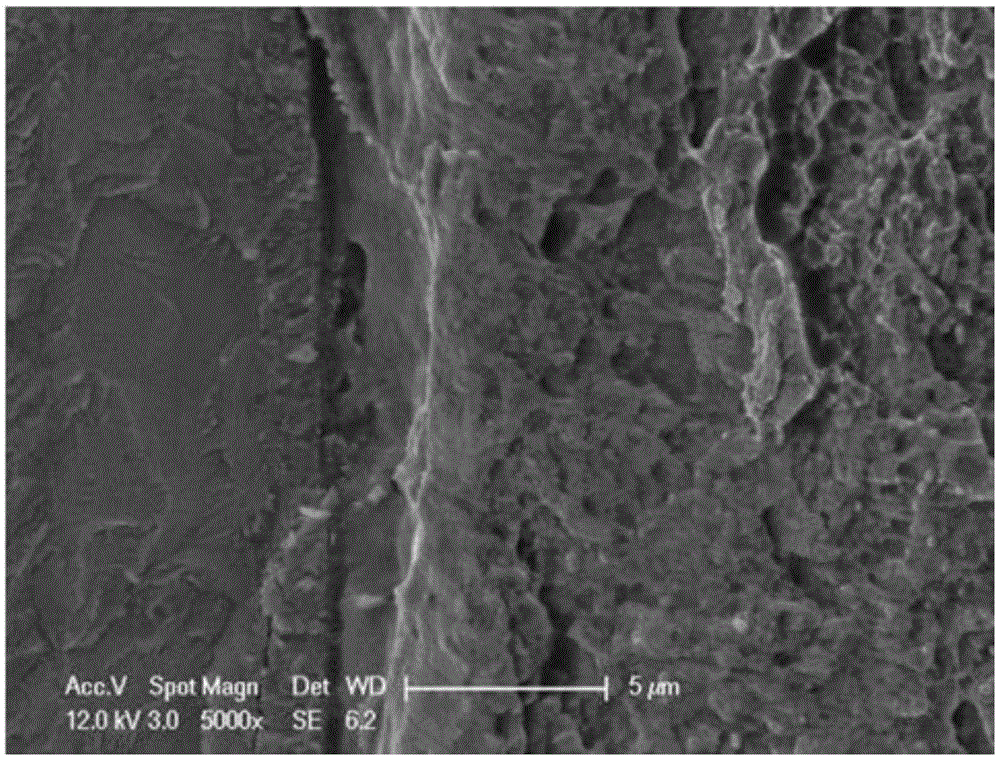

Embodiment 1

[0029] This embodiment is used to prepare a layered toughened ODS steel, which includes alternately laminating a base layer and a toughened layer. The thickness of the base layer is about 150 μm and the thickness of the toughened layer is 30 μm. The base layer includes master powder, Ti, Y 2 O 3 And CrN, Ti content is 0.3% of the mass fraction of the base layer, Y 2 O 3 The content is 0.35% of the mass fraction of the base layer, and the content of CrN is 1% of the mass fraction of the base layer. The components contained in the master powder and the mass percentages of each component in the master powder are: 0.1% C, 9% Cr, 2.5% W, 0.25% V, 0.5% Mn, the balance Fe and impurity elements. The toughening layer is a 30μm metal tantalum sheet. Specific steps are as follows:

[0030] S1: The master powder, Ti powder, Y 2 O 3 After the powder and CrN powder are mixed, they are mechanically alloyed by high-energy ball milling under the protection of Ar gas to prepare matrix powder.

[00...

Embodiment 2

[0039] This embodiment is used to prepare a layered toughened ODS steel, which includes alternately laminating a base layer and a toughened layer. The thickness of the base layer is 180 μm and the thickness of the toughened layer is 30 μm. The base layer includes master powder, Ti, Y 2 O 3 And CrN, Ti content is 0.3% of the mass fraction of the base layer, Y 2 O 3 The content is 0.35% of the mass fraction of the base layer, and the content of CrN is 0.5% of the mass fraction of the base layer. The components contained in the master powder and the mass percentages of each component in the master powder are: 0.1% C, 9% Cr, 2.5% W, 0.25% V, 0.5% Mn, the balance Fe and impurity elements. The toughening layer is a 30μm metal tantalum sheet. Specific steps are as follows:

[0040] S1: Mix the master powder, Ti powder, Y 2 O 3 After the powder and CrN powder are mixed, they are mechanically alloyed by high-energy ball milling under the protection of Ar gas to prepare matrix powder.

[00...

Embodiment 3

[0048] This embodiment is used to prepare layered toughened ODS steel, which includes alternately laminating a base layer and a toughened layer. The thickness of the base layer is 200 μm and the thickness of the toughened layer is 30 μm. The base layer includes master powder, Ti, Y 2 O 3 And CrN, Ti content is 0.3% of the mass fraction of the base layer, Y 2 O 3 The content is 0.35% of the mass fraction of the base layer, and the content of CrN is 0.75% of the mass fraction of the base layer. The components contained in the master powder and the mass percentages of each component in the master powder are: 0.1% C, 9% Cr, 2.5% W, 0.25% V, 0.5% Mn, the balance Fe and impurity elements. The toughening layer is a 30μm metal tantalum sheet. Specific steps are as follows:

[0049] S1: Mix the master powder, Ti powder, Y 2 O 3 After the powder and CrN powder are mixed, they are mechanically alloyed by high-energy ball milling under the protection of Ar gas to prepare matrix powder.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com