Sealing treatment method of micro arc oxidation ceramic membrane

A technology of micro-arc oxidation and sealing treatment, which is applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of poor corrosion resistance of aluminum-copper alloys and difficulty in meeting requirements, and achieve improved wear resistance and corrosion resistance. Effect of improving electrical insulation performance and reducing contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

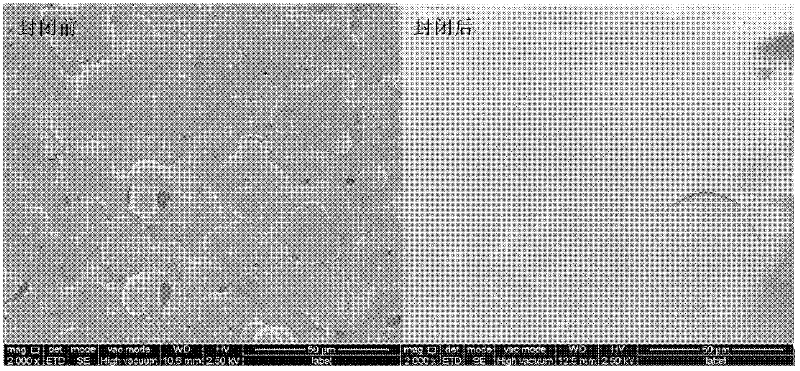

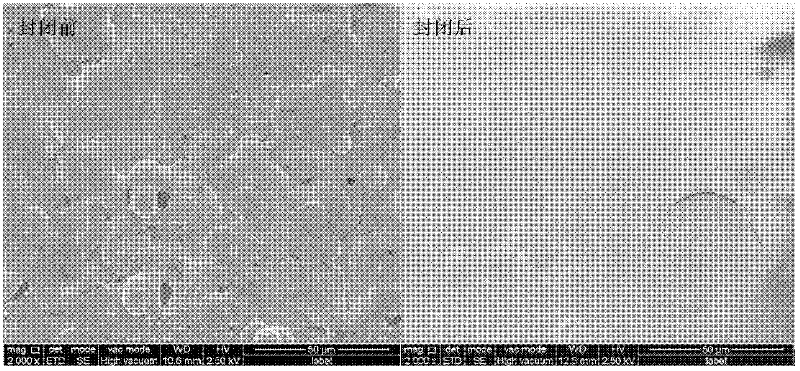

[0036] ZL101A micro-arc oxidation sample: 60×40×5mm, film thickness about 35μm, decontamination and degreasing.

[0037] Organosilicon sealing agent configuration: Stir and mix the organosilicon stock solution and more than 95% alcohol according to the mass ratio of 10:1.

[0038] Vacuum impregnation: the sample is put into a pressure-resistant container and sealed, then vacuumed, vacuum degree: 10 -4 MPa, inject the sealing agent to submerge all parts, release the vacuum, press the sealing agent into the micropores of the film layer by atmospheric pressure, and repeat the operation again.

[0039] Heating and curing: put the impregnated sample into the holding furnace and keep it warm at 150°C for 20 minutes.

Embodiment 2

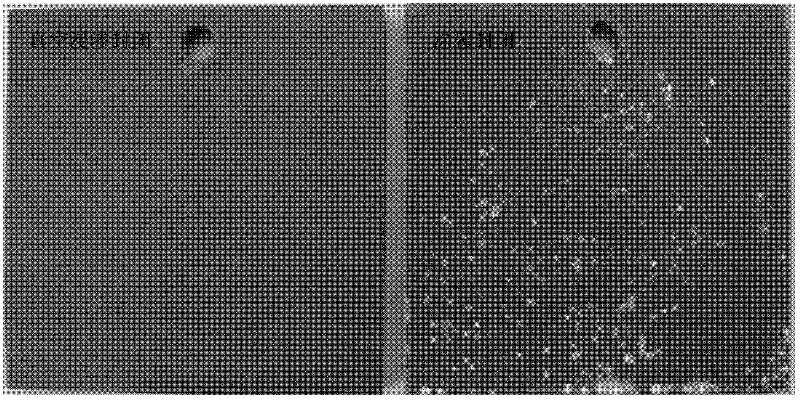

[0041] ZL205A micro-arc oxidation sample 60×40×5mm, film thickness about 35μm, decontamination and oil removal. Organosilicon sealing agent configuration: Stir and mix the organosilicon stock solution and more than 95% alcohol according to the mass ratio of 10:1.

[0042] Vacuum impregnation: the sample is put into a pressure-resistant container and sealed, then vacuumed, vacuum degree: 5×10 -3 MPa, inject the sealing agent to submerge all parts, release the vacuum, press the sealing agent into the micropores of the film layer by atmospheric pressure, and repeat the operation again.

[0043] Heating and curing: put the impregnated sample into a holding furnace and keep it warm at 150°C for 15 minutes.

Embodiment 3

[0045] AZ61 micro-arc oxidation sample: 60×40×5mm, film thickness about 35μm, decontamination and oil removal.

[0046] Organosilicon sealing agent configuration: Stir and mix the organosilicon stock solution and more than 95% alcohol according to the mass ratio of 8:1.

[0047] Vacuum impregnation: the sample is put into a pressure-resistant container and sealed, then vacuumed, vacuum degree: 10 -2 MPa, inject the sealing agent to submerge all parts, release the vacuum, press the sealing agent into the micropores of the film layer by atmospheric pressure, and repeat the operation again.

[0048] Heating and curing: put the impregnated sample into a holding furnace and keep it warm at 130°C for 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com