Patents

Literature

44results about How to "Lessen the tendency to corrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biocide agent coutaining bromine named as powered bromine chlorin

InactiveCN1430894AAchieve effectThe bactericidal effect is quiteBiocideAnimal repellantsCorrosionWater treatment

A bromine-contained biocide used for public place and sewage treatment contains chlorine supplying agnet, bromide and stabilizer of bromine and chlorine in ratio of (50-85):(10-45):(5-15). Its advantages are long acting period, good corrosion inhibiting effect.

Owner:BC P INC CHINA NAT PETROLEUM CORP

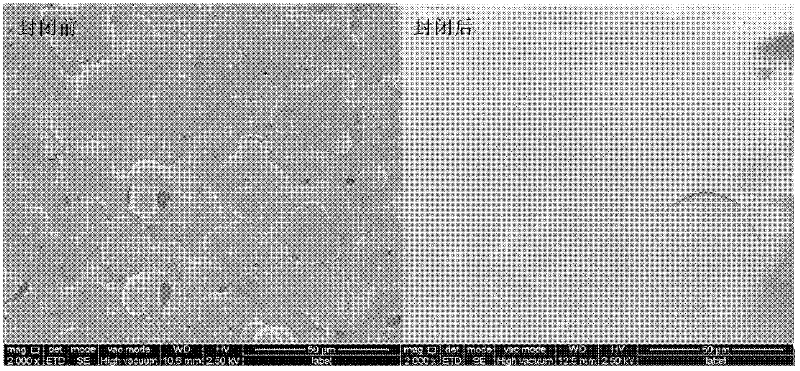

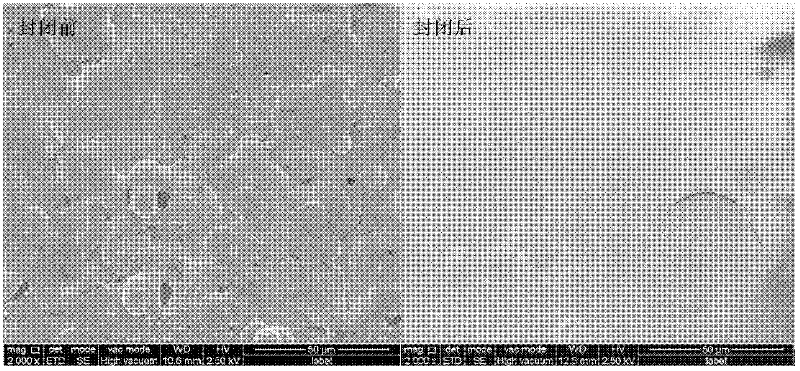

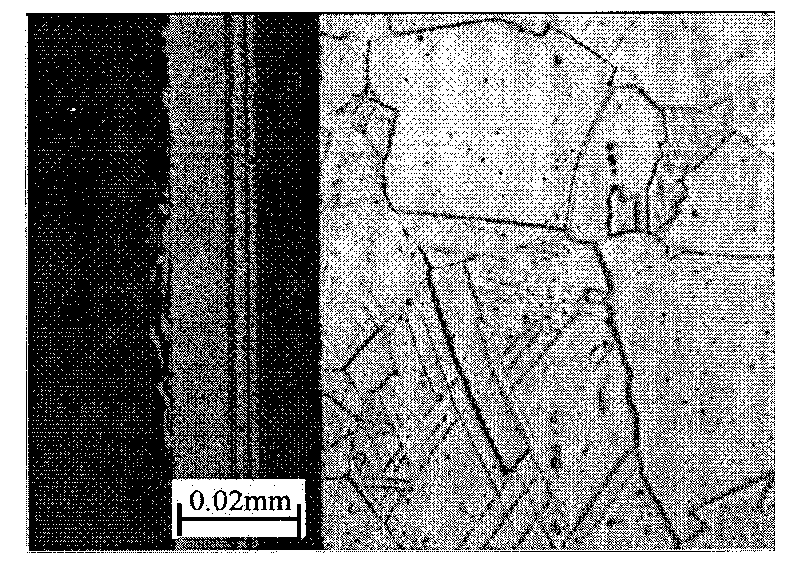

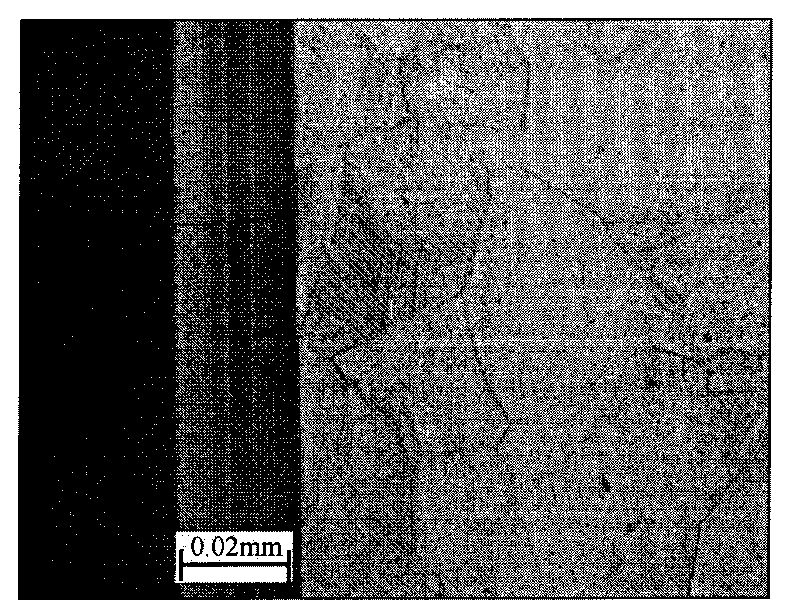

Sealing treatment method of micro arc oxidation ceramic membrane

InactiveCN102330139AReduce porosityImprove corrosion resistanceSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a sealing treatment method of a micro arc oxidation ceramic membrane. The sealing treatment method comprising the following steps: firstly, decontaminating and deoiling the surface of an aluminium alloy micro arc oxidation sample to be sealed with acetone; then carrying out ultrasonic vibration cleaning by adopting distilled water of 50-60 DEG C; subsequently, carrying out vacuum impregnation by adopting an organic silicon stock solution and more than 95% alcohol; and finally putting the aluminium alloy micro arc oxidation sample into a heat preserving furnace for heat preservation so as to complete sealing treatment. By applying the sealing treatment method of the micro arc oxidation ceramic membrane, the abrasion resistance and corrosion resistance performances of the micro arc oxidation membranous layer can be greatly improved, the contamination performance of the oxidation membranous layer can be effectively reduced, the electrical insulating property of the oxidation membranous layer is improved, and the toughness of the membrane layer is improved.

Owner:CSIC NO 12 RES INST

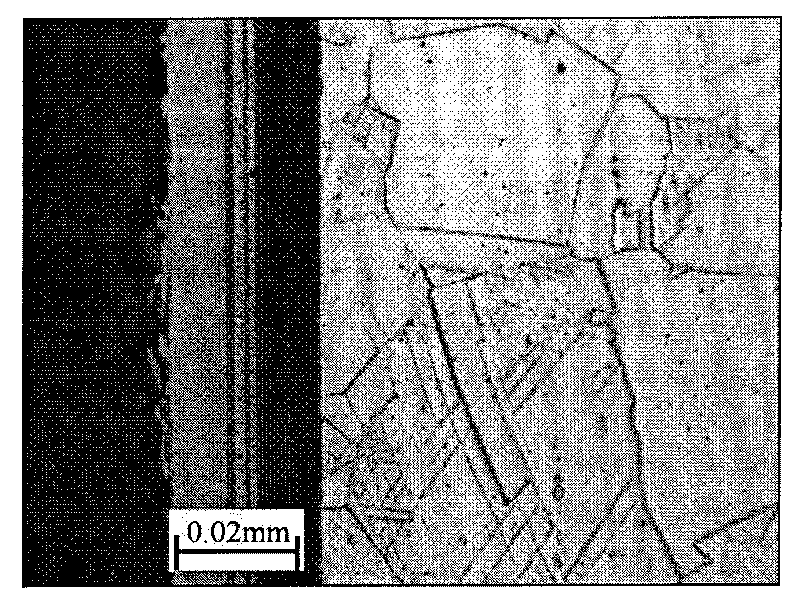

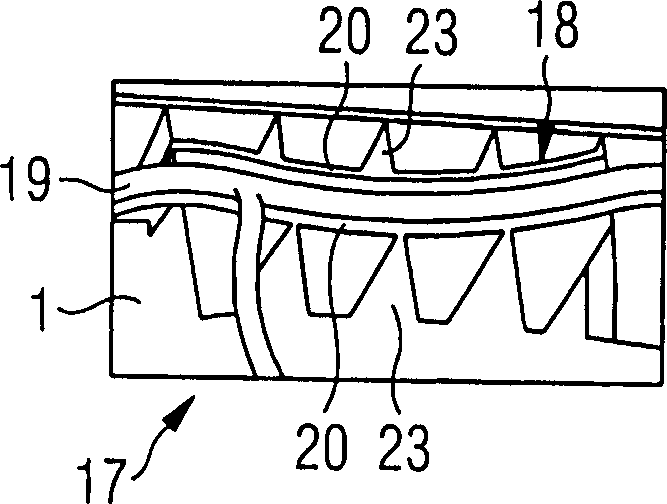

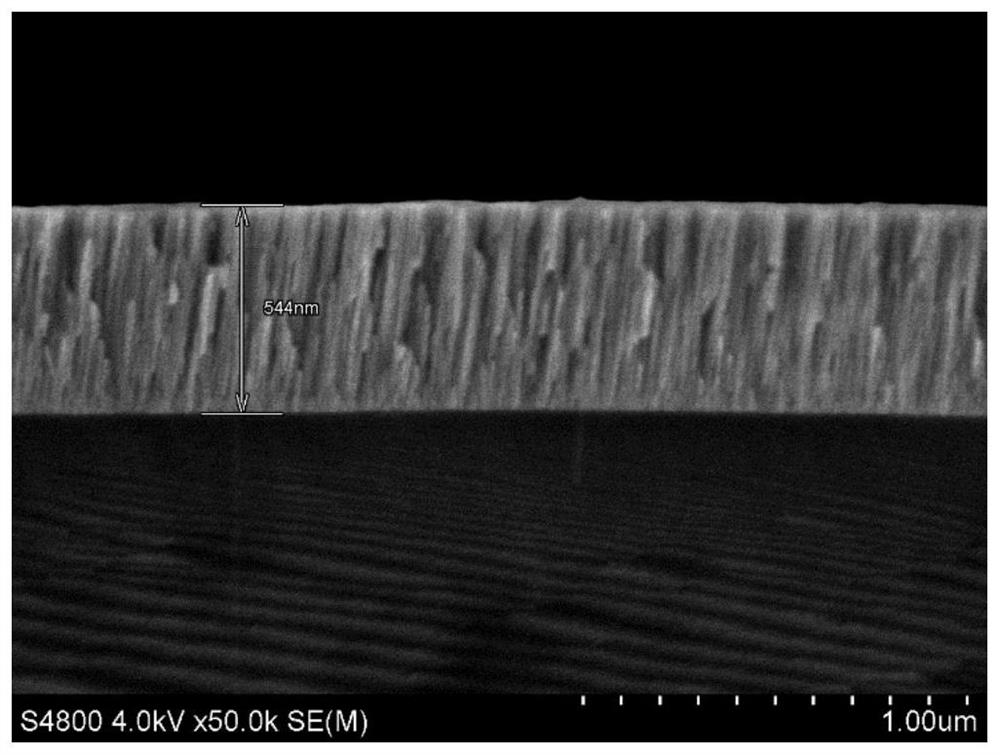

Fuel-cell bipolar plate with nitrified and enhanced surface and preparation method thereof

The invention discloses a fuel-cell bipolar plate with a nitrified and enhanced surface and a preparation method thereof and belongs to the technical field of fuel cells. The bipolar plate is prepared by the following steps of: preparing a nitrified layer, a chromium-nitride thin film and a carbon-based nano composite conductive thin film on the two side surfaces of a matrix of a stainless-steel plate or a titanium-alloy plate in sequence, cleaning and drying the matrix of the stainless-steel plate or the titanium-alloy plate, then putting the matrix in vacuum-arc ion-plating equipment, introducing nitrogen and hydrogen under the vacuum condition, starting bias voltage and hot wires, and preparing the nitrified layer; and introducing argon-nitrogen mixed gas, preparing the chromium-nitride thin film, opening a carbon target and preparing the carbon-based nano composite conductive thin film. The fuel-cell bipolar plate disclosed by the invention has the advantages that an ion nitrification technology is introduced into the field of surface modification of the fuel-cell bipolar plate, and the nitrified layer is prepared on the surface, so that the passivation of the matrix can be avoided, the condition that a coating fails due to corrosion can be effectively prevented; and a stepped transition method is adopted for multi-element composition of the chromium-nitride thin film and the nano composite conductive thin film, so that the peeling of the coating in the use process due to overlarge internal stress and oversmall bonding force is prevented.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

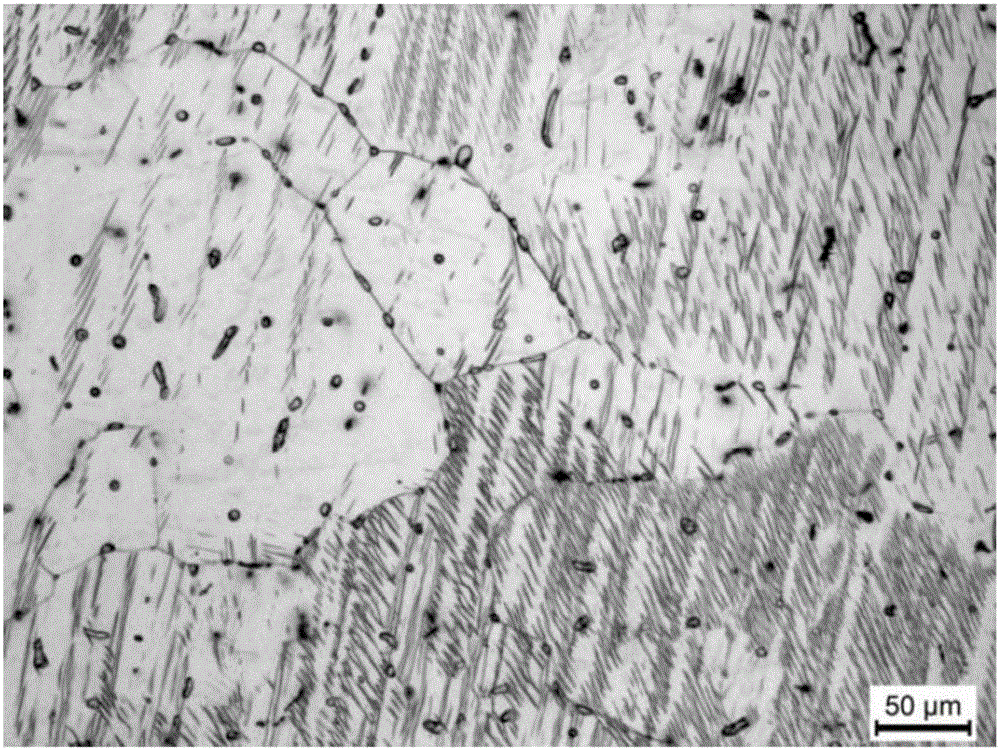

Degradable biomedical Mg-Nd-Sr magnesium alloy as well as preparation method and application thereof

InactiveCN105154735ADegradation without toxic effectGood biocompatibilityBiocompatibility TestingIntravascular stent

The invention belongs to the technical field of biomedical materials and particularly relates to degradable biomedical Mg-Nd-Sr magnesium alloy as well as a preparation method and application thereof. The degradable biomedical Mg-Nd-Sr magnesium alloy comprises the following components in percentage by weight: 1.00-3.00% of Nd, 0.10-3.00% of Sr and the balance of Mg and unavoidable impurity elements. The preparation method of the alloy comprises the thermal treatment technology and the hot extrusion processing technology, Mg, Mg-Nd intermediate alloy and Mg-Sr intermediate alloy are sequentially smelted under the condition of covering agent protection, a refining agent is added for refining after the smelting, and after component detection, casting moulding is performed to obtain cast-condition degradable biomedical Mg-Nd-Sr magnesium alloy. Through reasonable thermal treatment technology and hot extrusion processing technology, polymorphic Mg-Nd-Sr magnesium alloy with excellent biocompatibility and different mechanical properties can be obtained, and the obtained polymorphic Mg-Nd-Sr magnesium alloy can be applicable to orthopaedic implant materials and intravascular stent medical materials of different occasions as demanded.

Owner:SOUTH CHINA UNIV OF TECH

Surface treatment method for improving wear resistance and corrosion resistance of austenitic stainless steel shell

InactiveCN101709463AContent controlImprove bindingLiquid/solution decomposition chemical coatingChemical platingSand-paper

The invention discloses a surface treatment method for improving wear resistance and corrosion resistance of an austenitic stainless steel shell, which comprises the following steps: sanding the austenitic stainless steel shell with sand paper; deoiling, and washing with water to remove residual deoiling solution; and washing with acid to remove the film, activating the surface, washing with cold water and preheating, putting the austenitic stainless steel shell in a prepared plating solution to carry out plating for 1-2 hours, taking out, washing with hot water and cold water alternately to remove the residual plating solution on the sample surface, and finally drying to obtain the plating. The invention adopts the chemical plating technique to obtain the good-quality amorphous Ni-W-P ternary alloy plating on the surface of the austenitic stainless steel shell, thereby obviously improving the wear resistance of the product on the premise that the original silvery color and favorable glossiness of stainless steel are ensured.

Owner:SOUTH CHINA UNIV OF TECH

High petential magnesium alloy sacrificial anode material and its manufacturing method

A high-potential Mg alloy used as consumable anode for the underground oil or gas pipeline, storage tank and water pipe is prepared through micro-alloying the Mg-Mn alloy by Mg-Ca and Mg-RE intermediate alloys, and refining by use of special refining agent to obtain Mg MnRECa alloy, which contains proportionally Mn, Ce, Ca, Si, Cu, Ni, Fe and Mg. Its advantages are high open-circuit potential 1.7-1.8 (-V) and high current efficiency (55-60%).

Owner:TAIYUAN UNIV OF TECH

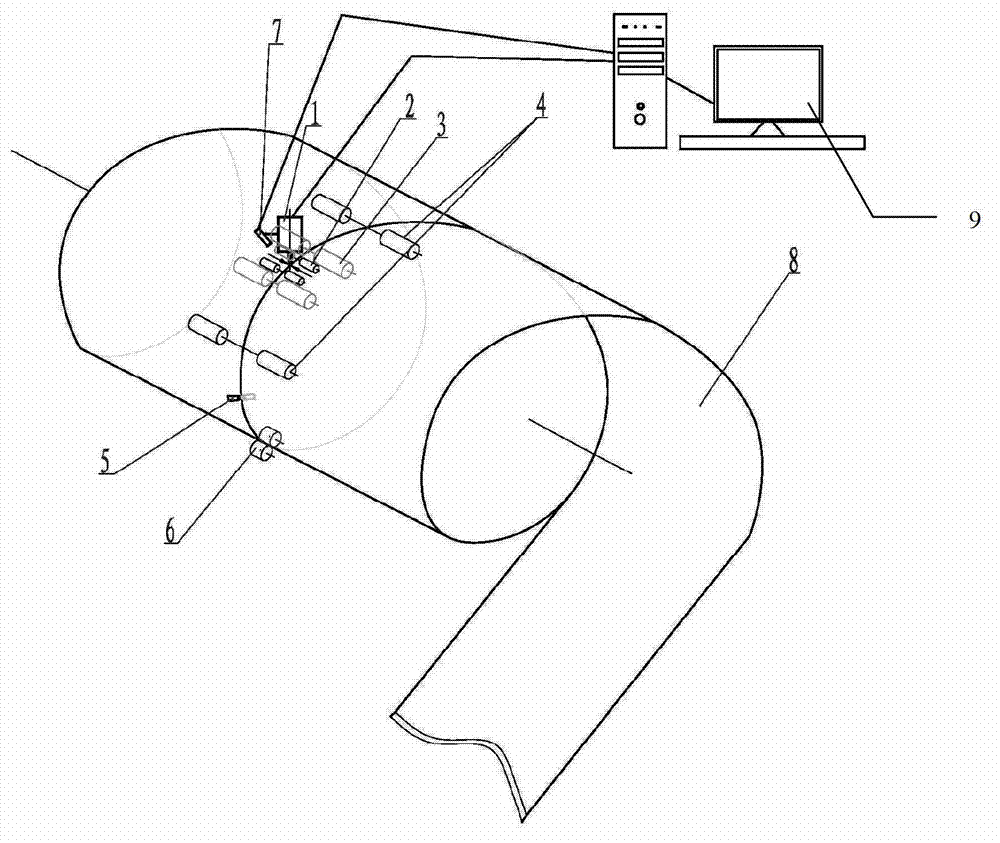

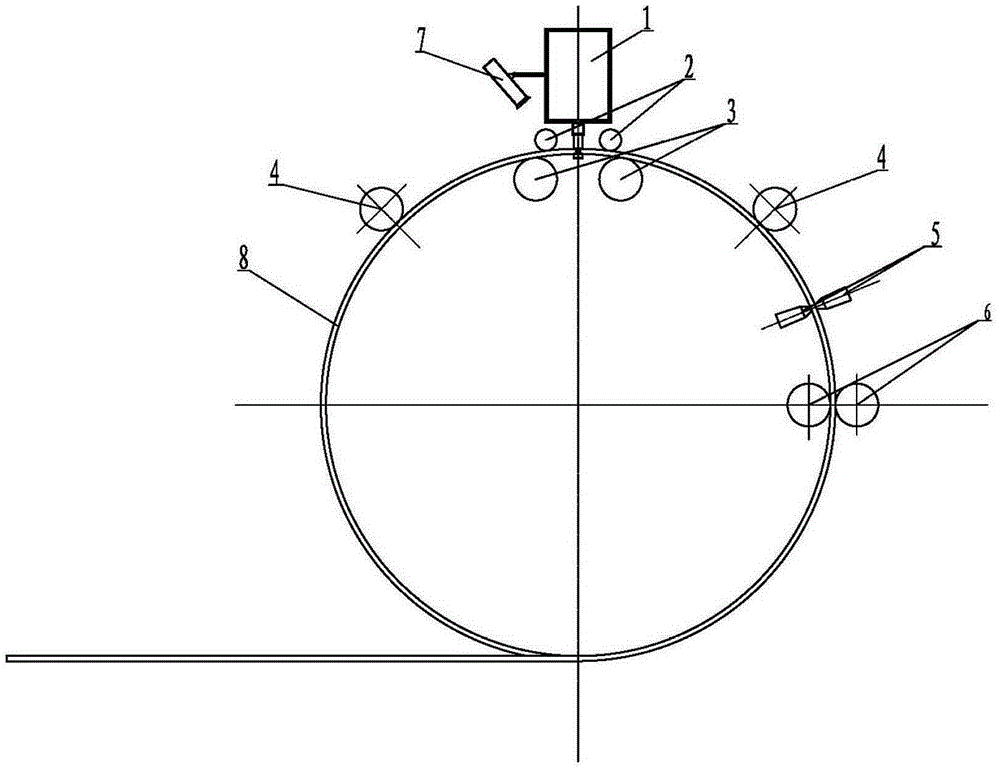

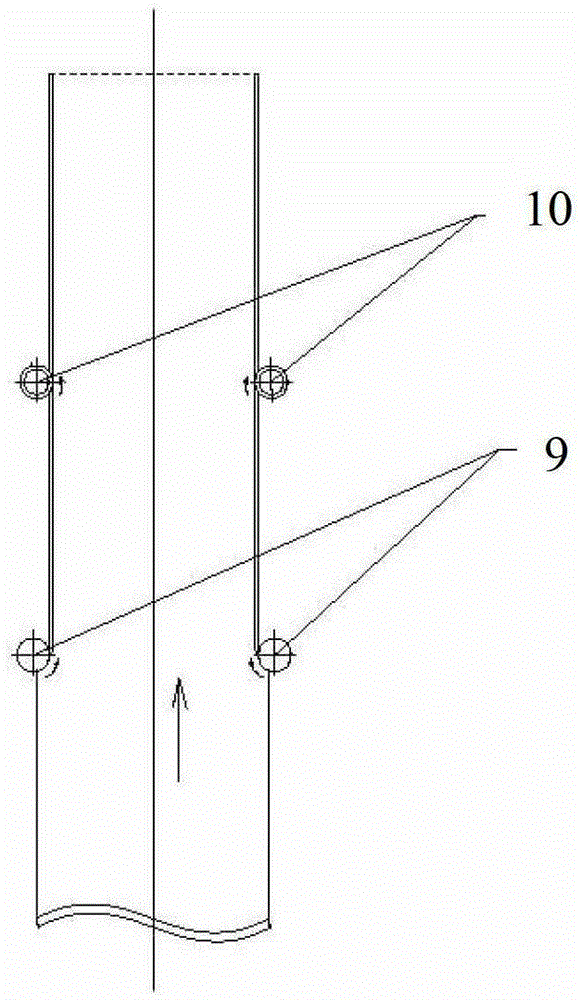

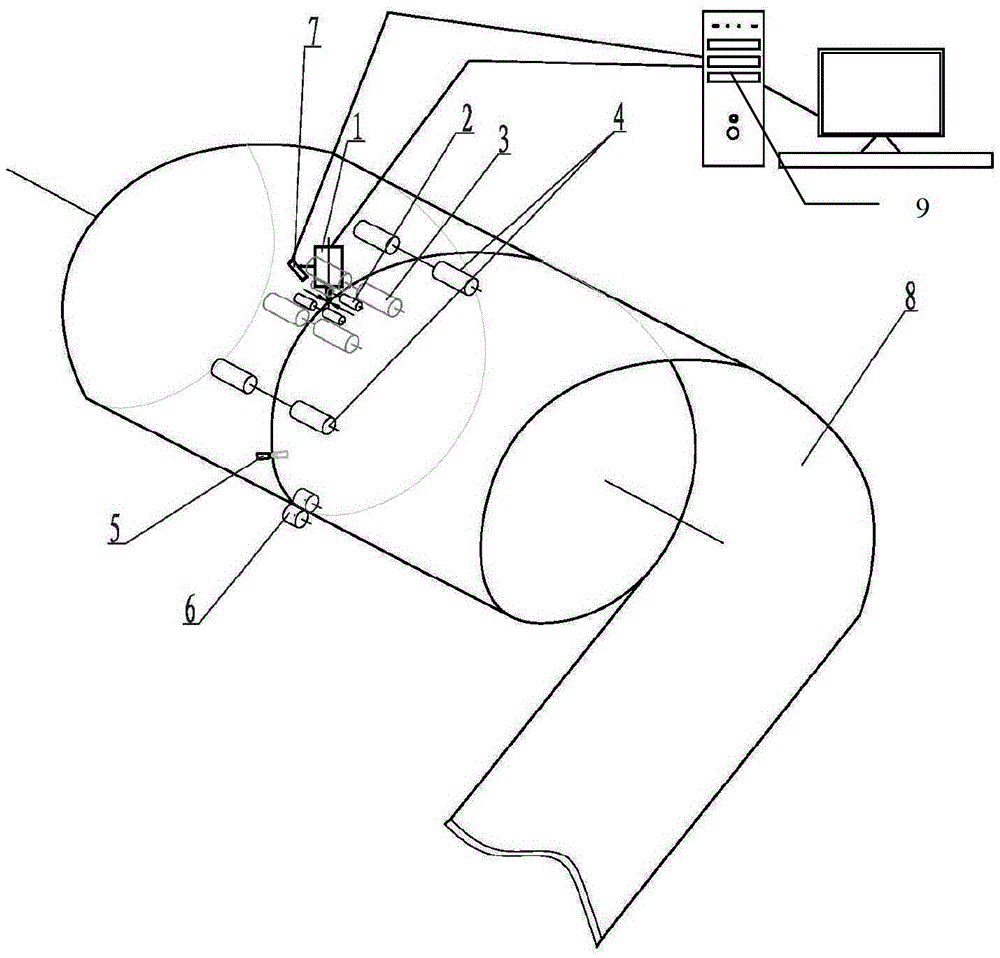

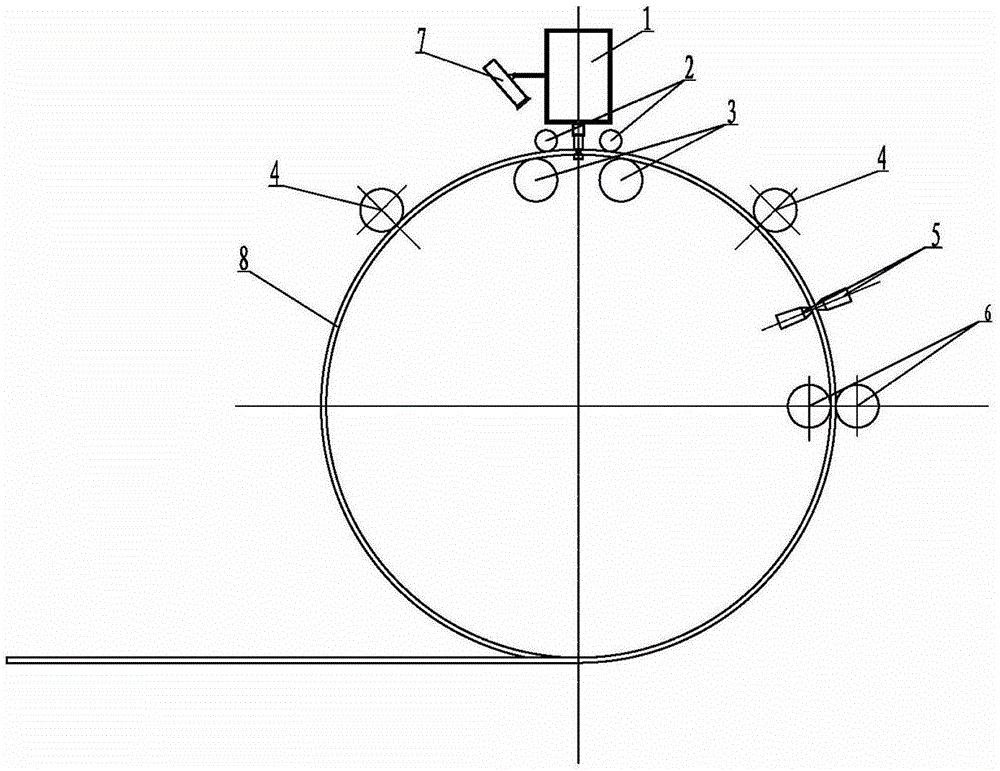

Aluminum and aluminum alloy spiral pipe forming stirring friction welding method

InactiveCN103240571ARealize digital inputRealize remote precise controlWelding/soldering/cutting articlesTubular articlesFriction weldingSeam welding

The invention discloses an aluminum and aluminum alloy spiral pipe forming stirring friction welding method which includes: coiling aluminum and aluminum alloy coiled materials into pipe billets according to preset angles; using rotation roll positioning to align pipe seams, and supporting formed pipe billets to avoid deformation; and using a stirring friction method for pipe seam welding. The method is widely applicable to welding of various grades of aluminum and aluminum alloy spiral pipes and high in efficiency.

Owner:姚雪飞

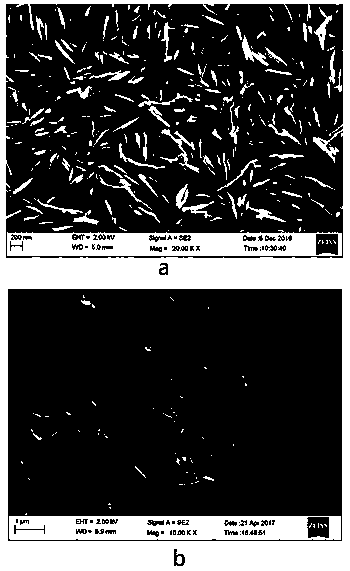

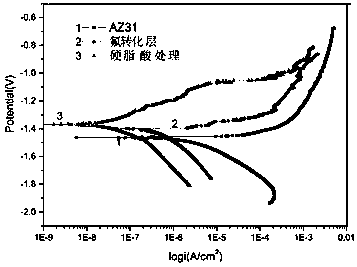

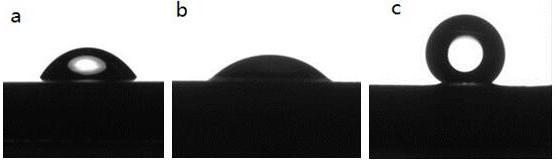

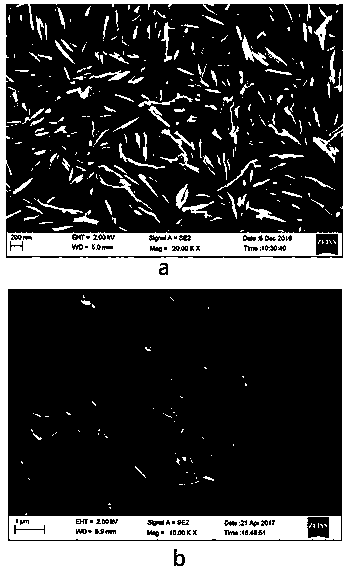

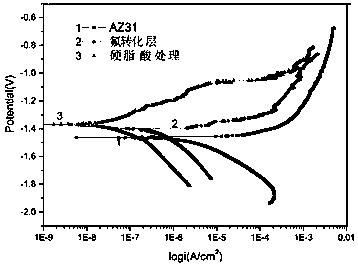

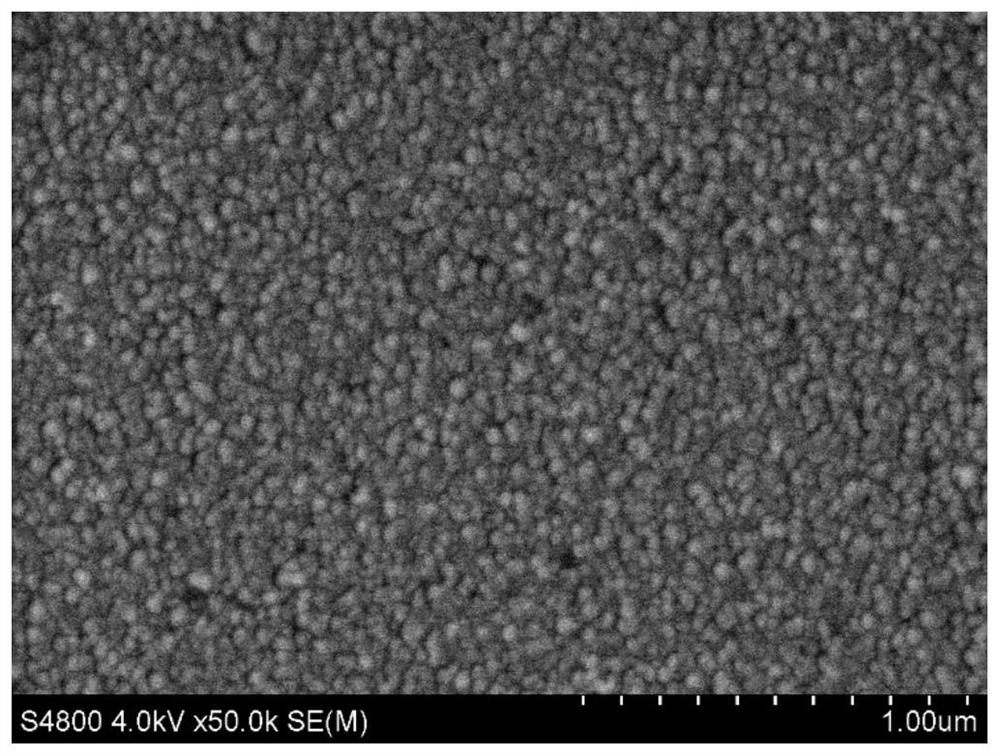

Preparation method of magnesium alloy surface super-hydrophobic fluorine conversion coating

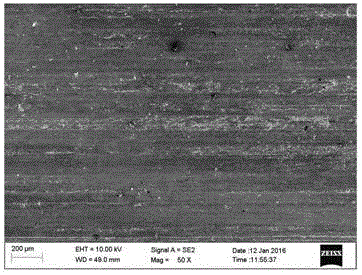

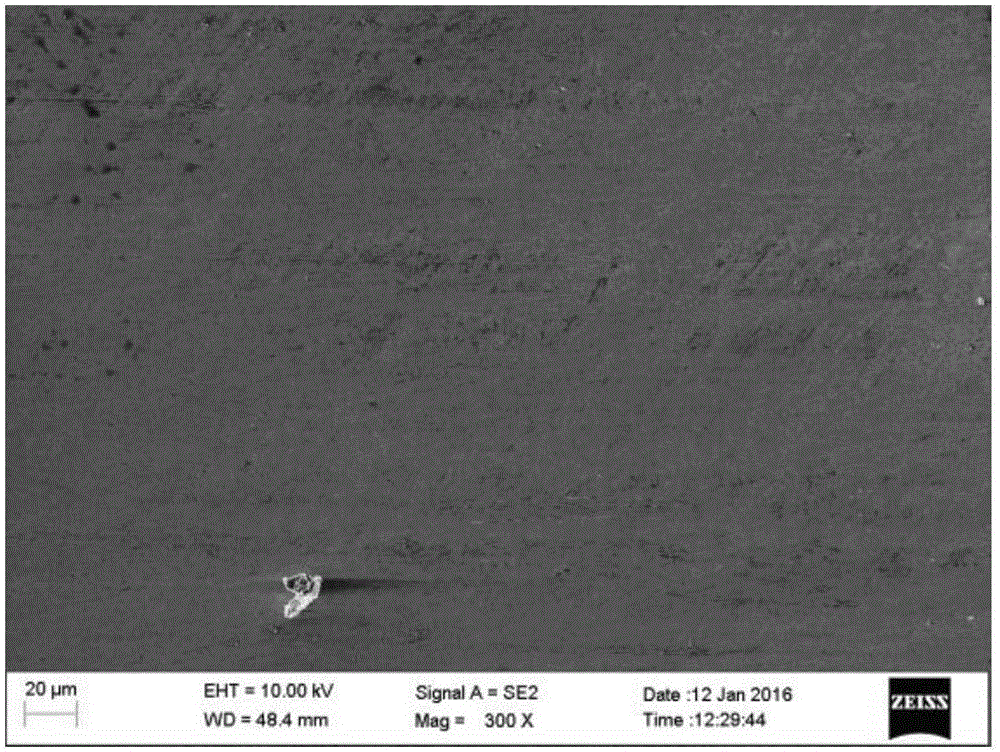

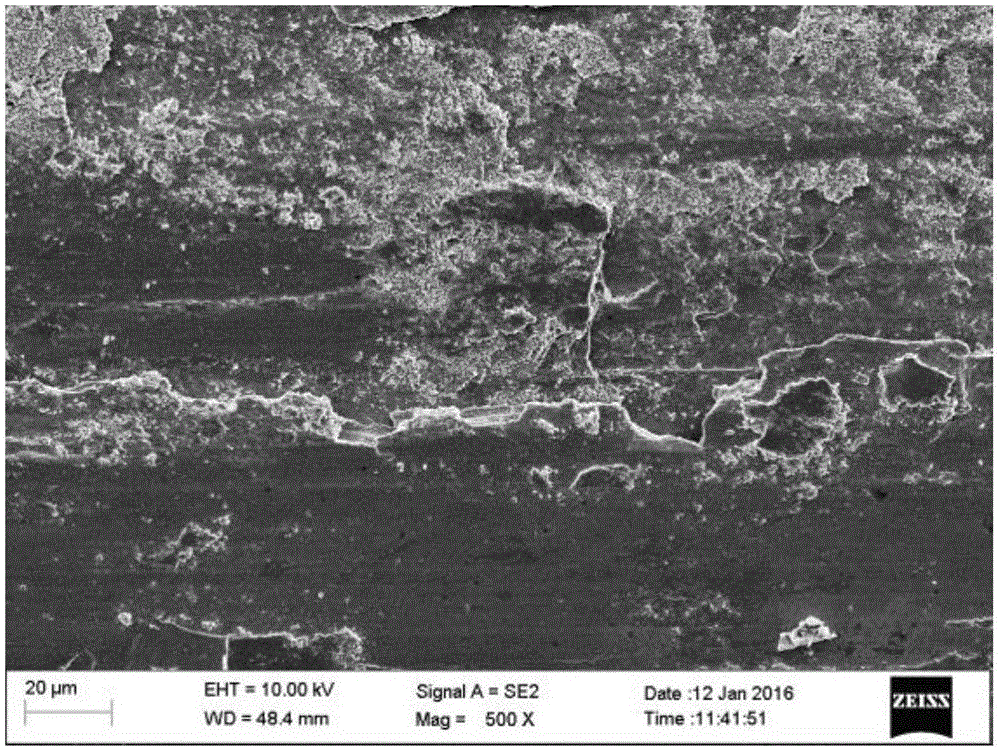

InactiveCN107740083AReduce corrosionLessen the tendency to corrodeMetallic material coating processesNano structuringSimulated body fluid

The invention discloses a preparation method of a magnesium alloy surface super-hydrophobic fluorine conversion coating. The super-hydrophobic fluorine conversion coating of a micro / nano structure isprepared on the surface of a magnesium alloy by the adoption of a liquid-phase growth and hydro-thermal treatment combined method. Through cleaning, polishing, preparation of a fluorine conversion layer and hydrophobization treatment, a porous hydrophobic coating of a micro / nano structure is formed on the film layer. The contact angle of the coating in simulated body fluid reaches 150 degrees, thecontact area between a magnesium alloy sample and the liquid can be reduced, the corrosion current density of the magnesium alloy can be lowered by 3 grades, and the impedance magnitude is increasedfrom 12000 omega.cm<2> to 1400000 Omega.cm<2> and is increased by 100 times. The preparation method of the hydrophobic coating of the nano-structure is simple, equipment is simple and easy to control,cost is low, and the controllability is good.

Owner:CHONGQING UNIV OF TECH

Composite coating material based on 45# steel substrate and preparing method of coating

InactiveCN105803454AImprove wear and corrosion resistanceThe preparation process can be completed under normal environment, and the preparation process is simpleMetallic material coating processesWear resistanceHeat treated

The invention discloses a composite coating material based on a 45# steel substrate and a preparing method of a coating. The coating comprises, by weight percent, 0% to 10% of WC powder, 0% to 1% of Y2O3 powder, and the balance 304 stainless steel powder. The WC powder, the Y2O3 powder and the 304 stainless steel powder which are prepared according to the ratio are mixed and are added into a ball milling tank together with ball milling media, and after ball milling is carried out for 4h to 6h, mixed powder is obtained; the mixed powder is subject to drying treatment under the vacuum environment, and the coating material is obtained; the surface of the 45# steel substrate is ground to be flat; a dedicated powder preset tool is used for flatly laying the coating material on the surface of the 45# steel substrate; and finally, laser heat treatment equipment is used for carrying out laser cladding on the material, and the coating is obtained. The obtained coating has the good wear resistance, and higher corrosion resistance, the preparing technology is simple, the cost is low, and batch production is easily achieved.

Owner:GUIZHOU UNIV

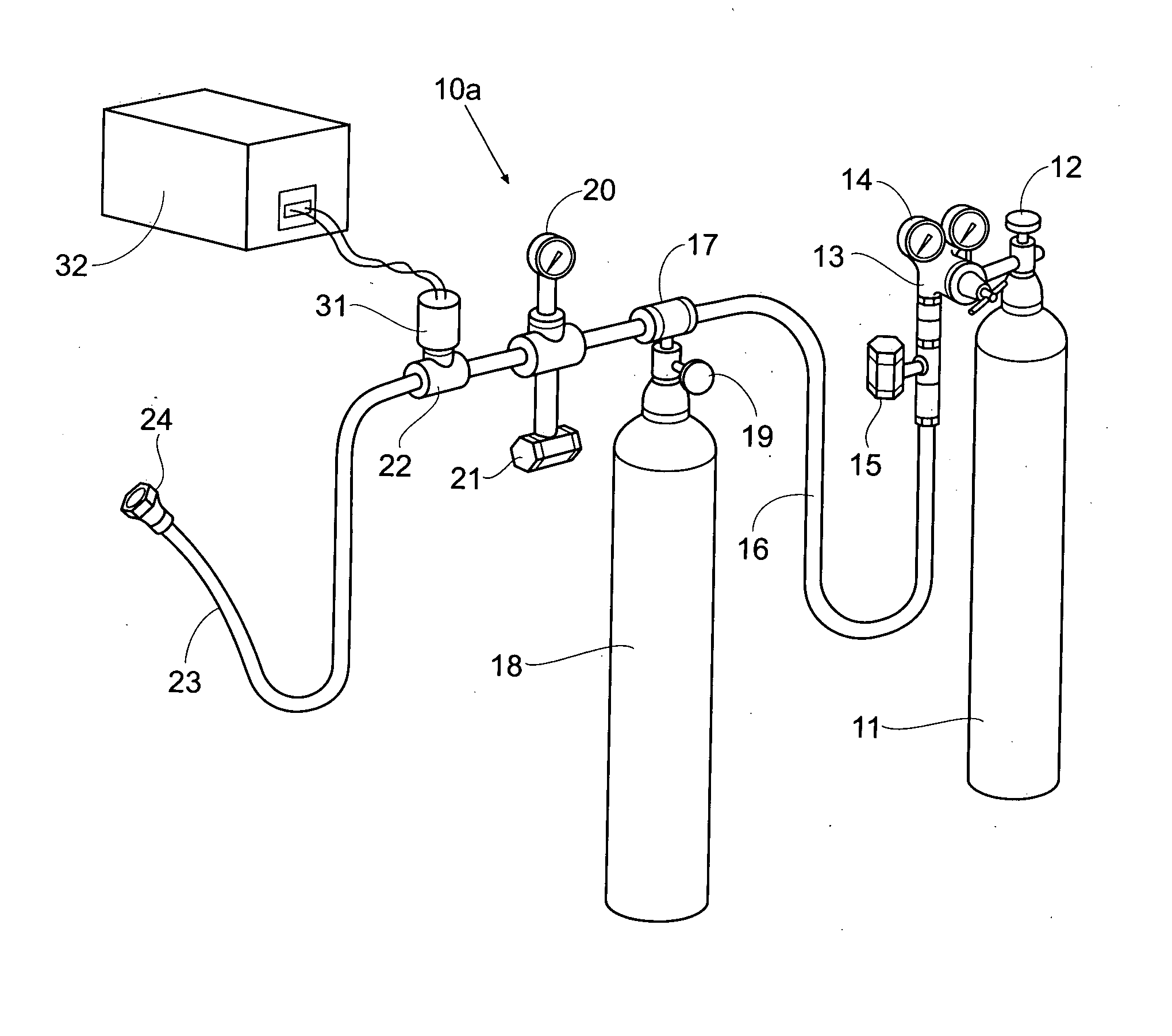

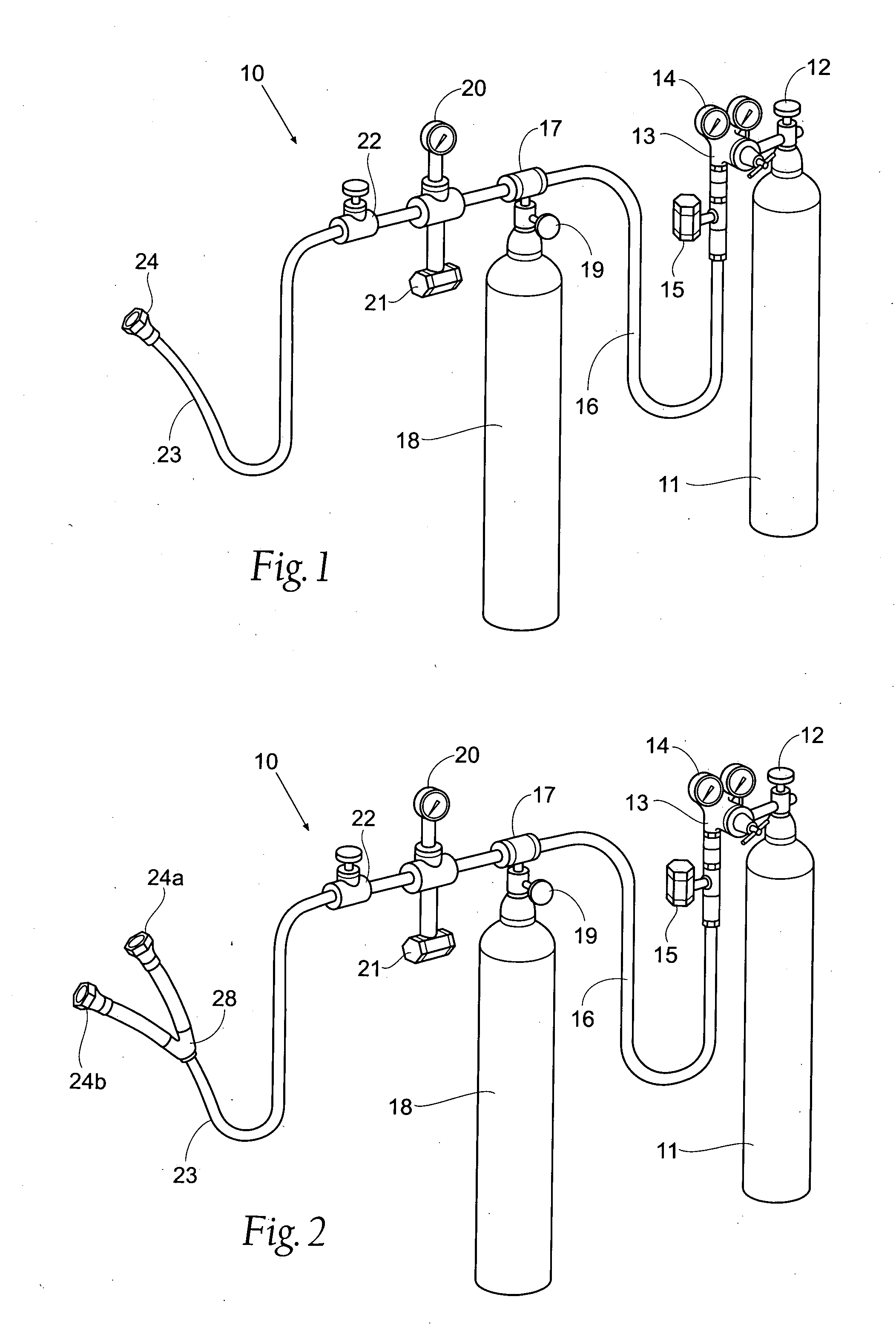

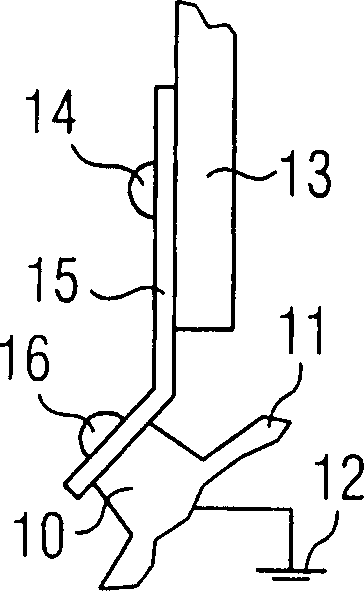

Marine engine corrosion prevention system

InactiveUS20050067045A1Easy to practiceLessen the tendency to corrodeLiquid coolingLiquid fillingWater vaporEngineering

An apparatus and method for prevention of corrosion with the cooling system of an internal combustion engine is disclosed. The apparatus includes a pressurized inert gas source and a fluid delivery system whereby the gas is dispersed within the cooling system to expel corrosion inducing fluids such as oxygen and water vapor. Methods of use are also disclosed.

Owner:IBM CORP

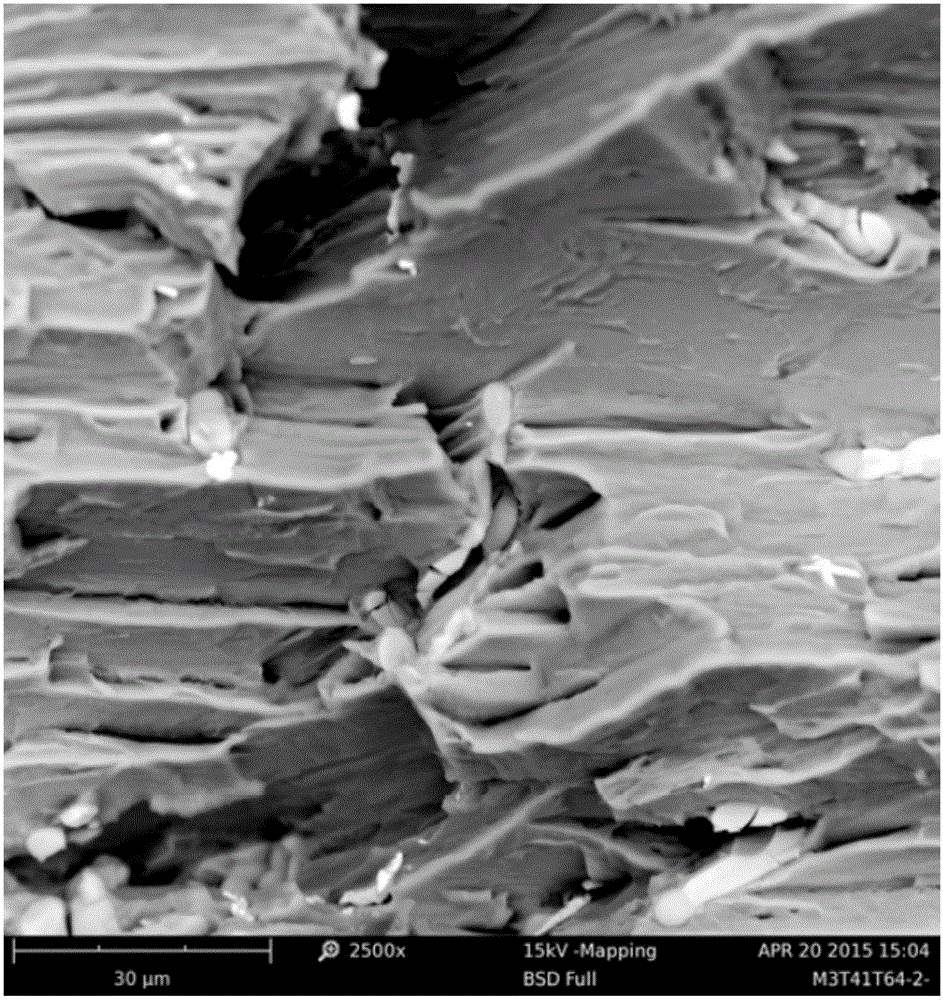

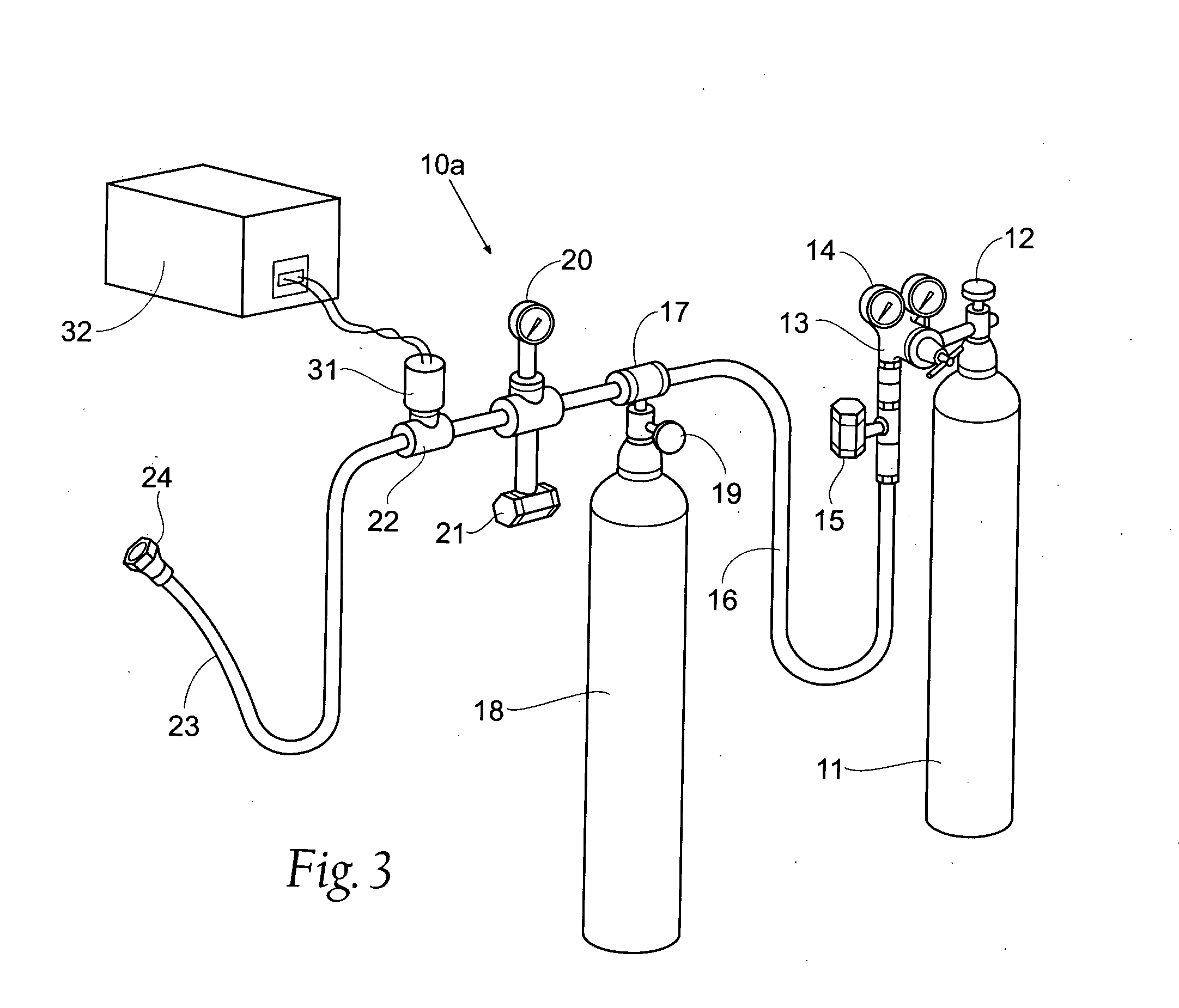

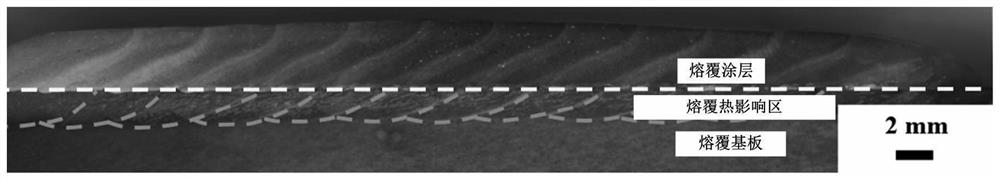

Iron-based alloy powder, laser cladding coating and preparation method of iron-based alloy powder

PendingCN114411056AHigh thermodynamic affinityRetain plasticityMetallic material coating processesCrack resistanceWear resistance

The invention discloses iron-based alloy powder, a laser cladding coating and a preparation method of the iron-based alloy powder and the laser cladding coating. The iron-based alloy powder is composed of, by mass, 1.5%-3.0% of C, 0.5%-1.5% of Si, 16%-18% of Cr, 1%-4% of Ni, 1%-3% of Mo, 0.2%-1% of Mn, 0.2%-1% of the total amount of Nb and V and the balance Fe. According to the invention, the laser cladding coating is formed by adopting the iron-based alloy powder and a laser cladding process, so that good balance of wear resistance, corrosion resistance and cracking resistance can be realized.

Owner:上交(徐州)新材料研究院有限公司 +2

Mg-Mn-Ca-Zn-Sr sacrificial anode with high current efficiency

The invention discloses an Mg-Mn-Ca-Zn-Sr sacrificial anode with high current efficiency, which belongs to the technical field of sacrificial anodes and is characterized by comprising the following elements in percentage by weight: 0.93 percent of Mn, 0.13 percent of Ca, 0.05 percent of Zn, 0.07 percent of Sr, less than 0.045 percent of Si, less than 0.018 percent of Cu, less than 0.001 percent ofNi, less than 0.030 percent of Fe, and the balance of Mg. Aiming at the defect that the conventional magnesium anode has low current efficiency, by adding trace elements, the dissolution evenness andcorrosion resistance of the magnesium anode are increased, and the current efficiency of the magnesium anode is improved.

Owner:山东宏泰科技有限公司

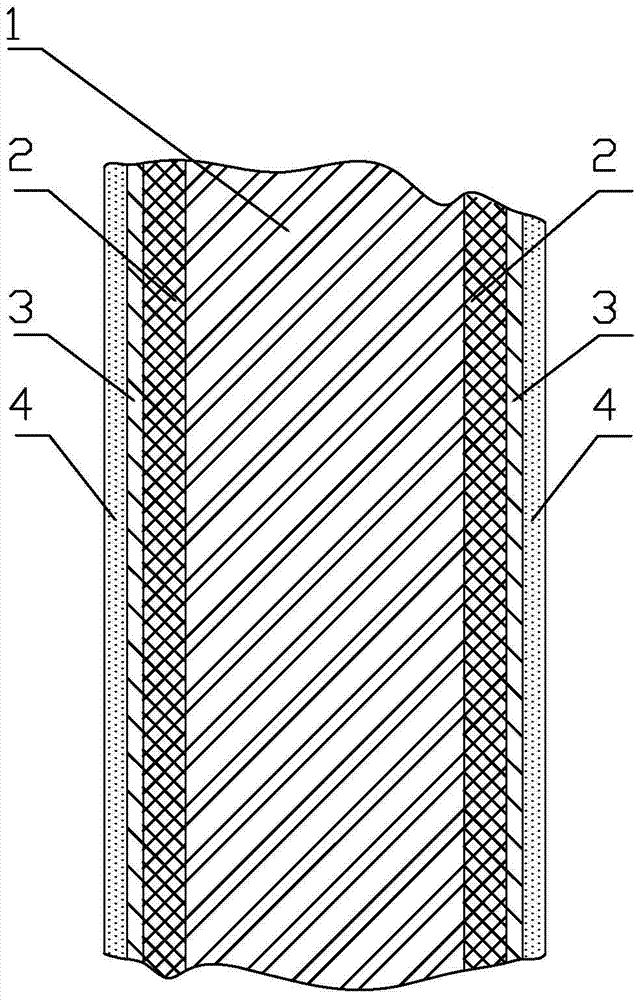

Anti-corrosion method of nickel-based alloy heating tube

InactiveCN102212809AReduced tendency to corrodeLessen the tendency to corrodeLiquid surface applicatorsSolid/suspension decomposition chemical coatingPolyethylene glycolAlloy

The invention discloses an anti-corrosion method of a nickel-based alloy heating tube, belonging to the anti-corrosion technical field. The method comprises the following steps of: polishing the nickel-based alloy heating tube matrix to No.800 by using abrasive paper, cleaning by using de-ionized water and alcohol in sequence and drying; uniformly mixing PEG200 (Polyethylene Glycol 200), PEG20000, TEOS (Tetraethyl Orthosilic), HCl and H2O in a mole ratio of (0.00293-0.0066):(0.0022-0.00587):0.1:13:100; reacting in a sealed way at 80 degrees centigrade for 3 h; aging for 3 d for later use; immersing the processed matrix in the prepared solution; lifting at constant speed of 10 cm / min; putting a sample in a muffle furnace; increasing temperature to 540 degrees centigrade at a speed of 2 degrees centigrade per minute; keeping temperature for 10 h; and naturally cooling to obtain a silicon dioxide film. The method disclosed by the invention has a simple process and good controllability. The prepared silicon dioxide film is compact and uniform and does not contain pores and bubbles.

Owner:BEIJING UNIV OF CHEM TECH

Method for inhibiting metallic corrosion

InactiveCN101100744APrevent oxidationAvoid corrosionMetallic material coating processesCorrosion reactionSubstrate surface

A process for preventing metal from corrosion is used to substrate materials containing metals is carried out by: making the substrate surfaces contacting with reacting solution that is mixed with ozone to form oxidized layer on the said substrate surfaces so as to stop oxidation and corrosion furthermore. The reacting solution can be regulated in some parameters, e.g. oxidation reduction performance, pH value, etc. to change corrosive reactivity of the reacting solution.

Owner:IND TECH RES INST

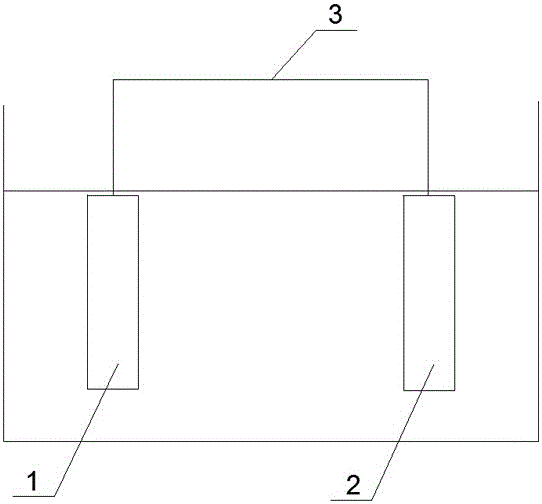

Method for inhibiting corrosion of hydraulic steel structural part by adopting strong electrolyte solution

The invention discloses a method for inhibiting corrosion of a hydraulic steel structural part by adopting a strong electrolyte solution. The method comprises the specific steps that 1, strong electrolyte is added into a solution in which the hydraulic steel structural part is located till the conductivity of the water solution is larger than 20000 microseconds per centimeter, and then the protected hydraulic steel structural part and a titanium anode are connected through a wire to form a closed loop; 2, after a period of time of polarization, the electric potential of the hydraulic steel structural part is measured; and 3, if the surface electric potential of the hydraulic steel structural part is lower than -0.85 V, it is indicated that corrosion of the hydraulic steel structural part is inhibited; if the surface electric potential of the hydraulic steel structural part is higher than -0.85V, the steps 1 and 2 are executed again till the surface electric potential is lower than -0.85V; and the strong electrolyte is strong acid and strong alkali salt. By the adoption of the method for inhibiting corrosion of the hydraulic steel structural part by adopting the strong electrolyte solution, metal can be prevented from continuing to be oxidized and corroded, the corrosion characteristic of the solution can be further changed by adjusting the conductivity of the reaction solution in which metal is located, and metal corrosion tendency is relieved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

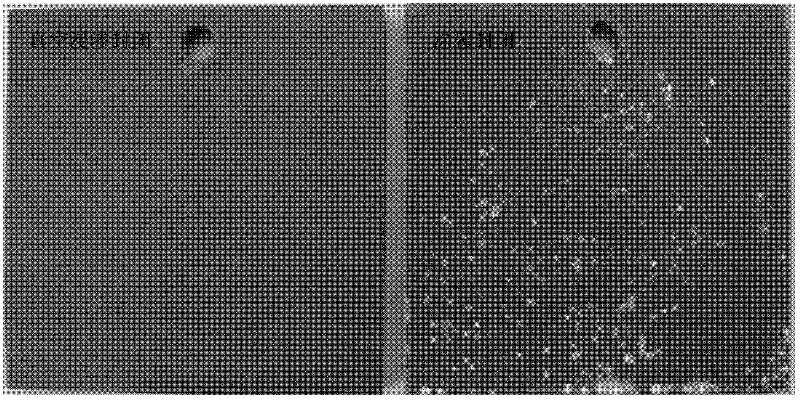

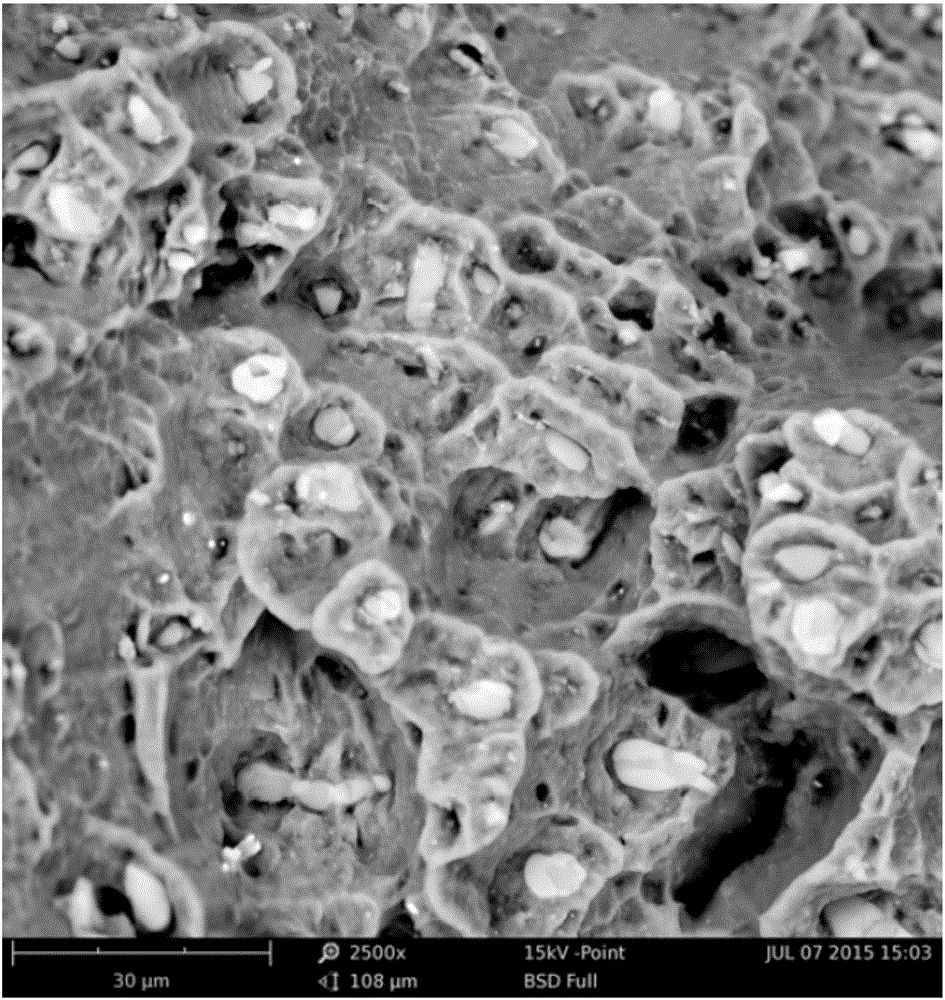

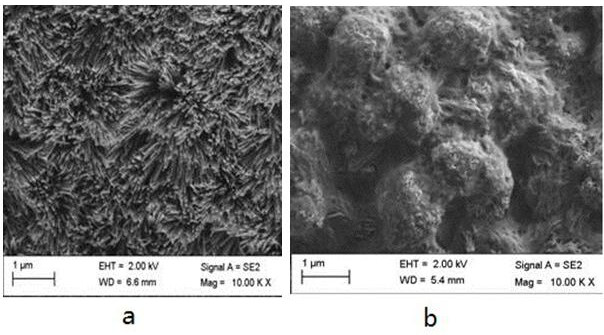

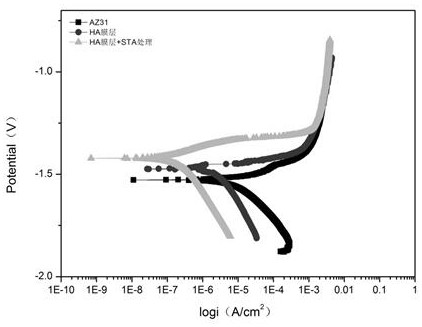

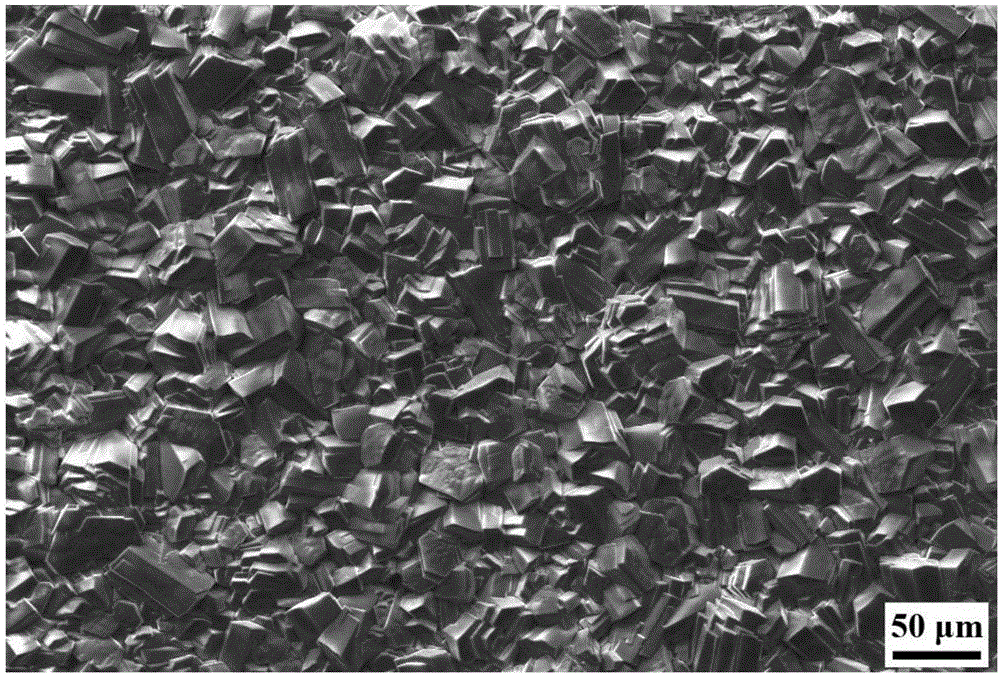

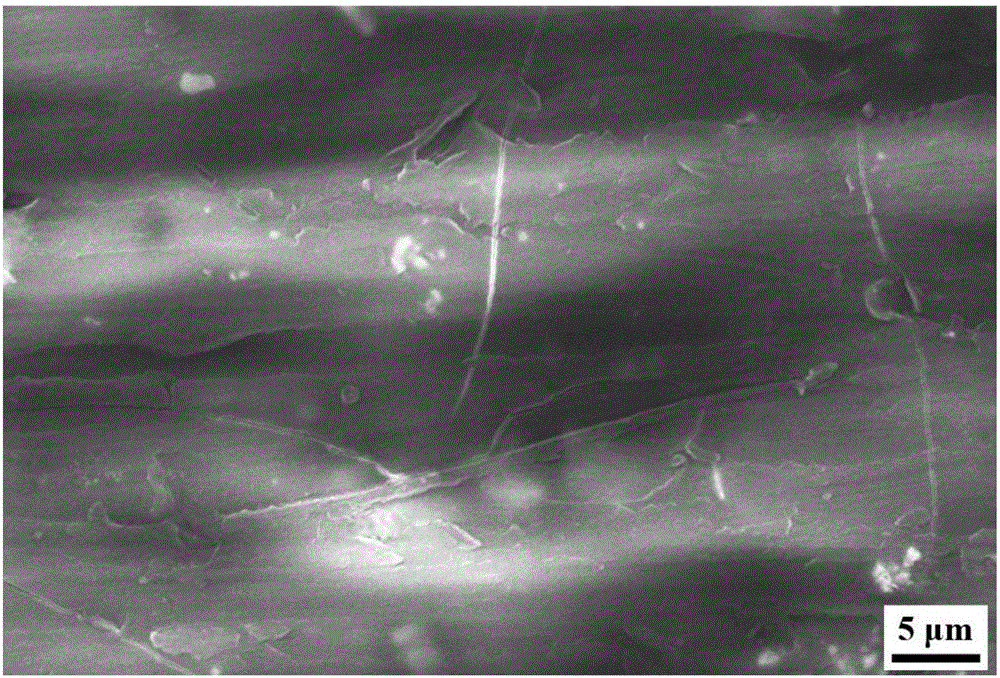

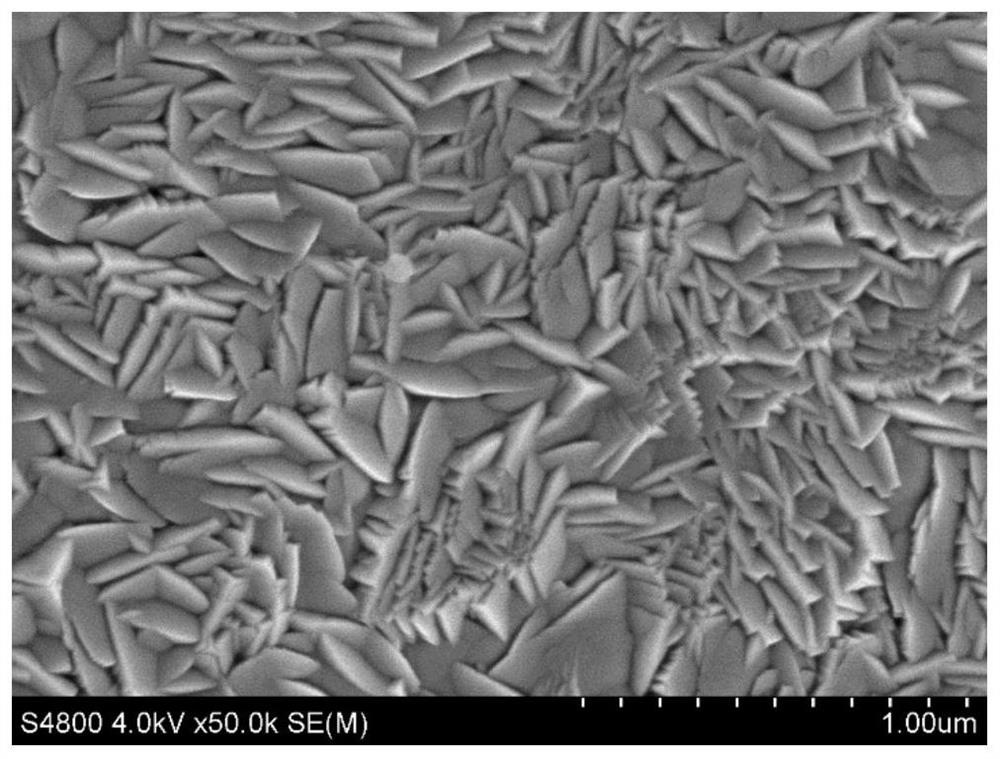

A kind of preparation method of superhydrophobic hydroxyapatite film layer on magnesium alloy surface

InactiveCN107789665BReduce corrosionLessen the tendency to corrodePharmaceutical delivery mechanismLiquid/solution decomposition chemical coatingStearic acidNanostructure

The invention provides a preparation method of a superhydrophobic hydroxyapatite film layer on the surface of magnesium alloy. The preparation method comprises the following steps: performing surfacepretreatment, preparing a nano-structured hydroxyapatite layer by a hydrothermal method and performing hydrophobization treatment to the hydroxyapatite layer. The hydrothermal method is designed, andby the hydrothermal method, a rod-shaped hydroxyapatite crystal layer adopting micron-scale length and nano-scale diameter is prepared on the surface of the magnesium alloy, then a stearic acid film is prepared on the surface of the nano-structured hydroxyapatite film layer to form a superhydrophobic film layer with the contact angle of 153 degrees under a static droplet, the film layer can reducethe corrosion current density of the magnesium alloy by 2 orders of magnitude and the impedance modulus of coating is increased from 2029 Omega.cm2 to 117674 Omega.cm2. The preparation method of thenano-structured hydrophobic coating is simple, equipment is simple and easy to control, the cost is low, and the controllability is good; the preparation method is suitable for large-scale production.

Owner:CHONGQING UNIV OF TECH

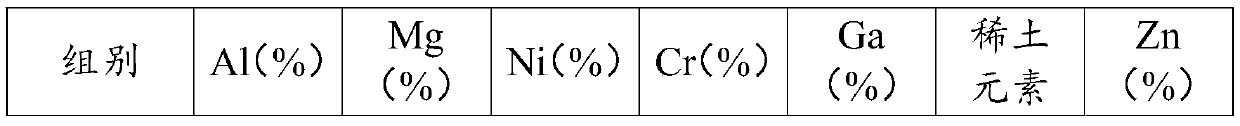

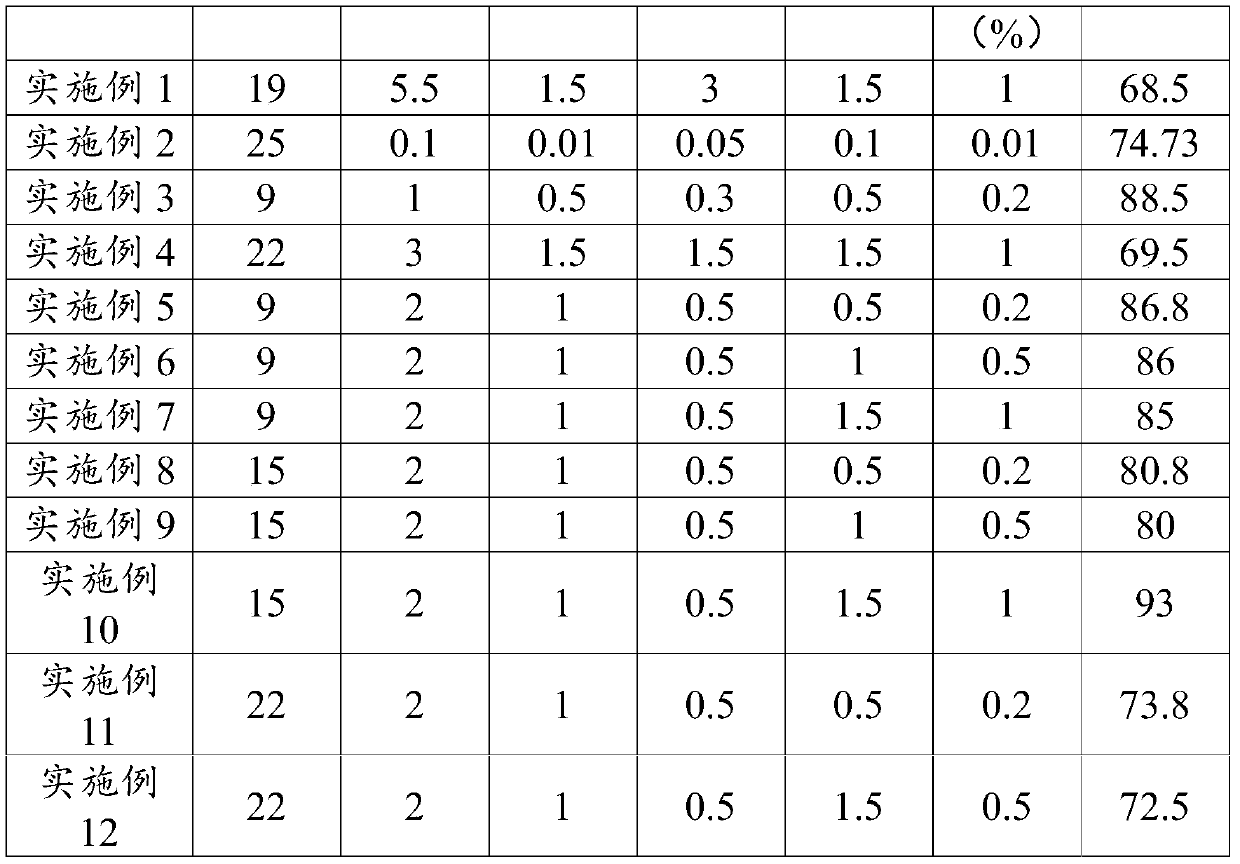

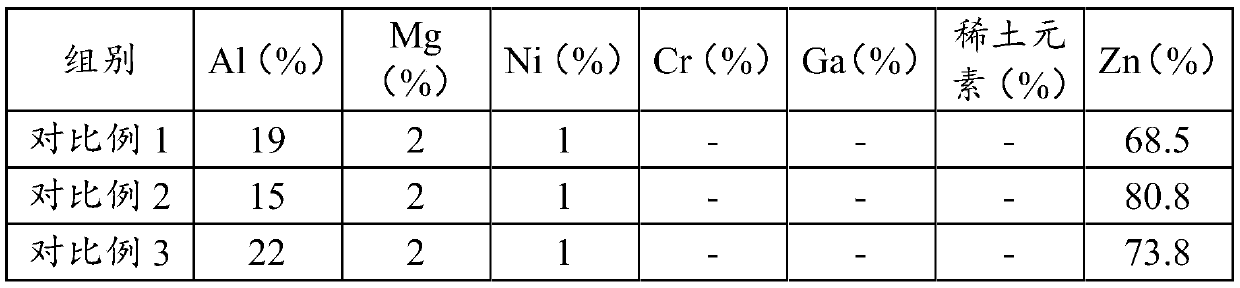

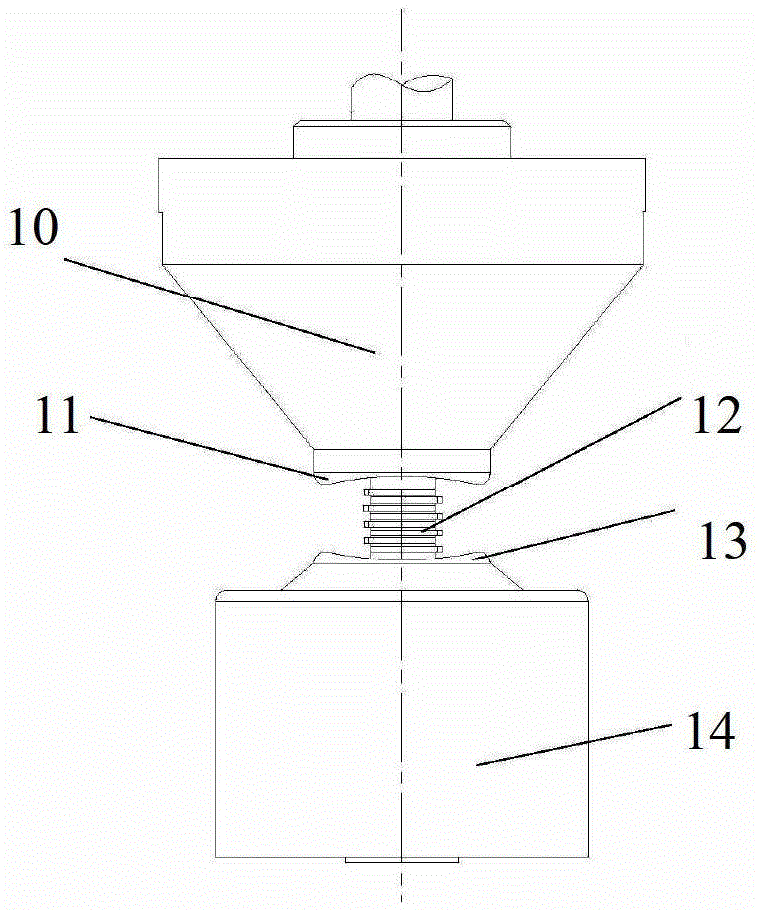

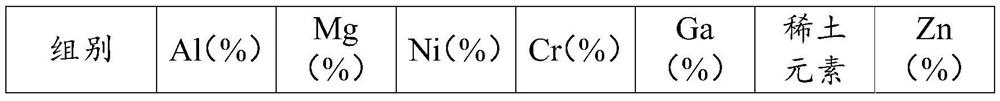

Brazing filler metal alloy, brazing filler metal, preparation method and application of brazing filler metal alloy, preparation method and application of brazing filler metal and prepared brazing product

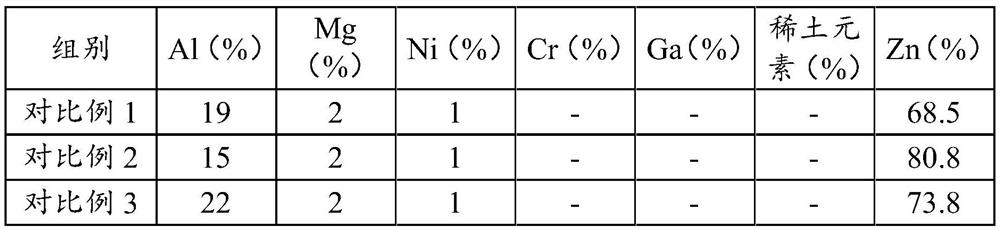

ActiveCN111545948ARealize large-scale industrial productionShort processWelding/cutting media/materialsSoldering mediaRare-earth elementElectrode potential

The invention provides a brazing filler metal alloy, brazing filler metal, a preparation method and application of the brazing filler metal alloy, a preparation method and application of the brazing filler metal and a prepared brazing product, and relates to the technical field of welding materials. On the basis of traditional Zn-Al based brazing filler metal, the brazing filler metal alloy is prepared by adding Mg, Ni, Cr, Ga and rare earth elements according to the specific component proportion. In the brazing filler metal alloy, the strength of the brazing filler metal can be improved through Ni; the electrode potential of the brazing filler metal can be improved through Mg; by means of Cr, a compact oxidization film can be formed, and the corrosion rate can be reduced; by means of Ga,the adhesion of corrosion products can be improved, so that the surface of the brazing filler metal is evenly covered with the corrosion products, and the exposed area of the brazing filler metal is reduced; and by means of the rare earth elements, grains can be refined, the interface can be purified, and the intergranular corrosion tendency can be reduced. Through the reasonable proportion between the components, the synergistic interaction function can be achieved, the brazing strength of the brazing filler metal is improved, it is guaranteed that the brazing filler metal has good corrosionresistance, and the existing process need of aluminum-copper material brazing connection can be met fully.

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

Ionic liquid containing divalent cation and monovalent anion and lubricant composition comprising same

ActiveUS20210087490A1Improve wear resistance and corrosion resistanceLessen the tendency to corrodeAmino preparation from aminesOrganic compound preparationSulfonatePhosphonium

Disclosed are an ionic liquid, having wear resistance maintained at low temperatures and containing a divalent cation including at least one of bis(ammonium) and bis(phosphonium) and a monovalent anion including at least one of sulfonate and phosphate, and a lubricant composition including the ionic liquid.

Owner:SK INNOVATION CO LTD

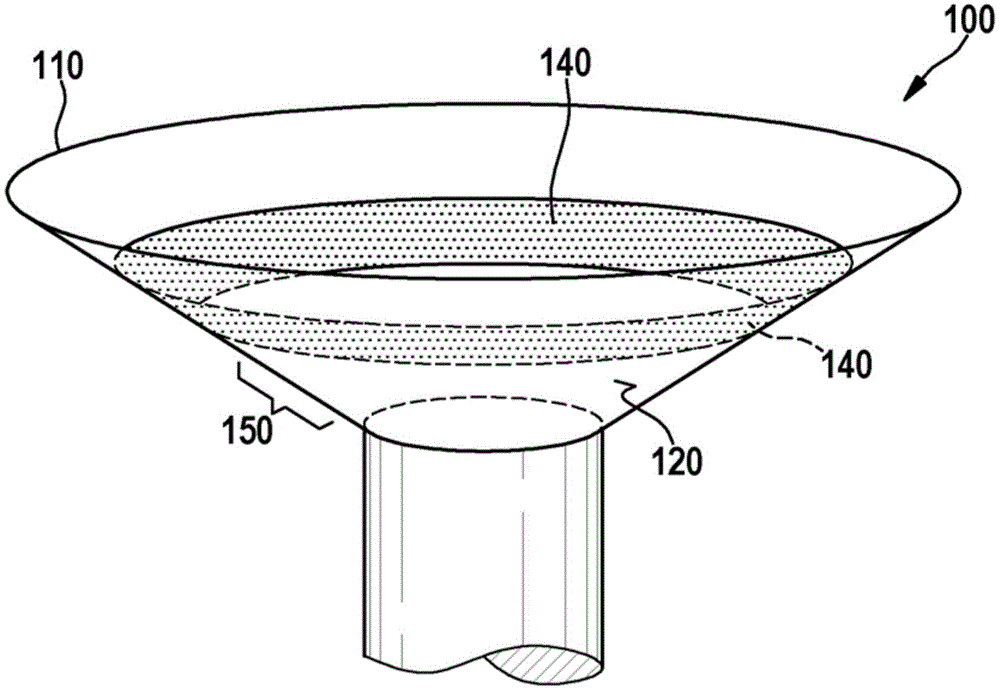

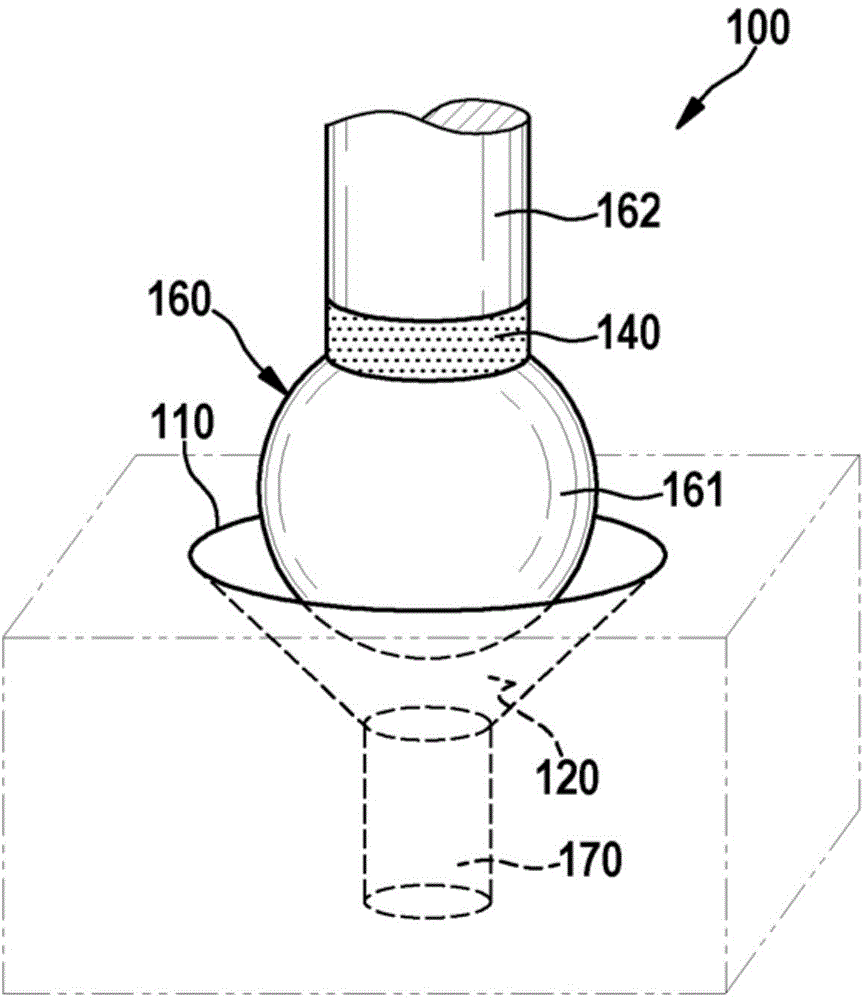

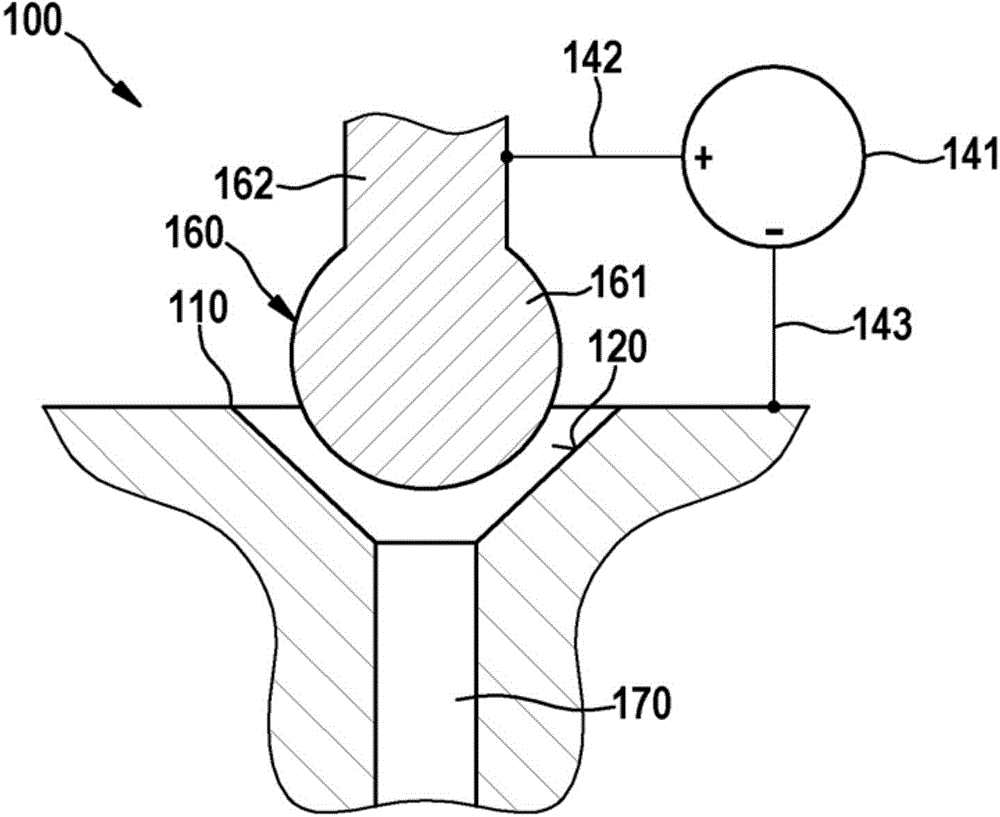

Component of a fuel injection system

InactiveCN104870804AImprove corrosion resistanceExtended service lifeCorrosion preventing fuel injectionFuel injecting pumpsAlloyMetal

The invention relates to a component (100) with at least two subcomponents made of metal. According to the invention, an alloy layer (140) is applied to the surface of a valve funnel (110) functioning as the subcomponent in a valve (100) functioning as the component, wherein the alloy layer (140) is made from a metal less noble than the valve funnel (110). The alloy layer (140) is arranged on a portion of the valve funnel (110) which is situated outside the direct mechanical action region (150) of the closing member (160) functioning as the second subcomponent, and is arranged as an annular portion running around the surface of the valve funnel (110), outside the mechanical action region of the closing member (160) relative to the closing member (160) resting in the valve seat (120) of the valve funnel in the closed state.

Owner:ROBERT BOSCH GMBH

A preparation method of superhydrophobic fluorine conversion coating on the surface of magnesium alloy

InactiveCN107740083BReduce corrosionLessen the tendency to corrodeMetallic material coating processesMicro nanoFluid phase

The invention discloses a preparation method of a magnesium alloy surface super-hydrophobic fluorine conversion coating. The super-hydrophobic fluorine conversion coating of a micro / nano structure isprepared on the surface of a magnesium alloy by the adoption of a liquid-phase growth and hydro-thermal treatment combined method. Through cleaning, polishing, preparation of a fluorine conversion layer and hydrophobization treatment, a porous hydrophobic coating of a micro / nano structure is formed on the film layer. The contact angle of the coating in simulated body fluid reaches 150 degrees, thecontact area between a magnesium alloy sample and the liquid can be reduced, the corrosion current density of the magnesium alloy can be lowered by 3 grades, and the impedance magnitude is increasedfrom 12000 omega.cm<2> to 1400000 Omega.cm<2> and is increased by 100 times. The preparation method of the hydrophobic coating of the nano-structure is simple, equipment is simple and easy to control,cost is low, and the controllability is good.

Owner:CHONGQING UNIV OF TECH

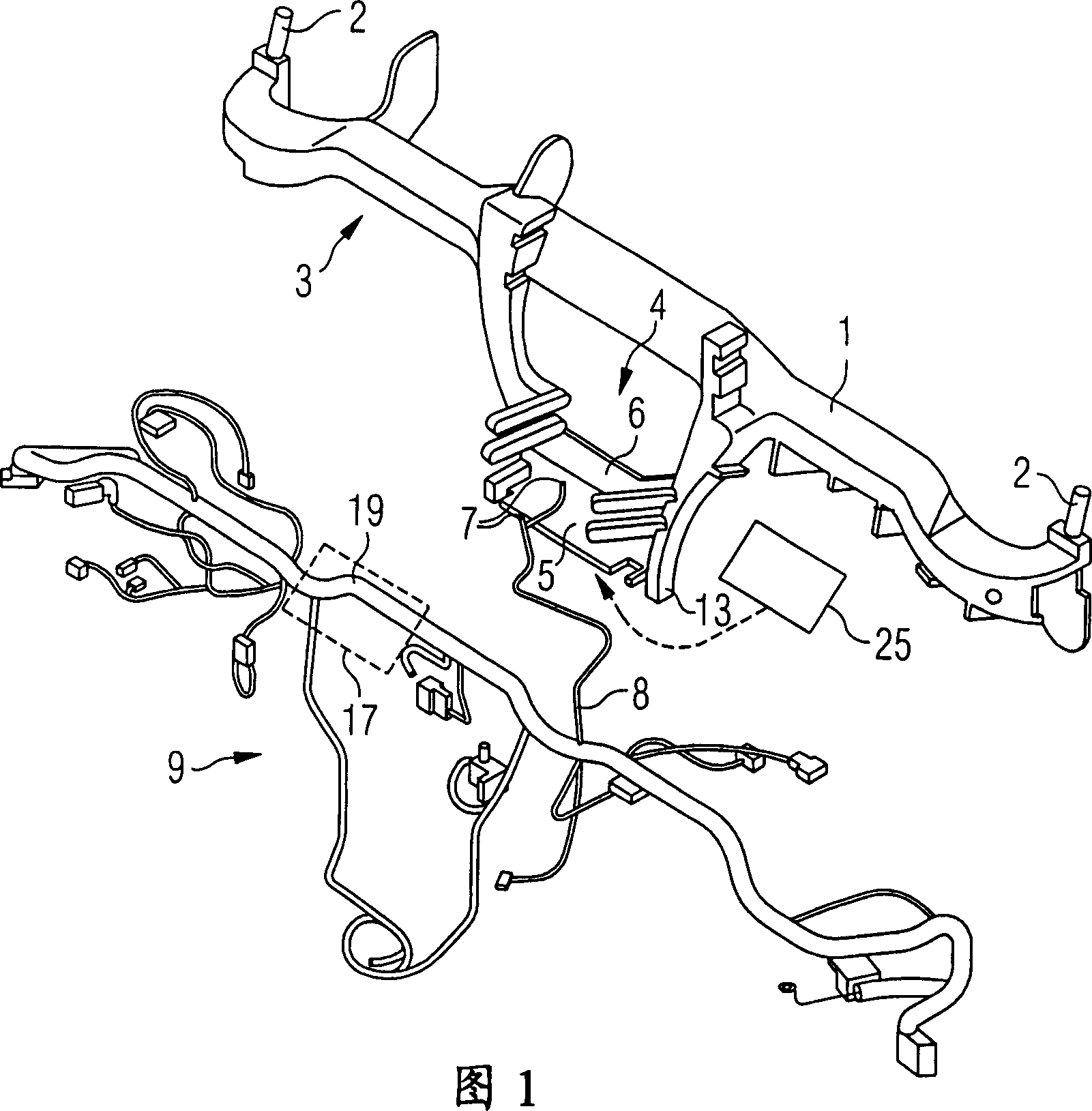

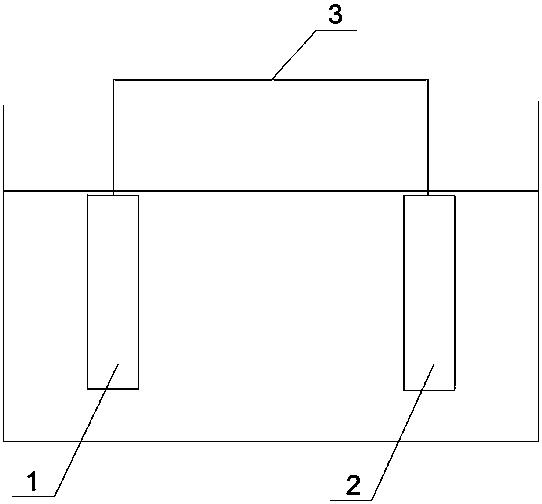

Arrangement for electrically connecting a magnesium support structure to the ground potential of a motor vehicle

InactiveCN1868784AReduce exchangeLessen the tendency to corrodeElectric/fluid circuitElectricityElectromagnetic interference

An arrangement in a motor vehicle includes a support structure which is made of magnesium or of a magnesium alloy and includes at least one solid portion. Further, the arrangement includes an electronic component which is supported or held by the support structure, and a connection arrangement having a connection element which is at a prespecified electrical potential. At least one self-tapping screw is self-tapped into the solid portion of the support structure and thereby mechanically connects the support structure to the connection arrangement.

Owner:SIEMENS AG

A bipolar plate for a fuel cell with a nitriding enhanced surface and a preparation method thereof

The invention discloses a fuel-cell bipolar plate with a nitrified and enhanced surface and a preparation method thereof and belongs to the technical field of fuel cells. The bipolar plate is prepared by the following steps of: preparing a nitrified layer, a chromium-nitride thin film and a carbon-based nano composite conductive thin film on the two side surfaces of a matrix of a stainless-steel plate or a titanium-alloy plate in sequence, cleaning and drying the matrix of the stainless-steel plate or the titanium-alloy plate, then putting the matrix in vacuum-arc ion-plating equipment, introducing nitrogen and hydrogen under the vacuum condition, starting bias voltage and hot wires, and preparing the nitrified layer; and introducing argon-nitrogen mixed gas, preparing the chromium-nitride thin film, opening a carbon target and preparing the carbon-based nano composite conductive thin film. The fuel-cell bipolar plate disclosed by the invention has the advantages that an ion nitrification technology is introduced into the field of surface modification of the fuel-cell bipolar plate, and the nitrified layer is prepared on the surface, so that the passivation of the matrix can be avoided, the condition that a coating fails due to corrosion can be effectively prevented; and a stepped transition method is adopted for multi-element composition of the chromium-nitride thin film and the nano composite conductive thin film, so that the peeling of the coating in the use process due to overlarge internal stress and oversmall bonding force is prevented.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

A method for inhibiting corrosion of hydraulic steel structural parts by using strong electrolyte solution

The invention discloses a method for using a strong electrolyte solution to inhibit the corrosion of a hydraulic steel structure. The specific steps are as follows: (1) Add a strong electrolyte to the solution where the hydraulic steel structure is located until the conductivity of the aqueous solution is greater than 20000µS / cm, and then connect the protected hydraulic steel structure with the titanium anode to form a closed loop; (2) polarize for a period of time, measure the potential of the hydraulic steel structure; (3) if the hydraulic steel structure If the surface potential is lower than ‑0.85V, it indicates that the corrosion of the hydraulic steel structure is inhibited; if the surface potential is higher than ‑0.85V, repeat steps (1)‑(2) until the surface potential is lower than ‑0.85V ; Strong electrolytes are salts of strong acids and strong bases. Adopting the method for inhibiting the corrosion of hydraulic steel structural parts provided by the present invention can prevent the metal from being continuously oxidized and corroded, and can further change the corrosion characteristics of the solution by adjusting the conductivity of the reaction solution in which the metal is located, so as to slow down the tendency of metal corrosion .

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

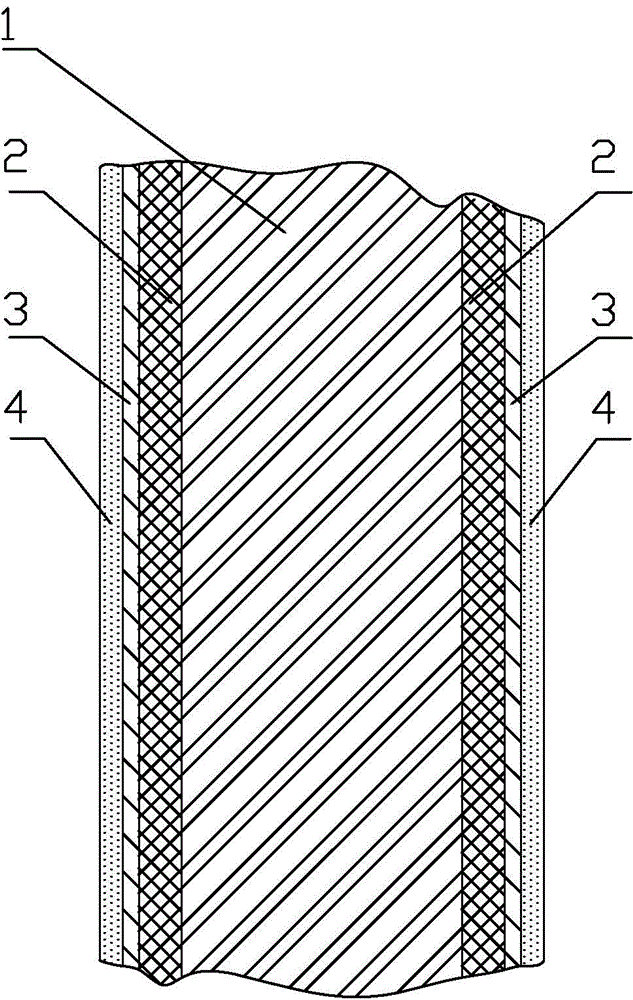

Method for overall protection of magnesium / aluminum dissimilar metal connector

ActiveCN107435145ALessen the tendency to corrodeImprove adhesionMetallic material coating processesMaterials scienceGalvanic corrosion

The invention discloses a method for overall protection of a magnesium / aluminum dissimilar metal connector, and the method comprises the following steps: 1) the magnesium / aluminum dissimilar metal connector is firstly phosphated with a phosphating solution to form a phosphate film layer on a magnesium side; 2) the phosphated magnesium / aluminum dissimilar metal connector is placed in a Baume solution for Baume treatment to form a Baume layer on an aluminum side, and the Baume layer meanwhile can close holes of the magnesium side phosphate film layer. The protection method can integrally protect the magnesium / aluminum dissimilar metal connector and reduce galvanic corrosion tendency. According to the difference between the properties of magnesium and aluminum, films can be formed respectively on the magnesium side and the aluminum side of the magnesium / aluminum dissimilar metal connector for matching, the films are highly targeted to protection of substrates, and the films have good adhesion. The protection method is simple and easy, low in cost, high in processing efficiency, and suitable for large-scale industrial production.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

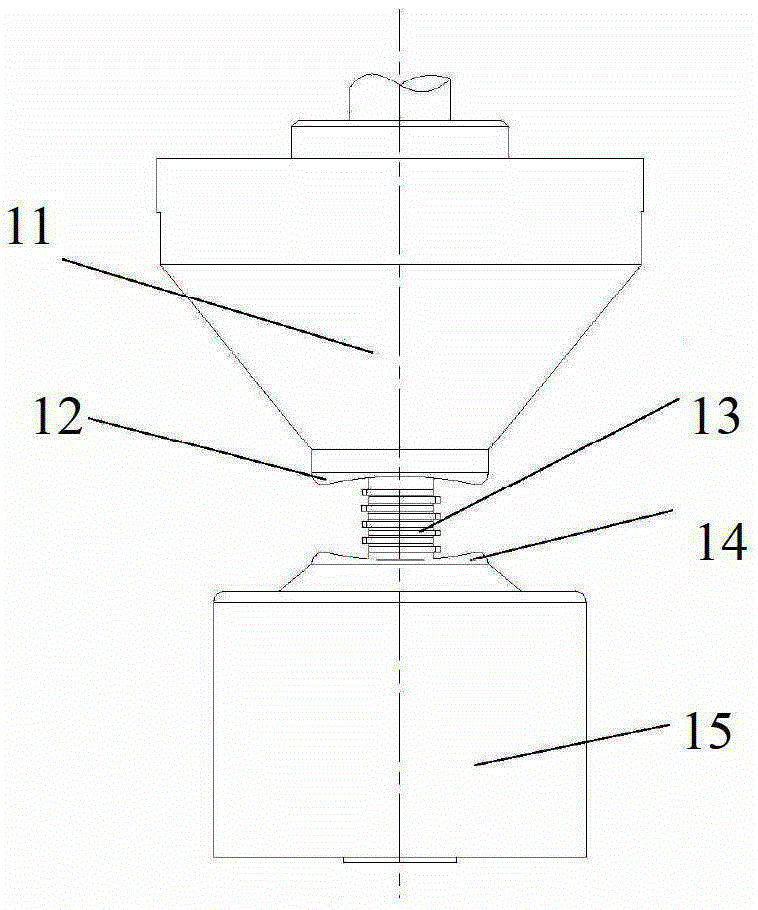

Friction stir welding device

ActiveCN103223554BHigh strengthDeformation pile heightNon-electric welding apparatusFriction weldingWeld seam

Owner:姚雪飞

High petential magnesium alloy sacrificial anode material and its manufacturing method

A high-potential Mg alloy used as consumable anode for the underground oil or gas pipeline, storage tank and water pipe is prepared through micro-alloying the Mg-Mn alloy by Mg-Ca and Mg-RE intermediate alloys, and refining by use of special refining agent to obtain Mg MnRECa alloy, which contains proportionally Mn, Ce, Ca, Si, Cu, Ni, Fe and Mg. Its advantages are high open-circuit potential 1.7-1.8 (-V) and high current efficiency (55-60%).

Owner:TAIYUAN UNIV OF TECH

TiAlMoNbW high-entropy alloy nitride film and preparation process thereof

ActiveCN114645254AWell formedStable formationVacuum evaporation coatingSputtering coatingHigh entropy alloysThin membrane

The invention relates to a TiAlMoNbW high-entropy alloy nitride film and a preparation process thereof, the component expression is TiaAlbMocNbdWeNx, a: 4-9, b: 4-8, c: 1-6, d: 6-10, e: 5-9, x: 55-70, a + b + c + d + e + x = 100, the film is of a columnar nanocrystalline structure, and the grain size is 10-70 nm. The high-entropy alloy nitride film has high wear resistance, high corrosion resistance and high mechanical property.

Owner:BEIHANG UNIV

Aluminum and aluminum alloy spiral tube forming welding equipment

ActiveCN103273187BRealize digital inputRealize remote precise controlOther manufacturing equipments/toolsNon-electric welding apparatusFriction weldingFriction stir welding

Owner:姚雪飞

Brazing filler metal, brazing filler metal, preparation method and application thereof, and prepared brazing product

ActiveCN111545948BHigh strengthRaise the electrode potentialWelding/cutting media/materialsSoldering mediaRare-earth elementElectrode potential

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

Mg-Mn-Ca-Zn-Sr sacrificial anode with high current efficiency

The invention discloses an Mg-Mn-Ca-Zn-Sr sacrificial anode with high current efficiency, which belongs to the technical field of sacrificial anodes and is characterized by comprising the following elements in percentage by weight: 0.93 percent of Mn, 0.13 percent of Ca, 0.05 percent of Zn, 0.07 percent of Sr, less than 0.045 percent of Si, less than 0.018 percent of Cu, less than 0.001 percent of Ni, less than 0.030 percent of Fe, and the balance of Mg. Aiming at the defect that the conventional magnesium anode has low current efficiency, by adding trace elements, the dissolution evenness and corrosion resistance of the magnesium anode are increased, and the current efficiency of the magnesium anode is improved.

Owner:山东宏泰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com