Friction stir welding device

A welding device and friction stir technology are applied in the field of aluminum and aluminum alloy welding, which can solve the problems of pipe weld strength defects, affecting the use range of pipes, and reducing weld strength, etc., and achieve excellent mechanical properties, grain refinement, and improvement. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

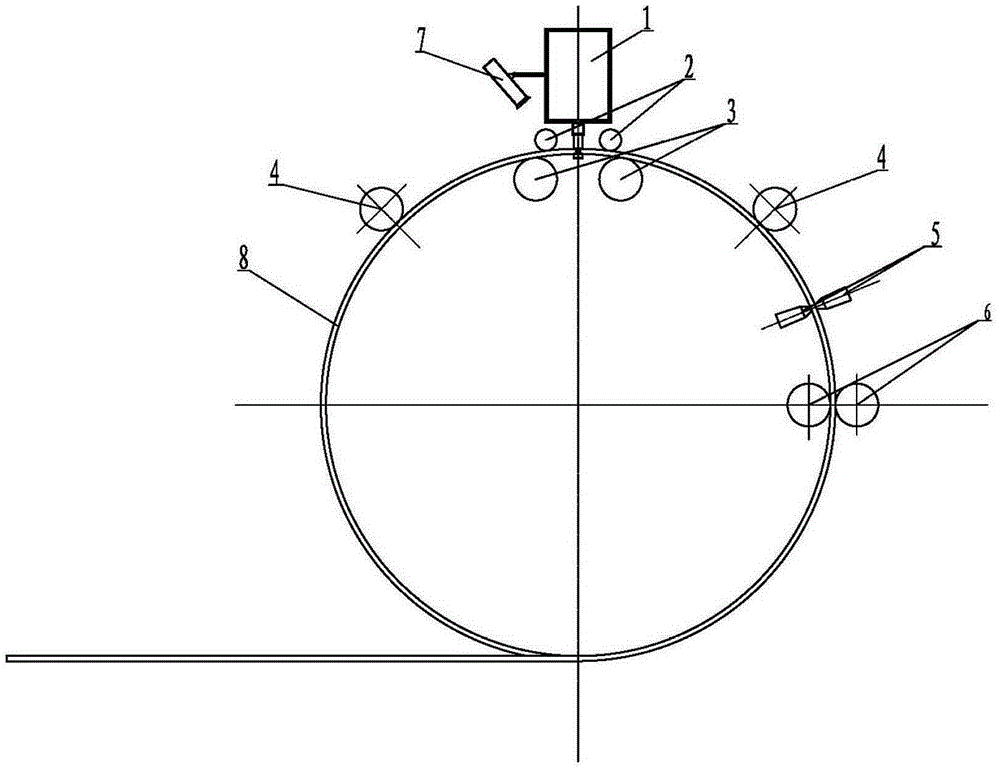

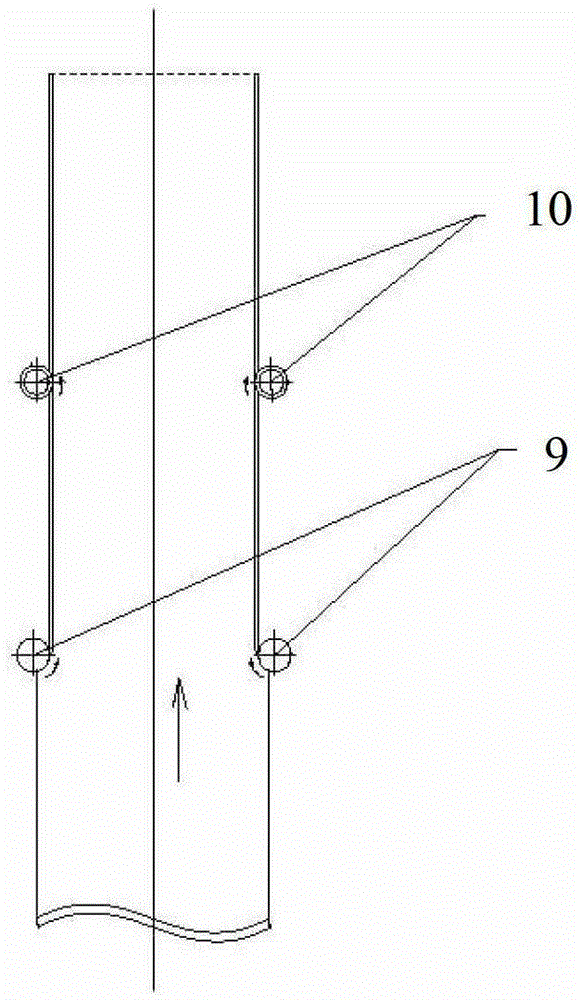

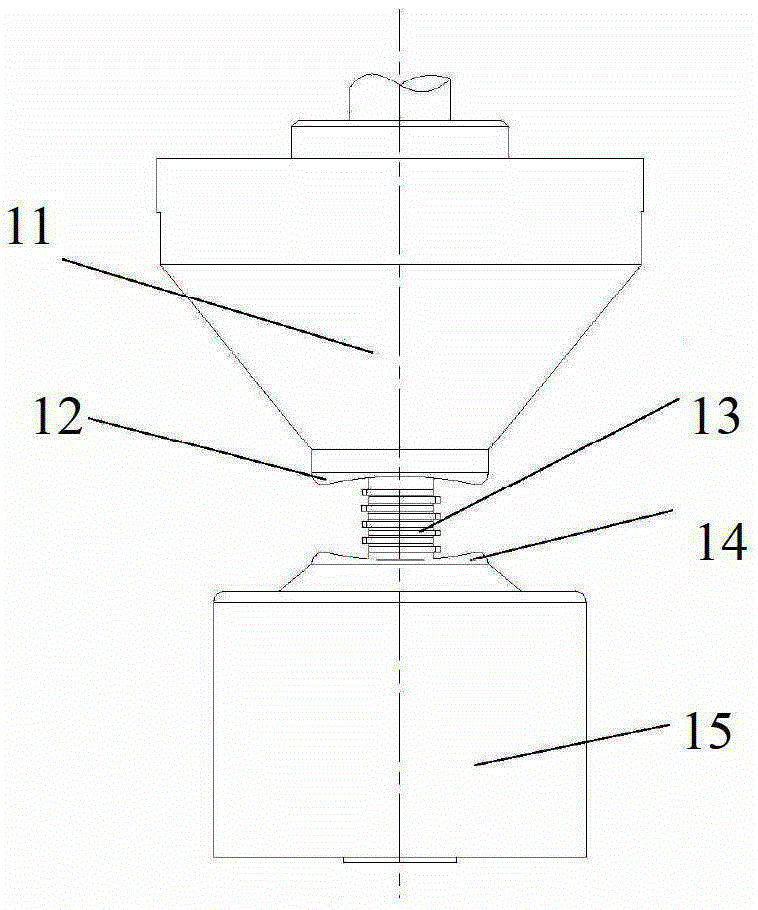

[0018] The present invention will be described in further detail below, so that those skilled in the art can implement it with reference to the description. figure 1 is a sectional view of a preferred embodiment of the friction stir welding apparatus according to the present invention. figure 2 It is a schematic diagram of the pressure roller of the stirring head of the friction stir welding equipment according to the present invention. image 3 It is a schematic diagram of the stirring head of the friction stir welding equipment according to the present invention. Such as figure 1 , figure 2 , image 3 As shown, the friction stir welding device includes: a high-speed motor (not shown); a stirring head 1, which is connected to the output shaft of the high-speed motor, including a stirring pin 13 and two shoulders 11, 15, two The surfaces 12 and 14 of the shaft shoulder contacting the weldment are arc-shaped support fans; when the friction stir welding equipment is used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com