Iron-based alloy powder, laser cladding coating and preparation method of iron-based alloy powder

An iron-based alloy, laser cladding technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of deterioration of material corrosion resistance, reduction of material corrosion resistance, reduction of coating toughness, etc., to reduce corrosion performance. Deterioration, improvement of corrosion resistance, and effect of suppressing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of iron-based alloy powder

[0032] The iron-based alloy powder is prepared by a gas atomization method, and the iron-based alloy powder is composed of the following elements in mass percentage: C is 1.5-3.0%, Si is 0.5-1.5%, Cr is 16-18%, and Ni is 1-4%, Mo is 1-3%, Mn is 0.2-1%, the total amount of Nb and V is 0.2-1%, and the rest is Fe. The grain size of the iron-based alloy powder is 53-150 μm.

[0033] 2. Preparation of laser cladding coating

[0034] Using a laser cladding machine, with argon as the protective gas, laser as the heat source, powder feeding in the form of a cone-shaped powder beam, the scanning speed is controlled at 2-7mm / s, the laser power is 1-5kW, and the powder feeding rate is 10- 20g / min, use the heat generated by the laser beam to melt the surface of the substrate and the iron-based alloy powder in step 1.1 to form a single cladding layer on the surface of the substrate, repeat the previous steps to obtain multiple cladding l...

Embodiment 2

[0036] 1. Preparation of iron-based alloy powder

[0037] The specific method is the same as step 1 in Example 1, the difference is that the composition of the iron-based alloy powder is: C is 2.0%, Si is 0.75%, Cr is 17%, Ni is 3%, and Mo is 2%. , Mn is 1%, the total amount of Nb and V is 1%, the rest is Fe, and the particle size of the iron-based alloy powder is 53-150 μm.

[0038] 2. Preparation of laser cladding coating

[0039]The specific method is the same as step 2 in Example 1, the difference is that 42CrMo steel is selected as the substrate, and the size of the substrate is 200mm×80mm×20mm. The surface of the substrate is polished with a grinder before cladding, and then cleaned with acetone; Power semiconductor laser cladding system (Laserline LDF-8000), control scanning speed 4mm / s, laser power 2kW, powder feeding rate about 12g / min, to obtain laser cladding coating with two cladding layers.

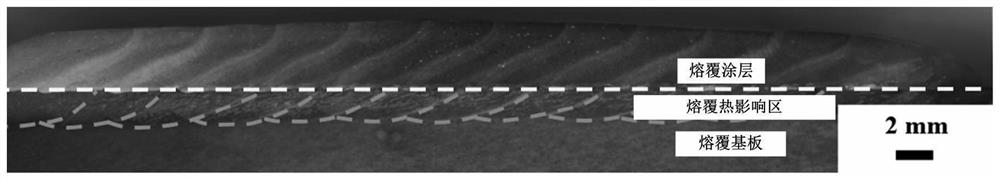

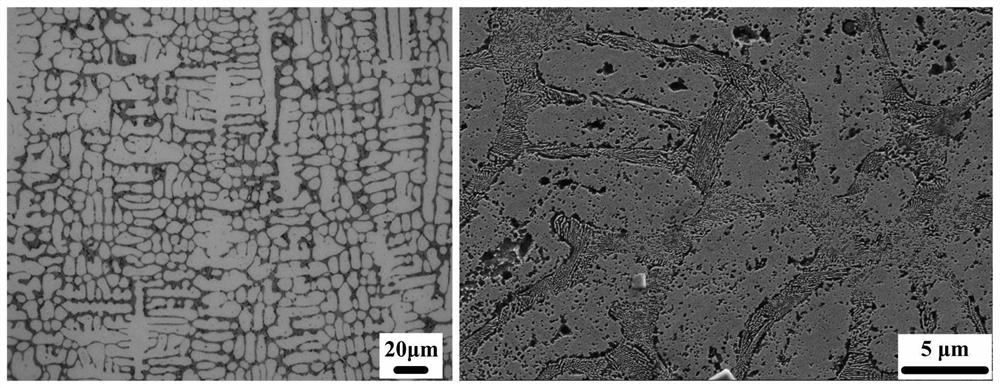

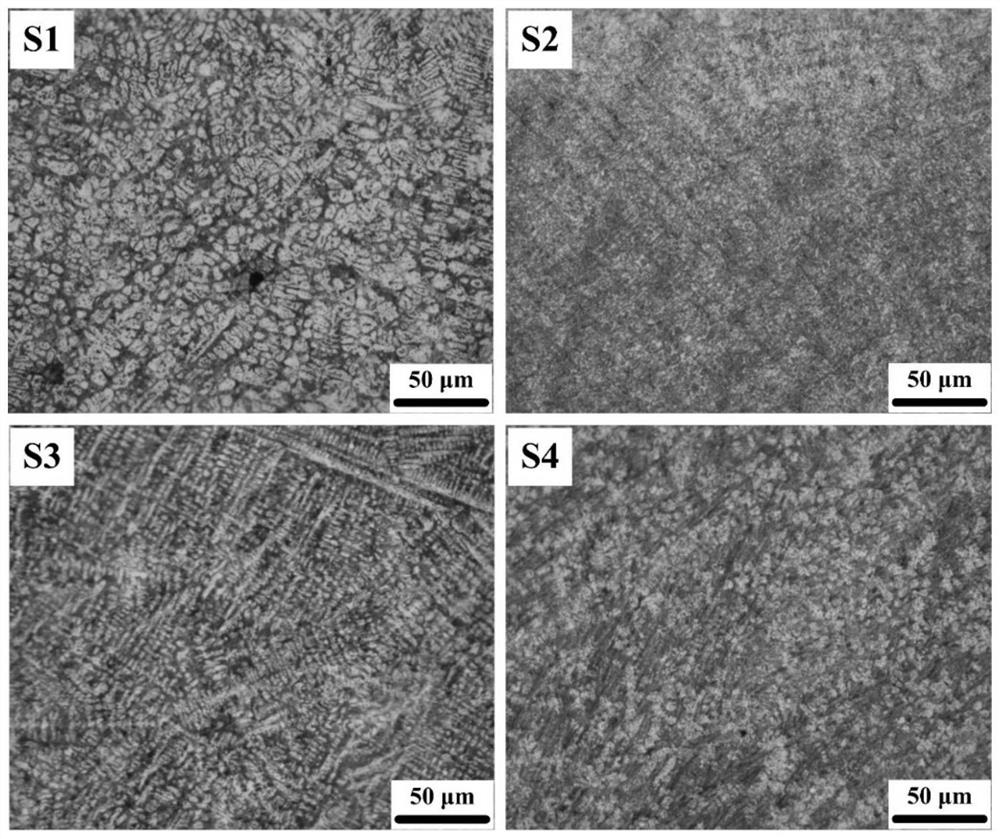

[0040] Such as figure 1 As shown, the thickness of the laser cladding...

Embodiment 3

[0043] 1. Preparation of iron-based alloy powder

[0044] The specific method is the same as step 1 in Example 2, except that the composition of the iron-based alloy powder is: C is 1.5%, Si is 1.5%, Cr is 16%, Ni is 4%, and Mo is 3%. , Mn is 1%, the total amount of Nb and V is 0.2%, the rest is Fe, and the particle size of the iron-based alloy powder is 53-150 μm.

[0045] 2. Preparation of laser cladding coating

[0046] The specific method is the same as step 2 in Example 2, the difference is that during laser cladding, the scanning speed is controlled to 6mm / s, the laser power is 3kW, and the powder feeding rate is about 15g / min to obtain a single-pass laser cladding coating. layer, the thickness of the coating is 1.2mm, the dilution rate of the substrate is 2.1%, and the hardness of the coating is 55HRC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com