Preparation method of copper alloy bar with bamboo joint structure and hard core gradient structure

A technology of gradient structure and copper alloy is applied in the field of preparation of copper alloy bars, which can solve the problems of weakened strengthening effect and inapplicability, and achieve the effects of simple equipment, low cost and wide size range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

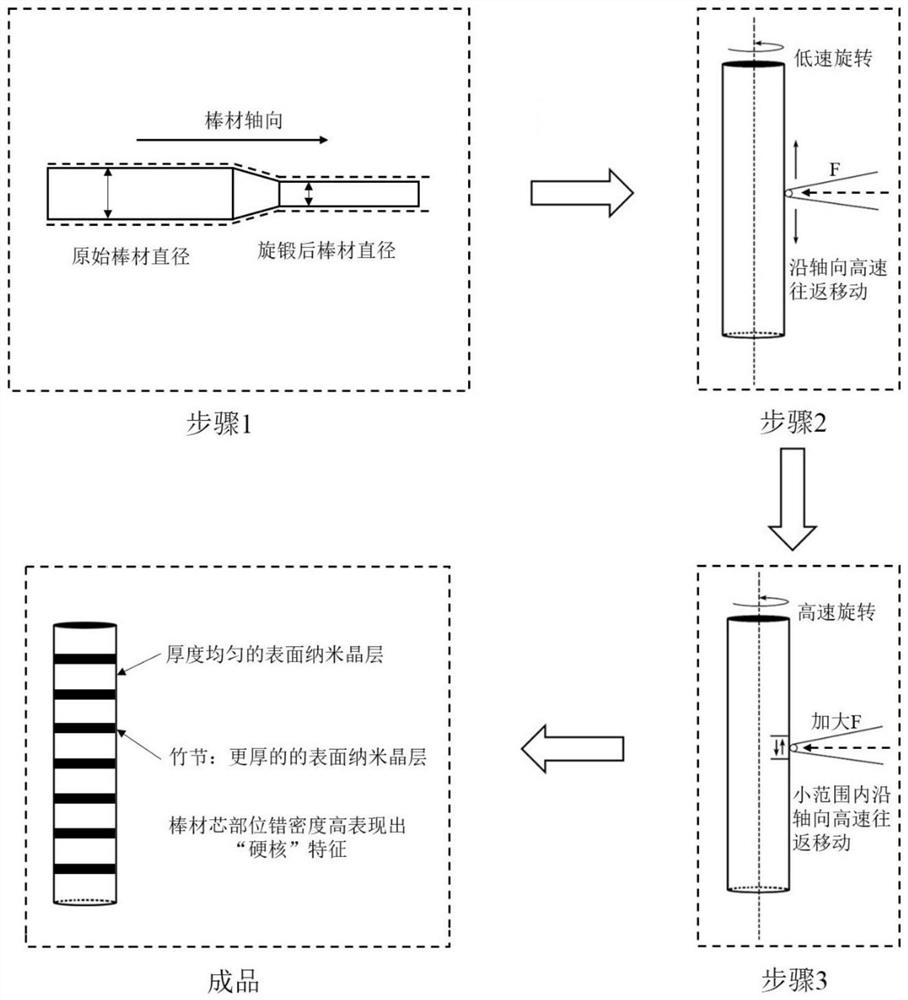

[0042] Such as figure 1 As shown, the following examples involve a three-step process including: rotary forging to obtain a hard core structure, longitudinal surface mechanical milling to obtain a surface nanocrystalline layer with a uniform thickness, and subsequent transverse surface mechanical milling to obtain a bamboo with a thicker surface nanocrystalline layer. Node structure, and this bamboo structure is evenly distributed along the axial direction.

[0043] (1) Rotary forging: take a copper alloy bar with a length of 30 cm and a diameter of 15 mm, and perform a small deformation rotary forging treatment, and the diameter of the bar after rotary forging is about 13 mm.

[0044] (2) Longitudinal surface mechanical grinding: the bar is placed vertically or horizontally, and it is rotated axially by an external device at a speed of about 1RPM. The force direction of the pressure head for surface mechanical grinding is perpendicular to the axial direction of the bar, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com