Fuel-cell bipolar plate with nitrified and enhanced surface and preparation method thereof

A fuel cell, nitriding enhanced technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of affecting the catalyst activity in the battery, the contact resistance becomes larger, and the coating bonding force is small, so as to improve the coating bonding force , reduce the potential difference, reduce the effect of coating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

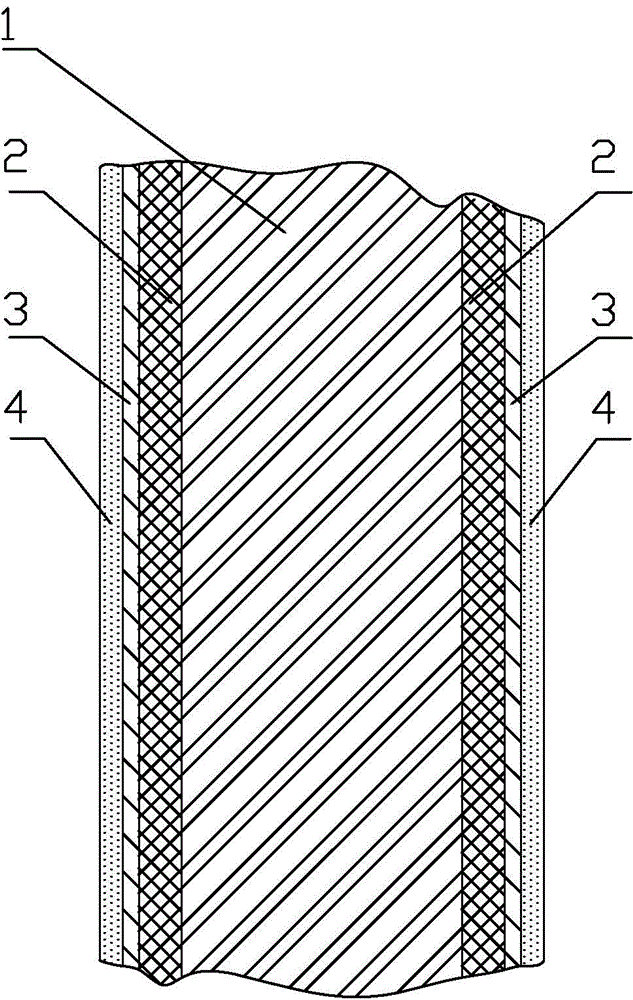

[0037] The method for nitriding enhanced surface modification of bipolar plates for fuel cells is characterized in that the method comprises the following process steps:

[0038] This embodiment is implemented according to the following steps under the following implementation conditions and technical requirements:

[0039] (1) Nitriding layer preparation

[0040] Put the stainless steel plate or titanium alloy plate substrate 1 into the ultrasonic cleaning equipment for cleaning, and after drying in the vacuum drying furnace, install it into the vacuum chamber of the pulse bias arc ion plating equipment with a special fixture, and put the vacuum in the vacuum system. After vacuuming the chamber to 0.5Pa, heat the vacuum chamber to 400°C, and control the flow meter to feed 3000SCCM of nitrogen and 1500SCCM of hydrogen to maintain the pressure in the vacuum chamber at 3pa, and apply a pulse bias of -500V on the bipolar plate. The duty cycle is 90%, the working frequency is 5KH...

Embodiment 2

[0049] The method for nitriding enhanced surface modification of bipolar plates for fuel cells is characterized in that the method comprises the following process steps:

[0050] This embodiment is implemented according to the following steps under the following implementation conditions and technical requirements:

[0051] (1) Nitriding layer preparation

[0052] Put the stainless steel plate or titanium alloy plate substrate 1 into the ultrasonic cleaning equipment for cleaning, and after drying in the vacuum drying furnace, install it into the vacuum chamber of the pulse bias arc ion plating equipment with a special fixture, and put the vacuum in the vacuum system. After vacuuming the chamber to 0.3Pa, heat the vacuum chamber to 250°C, and pass 3000SCCM of nitrogen and 800SCCM of hydrogen through the control flowmeter to maintain the pressure in the vacuum chamber at 1.5Pa, and apply a pulse of -750V on the bipolar plate Bias voltage, the duty cycle is 50%, the working fre...

Embodiment 3

[0060] The method for nitriding enhanced surface modification of bipolar plates for fuel cells is characterized in that the method comprises the following process steps:

[0061] This embodiment is implemented according to the following steps under the following implementation conditions and technical requirements:

[0062] (1) Nitriding layer preparation

[0063] Put the stainless steel plate or titanium alloy plate substrate 1 into the ultrasonic cleaning equipment for cleaning, and after drying in the vacuum drying furnace, install it into the vacuum chamber of the pulse bias arc ion plating equipment with a special fixture, and put the vacuum in the vacuum system. After vacuuming the chamber to 0.001Pa, heat the vacuum chamber to 100°C, and control the flow meter to feed 20SCCM of nitrogen and 10SCCM of hydrogen to maintain the pressure in the vacuum chamber at 0.1Pa, and apply a pulse of -1000V on the bipolar plate Bias voltage, the duty cycle is 10%, the working frequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com