A kind of preparation method of superhydrophobic hydroxyapatite film layer on magnesium alloy surface

A technology of hydrohydroxyapatite and magnesium alloy, which is applied in the direction of metal material coating technology, coating, and pharmaceutical formulations. The process is simple and easy, and the effect of uniformity is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Surface pretreatment

[0036] Cut the magnesium alloy AZ31 into a sample of 15mm×1.5mm×2mm. There is a small hole with a diameter of 1mm at the corner of the sample, which can be tied with a thin wire for hanging in the experiment. Use SiC sandpaper (the roughness of the sandpaper is 200#, 400#, 600#, 800#, 1000#) to polish the sample in turn until the surface is smooth and no scratches can be seen with the naked eye. Clean it in an ultrasonic cleaner, then put it into the polishing solution (the volume ratio is HF:HNO 3 :H 2 O=1:10:89), take it out immediately after soaking for 10 seconds, rinse the surface with deionized water, dry it with a hair dryer, and set it aside.

[0037] 2) Preparation of micro / nano-structured hydroxyapatite film by hydrothermal method

[0038] Formulated with disodium calcium salt of EDTA and NaH 2 PO 4 Aqueous solution in which disodium calcium salt of ethylenediaminetetraacetic acid and NaH 2 PO 4 The concentrations were all 0.25...

Embodiment 2

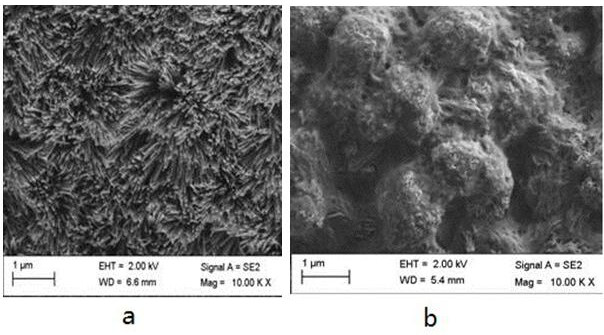

[0048] The morphology of the magnesium alloy coating prepared in Example 1 and Comparative Example 2 was observed with a Σ IGMA HDTM field emission scanning electron microscope (SEM) ( figure 1 ).

[0049] from figure 1 It can be seen that under SEM, a single hydroxyapatite film coating (comparative example 2) forms a needle-like hydroxyapatite crystal layer (such as figure 1 a), but there are many gaps between the crystals; and after further hydrophobic treatment on the surface of the hydroxyapatite film layer (Example 1), a superhydrophobic stearic acid film is formed on the surface of the hydroxyapatite film layer layer (eg figure 1 b), and the stearic acid film penetrates into the micro-nano structure hydroxyapatite film layer, filling many gaps between the crystals, effectively preventing the solution from penetrating through the gaps of the film structure to cause corrosion of the matrix.

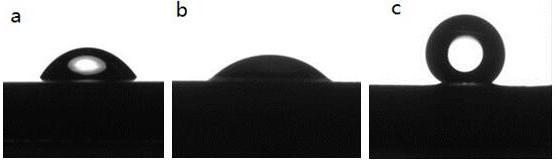

[0050] Use the Drop Meter A-100P surface and interfacial tension measuring...

Embodiment 3

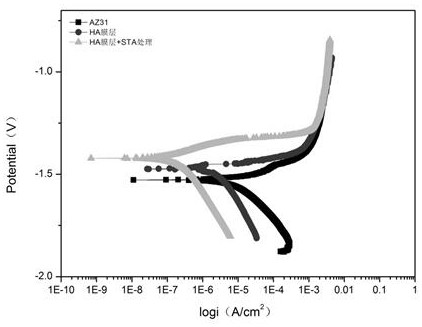

[0054] The electrochemical corrosion performance was tested by E G&G Model l273 electrochemical workstation. The measurement adopts a three-electrode system: the reference electrode is a saturated calomel electrode (SCE), the auxiliary electrode is a platinum electrode, and the working electrode is the sample to be tested. The corrosion medium is Hank's biomimetic solution with a pH of 7.4 (composition: NaCl: 8 g / l, KCl: 0.4 g / l, CaCl 2 :0.14 g / l, NaHCO 3 :0.35 g / l, C 6 h 6 o 6 : 1.0 g / l, MgCl 2 ·6H 2 O:0.1 g / l, MgSO 4 ·7H 2 O: 0.06 g / l, KH 2 PO4: 0.06 g / l, Na 2 HPO 4 12H 2 O: 0.06 g / l). The result is as image 3 shown.

[0055] from image 3 It can be seen that compared with the single hydroxyapatite film layer, the self-corrosion potential of the magnesium alloy sample with the hydroxyapatite film layer treated with stearic acid in Hank's solution is increased, and the self-corrosion current density decreases, and the passivation potential increases. The sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com