A method for inhibiting corrosion of hydraulic steel structural parts by using strong electrolyte solution

A technology of steel structural parts and strong electrolyte, applied in the field of metal anti-corrosion, can solve the problems of low efficiency and high energy loss, and achieve the effect of preventing oxidation and slowing down the tendency of metal corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for inhibiting corrosion of hydraulic steel structural parts by using a strong electrolyte solution, the specific steps are as follows:

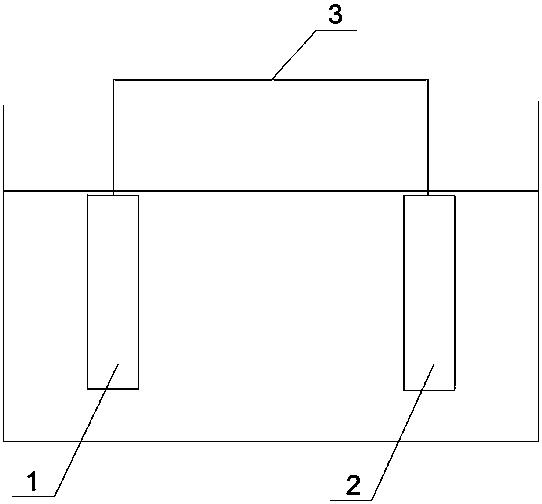

[0027] (1) Add a strong electrolyte to the solution where the hydraulic steel structure is located until the conductivity of the aqueous solution is greater than 20000µS / cm, and then connect the protected hydraulic steel structure 1 with the titanium anode 2 through a wire 3 to form a closed loop , the hydraulic steel structure 1 and the titanium anode 2 are both immersed in the solution;

[0028] (2) Polarize for a period of time to keep the surface potential of the hydraulic steel structure 1 consistent, and then measure the potential of the hydraulic steel structure 1;

[0029] (3) If the surface potential of the hydraulic steel structure 1 is lower than -0.85V, it indicates that the corrosion of the hydraulic steel structure 1 is inhibited and is in a protected state; if the surface potential of the hydraulic steel struct...

Embodiment 2

[0035] A method for inhibiting corrosion of hydraulic steel structural parts by using a strong electrolyte solution, the specific steps are as follows:

[0036] (1) Add sodium sulfate to the solution where the hydraulic steel structure is located until the conductivity of the aqueous solution is equal to 20000µS / cm, and then connect the protected hydraulic steel structure 1 with the titanium anode 2 through a wire 3 to form a closed loop , the hydraulic steel structure 1 and the titanium anode 2 are both immersed in the solution;

[0037] (2) Polarize for 24 hours to keep the surface potential of the hydraulic steel structure 1 consistent, and then measure the potential of the hydraulic steel structure 1;

[0038] (3) If the surface potential of the hydraulic steel structure 1 is lower than -0.85V, it indicates that the corrosion of the hydraulic steel structure 1 is inhibited and is in a protected state; if the surface potential of the hydraulic steel structure 1 is higher th...

Embodiment 3

[0040] A method for inhibiting corrosion of hydraulic steel structural parts by using a strong electrolyte solution, the specific steps are as follows:

[0041] (1) Add sodium chloride to the solution where the hydraulic steel structure is located until the conductivity of the aqueous solution is equal to 22000µS / cm, and then connect the protected hydraulic steel structure 1 with the titanium anode 2 through a wire 3 to form a closed The circuit, the hydraulic steel structure 1 and the titanium anode 2 are all immersed in the solution;

[0042] (2) Polarize for 32 hours to keep the surface potential of the hydraulic steel structure 1 consistent, and then measure the potential of the hydraulic steel structure 1;

[0043] (3) If the surface potential of the hydraulic steel structure 1 is lower than -0.85V, it indicates that the corrosion of the hydraulic steel structure 1 is inhibited and is in a protected state; if the surface potential of the hydraulic steel structure 1 is highe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com