Brazing filler metal alloy, brazing filler metal, preparation method and application of brazing filler metal alloy, preparation method and application of brazing filler metal and prepared brazing product

A technology of alloys and brazing materials, applied in metal processing equipment, welding media, manufacturing tools, etc., can solve the problems of unguaranteed joint reliability, low brazing strength, poor corrosion resistance, etc., to meet the requirements of brazing process performance and The mechanical properties of the joint, the simple and easy operation of the equipment, and the effect of high brazing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] According to one aspect of the present invention, a kind of preparation method of above-mentioned solder alloy, described preparation method comprises the following steps:

[0072] providing a mixture containing the components in formulated amounts, followed by alloying the mixture to produce a solder alloy;

[0073] The preparation method of the solder alloy provided by the present invention, the preparation method is to first provide a mixture containing the components of the formula, and then alloy the mixture to obtain the solder alloy. The above preparation method has the advantages of short process flow and simple equipment The advantages of easy operation can realize mass industrial production of solder alloys.

[0074] In a preferred embodiment of the present invention, the preparation method comprises the following steps:

[0075] (A), Mg, Ni, Cr, Ga and the rare earth element of formula quantity are mixed and alloyed with the Al of partial quantity respective...

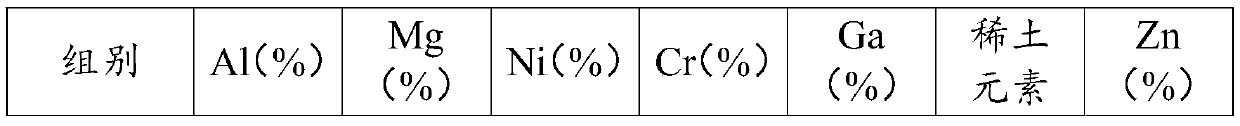

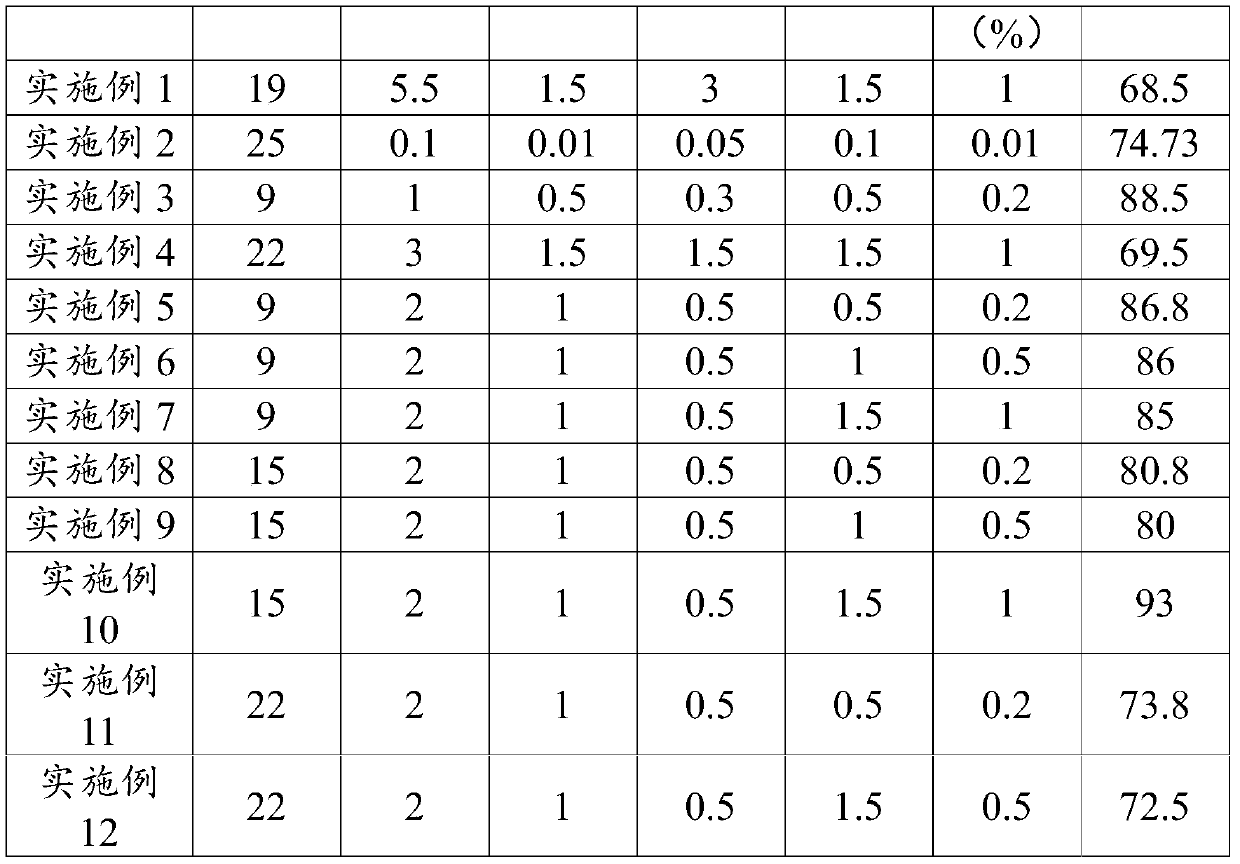

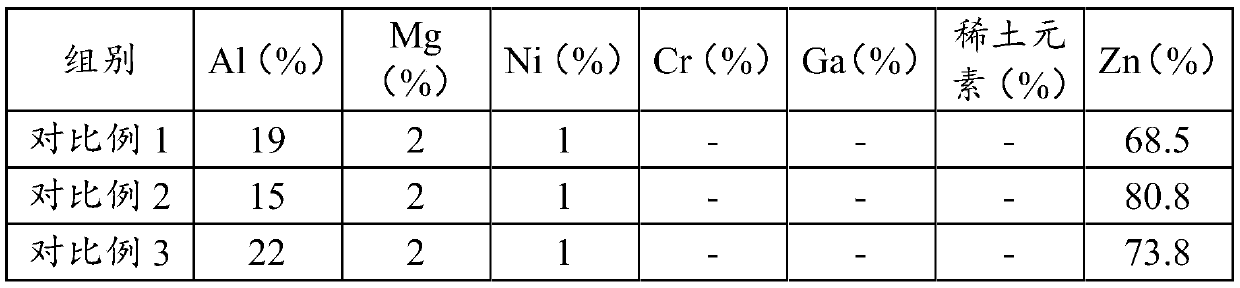

Embodiment 1~12

[0125] A kind of brazing filler metal, by mass percentage, described brazing filler metal is prepared from the following raw materials:

[0126]

[0127]

[0128] The preparation method of described solder comprises the following steps:

[0129] (1), Mg, Ni, Cr, Ga and the rare earth element of formula quantity are mixed and alloyed with the Al of partial quantity respectively, form AlMg alloy, AlNi alloy, AlCr alloy, AlGa alloy and Al-rare earth alloy respectively;

[0130] Wherein, the Mg content in the AlMg alloy is 15wt%; the Ni content in the AlNi alloy is 10wt%; the Cr content in the AlCr alloy is 10wt%; the Ga content in the AlGa alloy is 30wt%;

[0131] (2), put the graphite crucible in the resistance furnace to preheat, place the remaining amount of Al in the crucible, and then raise the temperature of the resistance furnace to 725-735°C;

[0132] (3) After the remaining amount of Al is completely melted, add AlNi alloy and AlCr alloy, heat up to 780-860°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com