Embedded electrode frame of flow cell pile

An embedded electrode, flow battery technology, applied in the direction of fuel cell components, fuel cells, circuits, etc., can solve the problems of difficult production efficiency, production and assembly obstacles, complex structure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

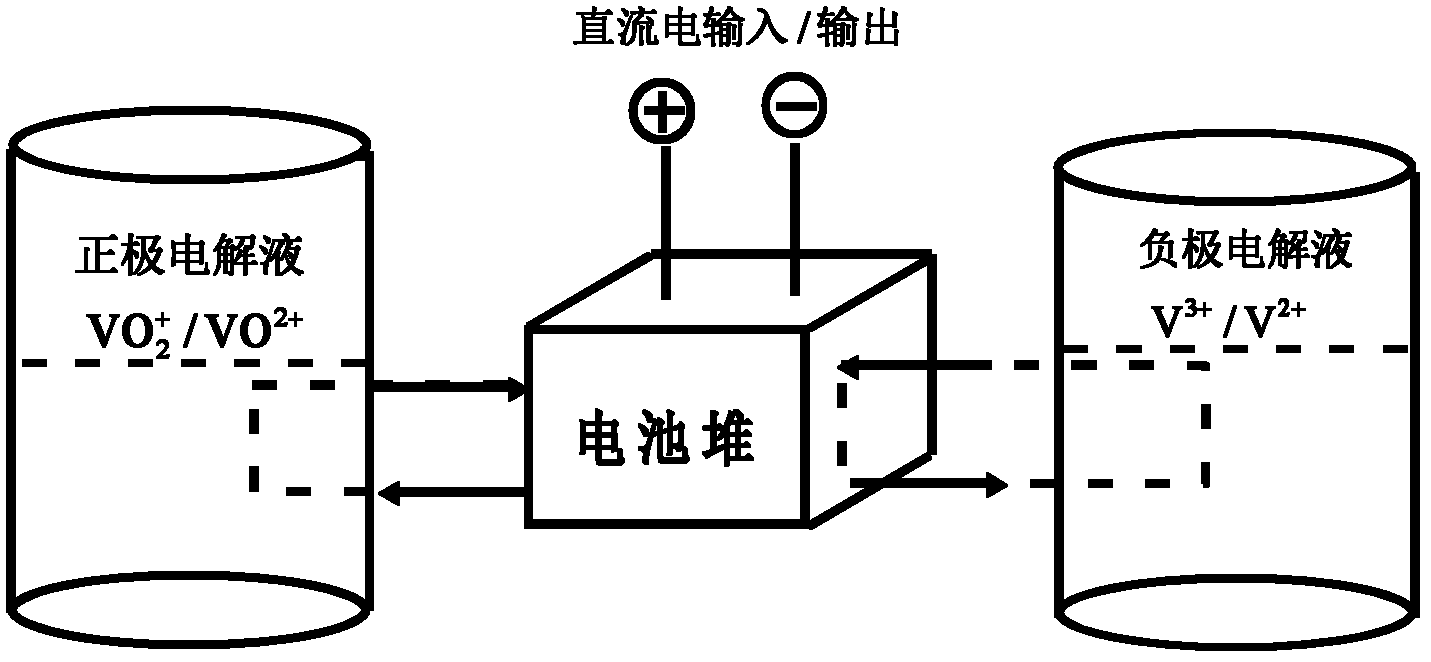

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

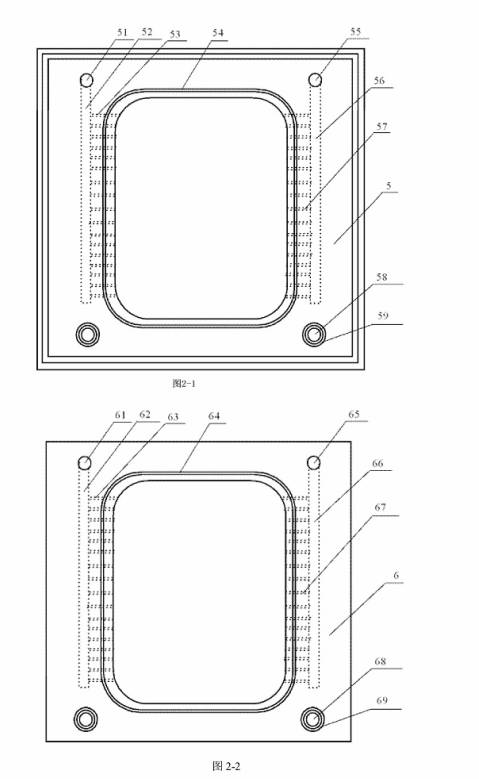

[0085] like image 3 Shown is the structure diagram of the I-type electrode frame.

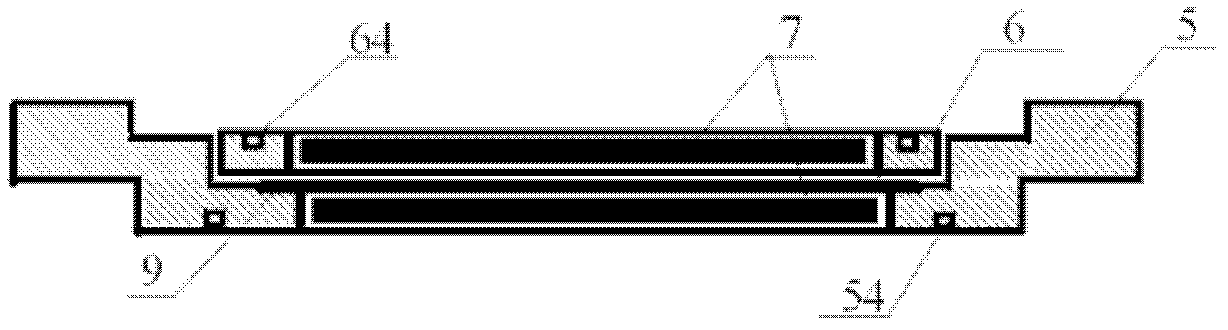

[0086] The length and width of the first bipolar plate frame (5) are both 220 mm and 10 mm thick, and are made of polyvinyl chloride. The edge part is provided with double-layer grooves, the depth of the lower groove is 3mm, and the depth of the upper groove is 3mm. The height of the boss at the back is 4.5 millimeters, and an O-ring groove with a wire diameter of 2.4 millimeters is set on the periphery of the part where the electrode (7) is placed. The length and width of the second bipolar plate frame (6) are both 200 mm and 3.2 mm thick, and are made of polyvinyl chloride. A conductive plastic bipolar plate (9) with a thickness of 0.8 mm is placed between the first bipolar plate frame (5) and the second bipolar plate frame (6), and a polyvinyl chloride adhesive is used to The three are bonded to form an integral electrode frame (4) part, and electrodes (7) are placed in the electrode fra...

Embodiment 2

[0088] like Figure 4 Shown is the structure diagram of type II electrode frame.

[0089] The length and width of the first bipolar plate frame (5) are both 420 mm, and the thickness is 6.2 mm, made of polyvinyl chloride. The grooves are 1.5mm deep on the front and 1.5mm deep on the back. An O-ring groove with a wire diameter of 2.4 mm is arranged on the periphery of the part where the electrode (7) is placed on the front side. The length and width of the second bipolar plate frame (6) are both 400 mm and 3.2 mm thick, and are made of polyvinyl chloride. A conductive plastic bipolar plate (9) with a thickness of 0.6 mm is placed between the first bipolar plate frame (5) and the second bipolar plate frame (6), and a polyvinyl chloride adhesive is used to The three are bonded to form an integral electrode frame (4) part, and electrodes (7) are placed in the electrode frames of the first bipolar plate frame (5) and the second bipolar plate frame (6) to become The electrode fr...

Embodiment 3

[0091] like Figure 5 Shown is a structure diagram of a type III electrode frame.

[0092] The length and width of the first bipolar plate frame (5) are both 620 mm, and the thickness is 7 mm, made of polyvinyl chloride. The length and width of the front groove are 602 mm, and the depth is 3 mm. The length and width of the back boss are 588 mm, and the height is 2 mm. An O-ring groove with a wire diameter of 2.65 mm is arranged around the portion where the electrode (7) is placed on the first bipolar plate frame (5). The length and width of the second bipolar plate frame (6) are 600 mm, and the thickness is 4.7 mm. The length and width of the front groove are 590 mm, and the depth is 1.5 mm. It is made of polyvinyl chloride. A conductive plastic bipolar plate (9) with a thickness of 0.6 mm is placed between the first bipolar plate frame (5) and the second bipolar plate frame (6), and a polyvinyl chloride adhesive is used to The three are bonded to form an integral electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com