Patents

Literature

53results about How to "Improve brazing strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

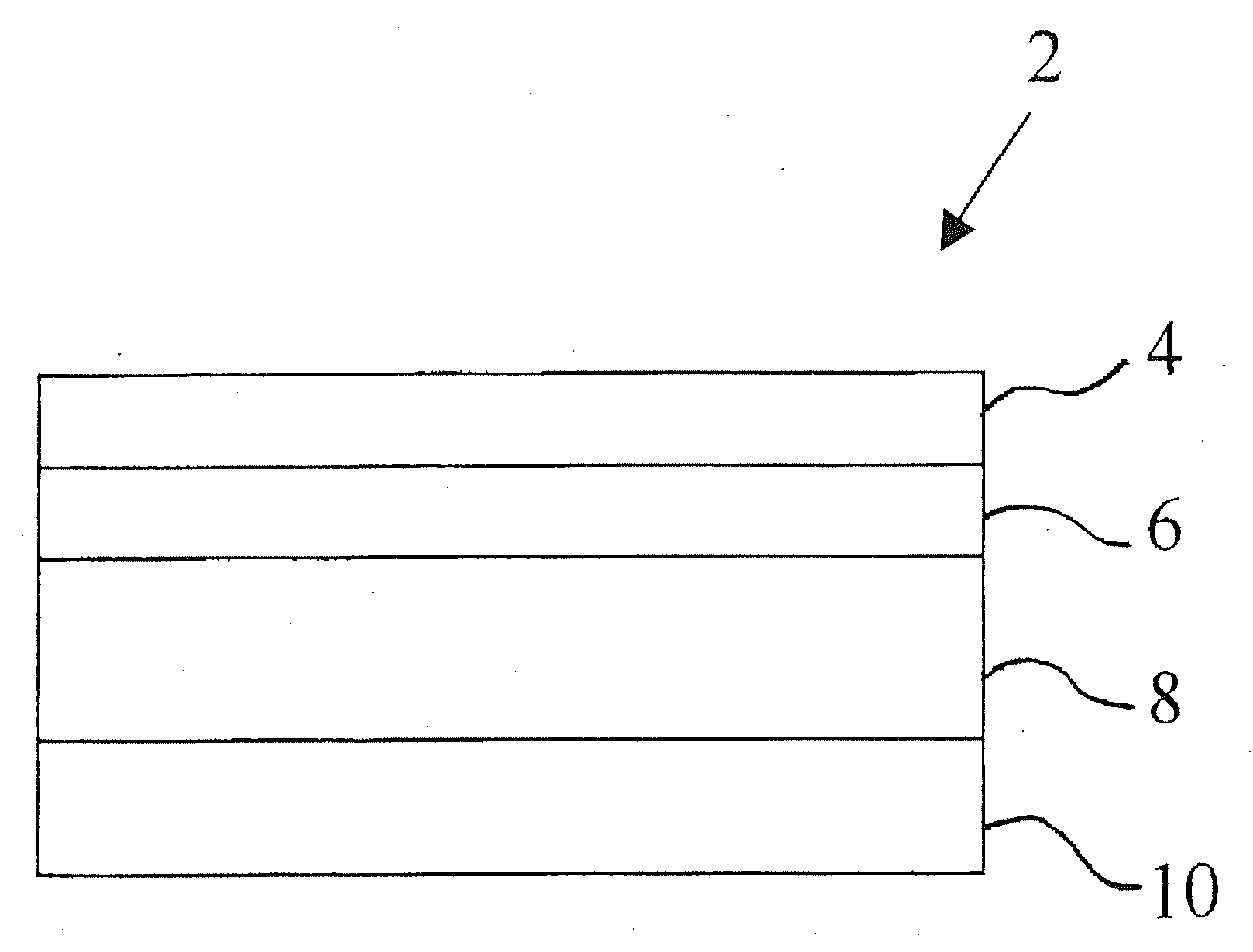

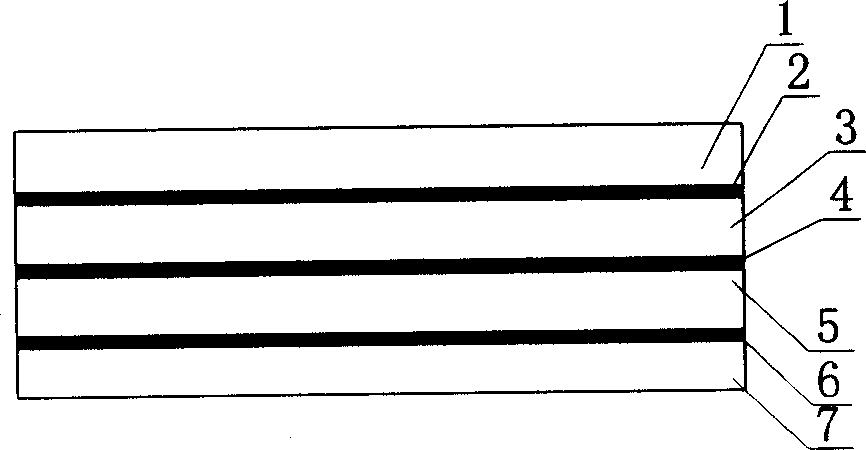

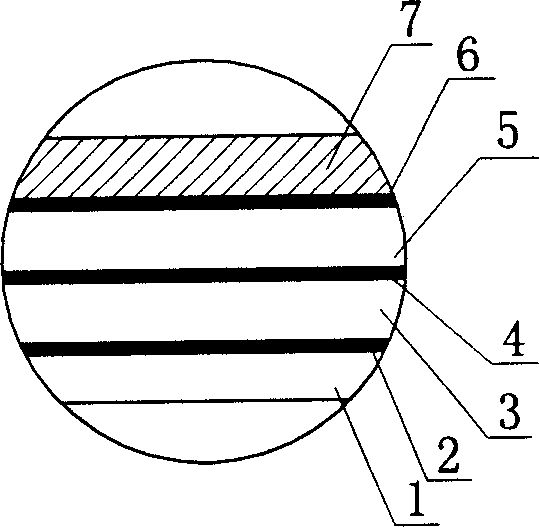

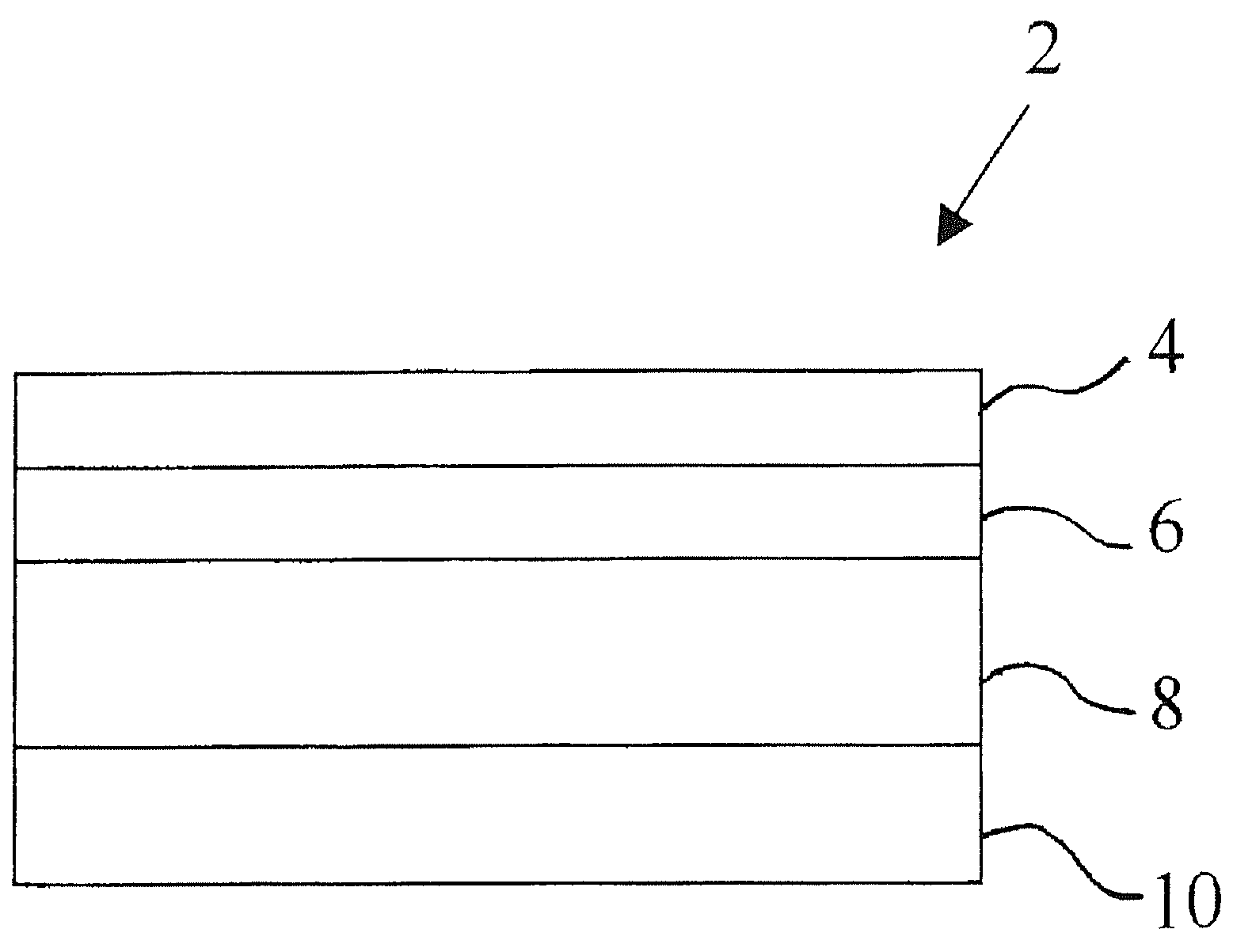

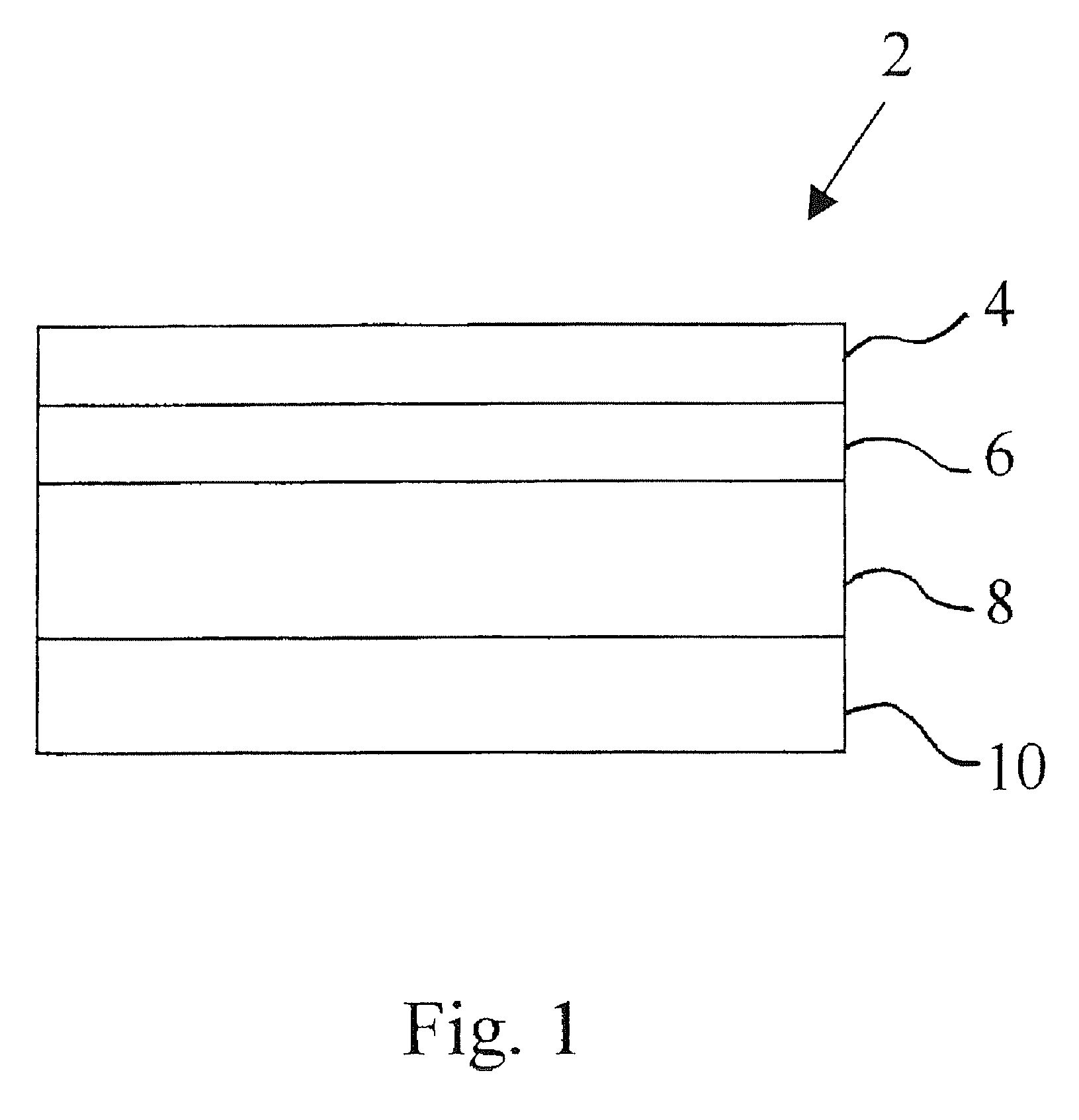

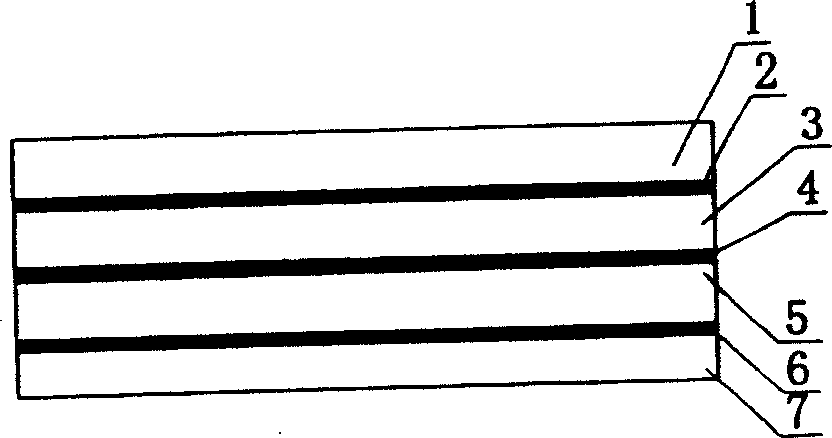

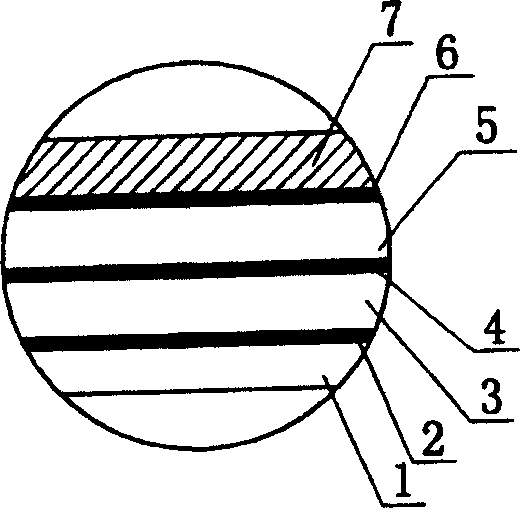

Multilayer braze-able sheet

InactiveUS20070246509A1Increased post braze strengthShorten aging timeCooking-vessel materialsWelding/cutting media/materialsManganeseCopper

A multi-layer aluminum brazing sheet including a core layer, interliner, braze clad layer and a sacrificial layer, in which the post-braze strength of the brazing sheet is optimized by controlling the manganese (Mn), silicon (Si), copper (Cu) and magnesium (Mg) contents of the core layer and the Mn, Si and Cu content of the interliner and the Mn, Si and Zn content of the sacrificial layer and the specifics of the braze thermal cycle. The brazing sheet maintains corrosion resistance, while optimizing post-braze strength, by utilizing 0.5 wt. % to 1.2 wt. % Cu in the interliner. Further, the interliner and sacrificial layer of the brazing sheet contain low or no magnesium to maintain the brazing sheet's braze-ability.

Owner:ARCONIC TECH LLC +1

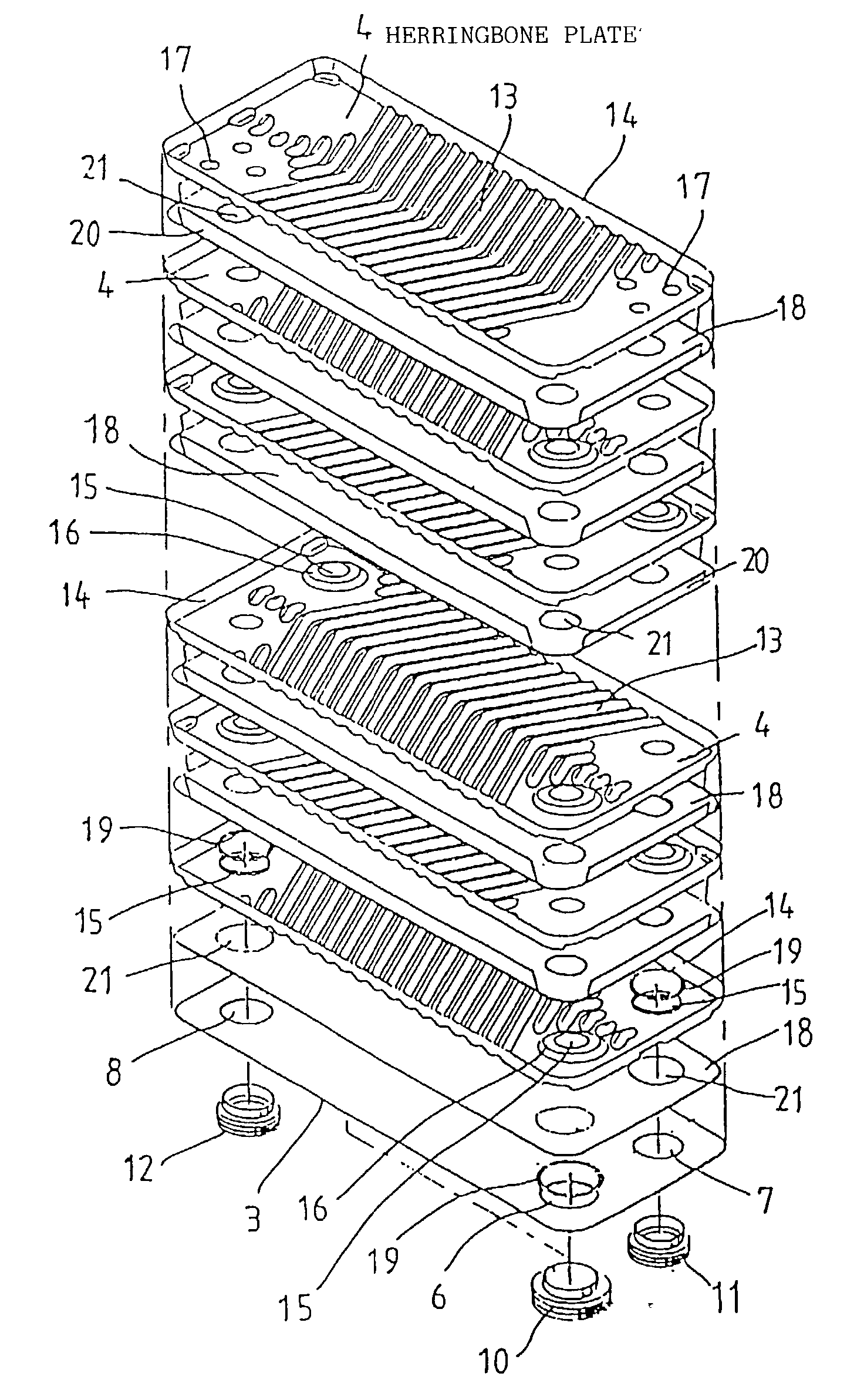

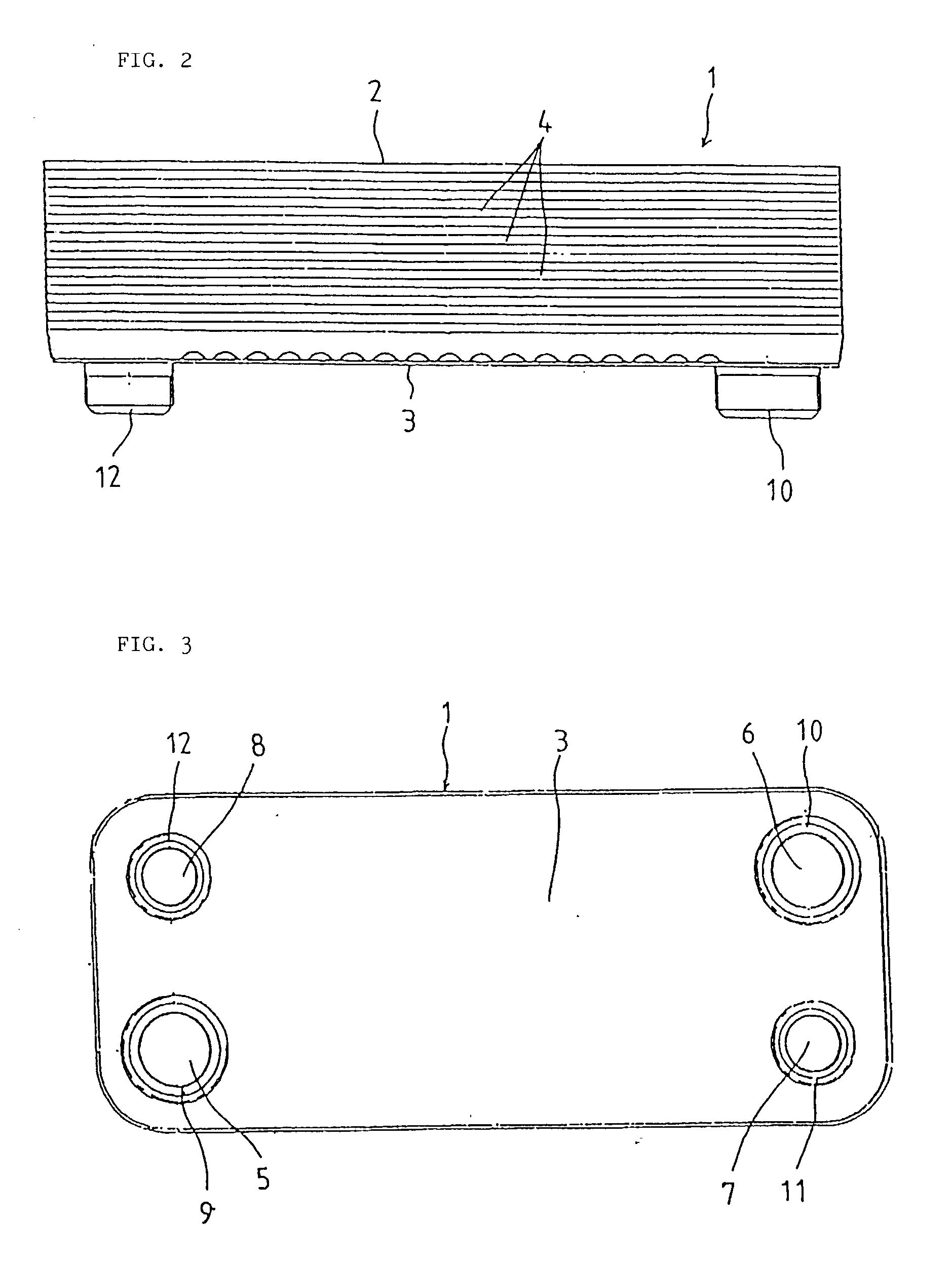

Method of manufacturing plate type titanium heat exchanger

InactiveUS20040069837A1Increased durabilityImprove air tightnessStationary conduit assembliesWelding/cutting media/materialsVacuum pressureTitanium

In a method of manufacturing a plate type titanium heat exchanger in which a plurality of titanium herringbone plates are laminated and flow paths are formed between the respective herringbone plates, after brazing materials are charged or coated to the joints between the herringbone plates, respectively, the herringbone plates are placed in a vacuum heating furnace, subjected to vacuum degas processing while being gradually heated, and joined to each other by brazing by being more heated after a prescribed vacuum pressure has been obtained.

Owner:FUJIYAMA AKIRA +3

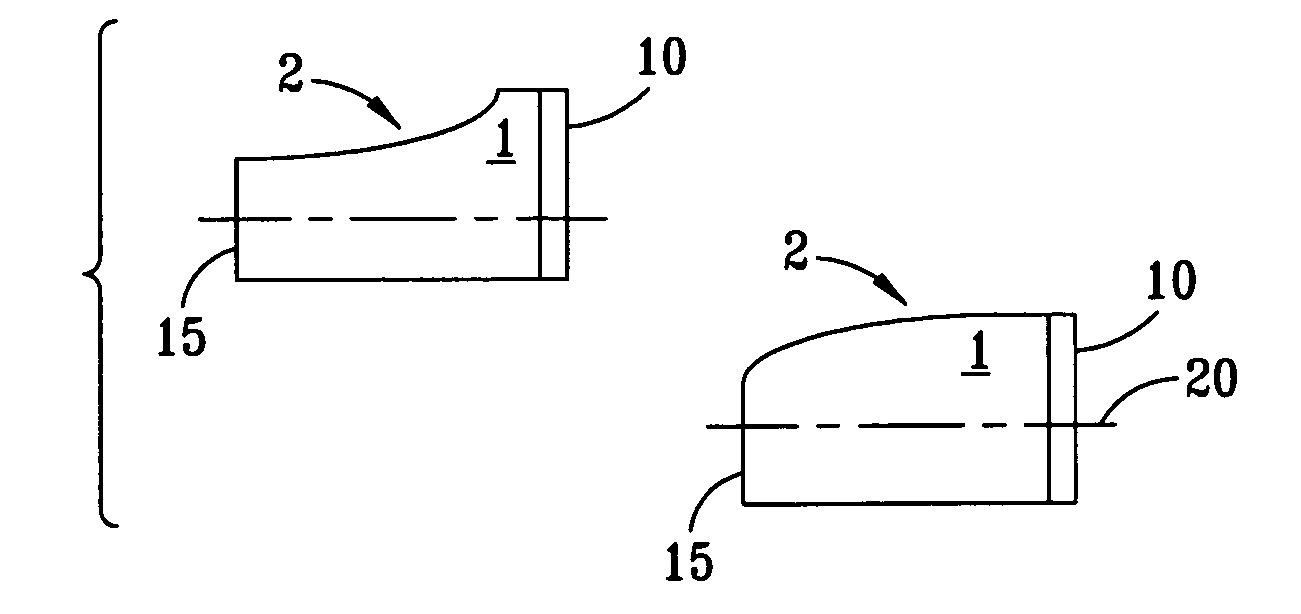

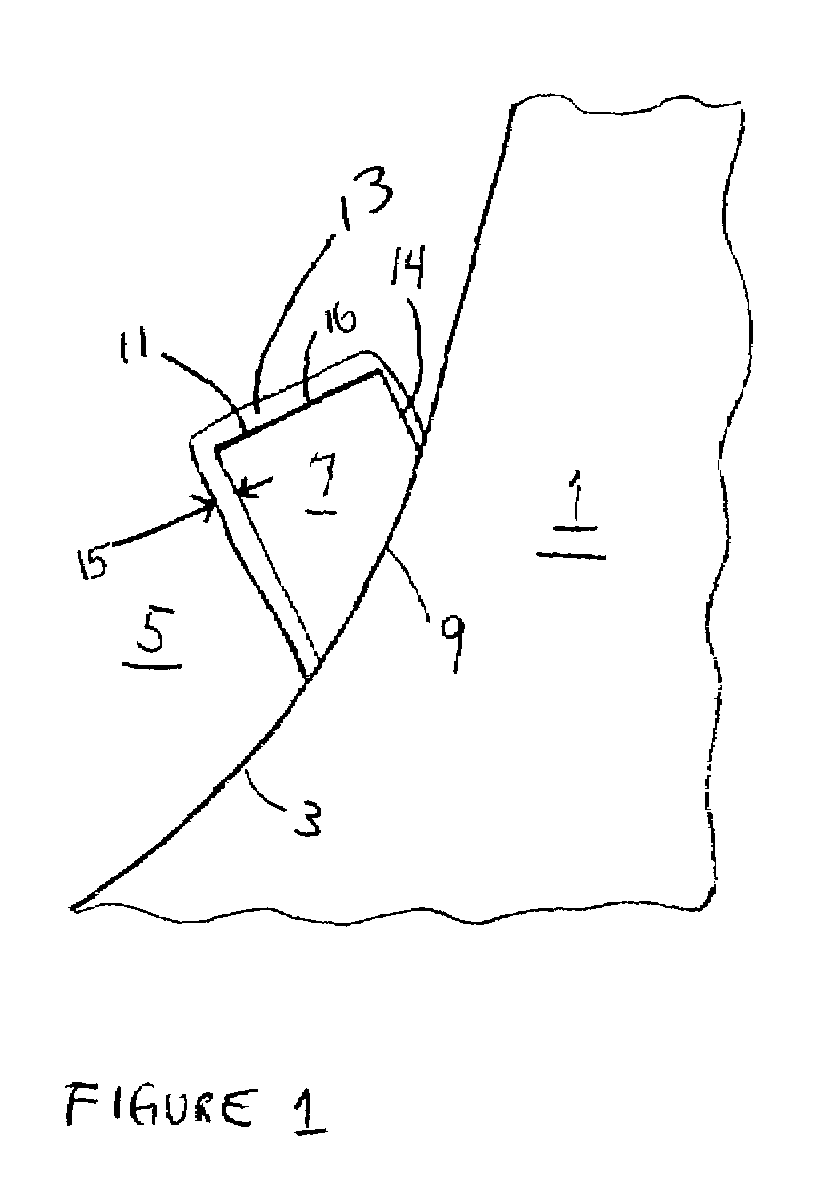

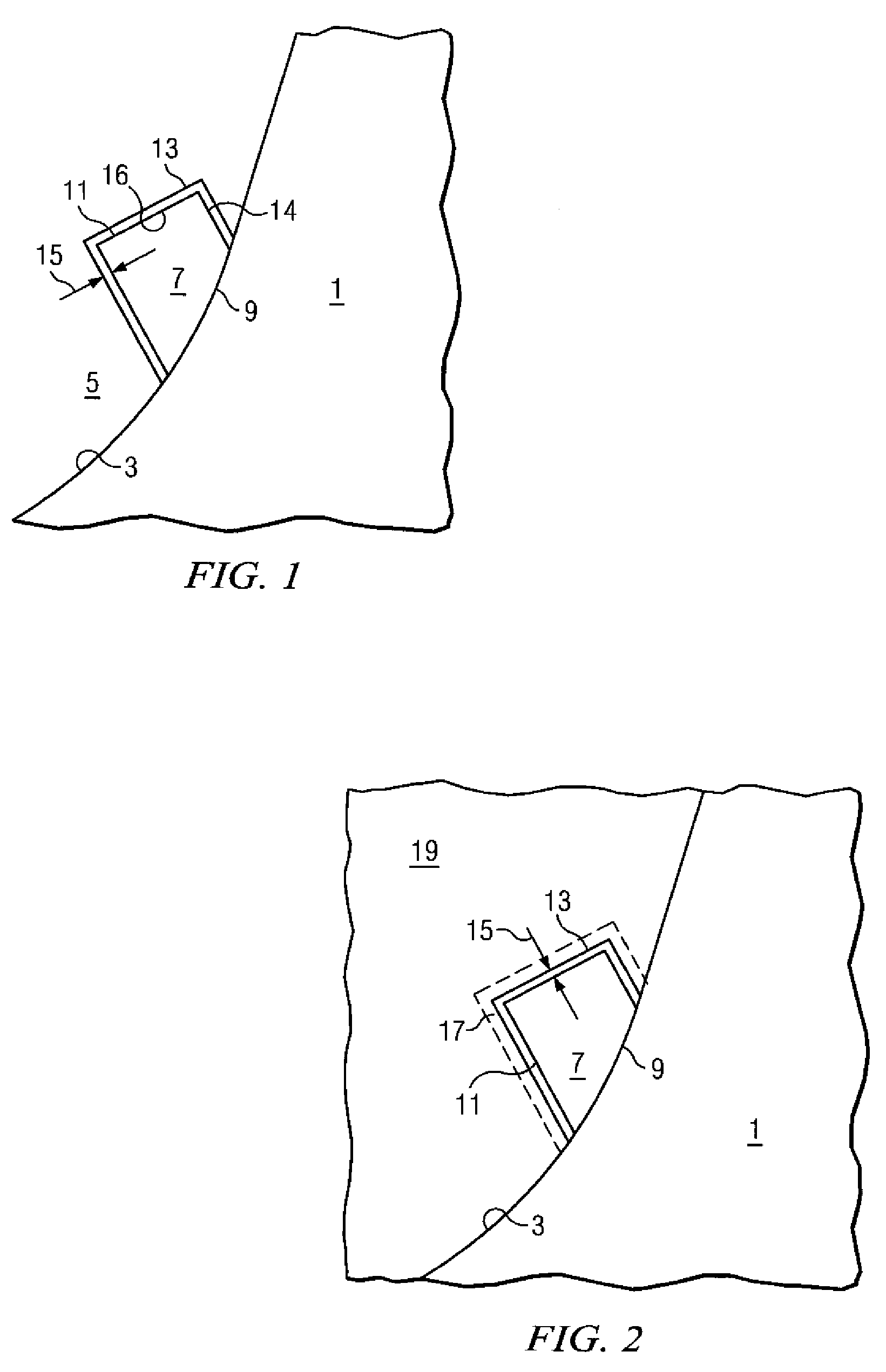

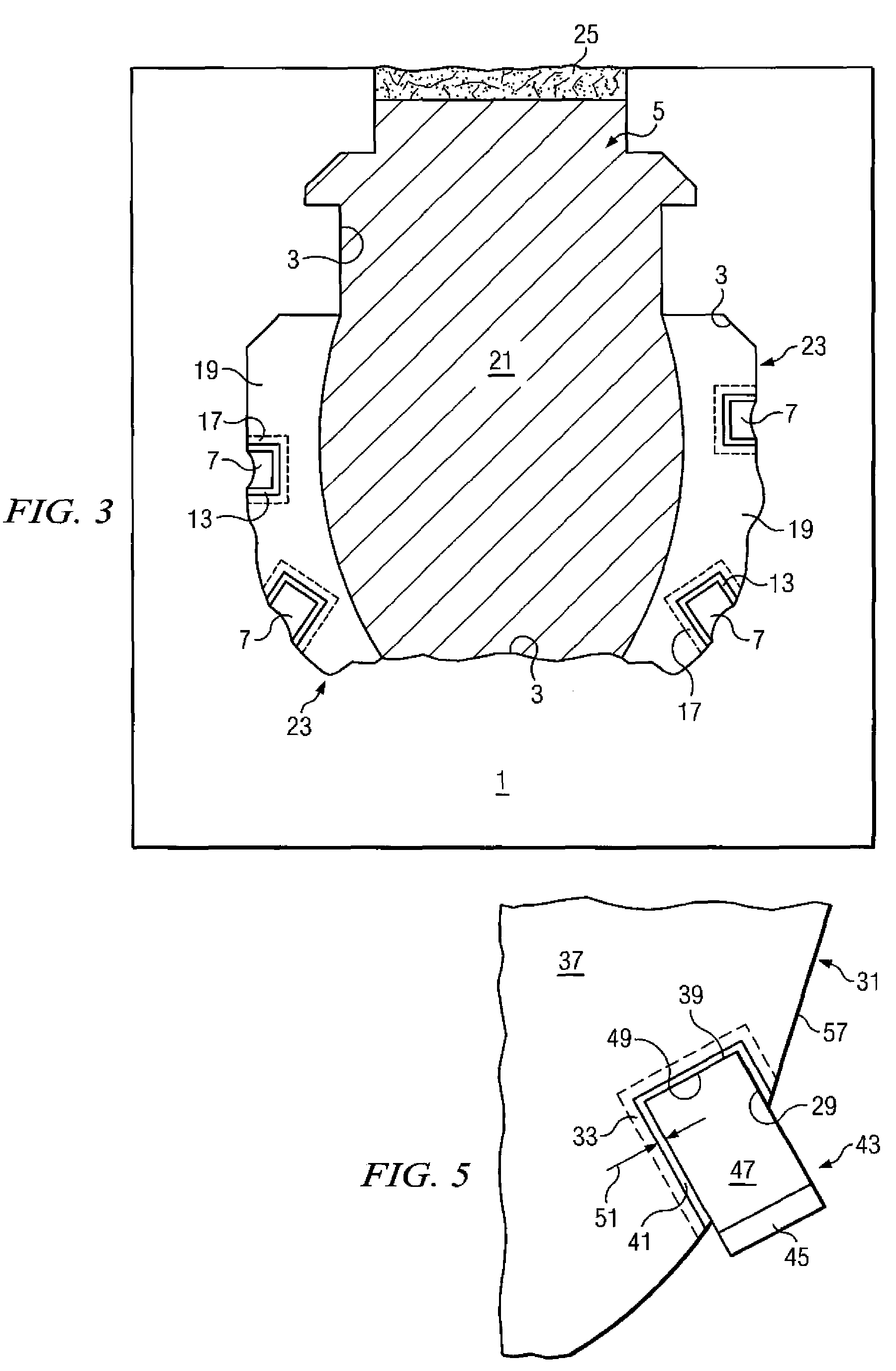

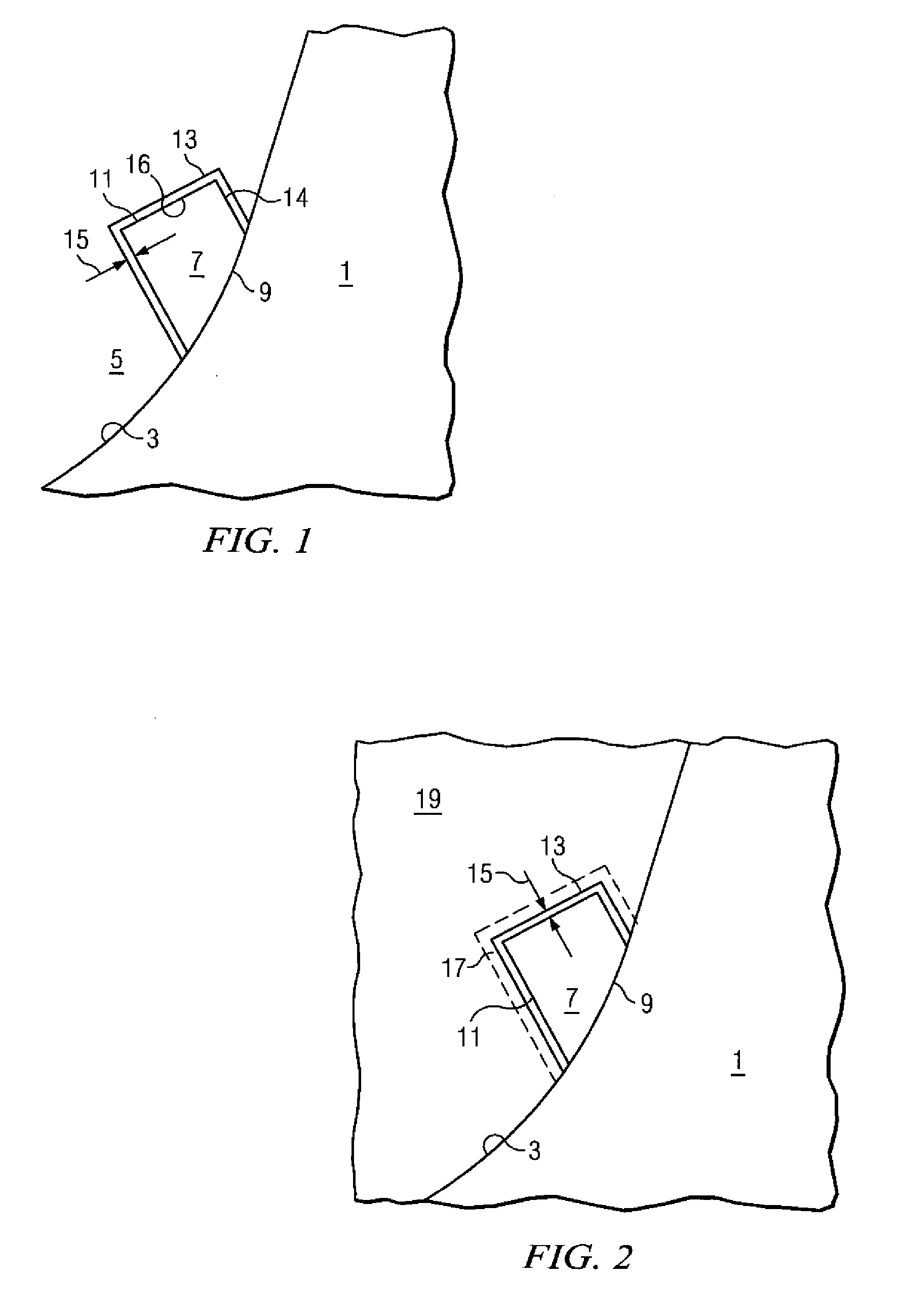

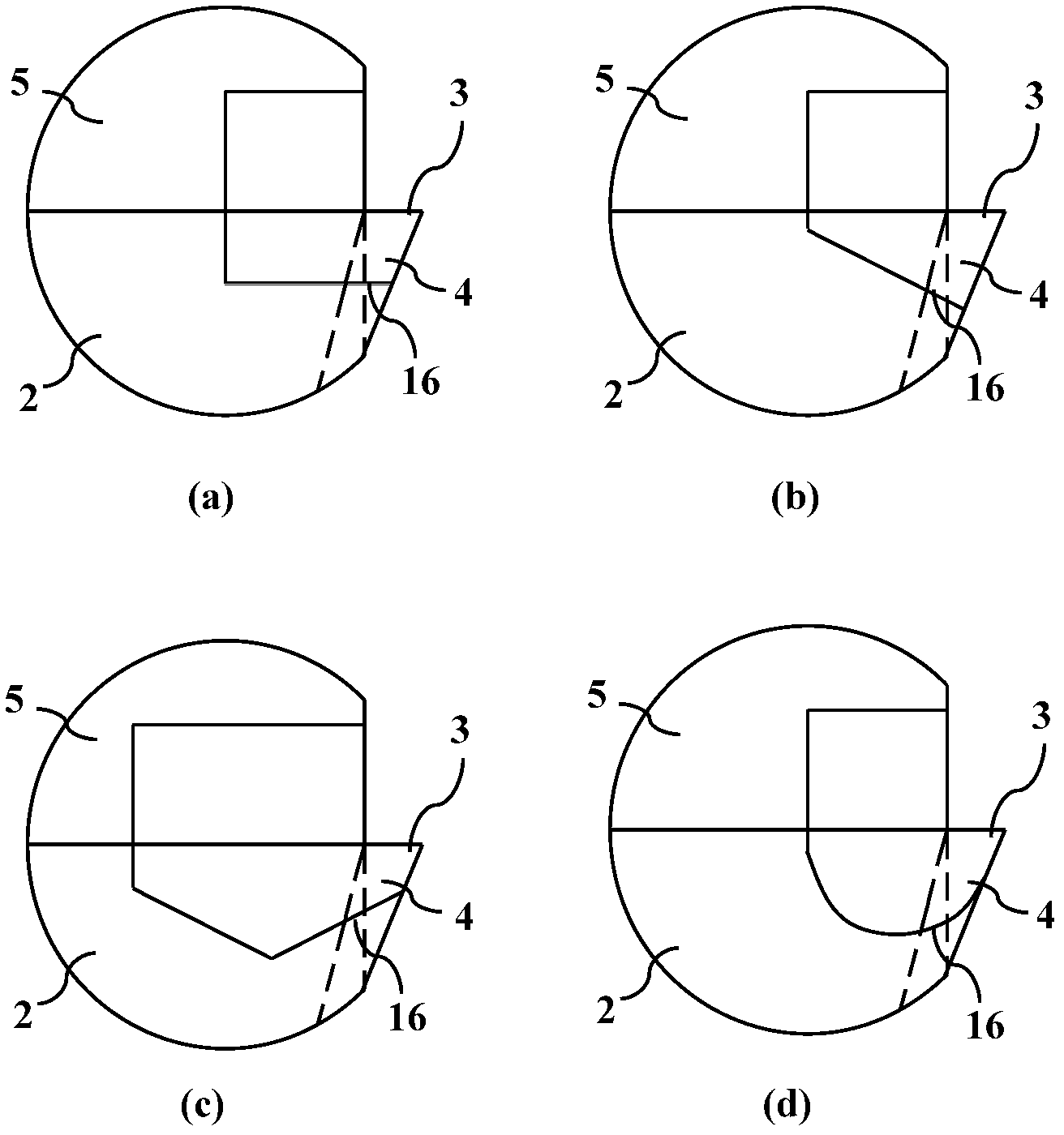

Cutting element with improved cutter to blade transition

InactiveUS7373998B2Easy transitionIncrease exposureDrill bitsConstructionsMechanical engineeringDrill bit

Cutting elements having a slanted top surface for an improved cutter to blade transition, the slanted top surface being integratable into a receiving pocket of a bit blade such that the slanted top surface and the perimeter of the receiving pocket are relatively contiguous when the slanted cutter is mounted within the receiving pocket. Also, a bit with slanted cutters as well as a method of manufacturing a bit having slanted cutters.

Owner:SMITH INT INC

Copper, aluminium, stainless steel composite brazing method

InactiveCN1522820AImprove brazing strengthOvercoming the disadvantages of poor welding qualityHigh frequency current welding apparatusPotassiumCopper

The present invention relates to a copper, aluminium and stainless steel combined brazing method, including the following steps: between copper and aluminium setting a transition layer, the described transition layer is a stainless steel sheet, and its thickness is 0.1-0.5 mm; cleaning copper, aluminium and stainless steel workpieces to be brazed, degreasing, brush-coating two surfaces of aluminium workpiece with potassium fluoroaluminate eutectic brazing flux, spreading aluminium-silicon eutectic brazing filter metal, placing it on the brazed surface of stainless steel workpiece, coating one side surface of transition layer stainless steel sheet with potassium fluoroborate brazing flux, spreading copper-phosphorus base brazing filler metal, placing one surface which is not coated with brazing flux and brazing filler metal on aluminium workpiece with brazing flux and brazing filler metal, then covering them with copper sheet for brazing.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

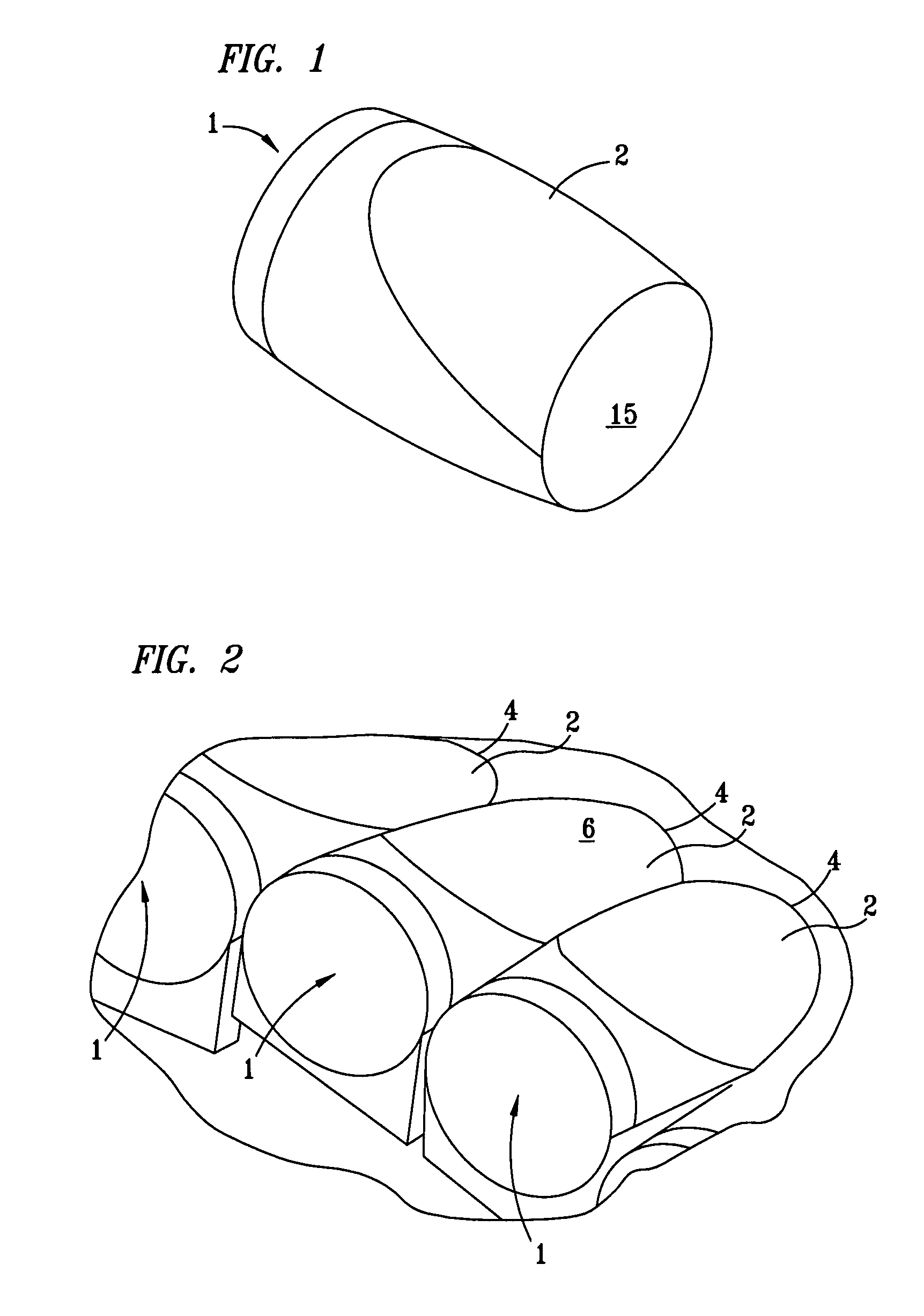

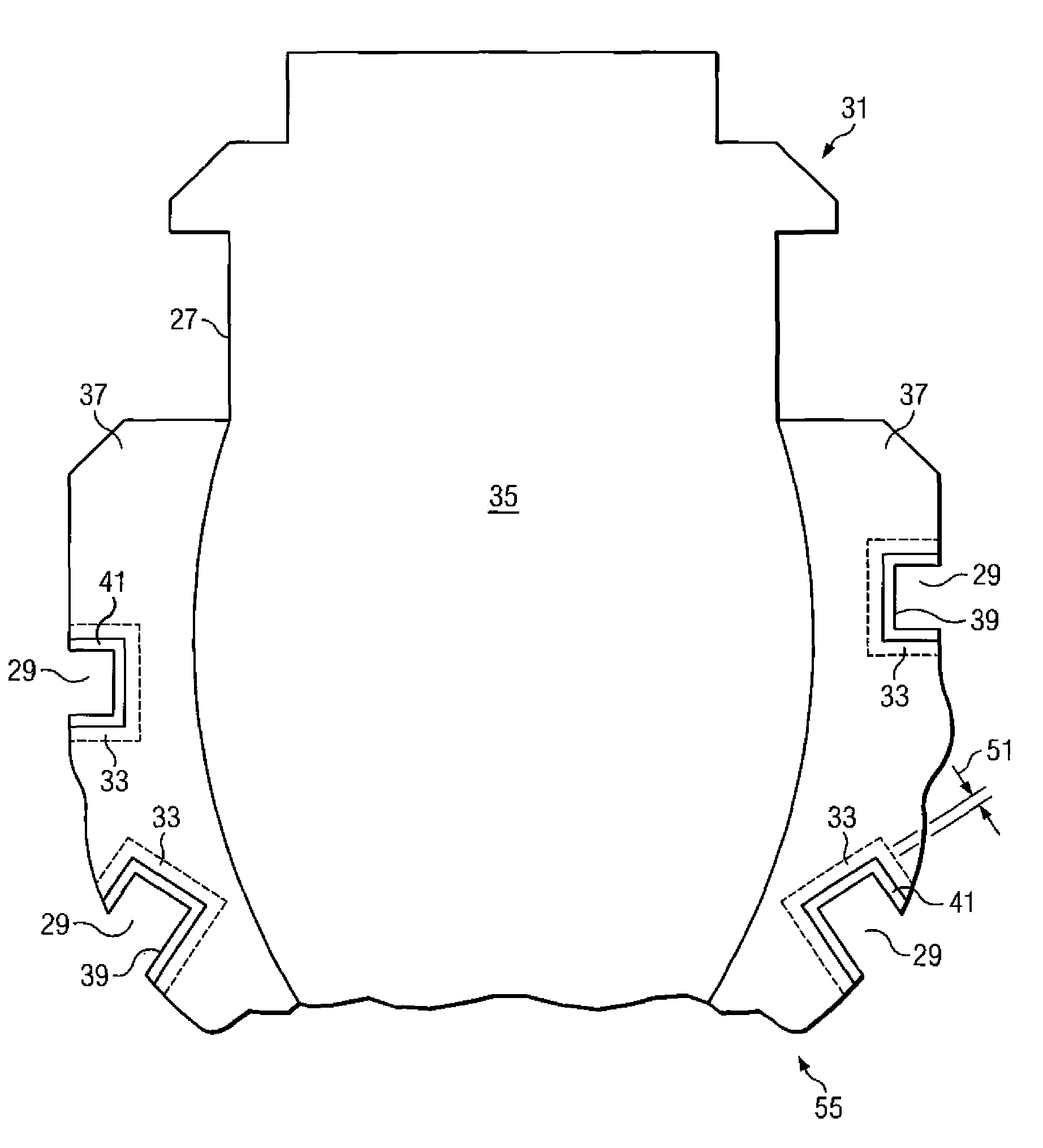

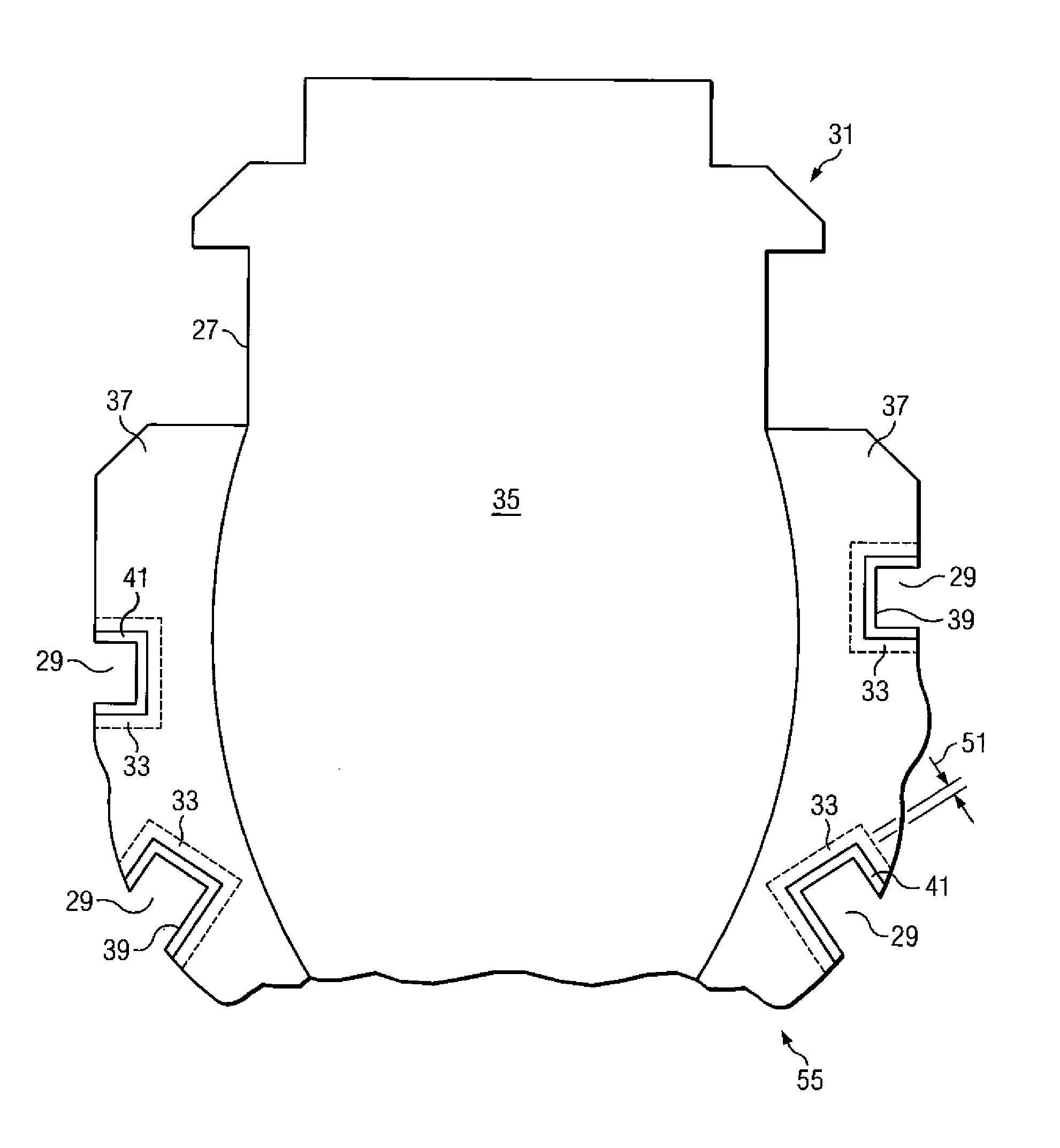

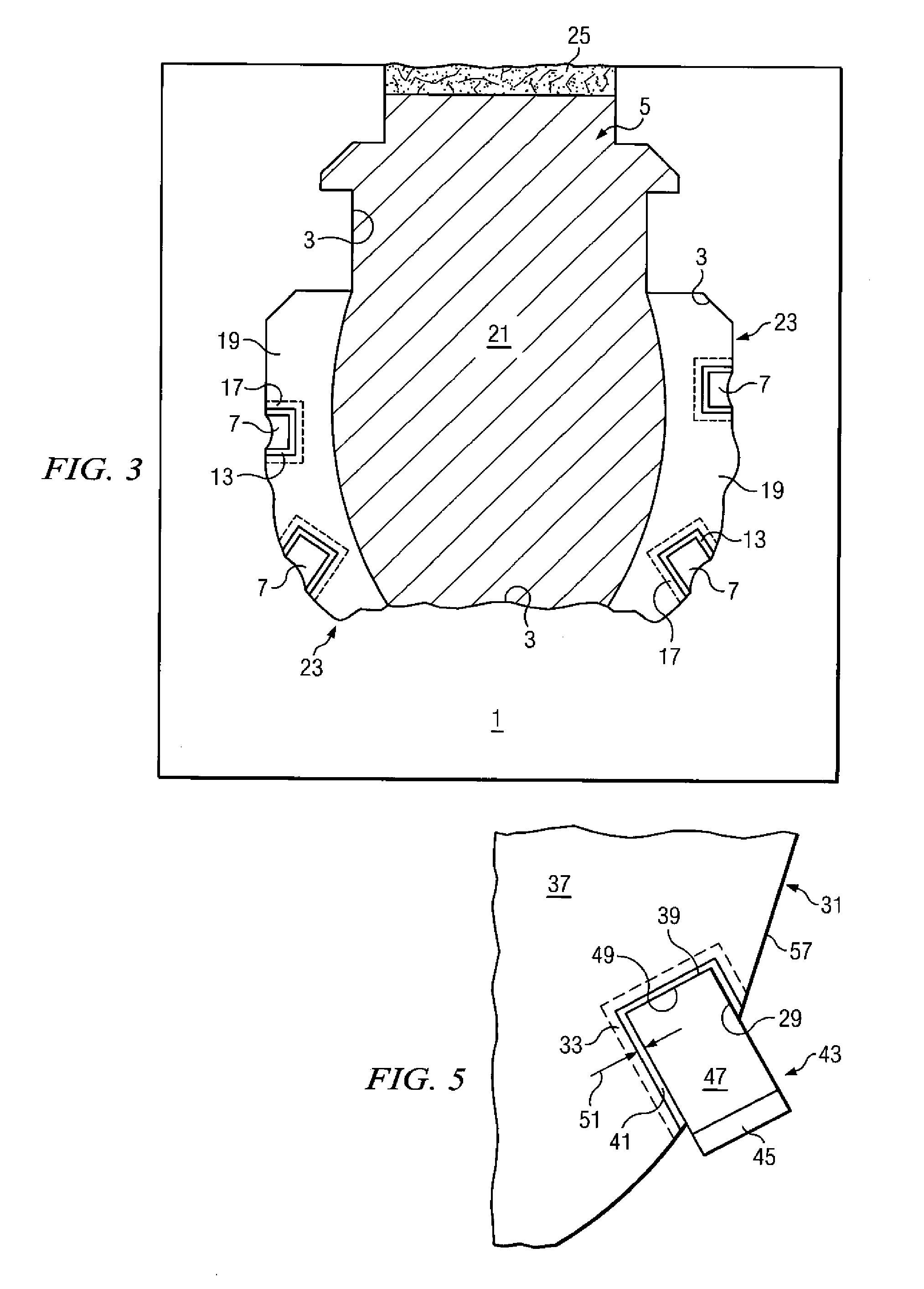

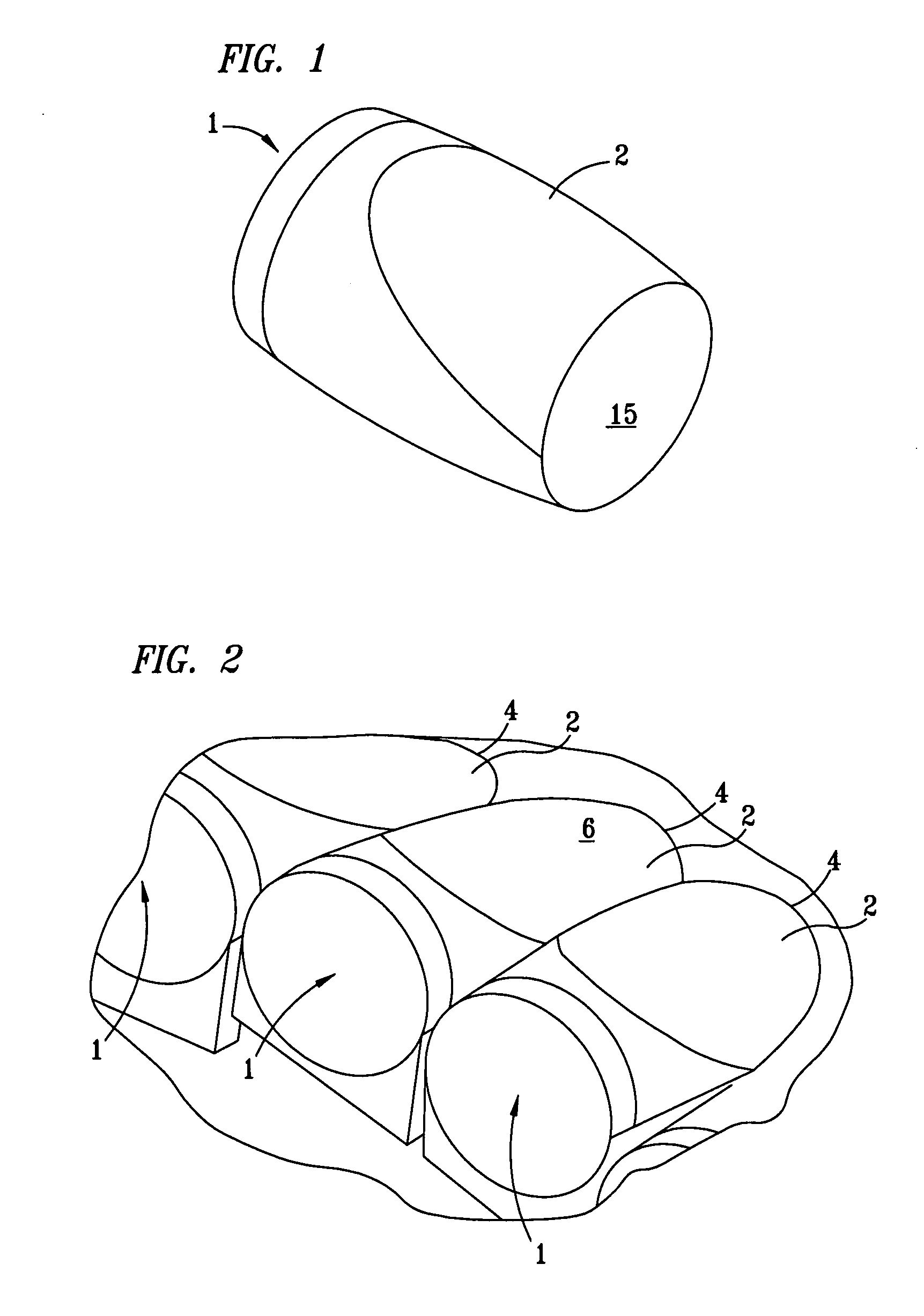

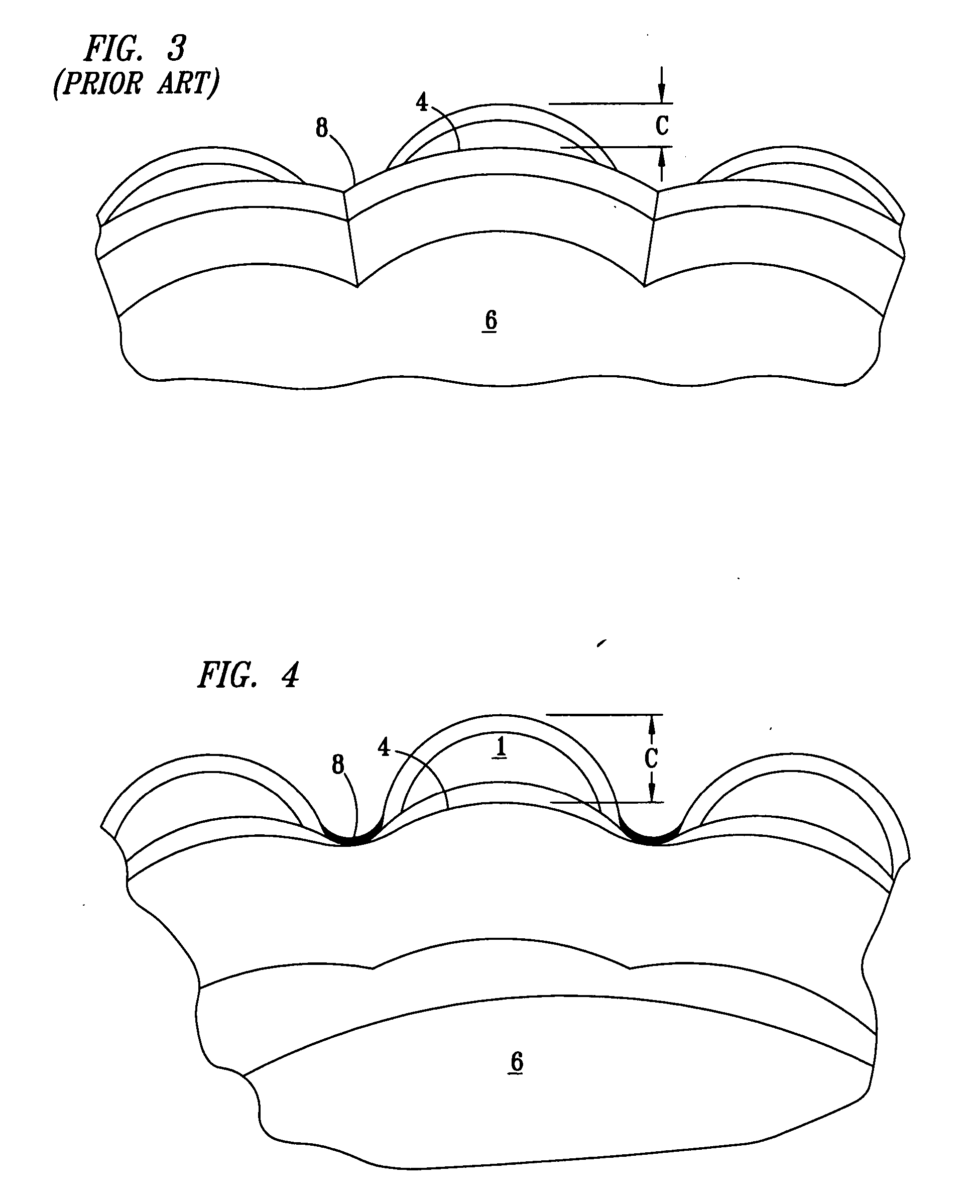

Bonding of cutters in drill bits

InactiveUS7625521B2Improve brazing strengthDrill bitsConstructionsBoron nitrideUltimate tensile strength

A bit body formed of a mixture of matrix material and superabrasive powder and including pockets lined with superabrasive-free matrix material, and a method for forming the same, are provided. The pockets are shaped to receive cutting elements therein. The superabrasive-free matrix material enhances braze strength when a cutting element is brazed to surfaces of the pocket. The method for forming the drill bit body includes providing a mold and displacements. The displacements are coated with a mixture of superabrasive free matrix-material and an organic binder. The mold is packed with a mixture of matrix material and superabrasive powder and the arrangement heated to form a solid drill bit body. When the solid bit body is removed from the mold, pockets are formed by the displacements in the bit body and are lined with the layer of superabrasive-free matrix material. The superabrasive material may be diamond, polycrystalline cubic boron nitride, SiC or TiB2 in exemplary embodiments.

Owner:SMITH INT INC

Iron-base heat- and corrosion-resistant brazing material

InactiveUS20110020166A1Improve heat resistanceImprove brazing strengthTransportation and packagingWelding/cutting media/materialsCorrosion resistantWetting

The object of the present invention is to provide at a low cost iron-base heat- and corrosion-resistant brazing material which make it possible to braze parts made of a base metal selected from among various stainless steels, particularly ferritic stainless steels, at a practical temperature (of 1120° C. or lower) and are excellent in the wetting property against the base metal and which can attain excellent resistance to corrosion by sulfuric acid or nitric acid and high strength without coarsening the structure of the base metal. The iron-base heat- and corrosion-resistant brazing material is characterized by comprising 30 to 75 wt % of Fe, 35 wt % or less of Ni and 5 to 20 wt % of Cr in a total amount of Ni and Cr of 15 to 50 wt %, and 7 wt % or less of Si and 4 to 10 wt % of P in a total amount of Si and P of 9 to 13 wt %. The iron-base heat- and corrosion-resistant brazing material further comprising 0.5 to 5 wt % of Mo and / or 0.3 to 5 wt % of Cu in a total amount of Mo and Cu of 1 to 7 wt % is more preferable.

Owner:FUKUKA METAL FOIL & POWDER CO LTD

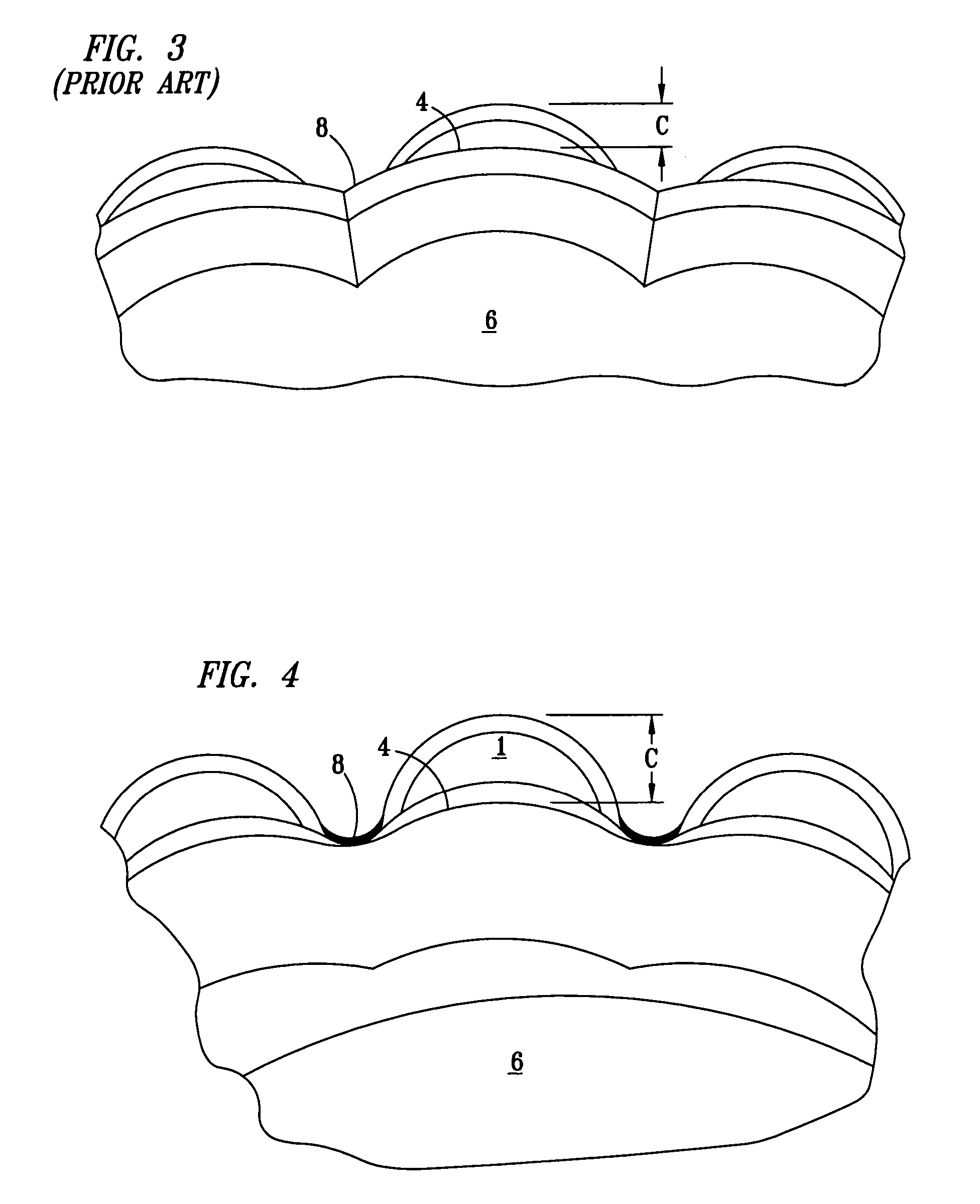

Bonding of cutters in diamond drill bits

InactiveUS7997358B2Improve brazing strengthDrill bitsConstructionsBoron nitrideUltimate tensile strength

A bit body formed of a mixture of matrix material and superabrasive powder and including pockets lined with superabrasive-free matrix material, and a method for forming the same, are provided. The pockets are shaped to receive cutting elements therein. The superabrasive-free matrix material enhances braze strength when a cutting element is brazed to surfaces of the pocket. The method for forming the drill bit body includes providing a mold and displacements. The displacements are coated with a mixture of superabrasive free matrix-material and an organic binder. The mold is packed with a mixture of matrix material and superabrasive powder and the arrangement heated to form a solid drill bit body. When the solid bit body is removed from the mold, pockets are formed by the displacements in the bit body and are lined with the layer of superabrasive-free matrix material. The superabrasive material may be diamond, polycrystalline cubic boron nitride, SiC or TiB2 in exemplary embodiments.

Owner:SMITH INT INC

Bonding of cutters in diamond drill bits

InactiveUS20100101868A1Improve brazing strengthPigmenting treatmentDrill bitsBoron nitrideUltimate tensile strength

A bit body formed of a mixture of matrix material and superabrasive powder and including pockets lined with superabrasive-free matrix material, and a method for forming the same, are provided. The pockets are shaped to receive cutting elements therein. The superabrasive-free matrix material enhances braze strength when a cutting element is brazed to surfaces of the pocket. The method for forming the drill bit body includes providing a mold and displacements. The displacements are coated with a mixture of superabrasive free matrix-material and an organic binder. The mold is packed with a mixture of matrix material and superabrasive powder and the arrangement heated to form a solid drill bit body. When the solid bit body is removed from the mold, pockets are formed by the displacements in the bit body and are lined with the layer of superabrasive-free matrix material. The superabrasive material may be diamond, polycrystalline cubic boron nitride, SiC or TiB2 in exemplary embodiments.

Owner:SMITH INT INC

Multilayer braze-able sheet

InactiveUS7749613B2Improve brazing strengthShorten aging timeCooking-vessel materialsWelding/cutting media/materialsManganeseCopper

A multi-layer aluminum brazing sheet including a core layer, interliner, braze clad layer and a sacrificial layer, in which the post-braze strength of the brazing sheet is optimized by controlling the manganese (Mn), silicon (Si), copper (Cu) and magnesium (Mg) contents of the core layer and the Mn, Si and Cu content of the interliner and the Mn, Si and Zn content of the sacrificial layer and the specifics of the braze thermal cycle. The brazing sheet maintains corrosion resistance, while optimizing post-braze strength, by utilizing 0.5 wt. % to 1.2 wt. % Cu in the interliner. Further, the interliner and sacrificial layer of the brazing sheet contain low or no magnesium to maintain the brazing sheet's braze-ability.

Owner:ARCONIC TECH LLC +1

Copper-based amorphous brazing material and preparation method thereof, as well as strip and preparation method thereof

InactiveCN103231183AImprove toughnessGuaranteed mechanical propertiesWelding/cutting media/materialsSoldering mediaGroup elementCopper

The invention discloses a copper-based amorphous brazing material and a preparation method thereof, as well as a strip and a preparation method thereof. The copper-based amorphous brazing material doesn't contain a P element and a B element, but comprises Cu, Si, Sn, Ni and at least one IVB group element in Ti, Zr and Hf. The weight ratio of Cu, Si, Sn and at least one IVB group metal in Ti, Zr and Hf is (71-83):(0.15-0.22):(4.0-6.8):(13.5-14.3):(0.02-0.06). The copper-based amorphous brazing material and the preparation method thereof, as well as the strip and the preparation method thereof have the advantages as follows: 1), the P element is removed, so that the toughness of the brazing material is greatly improved; and 2), a micro amount of one or combinations of three IBV group elements, namely Ti, Zr and Hf is or are added, so that the brazing temperature is not increased, and the brazing strength is improved and a mechanical property of a brazing joint is guaranteed at the same time. The invention further discloses the preparation method of the copper-based amorphous brazing material, the copper-based amorphous brazing material strip made of the copper-based amorphous brazing material and the preparation method of the copper-based amorphous brazing material strip.

Owner:安庆天瑞新材料科技股份有限公司

Brazing filler metal for braze welding of titanium and titanium alloy, preparation method and braze welding method

ActiveCN102319966AReduce manufacturing costEasy to processWelding/cutting media/materialsWelding/soldering/cutting articlesManufacturing cost reductionIngot

The invention discloses a brazing filler metal for the braze welding of titanium and titanium alloy, which contains 22 to 32 percent by weight of Ni, 1 to 1.5 percent by weight of Al, 0.5 to 1.0 percent by weight of Mn, 0.3 to 0.6 percent by weight of V, 0.6 to 1.0 percent by weight of Sn, 1.5 to 2 percent by weight of Zr and the balance of Cu. The preparation method for the brazing filler metal includes the following steps: weighing the materials, casting the smelted materials to form a brazing filler metal ingot, and then extruding and rolling the brazing filler metal ingot into a braze welding foil. An argon-shielded condenser discharge resistance heating method is adopted to weld titanium with the brazing filler metal. The brazing filler metal does not contain precious metals, i.e. palladium and silver, and thereby the manufacturing cost can be greatly reduced; the processability of the brazing filler metal is good, the inter-annealing processing rate is high, a foil strip which is 0.1mm can be rolled, and the rate of finished products is 80 to 85 percent. Meanwhile, the preparation method is simple, the strength of a braze-welded titanium joint is high, the braze-welding timeis short, the metallic texture of the titanium alloy matrix cannot be changed, and in particular, the invention is suitable for the braze welding of titanium alloy parts of small specifications in large batches.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

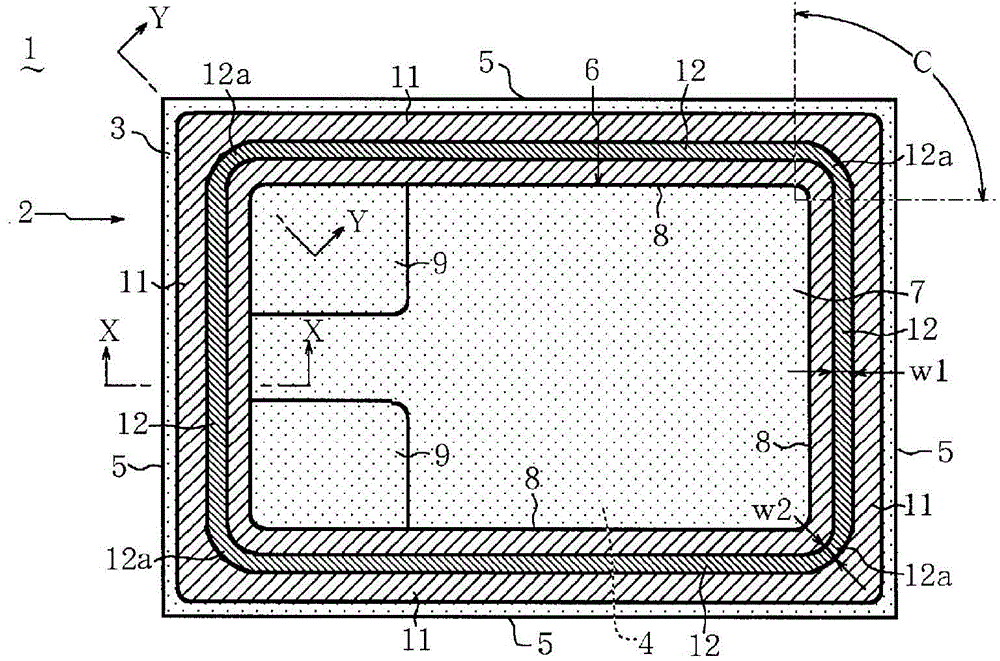

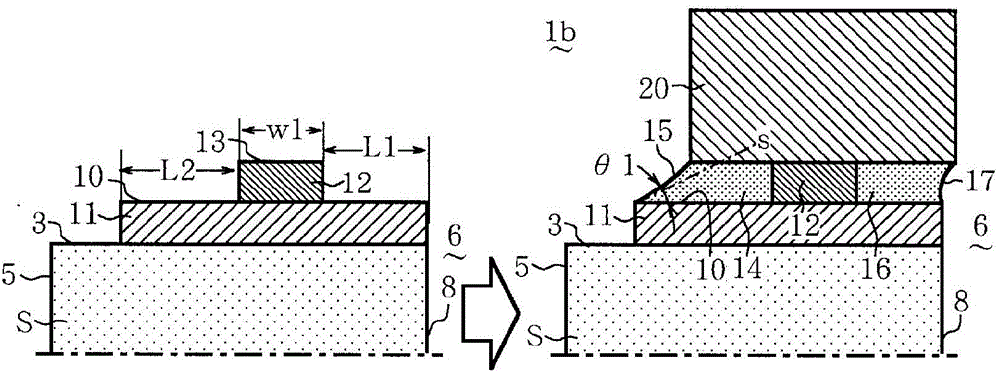

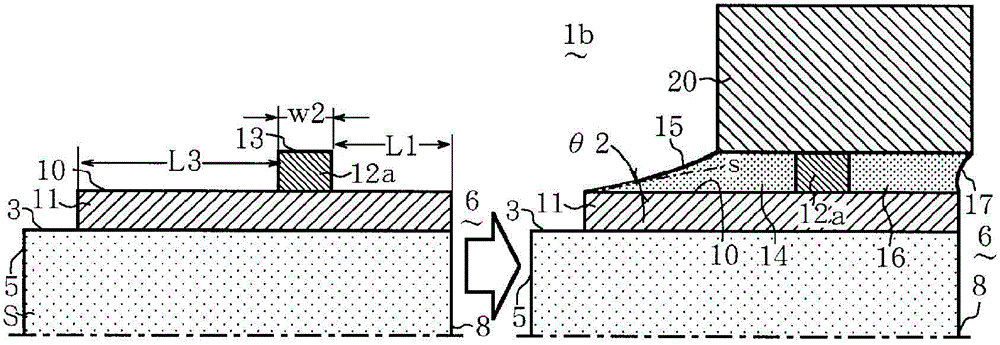

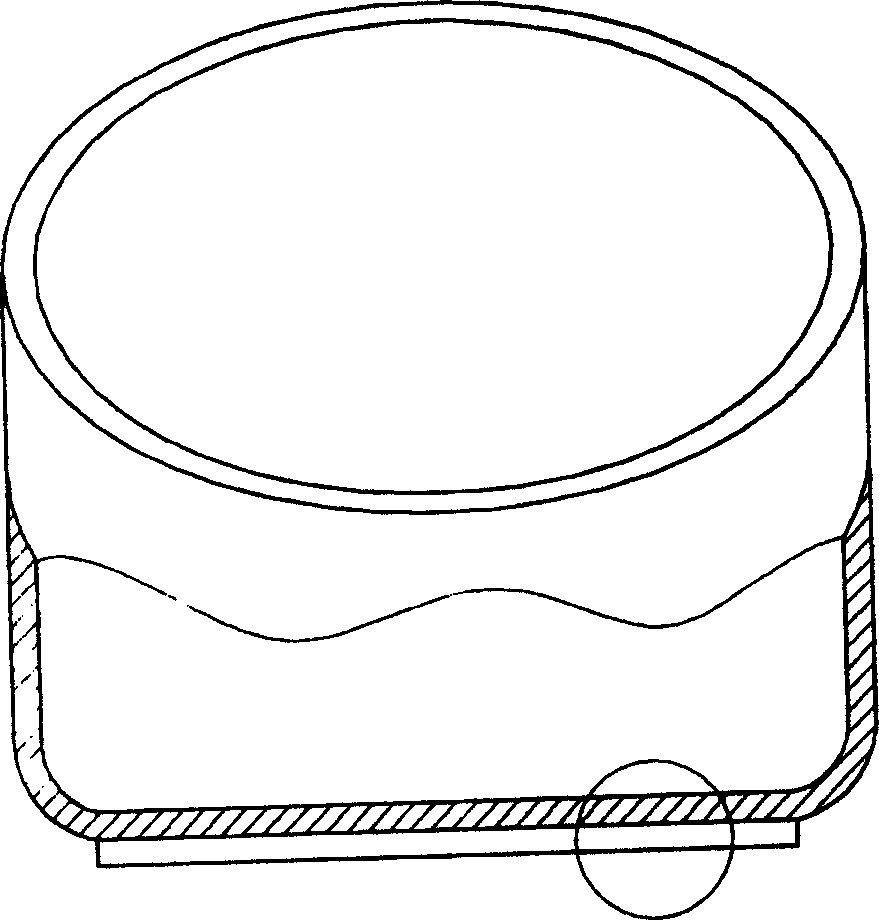

Ceramic package

InactiveCN103959461AReduce peelingImprove brazing strengthImpedence networksSemiconductor/solid-state device detailsElectronic componentCrystal oscillator

Provided is a ceramic package having a cavity for mounting of an electronic component such as a crystal oscillator, whereby a metal frame can be joined evenly around the opening, and sealing of the opening performed in a reliable manner. The ceramic package (1) is provided with: a package body (2) made of a ceramic, having a front surface (3) and a back surface (4) of rectangular shape in plan view, and a cavity (6) opening onto the front surface (3); a first metallization layer (11) of frame shape in plan view formed on the front surface (3); and a second metallization layer (12) of frame shape in plan view formed on the surface (10) of the first metallization layer (11), and having width (w2) along the mediolateral direction of the package body (2) that is narrower than the width (w1) of the first metallization layer (11), wherein in the ceramic package (1), the width (w2) of the second metallization layer (12a) along the mediolateral direction at the corners (C) of the front surface (3) in plan view is narrower than the width (w1) along the mediolateral direction of the second metallization layer (12) in regions other than the corners (C) in plan view.

Owner:NGK SPARK PLUG CO LTD

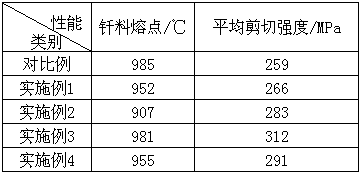

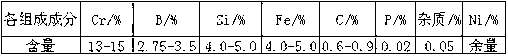

CVD (chemical vapor deposition) diamond brazing nickel-based alloy brazing sheet and preparation method thereof

InactiveCN103302419AOvercome costsOvercome the problems of high melting point and poor filling abilityWelding/cutting media/materialsSoldering mediaLanthanumChemical vapor deposition

The invention discloses a CVD (chemical vapor deposition) diamond brazing nickel-based alloy brazing sheet and a preparation method thereof. The CVD diamond brazing nickel-based alloy brazing sheet comprises the following components in weight percentage: 8.0-12% of Cr, 2.5-4.0% of Si, 1.5-2.0% of B, 7.8-11% of Sn, 0.4-1.0% of Ag, 0.1-1.0% of lanthanum neodymium, not more than 0.05% of impurities and the balance of Ni. The CVD diamond brazing nickel-based alloy brazing sheet overcomes the defects that the conventional Ag-based brazing material is high in cost and low in strength; the CVD diamond brazing nickel-based alloy brazing sheet contains Sn, so that the problems that the conventional Ni-Cr brazing material is high in melting point and poor in filling ability are solved; when the prepared nickel-based alloy brazing sheet is used for brazing a CVD diamond, the CVD diamond and the brazing sheet can form a chromium carbide compound, so that the bonding strength between the CVD diamond and the brazing sheet is high; the melting point of the brazing sheet is relatively low, so that heat damage to the CVD diamond is relatively small and the brazing sheet is easy to braze.

Owner:HENAN UNIV OF SCI & TECH

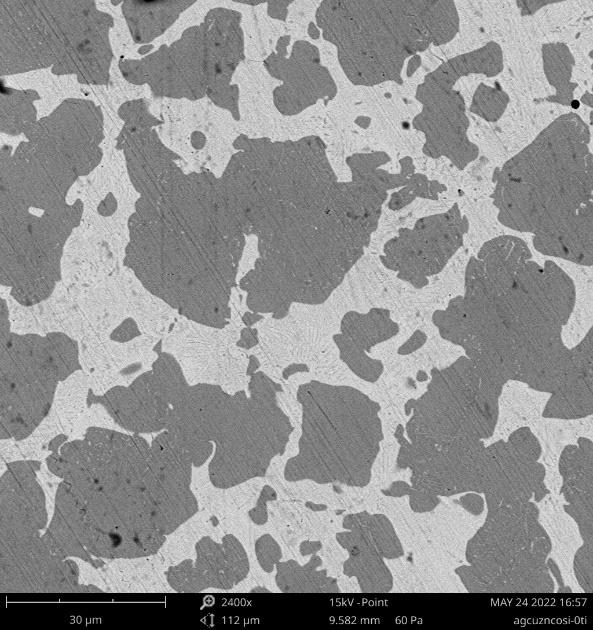

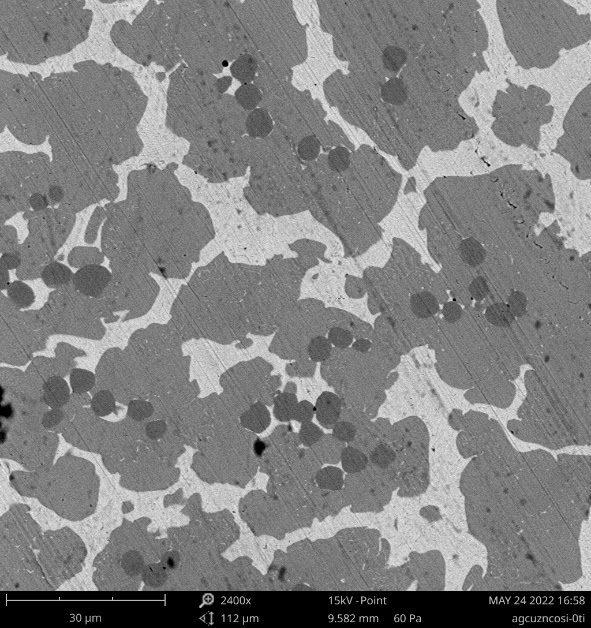

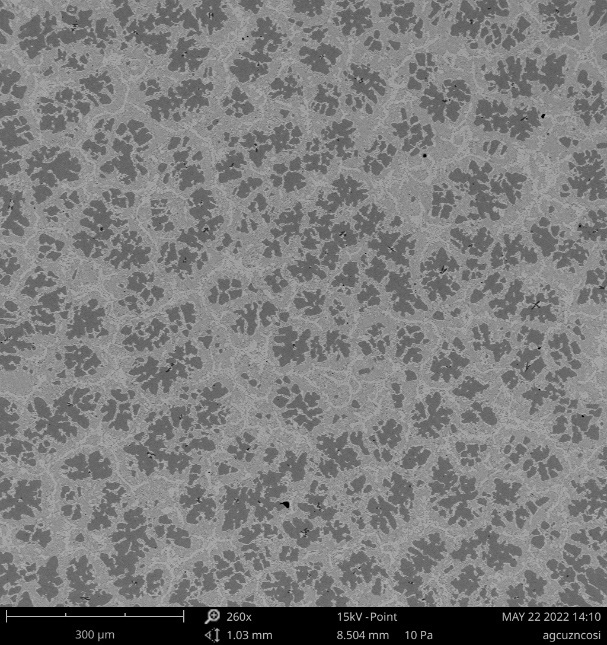

Lead-free copper-based amorphous brazing material

InactiveCN104384750AHigh tensile strengthHigh hardnessWelding/cutting media/materialsSoldering mediaGrain shapeZinc

The invention discloses a lead-free copper-based amorphous brazing material. The lead-free copper-based amorphous brazing material comprises the following components according to the total mass percent of 100%: greater than or equal to 0.02% and less than or equal to 0.06% of P, greater than or equal to 0.02% and less than or equal to 0.06% of Bi, greater than or equal to 4.0% and less than or equal to 6.8% of Sn, greater than or equal to 13.5% and less than or equal to 14.3% of Zn, greater than or equal to 0.15% and less than or equal to 0.22% of Ce, greater than or equal to 71% and less than or equal to 83% of Cu and the balance of impurities. According to the lead-free copper-based amorphous brazing material, the Bi element is specially added and the Cu element is completely removed; a microscopic structure morphology of the lead-free copper-based amorphous brazing material is analyzed, and the tensile strength, the percentage elongation after fracture and the Vickers hardness of the lead-free copper-based amorphous brazing material are tested; a result shows that the Bi element is added so that the tensile strength and the hardness of the lead-free copper-based amorphous brazing material can be remarkably improved and the Bi is added so that a needle-shaped or grain-shaped zinc-enriched phase can be separated out from the brazing material.

Owner:刘桂芹

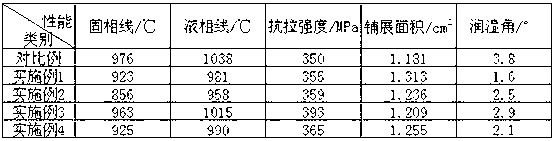

Composite brazing aluminum foil material for automobile radiator and manufacturing method thereof

InactiveCN102285163AImprove brazing strengthImprove thermal conductivityMetal rolling arrangementsMetal layered productsSlagManganese

A composite brazing aluminum foil material for an automobile radiator and a method for producing the material, the core layer of which is composed of: 0.5-0.8% of silicon, 0.20-0.30% of iron, 0.30-0.40% of copper, 1.0-1.8% of manganese, and 0.005-0.005% of chromium 0.035%, titanium 0.12-0.20%, the rest is aluminum. The production method is characterized in that: After melting the industrial pure aluminum ingot (Al99.70A) for remelting, add iron, copper, manganese, chromium and titanium in the above ratio, heat to 740°C-760°C, stir , to make the composition uniform, let stand after removing slag, cast at 720°C ~ 740°C, and then cast into an ingot. Aluminum-silicon type brazing material (AA4343 or AA4045 alloy), heated to 520°C-540°C after being fixed, kept for 10 hours, and then hot-rolled to obtain hot-rolled coils, which were then cold-rolled.

Owner:南通华特铝热传输材料有限公司

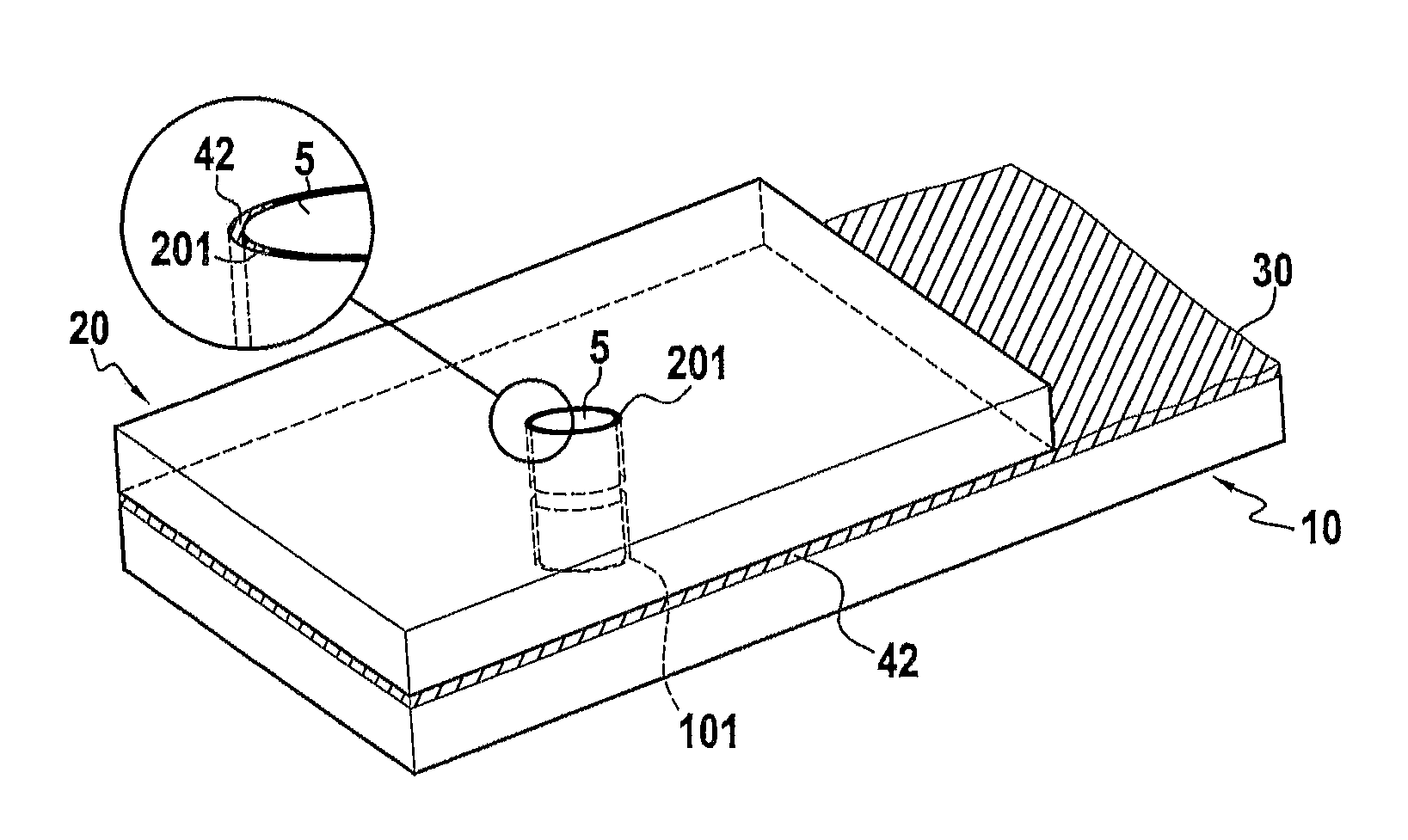

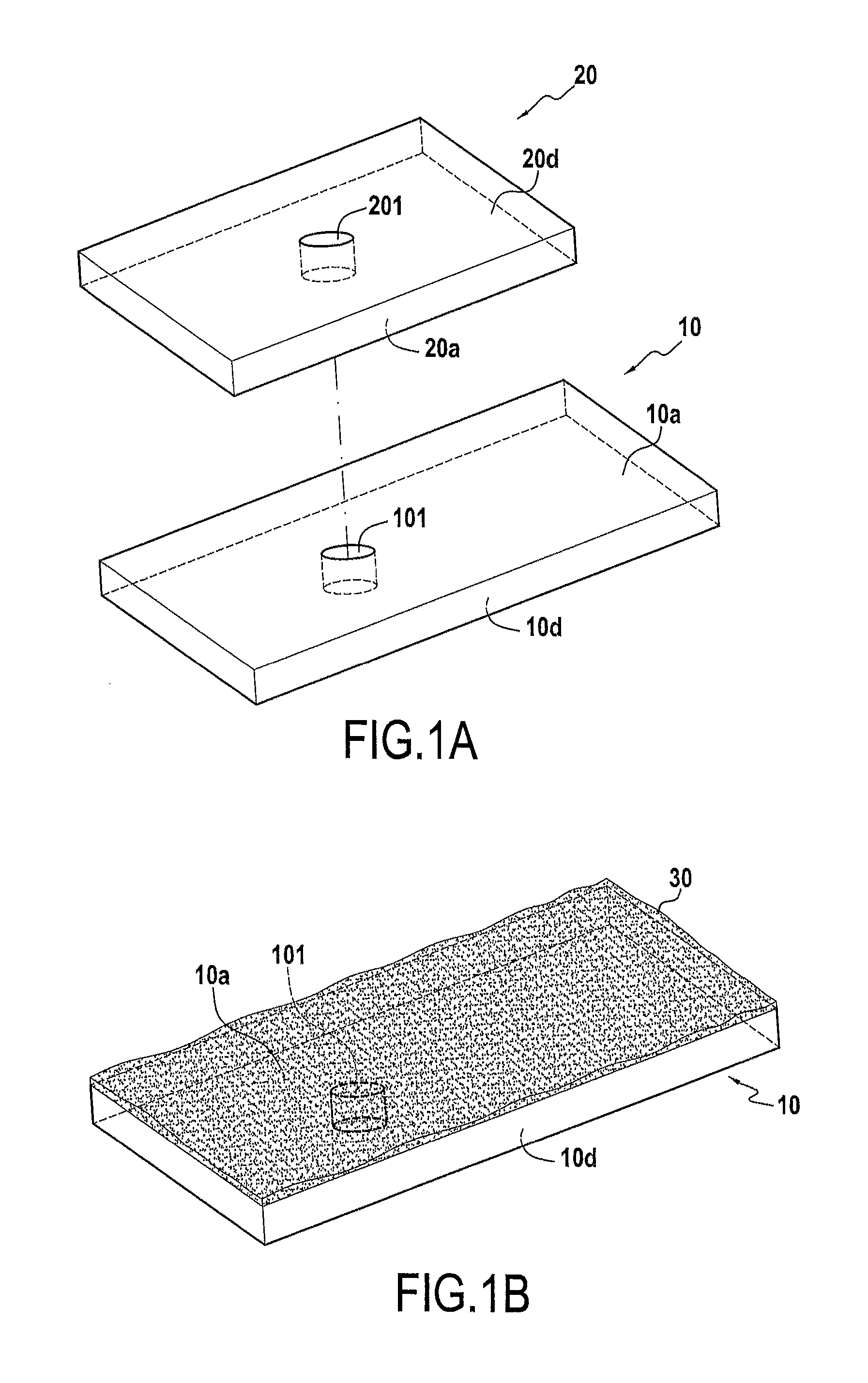

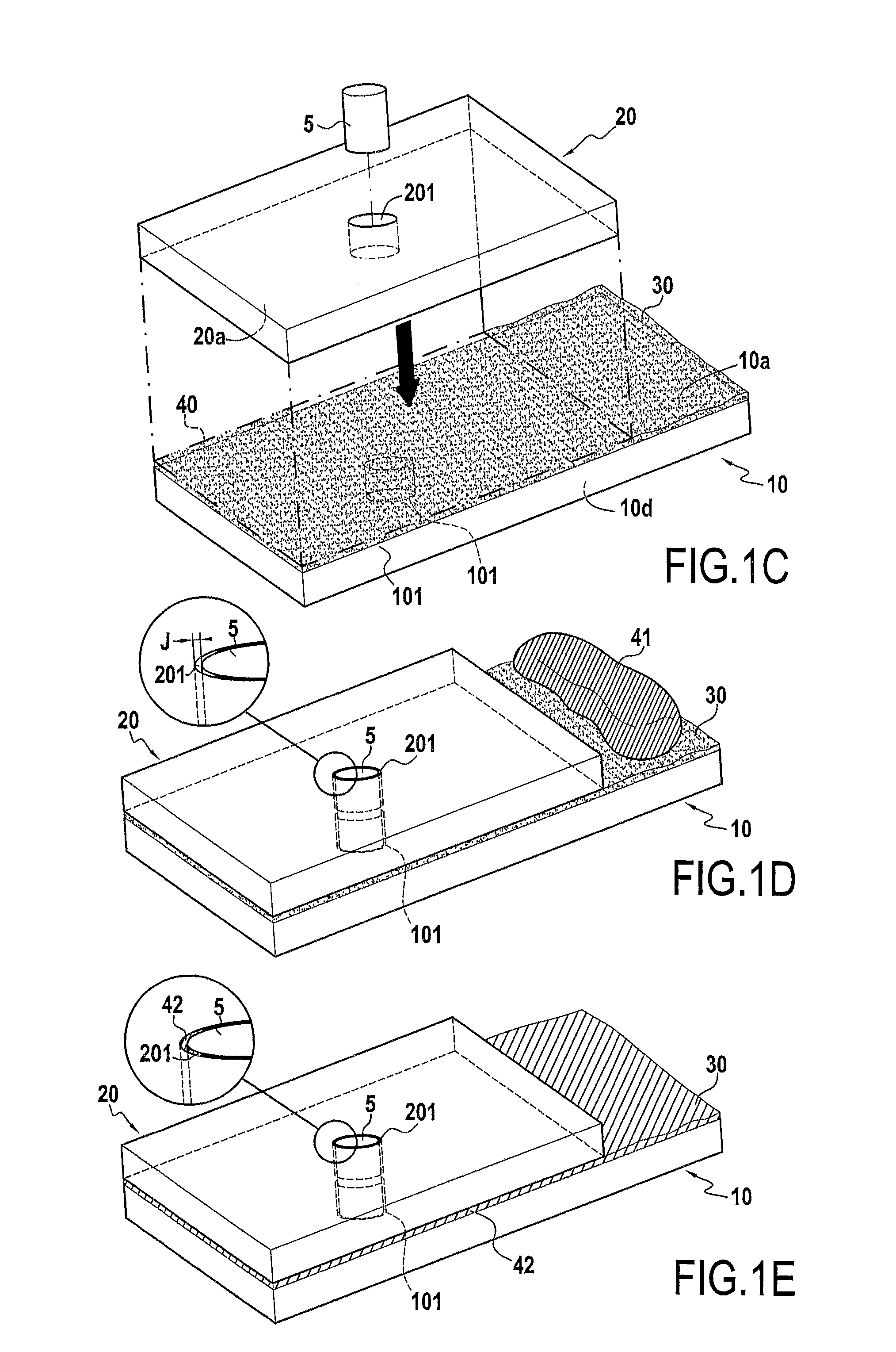

Method for the brazing of parts made from a composite material, incorporating a slug in the bond

ActiveUS9403240B2Increase shear forceImprove brazing strengthMaterial nanotechnologySoldering apparatusEngineeringThermal treatment

A method of assembling together by brazing first and second parts made of composite material, each of the first and second parts having an assembly face for brazing with the assembly face of the other part, the method including making at least one perforation in the assembly face of the first part; interposing capillary elements between the assembly faces of the first and second parts made of composite material; placing the first and second parts facing each other while inserting a peg in each perforation of the first part; placing a brazing composition in contact with a portion of the capillary elements; and applying heat treatment to liquefy the brazing composition so as to cause the molten brazing composition to spread by capillarity between the assembly faces of the composite material parts.

Owner:SAFRAN CERAMICS SA +1

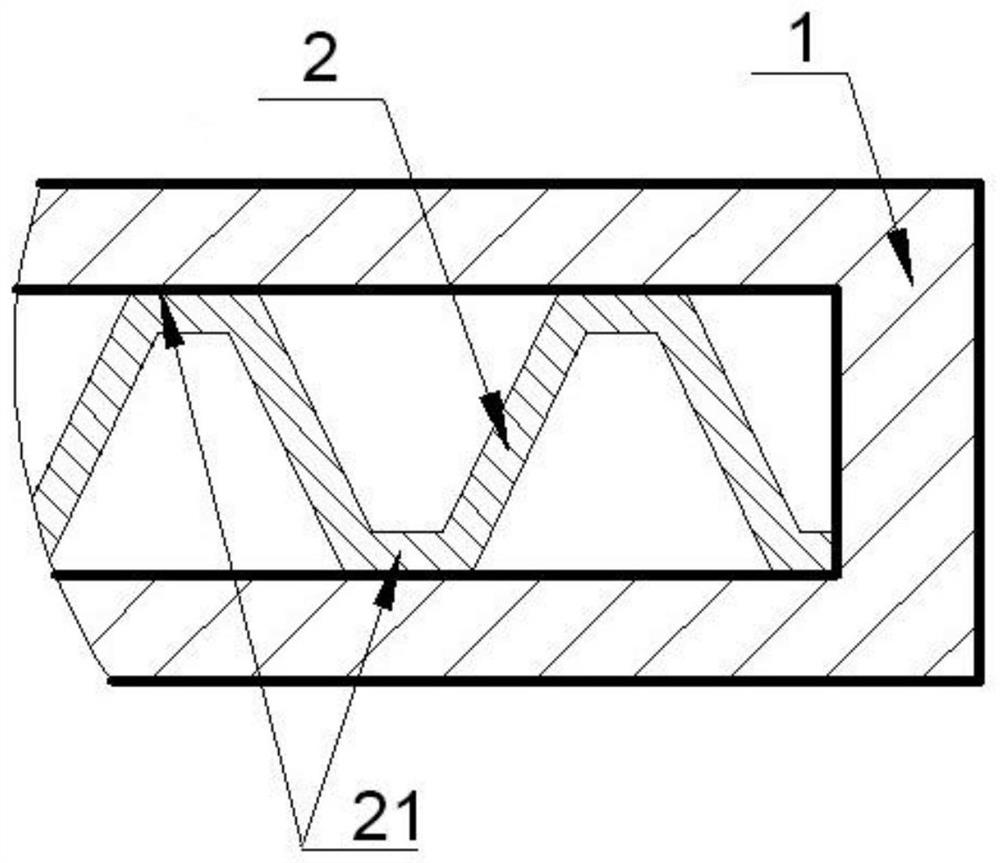

Preparation method of corrugated sheet sandwich partition board assembly

The invention belongs to the technical field of structural part processing, and discloses a preparation method of a corrugated sheet sandwich partition board assembly. The preparation method comprisesthe following steps that finish milling is carried out on a rough material, after holes are punched in the rough material by using electric sparks, linear cutting is carried out to obtain an inner cavity and the peripheral shape of a concentric-square-shaped square frame, then surface burrs are removed, grinding is carried out to remove an electric ablation layer, the inner cavity is subjected topolishing treatment, and an outer partition board is obtained; a blank is subjected to fine milling, linear cutting is carried out on the blank according to the size requirement to obtain a corrugated shape, surface burrs are removed, grinding is carried out to remove the electric ablation layer, the surface is subjected to polishing treatment, and a corrugated sheet is obtained; and the obtainedouter partition board and corrugated sheet are cleaned, amorphous foil-shaped brazing filler metal of 0.05 mm is prearranged on the surface of the corrugated sheet through spot welding treatment, then the corrugated sheet and the brazing filler metal are pressed into an inner cavity of the outer partition board together, the outer partition board is pressed through a pressing plate tool, the corrugated sheet is welded into the inner cavity of the outer partition board through brazing treatment, and the corrugated sheet sandwich partition board assembly is obtained. The preparation method is simple and scientific in link.

Owner:XIAN YUANHANG VACUUM BRAZING TECH

Manufacturing method for lead-free copper-based amorphous brazing filler metal

InactiveCN104439755AHigh tensile strengthHigh hardnessWelding/cutting media/materialsSoldering mediaZincFiller metal

The invention discloses a manufacturing method for lead-free copper-based amorphous brazing filler metal. The total mass percent of the lead-free copper-based amorphous brazing filler metal is 100%, wherein 0.02%<=P<=0.06%, 0.02%<=Bi<=0.06%, 4.0%<=Sn<=6.8%, 13.5%<=Zn<=14.3%, 0.15%<=Ce<=0.22%, 71%<=Cu<=83%, and the balance is impurities. The manufacturing method includes the steps of material preparing and alloy smelting. The Bi element is specially added, meanwhile, the Cu element is thoroughly removed, the microscopic structure morphology of the lead-free copper-based amorphous brazing filler metal is analyzed, the tensile strength, elongation percentage after fracture and Vickers hardness of the lead-free copper-based amorphous brazing filler metal are tested, and the results show that by adding the Bi element, the tensile strength and hardness of the lead-free copper-based amorphous brazing filler metal can be obviously improved, and the brazing filler metal can be promoted to be precipitated to obtain needle-shaped or particle-shaped zinc-rich phases.

Owner:刘桂芹

Brazing copper alloy with high strength and corrosion resistance

InactiveCN102310298AImprove brazing strengthStrong corrosion resistanceWelding/cutting media/materialsSoldering mediaCorrosion resistantHigh intensity

The invention discloses a brazing copper alloy with high strength and corrosion resistance. The brazing copper alloy comprises the following ingredients in percentage by mass: 2.8-4.0% of Si, 0.5-1.5% of Mn, 0.2-1.0% of Mg, 0.1-0.8% of Ti, 0.01-0.1% of Ce and the rest amount of Cu. The brazing copper alloy disclosed by the invention has the advantages of high brazing strength, excellent corrosion resistance and good machining performance. As a small amount of Ti, Ce and Mg is added in the Cu-Si alloy, the brazing alloy provided by the invention has an obviously-fined grain size for casting line blanks, and the grain size is about one third of that of the S211 alloy; and the machining hardening ratio is obviously lowered, and the processing capability is enhanced.

Owner:TIANJIN JINLONG WELDING MATERIAL

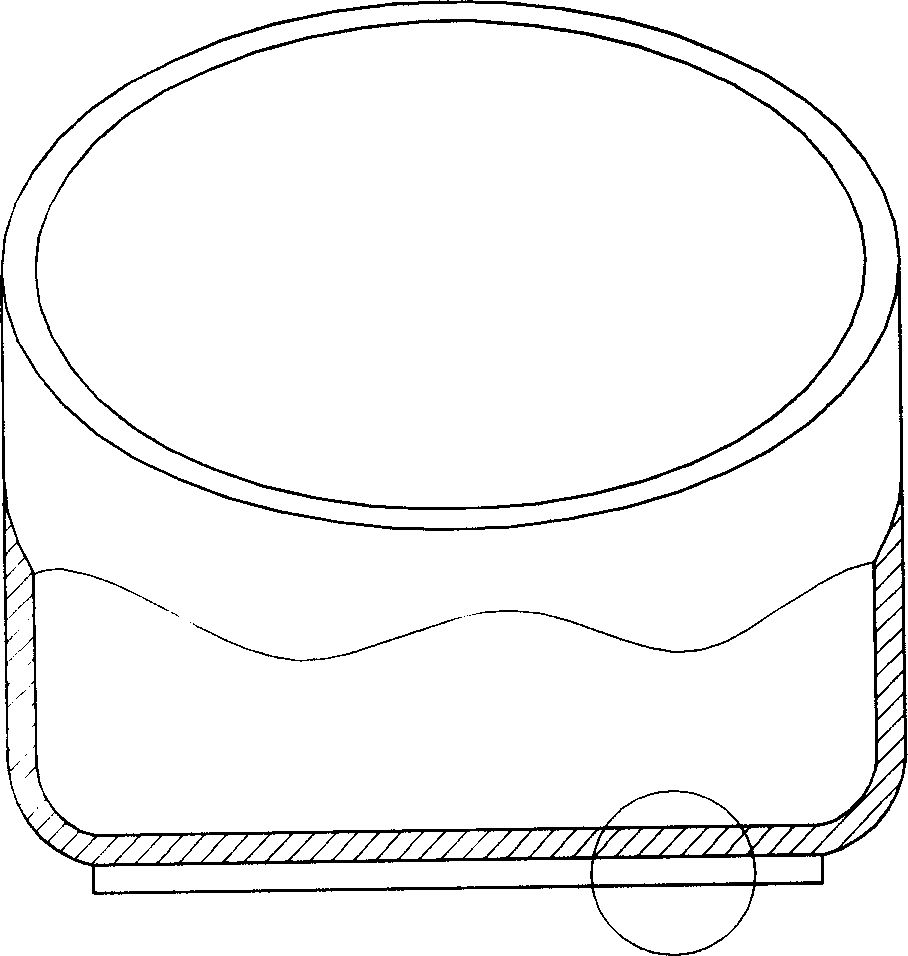

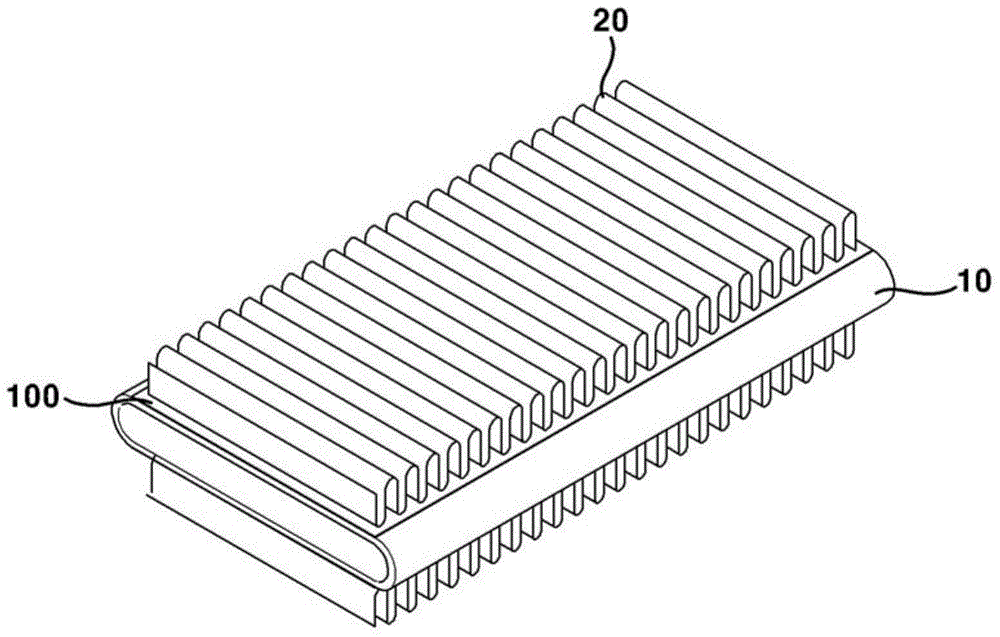

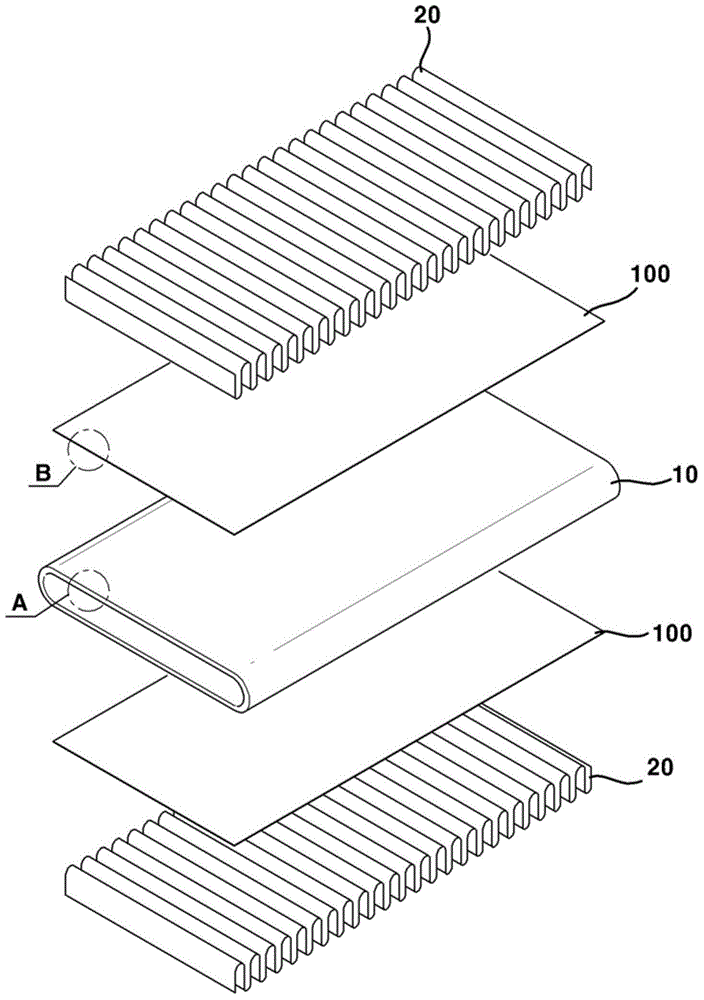

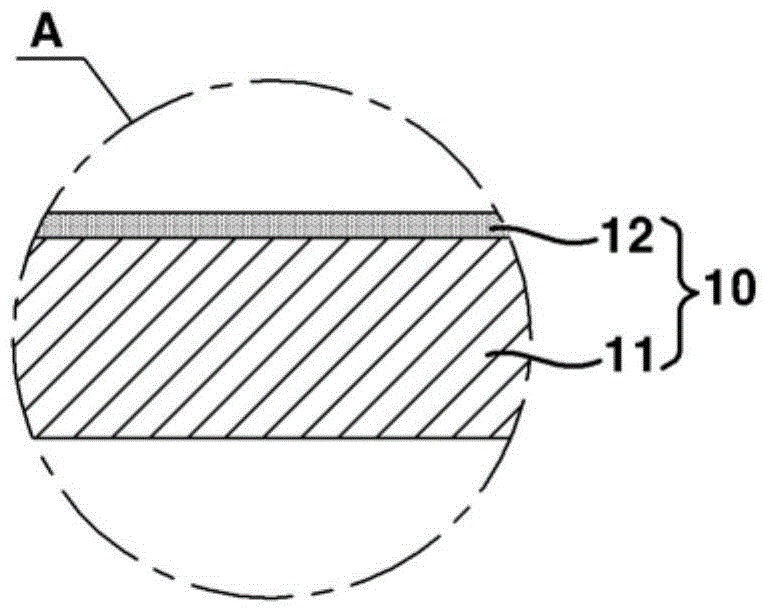

Steam Condensing Heat Conduction Pipe For Air Cooling Steam Condensing Plant

InactiveCN104654878ASave material costOmit processHeat exchanger casingsTubular elementsSteam condensationEngineering

The present invention discloses a steam condensing heat conduction pipe for an air cooling steam condensing plant. The steam condensing heat conduction pipe for the air cooling steam condensing plant comprises a composite metal cavity possessing the opening part at the two ends and comprising at least one pair of flat heat conduction parts; strip-like fin components arranged on the pair of heat conduction parts, and radiating the heat transmitted in the composite metal cavity to the air; and a pair of foil-shaped parts arranged between the composite metal cavity and the strip-like fin components and comprising an aluminum layer and a solder coating which are formed on the opposite surfaces of the composite metal cavity and the strip-like fin components, and the composite metal cavity and the strip-like fin components are fixed and combined via a brazing process.

Owner:JNK HEATERS

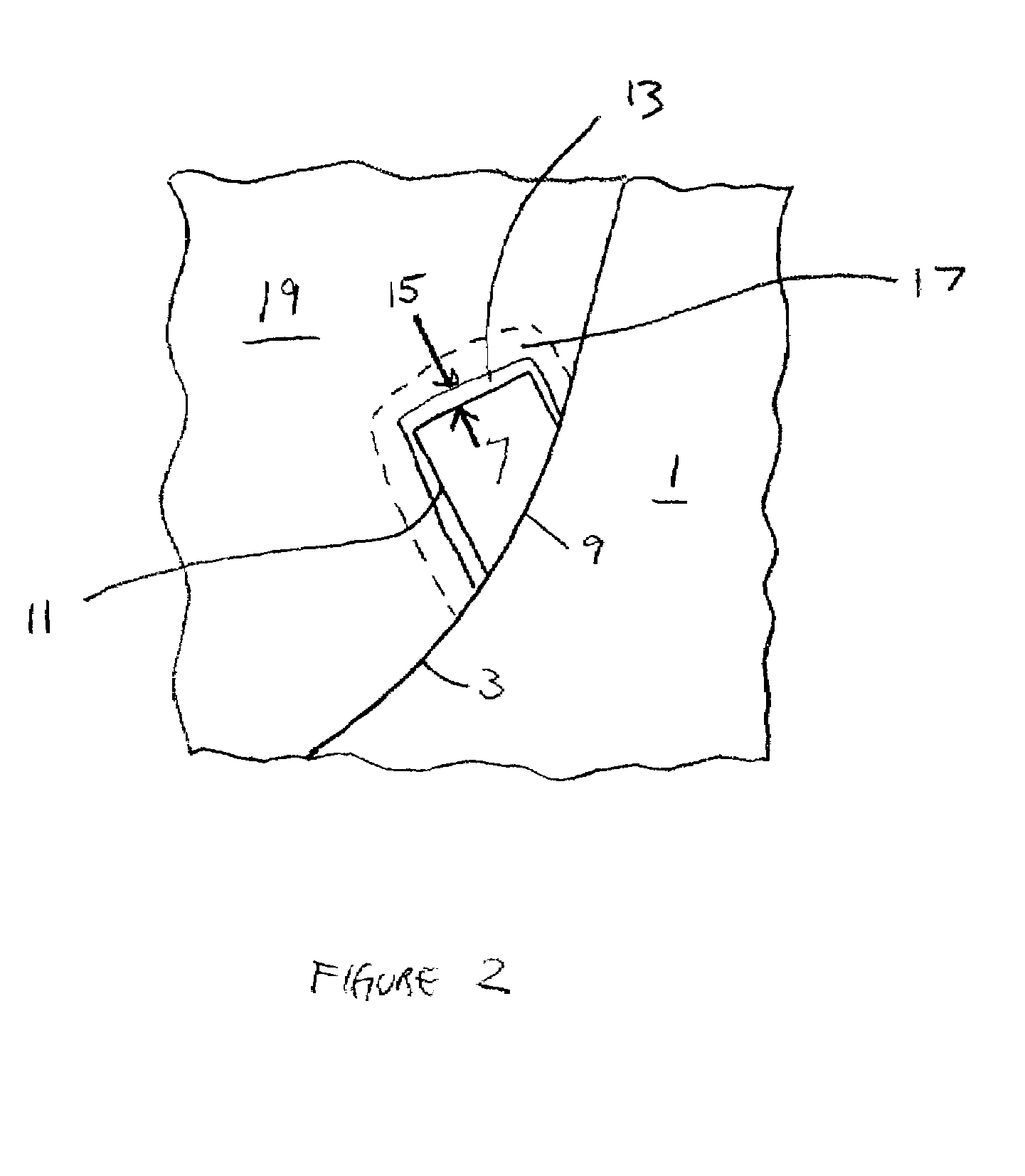

Cutting element with improved cutter to blade transition

InactiveUS20050241861A1Easy transitionIncrease exposureDrill bitsConstructionsEngineeringMechanical engineering

Cutting elements having a slanted top surface for an improved cutter to blade transition, the slanted top surface being integratable into a receiving pocket of a bit blade such that the slanted top surface and the perimeter of the receiving pocket are relatively contiguous when the slanted cutter is mounted within the receiving pocket. Also, a bit with slanted cutters as well as a method of manufacturing a bit having slanted cutters.

Owner:SMITH INT INC

Copper, aluminium, stainless steel composite brazing method

InactiveCN1211179CImprove brazing strengthOvercoming the disadvantages of poor welding qualityHigh frequency current welding apparatusPotassiumCopper

The present invention relates to a copper, aluminium and stainless steel combined brazing method, including the following steps: between copper and aluminium setting a transition layer, the described transition layer is a stainless steel sheet, and its thickness is 0.1-0.5 mm; cleaning copper, aluminium and stainless steel workpieces to be brazed, degreasing, brush-coating two surfaces of aluminium workpiece with potassium fluoroaluminate eutectic brazing flux, spreading aluminium-silicon eutectic brazing filter metal, placing it on the brazed surface of stainless steel workpiece, coating one side surface of transition layer stainless steel sheet with potassium fluoroborate brazing flux, spreading copper-phosphorus base brazing filler metal, placing one surface which is not coated with brazing flux and brazing filler metal on aluminium workpiece with brazing flux and brazing filler metal, then covering them with copper sheet for brazing.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Brazing titanium-copper alloy with high strength and corrosion resistance

InactiveCN102310296AImprove brazing strengthImprove corrosion resistanceWelding/cutting media/materialsSoldering mediaAdditive ingredientTitanium

The invention discloses a brazing titanium-copper alloy with high strength and corrosion resistance. The brazing titanium-copper alloy comprises the following ingredients in percentage by mass: 2.8-3.5% of Si, 1.0-1.2% of Mn, 0.2-0.4% of Ti, 0.05-0.08% of Ce and the rest amount of Cu. The brazing titanium-copper alloy disclosed by the invention has the advantages of high brazing strength, excellent corrosion resistance and good machining performance. As a small amount of Ti and Ce is added in the Cu-Si alloy, the brazing alloy provided by the invention has an obviously-fined grain size for casting line blanks, and the grain size is about one third of that of the S211 alloy.

Owner:TIANJIN JINLONG WELDING MATERIAL

Lead-free copper-based amorphous solder strip

InactiveCN104551439AHigh tensile strengthHigh hardnessWelding/cutting media/materialsSoldering mediaHardnessCopper

The invention discloses a lead-free copper-based amorphous solder strip, which is prepared from lead-free copper-based amorphous solder. Based on the total mass of 100 percent, the lead-free copper-based amorphous solder comprises the following components in percentage by mass: more than or equal to 0.02 percent and less than or equal to 0.06 percent of P, more than or equal to 0.02 percent and less than or equal to 0.06 percent of Bi, more than or equal to 4.0 percent and less than or equal to 6.8 percent of Sn, more than or equal to 13.5 percent and less than or equal to 14.3 percent of Zn, more than or equal to 0.15 percent and less than or equal to 0.22 percent of Ce, more than or equal to 71 percent and less than or equal to 83 percent of Cu and the balance of impurities. According to the lead-free copper-based amorphous solder strip, Bi is added, meanwhile, Cu is completely eliminated, and results obtained by analyzing the microstructure morphology of the lead-free copper-based amorphous solder strip and testing the tensile strength, the percentage elongation after fracture and the Vickers hardness of the lead-free copper-based amorphous solder strip show that by the addition of Bi, the tensile strength and the hardness of the lead-free copper-based amorphous solder strip can be remarkably improved and a needlelike or granular zinc-rich phase can be promoted to be separated from the solder.

Owner:刘桂芹

High-activity flux-cored brazing filler metal capable of improving brazing strength of heterogeneous materials and preparation method of high-activity flux-cored brazing filler metal

ActiveCN114769945AImprove brazing strengthEasy to operateWelding/cutting media/materialsSoldering mediaCobaltHigh activity

The invention provides high-activity flux-cored brazing filler metal capable of improving the brazing strength of heterogeneous materials and a preparation method of the high-activity flux-cored brazing filler metal. The flux-cored brazing filler metal comprises a flux core and an outer skin at least partially wrapping the surface of the flux core. Wherein the outer skin comprises the following components in parts by mass: 30-55 parts of silver; 25 parts by mass to 50 parts by mass of copper; 20 parts by mass to 45 parts by mass of zinc; 1.5 parts by mass to 2.5 parts by mass of cobalt; the outer skin further comprises 0.2-0.7 part by mass of germanium; and / or 0.2 to 0.7 part by mass of silicon; and / or 0.1 to 0.3 part by mass of an active metal; the active metal comprises at least one of titanium, chromium and zirconium; the flux core comprises silver-based brazing flux; the flux core further comprises aluminum and / or silicon. Alloy components are optimized, cobalt and trace active metal elements are added, and the strength of brazed joints between steel and hard alloy and between high-temperature alloy and hard alloy and other dissimilar metal is improved.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD +1

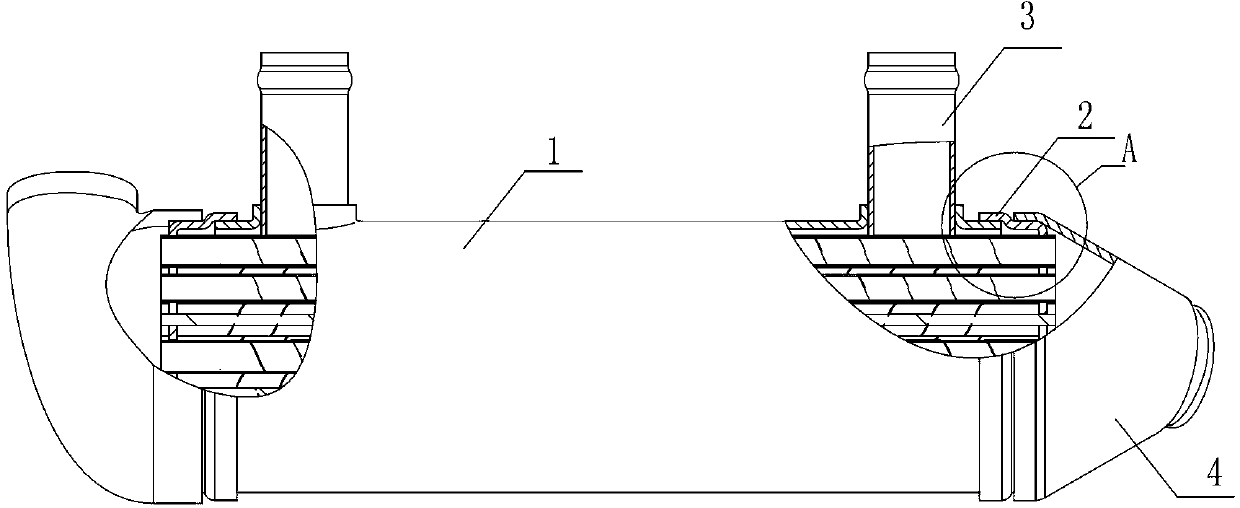

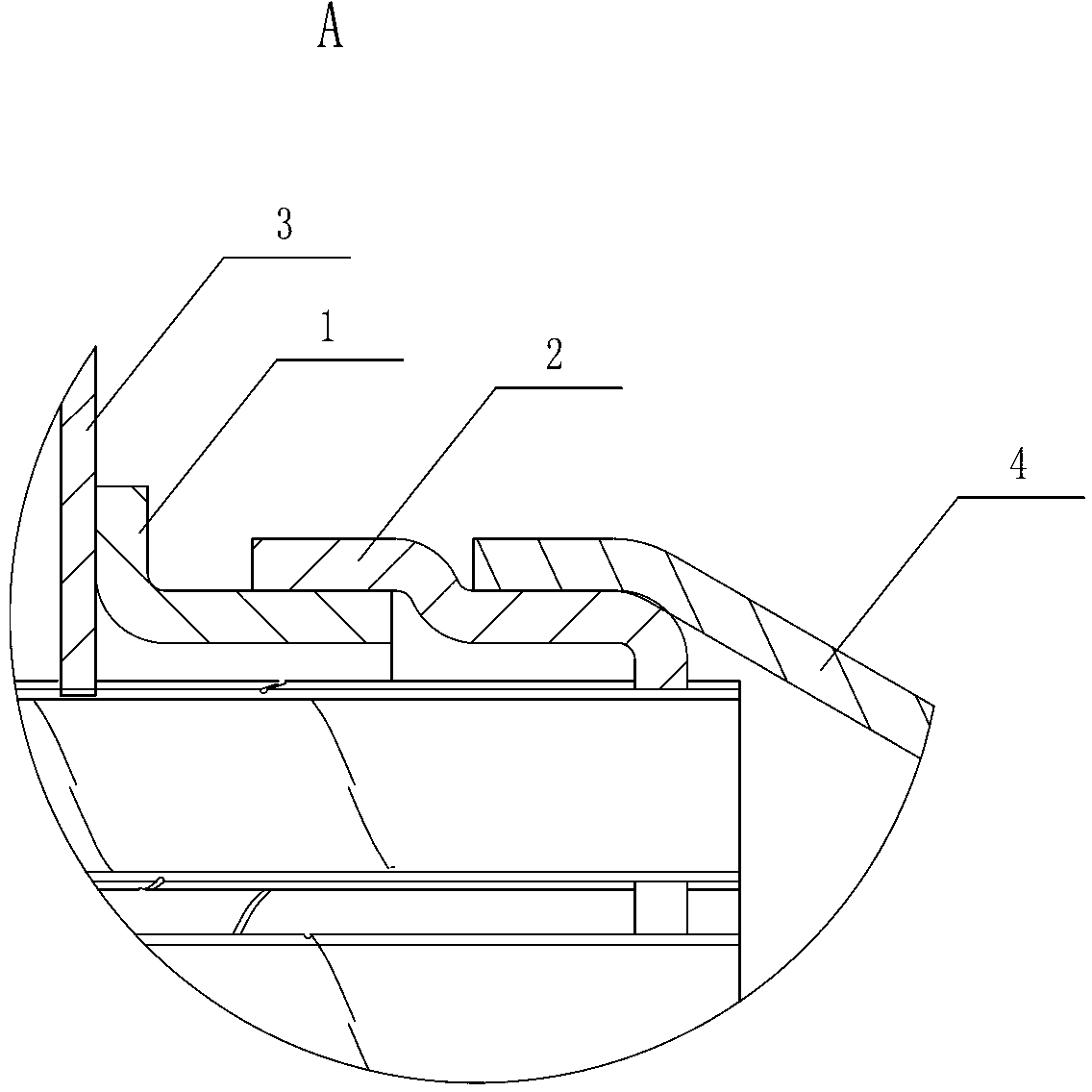

Exhaust gas recirculation (EGR) cooler

InactiveCN103104377AMeet the requirements of brazingReduce manufacturing costNon-fuel substance addition to fuelInternal combustion piston enginesManufacturing cost reductionPunching

The invention relates to the field of coolers, in particular to an exhaust gas recirculation (EGR) cooler suitable for exhaust gas recirculation in an engine system. The EGR cooler comprises a water pipe welded on a barrel body and fixing plates installed at two ends of the barrel body, wherein end covers are fixedly installed on the fixing plates at two ends of the barrel body, the connecting position of the barrel body and the water pipe is provided with a turnup structure, and the edges of the fixing plates are bent to form stepped structures. Improvement of an existing EGR cooler structure is that the barrel body is connected with the water pipe by adopting a punching turnup structure, and simultaneously the fixing plates are designed into the stepped structures, so that the EGR cooler can meet the braze welding requirement, remarkably reduce the manufacture cost and accordingly improve product competitiveness. By means of the structure, the production efficiency is high, the braze welding strength is high, and the quality is stable. The EGR cooler is simple, reliable, convenient to use, low in manufacture cost and easy to maintain.

Owner:无锡双翼汽车环保科技有限公司

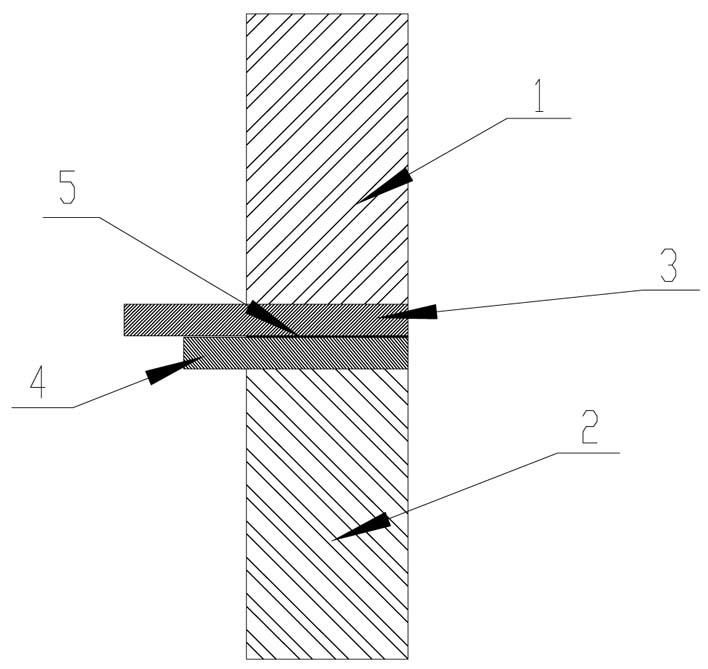

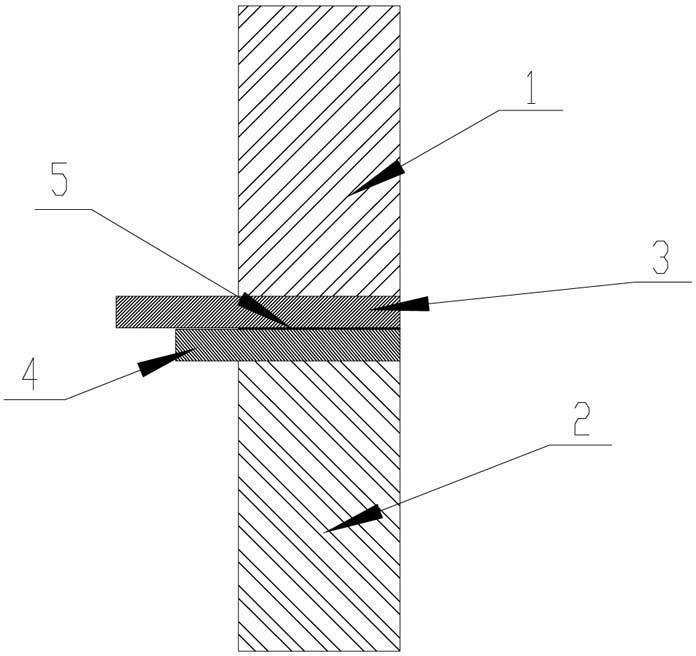

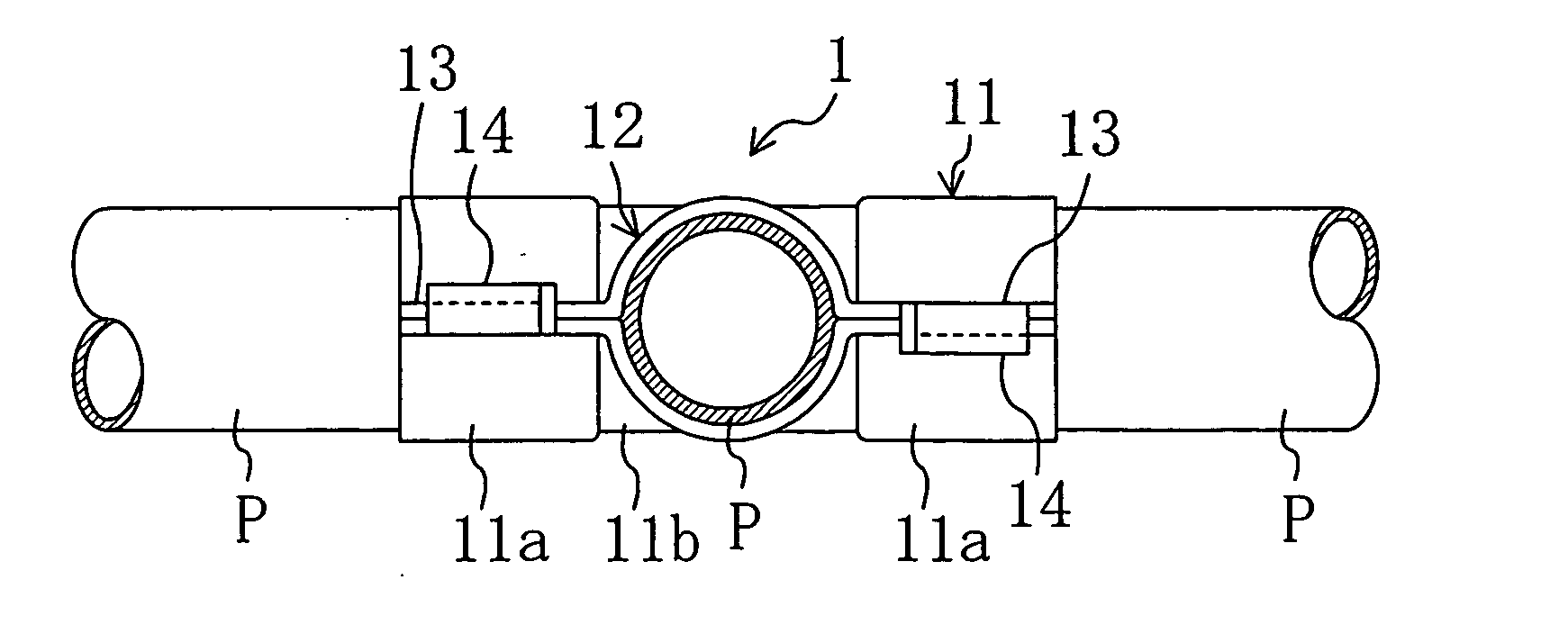

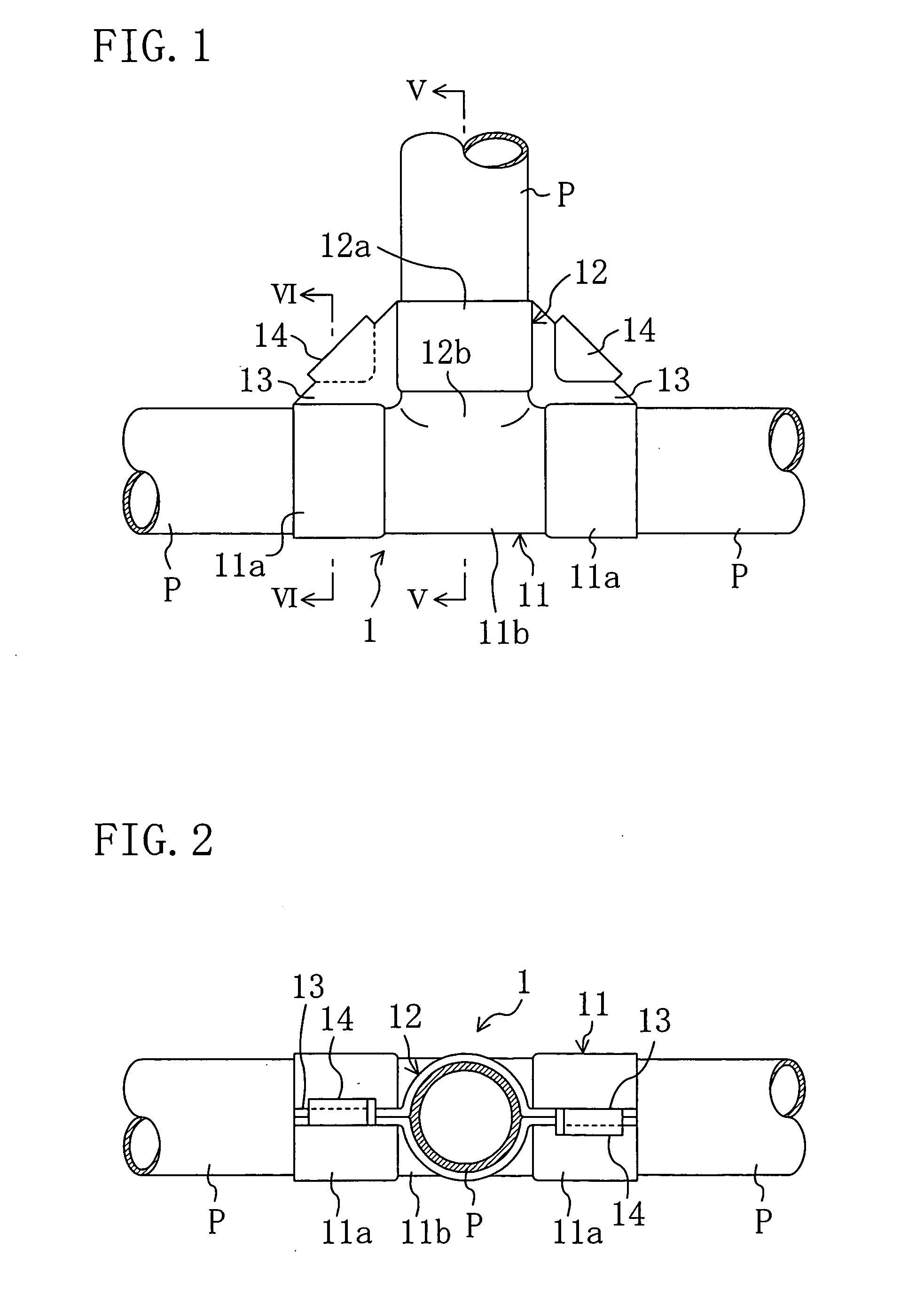

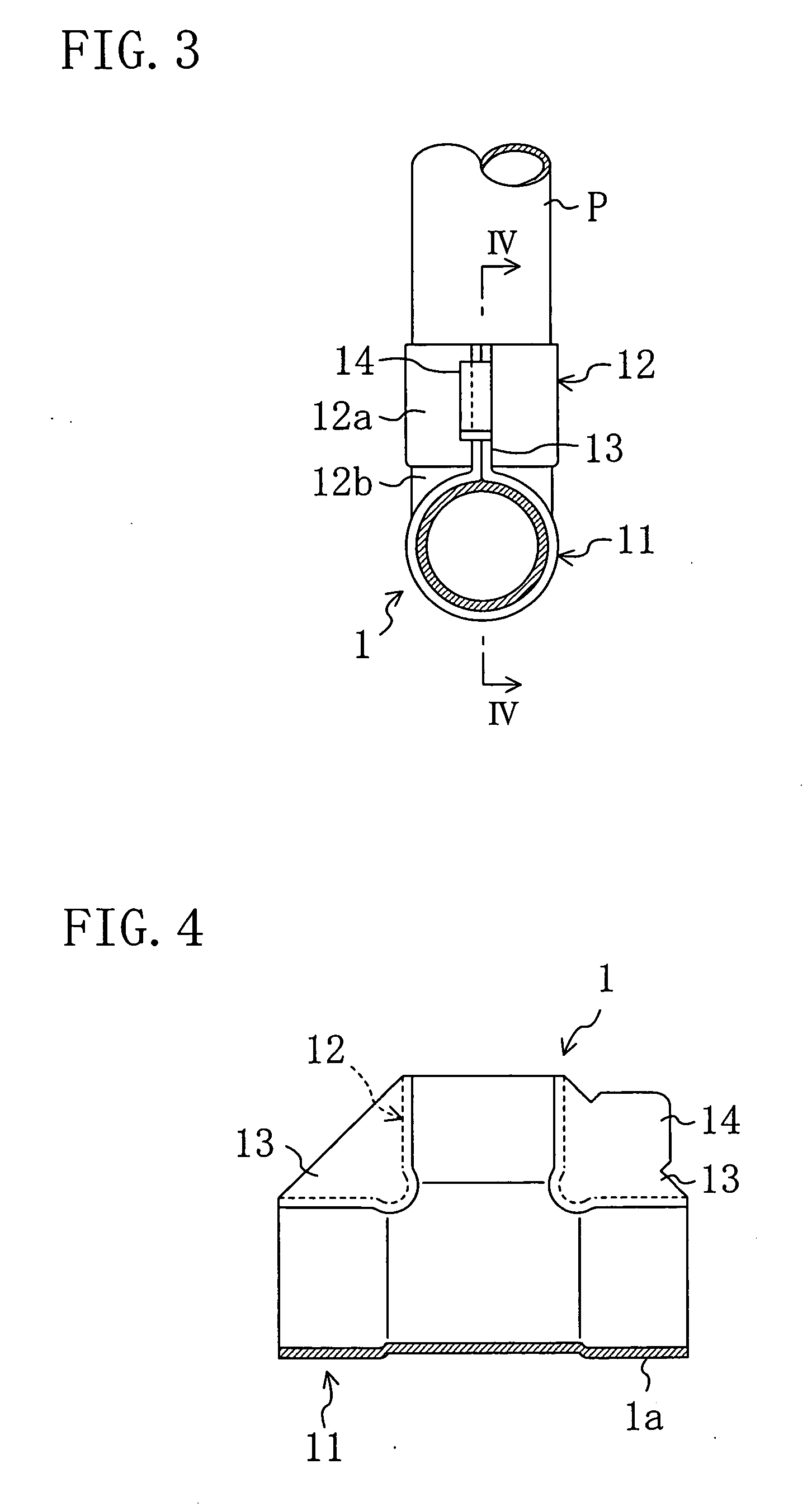

Branch tee fitting

InactiveUS20070102925A1Improve brazing qualityImprove brazing strengthPipeline expansion-compensationBranching pipesClassical mechanicsStructural engineering

In a branch tee fitting (1) fabricated by press forming, in order to enhance the brazing strength thereof and the brazing workability thereof by allowing separate brazing of pipes (P) to a tubular body portion (11) and a tubular branch portion (12), engaging pawls (14) are provided which engage flat portions (13) superposed to each other in angles between the tubular body portion (11) and the tubular branch portion (12).

Owner:DAIKIN IND LTD

Manufacturing method for lead-free copper-based amorphous brazing filler metal strip

InactiveCN104439764AHigh tensile strengthHigh hardnessWelding/cutting media/materialsSoldering mediaCu elementHardness

The invention discloses a manufacturing method for a lead-free copper-based amorphous brazing filler metal strip. The lead-free copper-based amorphous brazing filler metal strip is made of lead-free copper-based amorphous brazing filler metal. The total mass percent of the lead-free copper-based amorphous brazing filler metal is 100%, wherein 0.02%<=P<=0.06%, 0.02%<=Bi<=0.06%, 4.0%<=Sn<=6.8%, 13.5%<=Zn<=14.3%, 0.15%<=Ce<=0.22%, 71%<=Cu<=83%, and the balance is impurities. The manufacturing method includes the steps of material preparing, alloy smelting and strip manufacturing. The Bi element is specially added, meanwhile, the Cu element is thoroughly removed, the microscopic structure morphology of the lead-free copper-based amorphous brazing filler metal is analyzed, the tensile strength, elongation percentage after fracture and Vickers hardness of the lead-free copper-based amorphous brazing filler metal are tested, and the results show that by adding the Bi element, the tensile strength and hardness of the lead-free copper-based amorphous brazing filler metal can be obviously improved, and the brazing filler metal can be promoted to be precipitated to obtain needle-shaped or particle-shaped zinc-rich phases.

Owner:刘桂芹

Preparation method of aluminum-silicon alloy welding rod for soldering

ActiveCN108436326AImprove brazing strengthReduce consumptionWelding/cutting media/materialsSoldering mediaSilicon alloySoldering

The invention provides a preparation method of an aluminum-silicon alloy welding rod for soldering. The preparation method comprises the steps that aluminum-silicon alloy powder and soldering flux powder are evenly mixed and then pressed into a bar billet with the diameter of 20 mm through a tablet press, and then an insulation barrel is placed into a microwave sintering furnace; then a furnace chamber is vacuumized till the vacuum degree in the furnace chamber is lower than 0.1 Pa, then argon with the purity of 99.99% is introduced into the furnace chamber, the output power of the microwave sintering furnace is controlled, the temperature is increased at a certain speed, and heat preservation is conducted; afterwards, the microwave sintering furnace is stopped, so that a sample is cooledalong with the furnace to obtain an aluminum-silicon alloy bar; and finally, the bar is placed into an extrusion die so as to be hot-extruded at a time to make the diameter of the bar reach 3 mm, andthus, the aluminum-silicon alloy welding rod for soldering is obtained. The preparation method is easy and convenient to implement, low in equipment requirement, high in production efficiency, low inenergy consumption and suitable for industrial production; and the welding rod has the advantages that the wettability of the welding rod is as good as that of base metal, and the soldering strength is high.

Owner:桂林南箭焊接材料有限公司

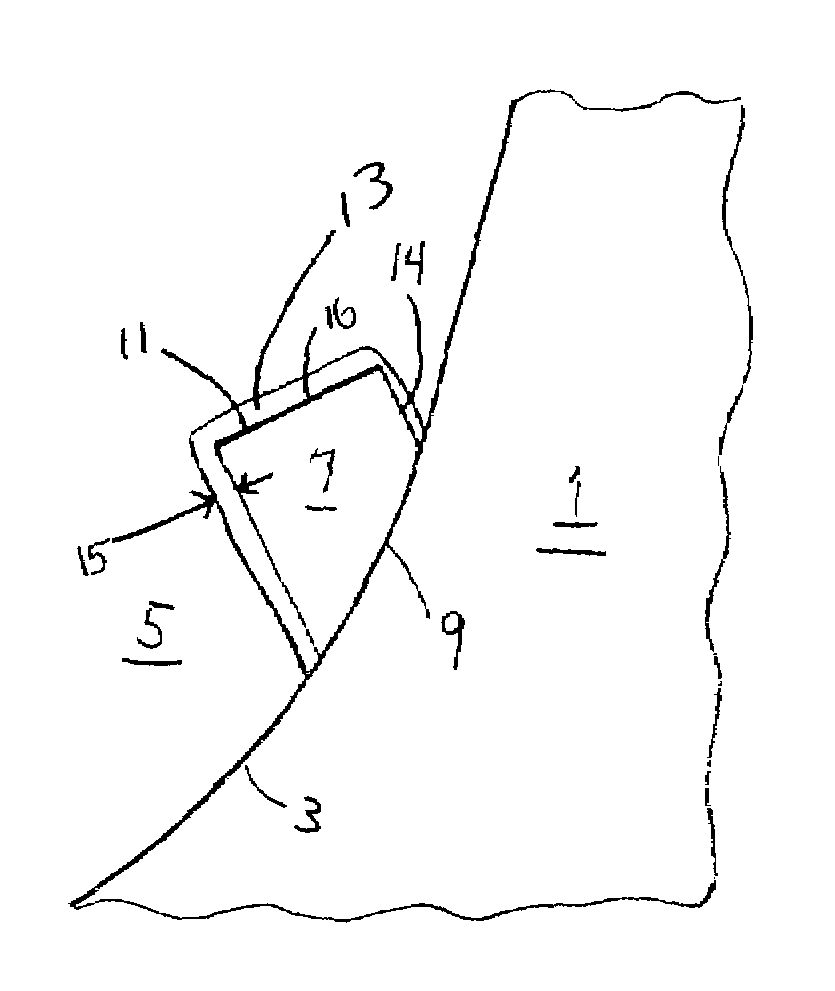

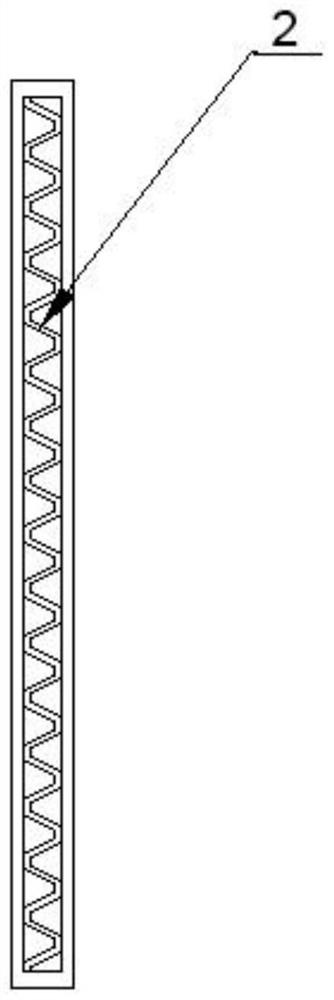

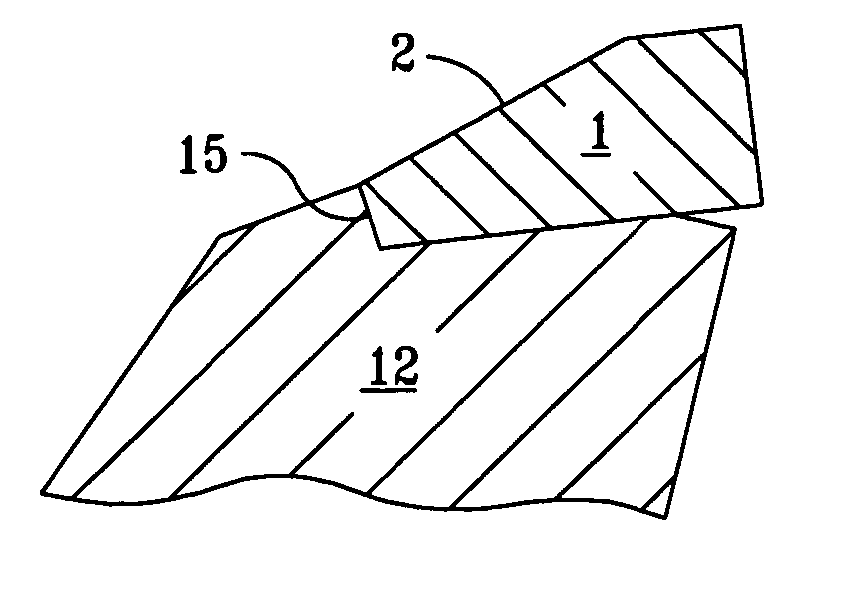

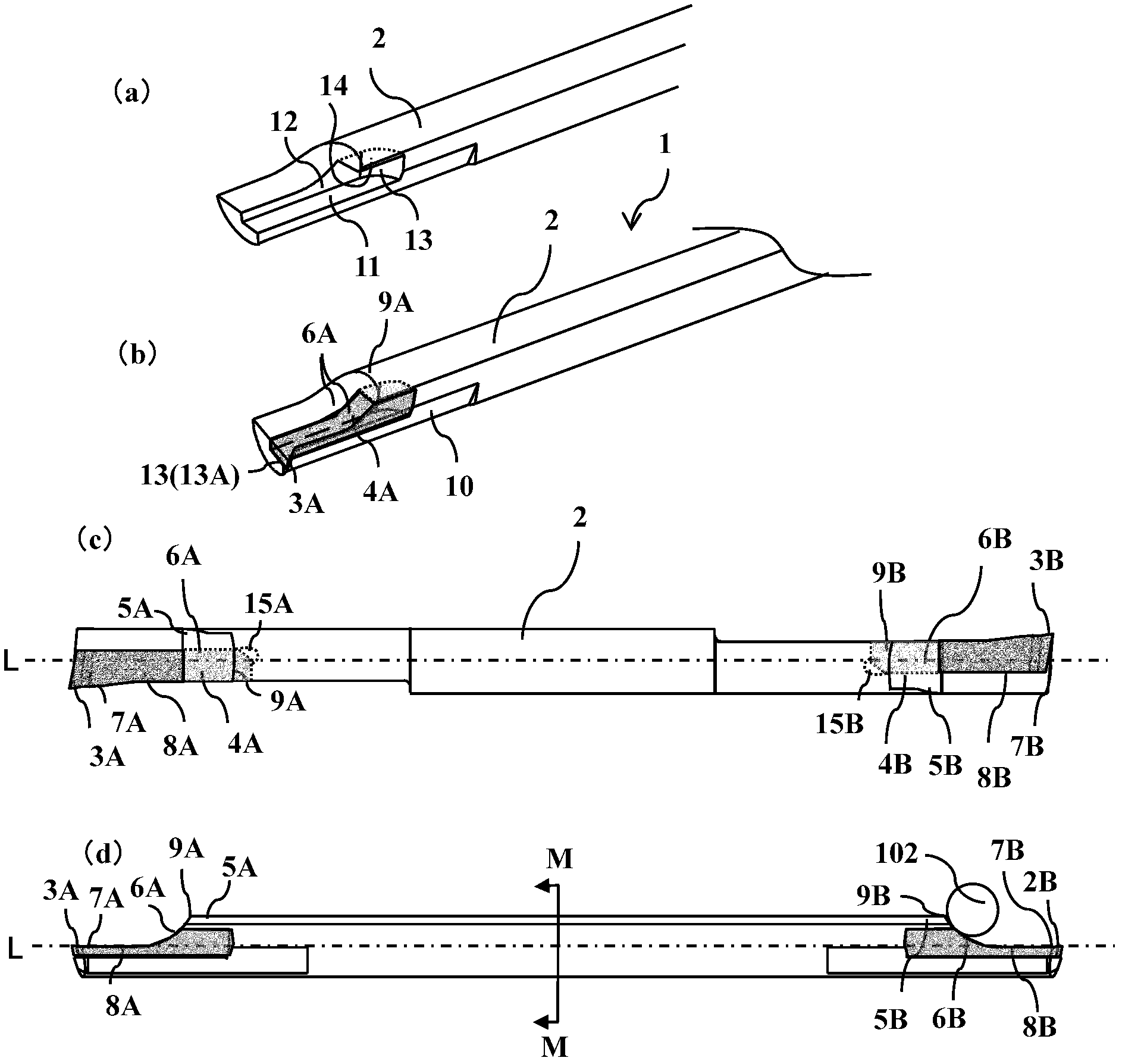

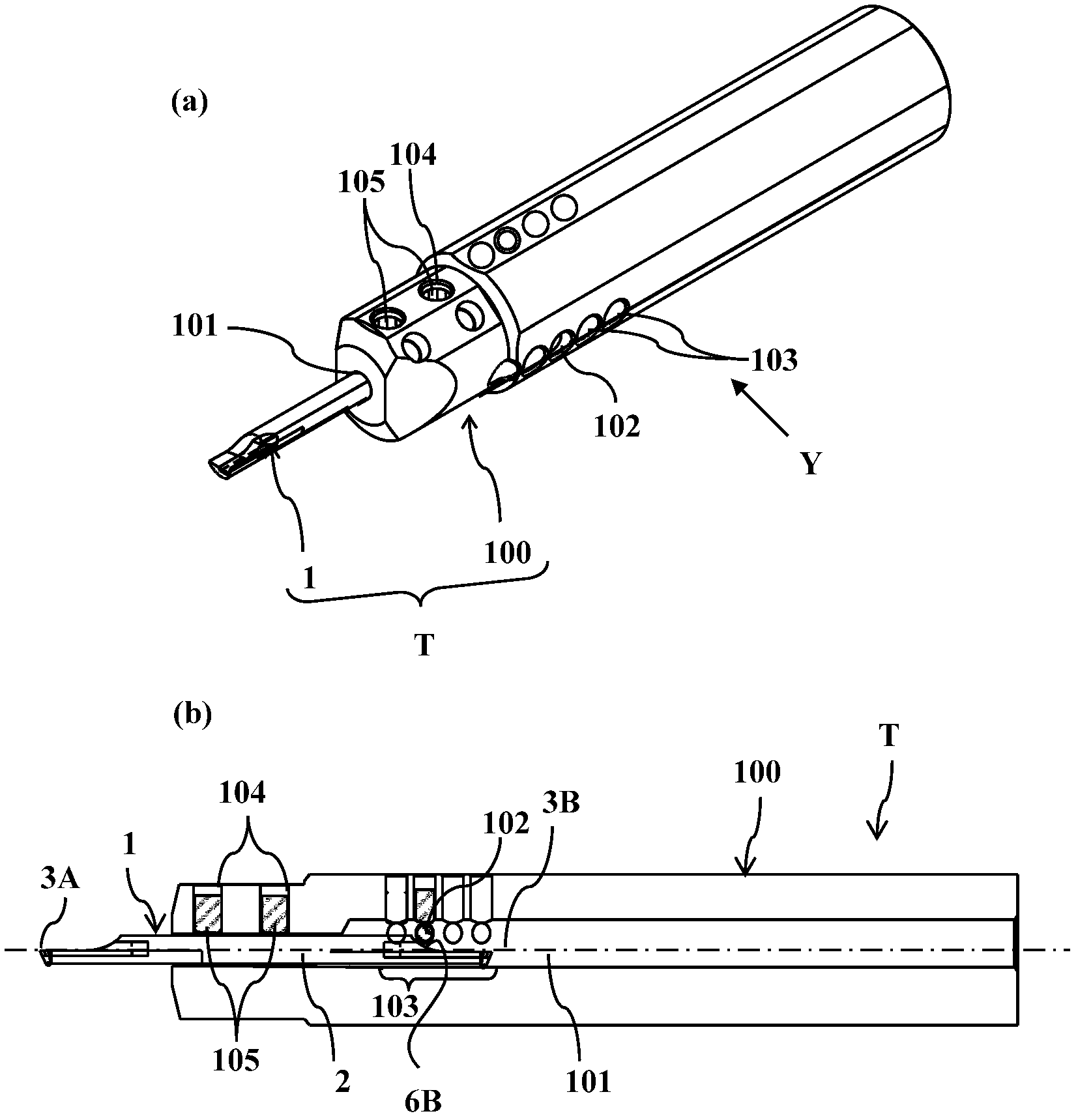

Bore machining cutter head and bore machining cutting tool

The invention provides a bore machining cutter head and a bore machining cutting tool, which are cheap to manufacture and high in brazing strength. The bore machining cutting tool (T) is formed by installing a bore machining cutter head (1) onto a cutter rod (100). The bore machining cutter head (1) comprises a rod-shaped tool body (2); and a cutter head (4) of a cutting edge (3) protruded to the side (17) out of the rod-shaped tool body (2) with the lower surface (16) thereof arranged on the tool body (2). The lower surface (16) and the upper surface (18) of the cutter head (4) of the cutting edge (3) are partially clamped by the tool body (2). The upper surface (18) of the cutter head (4) of the cutting edge (3) is partially brazed to the tool body (2).

Owner:KYOCERA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com