Ceramic package

A ceramic packaging and ceramic technology, applied in printed circuits, electrical components, circuits, etc., can solve the problem of not being able to seal the cavity with a metal cover, and achieve the effect of reducing the peeling of ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, modes for implementing the present invention will be described.

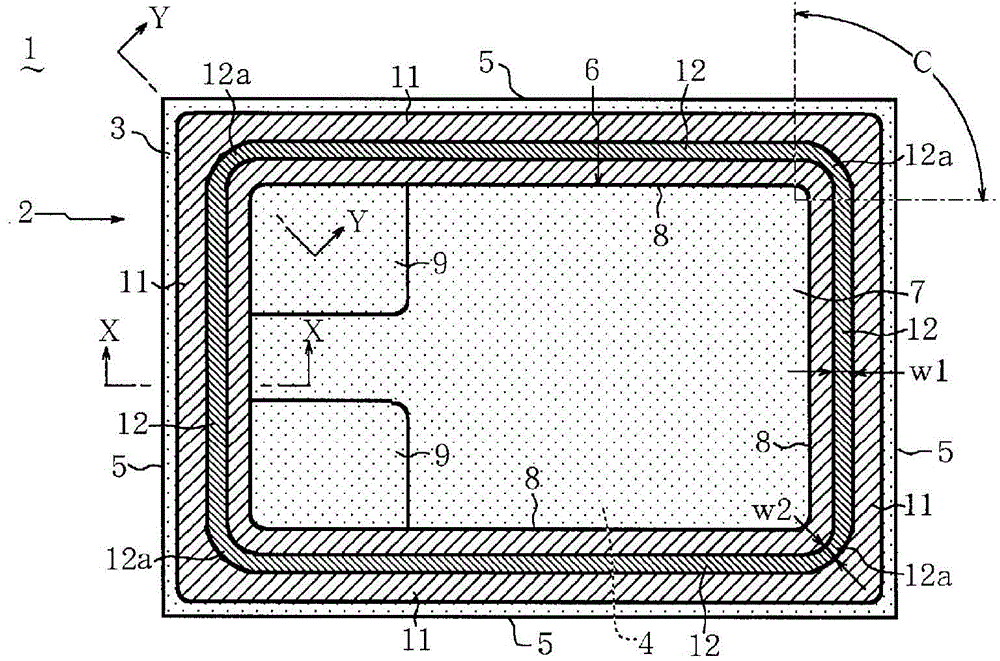

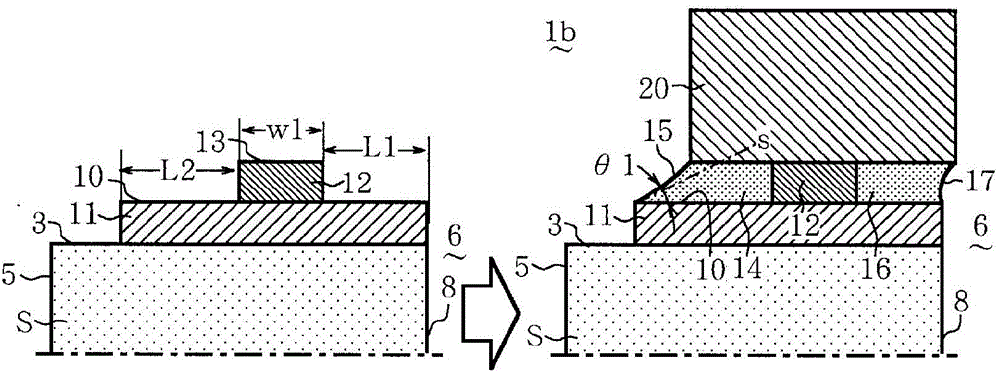

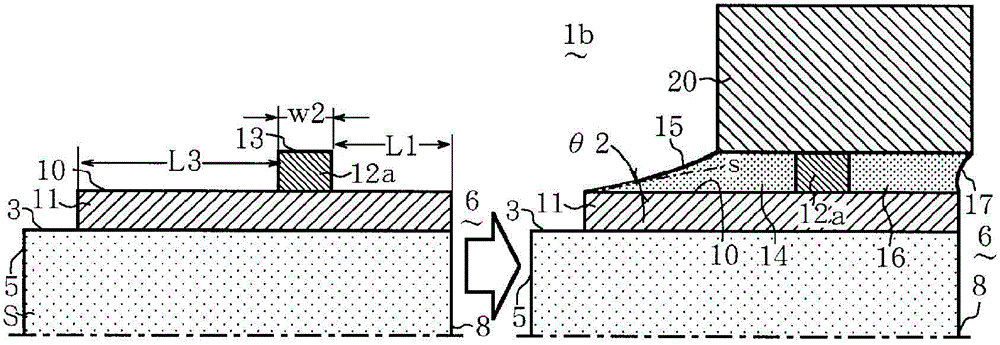

[0054] figure 1 It is a plan view showing the first ceramic package 1 of the present invention, figure 2 the left side is along the figure 1 The partial enlarged cross-sectional view of the side part seen by the arrow of the X-X line in image 3 the left side is along the figure 1 Partial enlarged cross-sectional view of the corner viewed by the arrow of the Y-Y line in .

[0055] Such as Figure 1 ~ Figure 3 As shown, the first ceramic package 1 includes: a package body 2, which has a frame-shaped surface 3 when viewed from above and a rectangular (rectangular) back 4 when viewed from above, and has a cavity 6 opening on the surface 3; The first metal layer 11 and the second metal layer 12 formed on the surface 3 above.

[0056] The package main body 2 is a box-shaped body including four outer surfaces 5 and a plurality of laminated ceramic layers made of, for example, ceramic S su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com