High cooling circuit board and preparation thereof

A manufacturing method and circuit board technology, which is applied in the direction of circuit substrate materials, printed circuit manufacturing, printed circuits, etc., can solve the problems of affecting thermal conductivity and poor thermal conductivity of resin substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make those familiar with the art understand the purpose, characteristics and effects of the present invention, the following specific examples are used to illustrate this creation in detail, as follows:

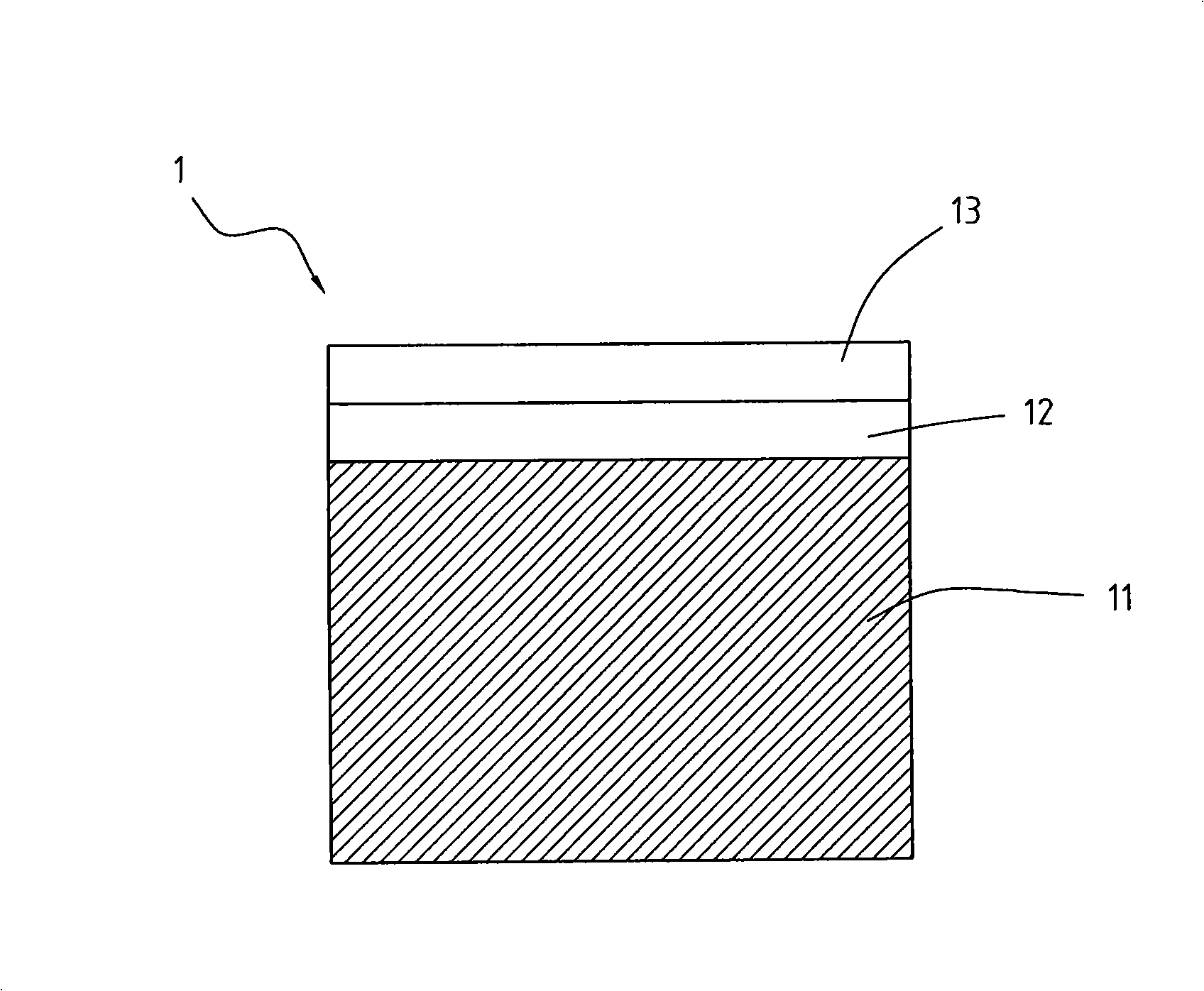

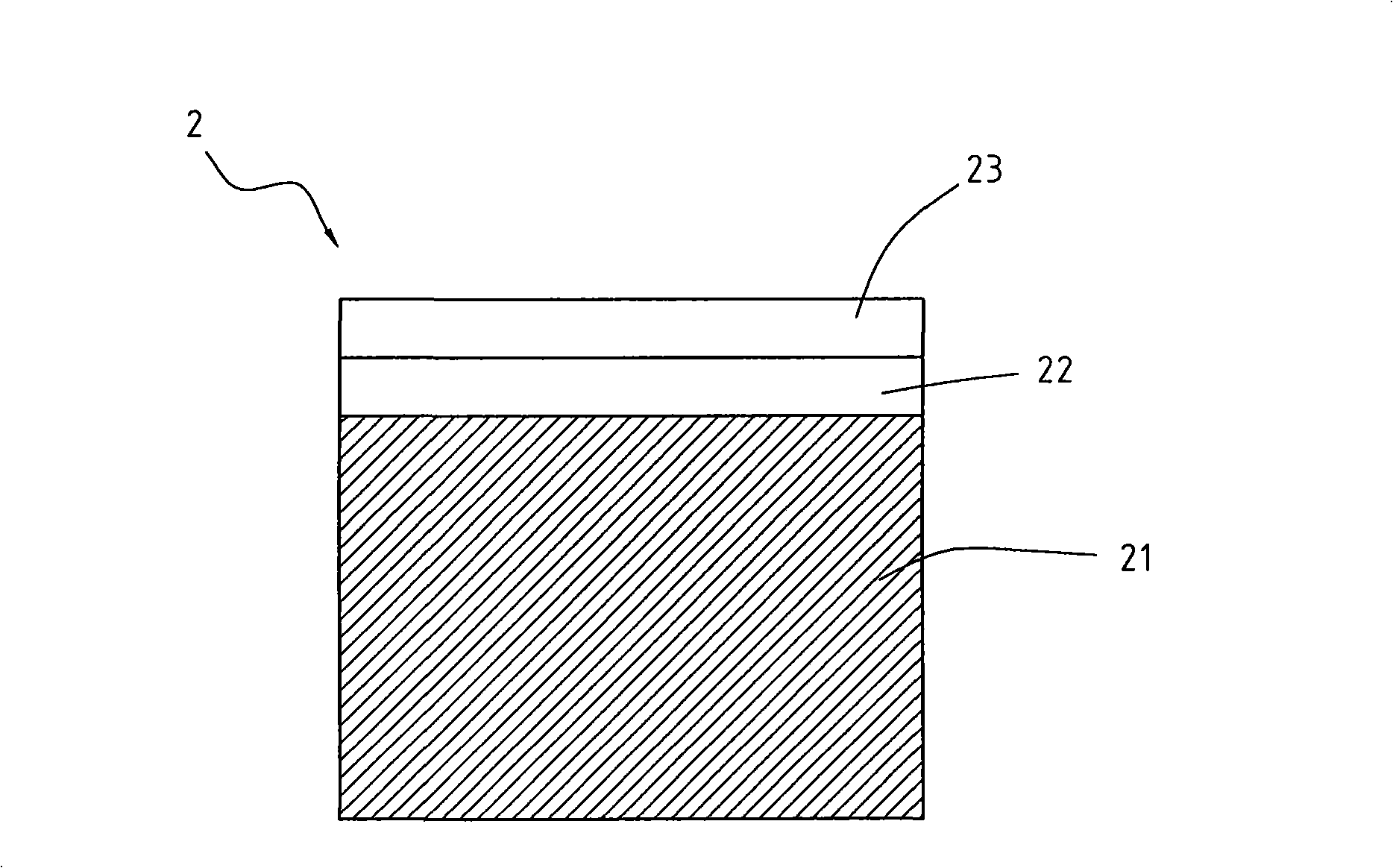

[0034] Please refer to figure 2 , illustrating a schematic structural view of the high heat dissipation circuit board of the present invention, the high heat dissipation circuit board 2 includes: at least one metal substrate 21; an insulating layer 23, the insulating layer 23 is an insulating surface with thermal conductivity, to implant conductive lines; And a buffer layer 22, the buffer layer 22 is interposed between the metal substrate 21 and the insulating layer 23, so as to improve the joint adhesion between the metal substrate 21 and the insulating layer 23, and reduce the peeling or peeling of the plating due to thermal stress. phenomenon of rupture.

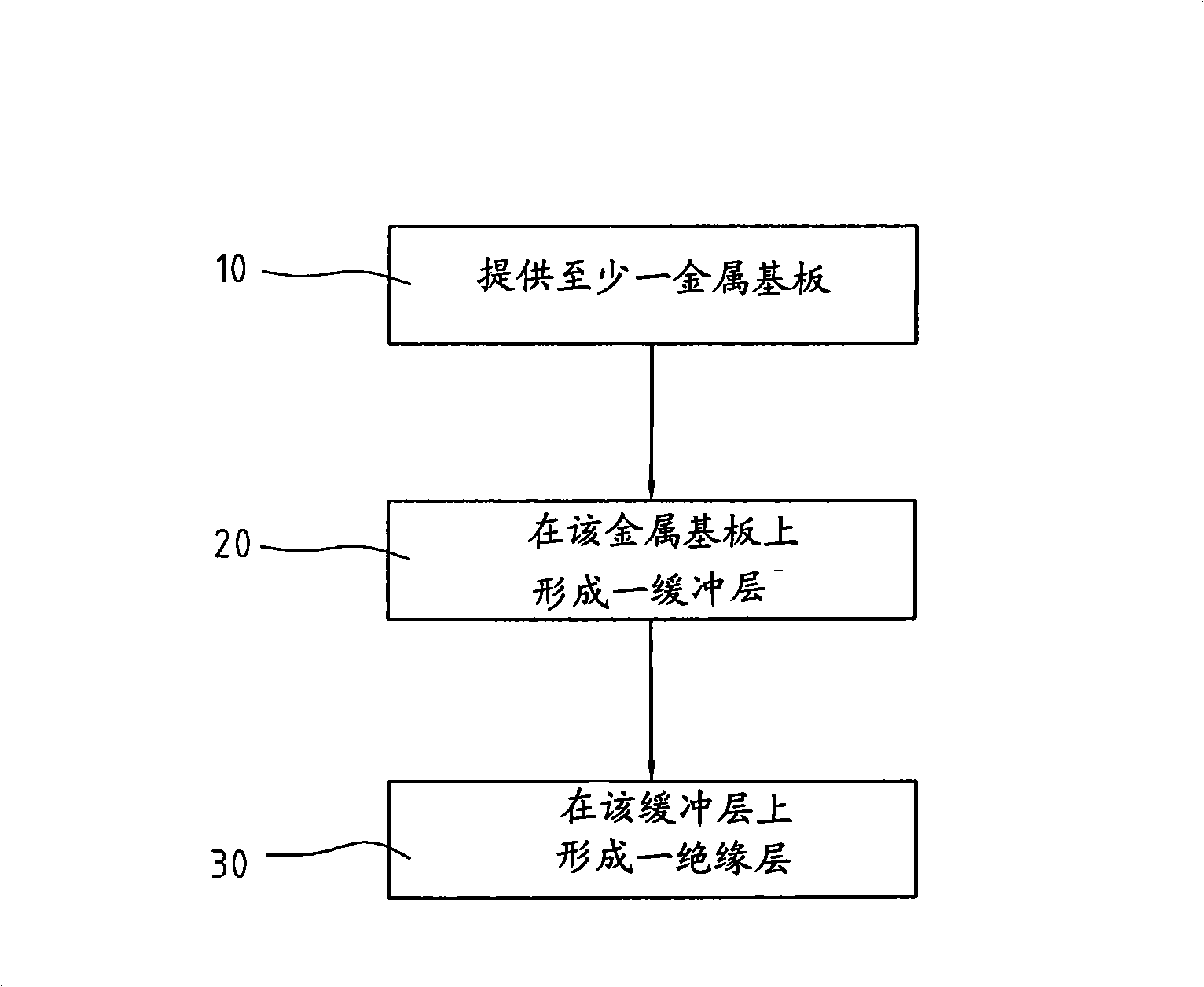

[0035] Please refer to image 3 , illustrating the flow chart of the manufacturing method of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com