Patents

Literature

272results about How to "Omit process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

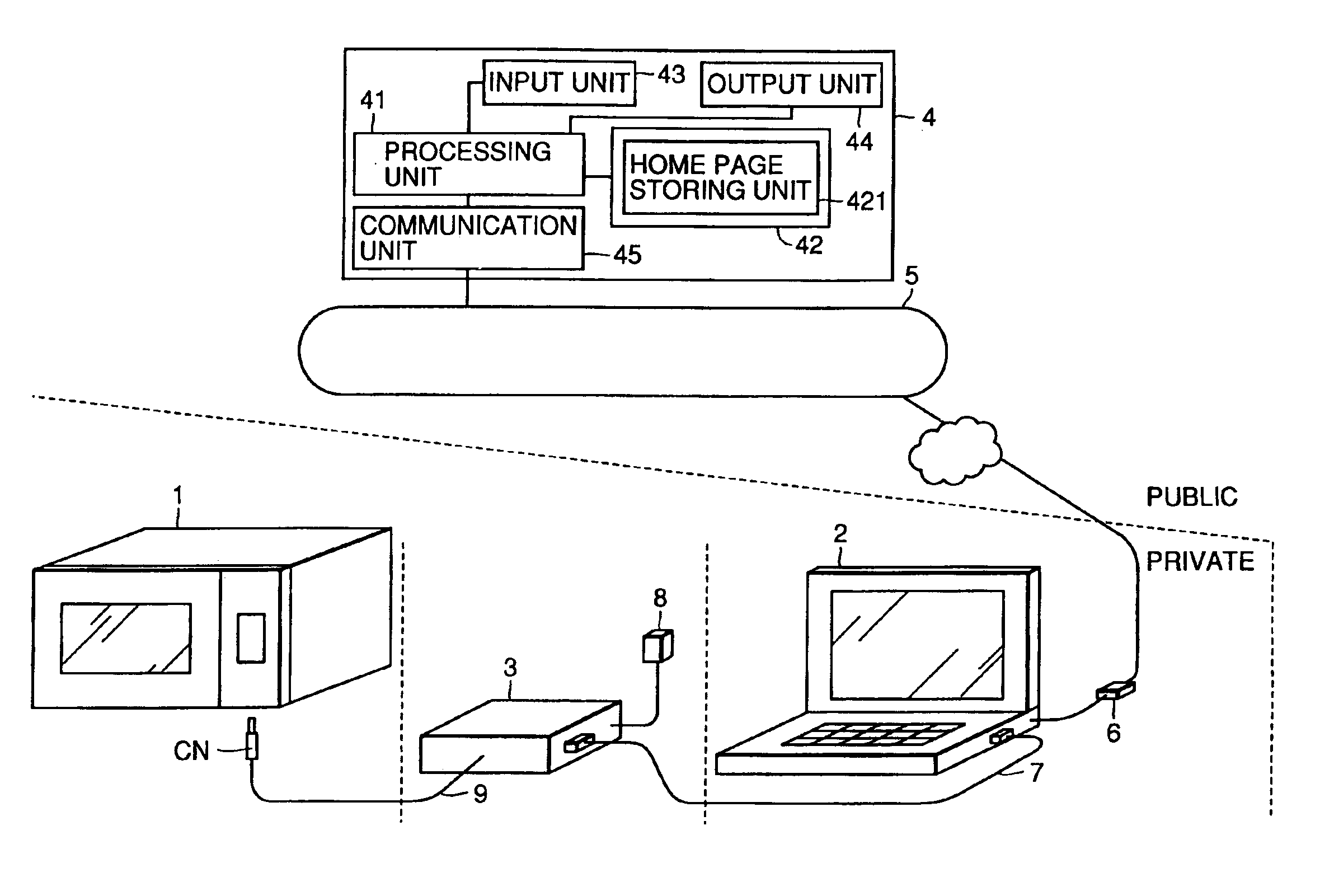

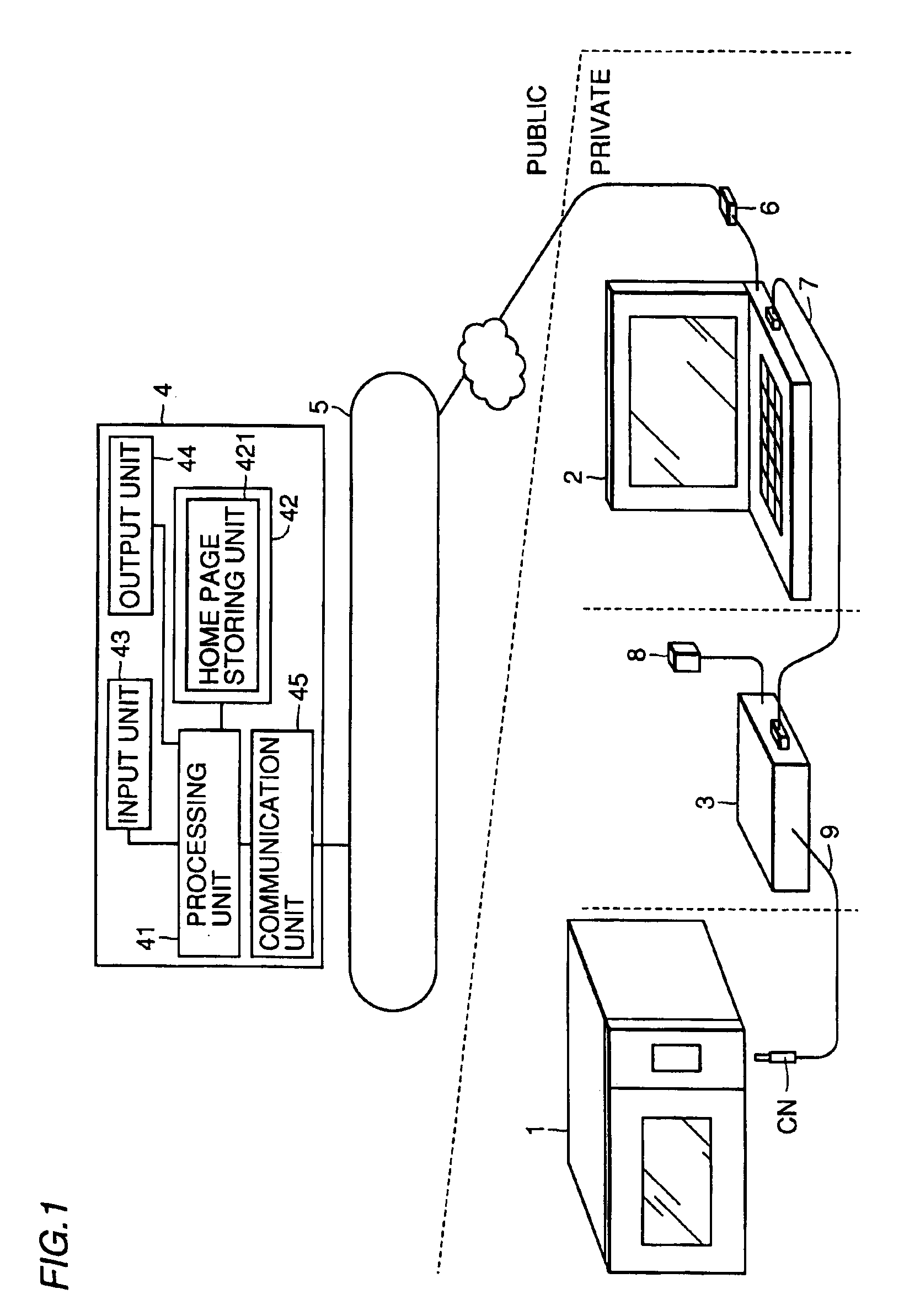

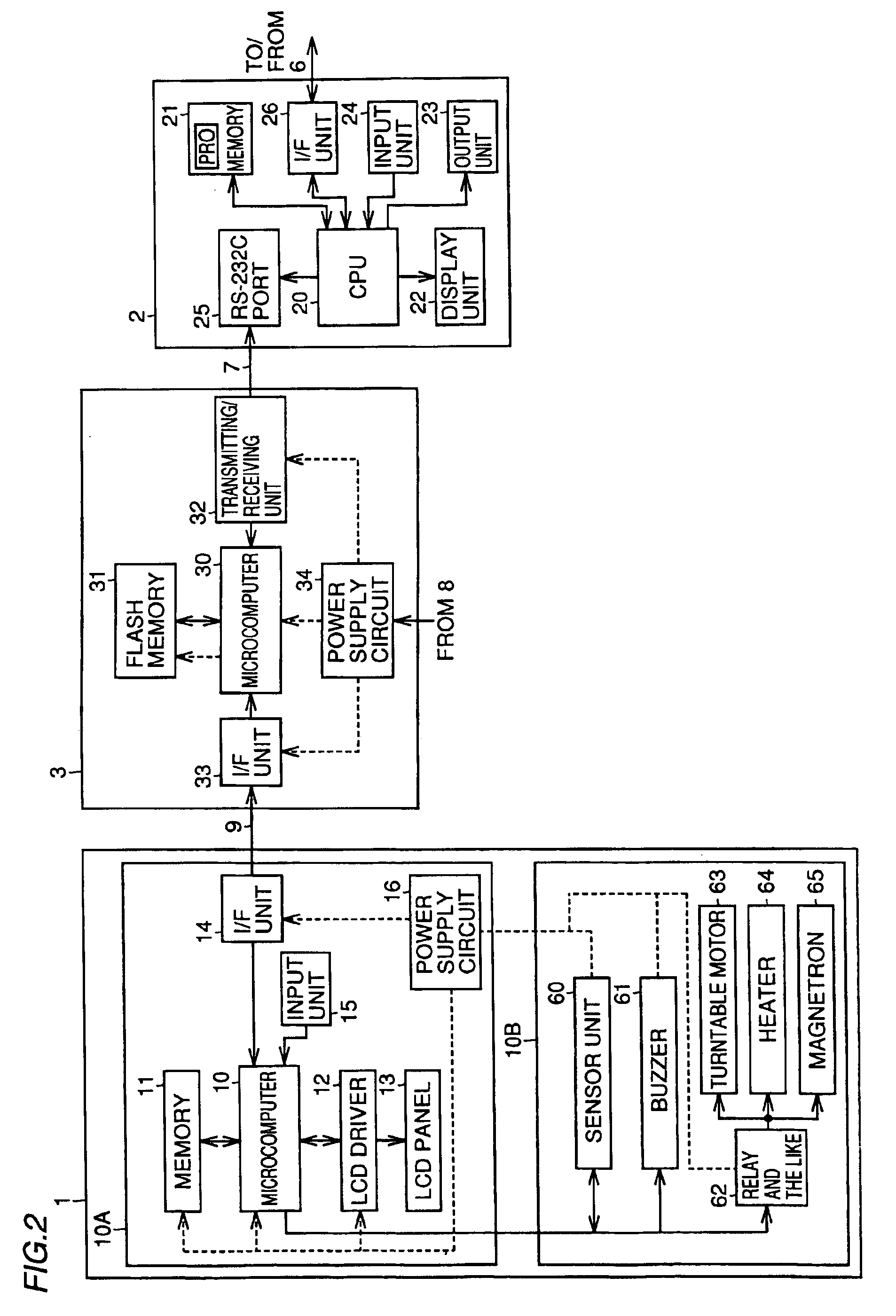

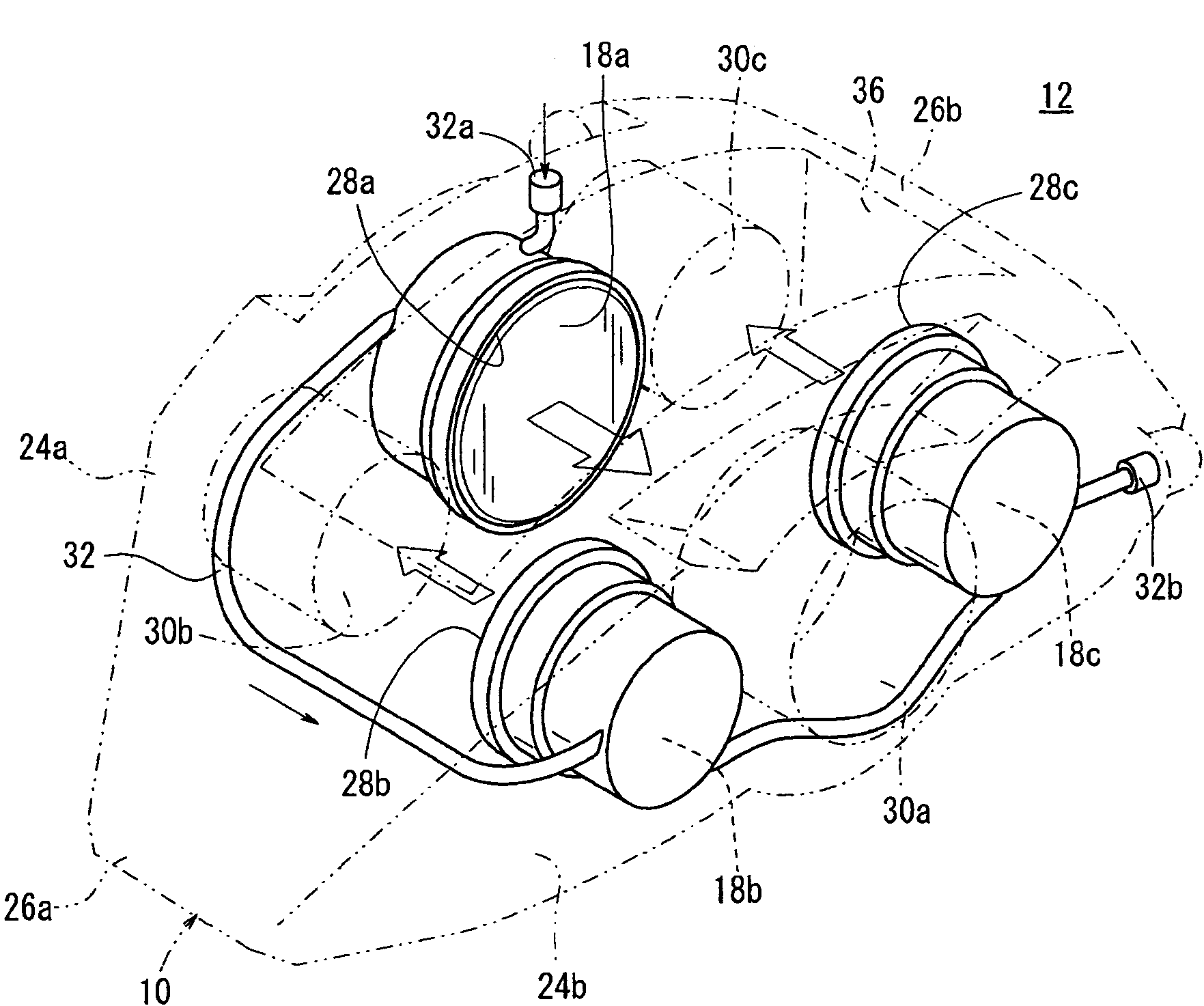

Methods and apparatus for controlling operation of a microwave oven in a network

InactiveUS6949729B1Vary and improve dietSimple wayDielectric heating circuitsCooking vesselsMicrowave ovenHome page

A microwave oven, a relay box communicating with the microwave oven and a personal computer communicating with the relay box are provided in private. The personal computer is connected to a host computer storing home page information, through the public Internet. A home page storing unit of the host computer stores, corresponding to each of a plurality of cooking recipes, recipe data directly recognized by microwave oven including heating control data for heating and cooking the cooking recipe by the microwave oven, a button to be operated for transferring the recipe data through the Internet to personal computer and image display data for displaying information related to the cooking recipe as a home page image display. Therefore, in accordance with the heating control data downloaded and supplied to personal computer, microwave oven is controlled to heat and cook the desired cooking recipe.

Owner:SHARP KK

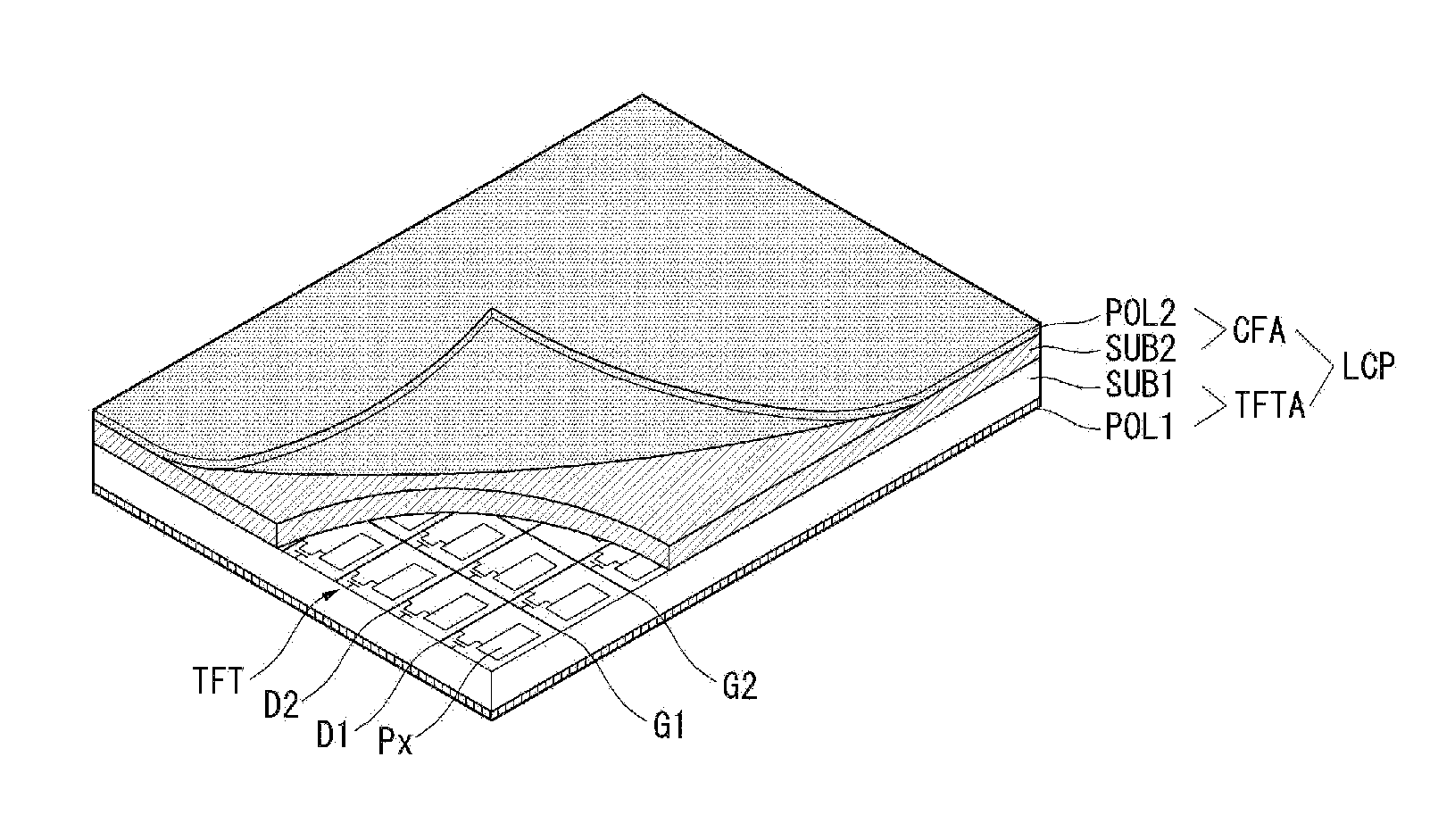

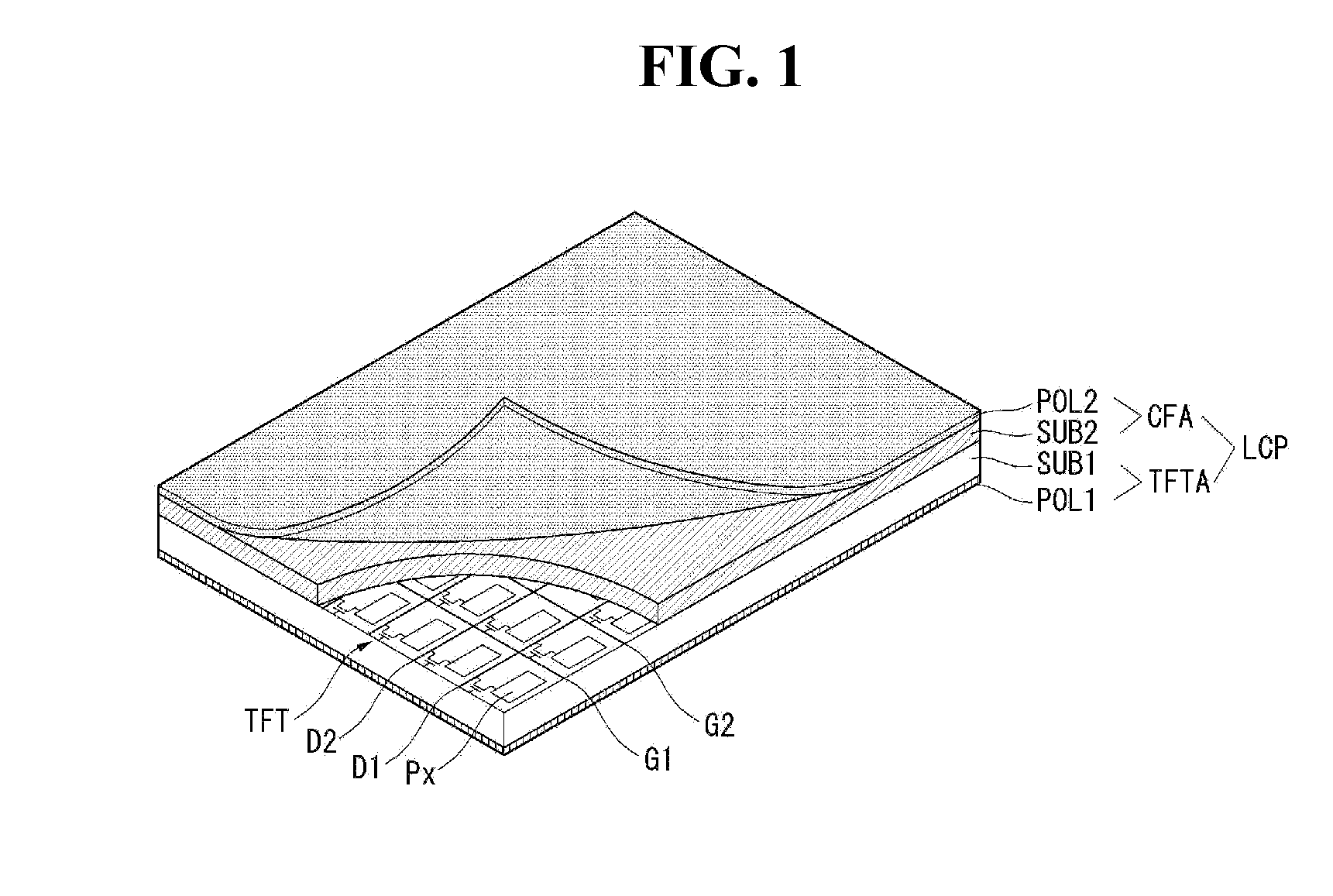

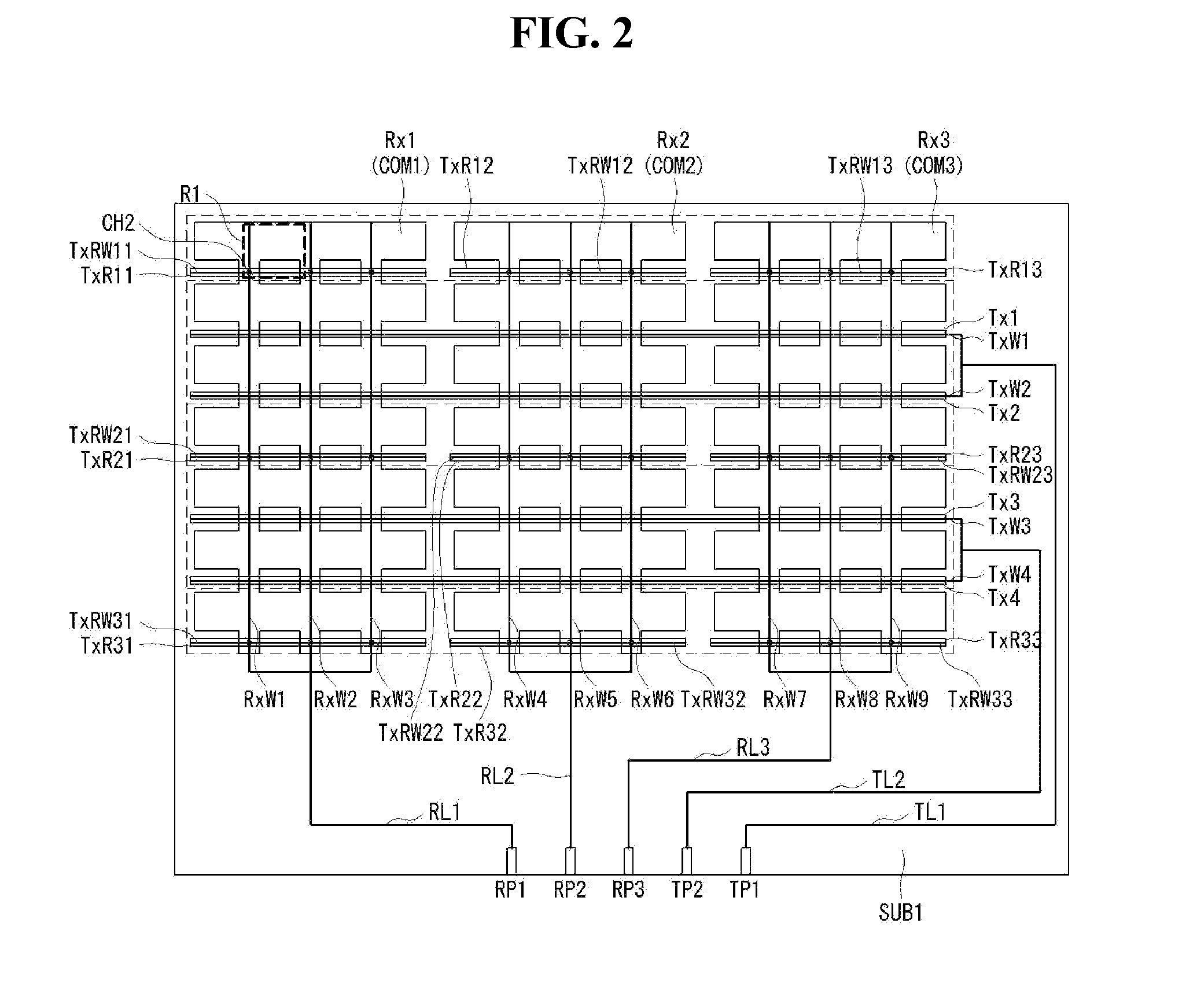

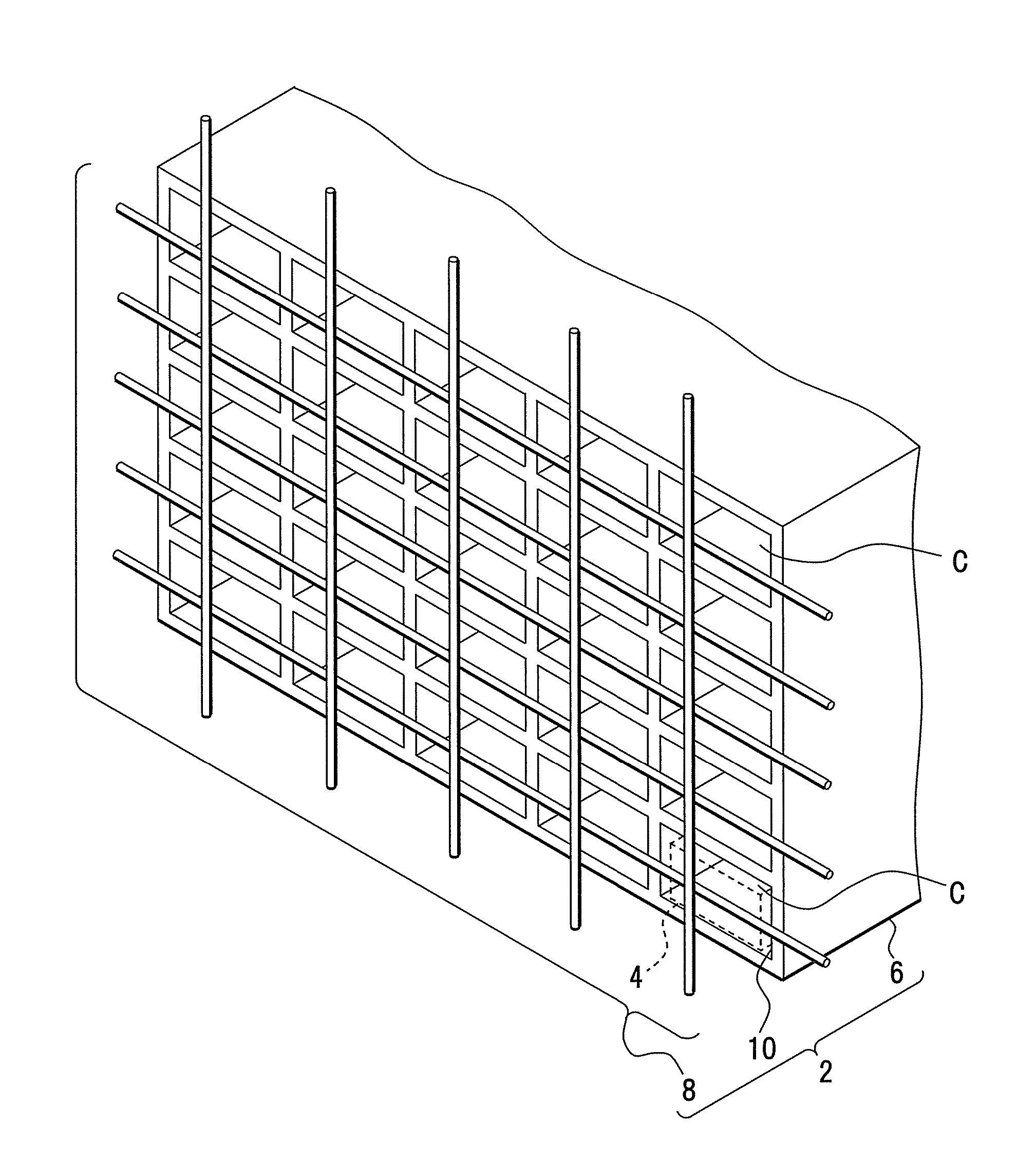

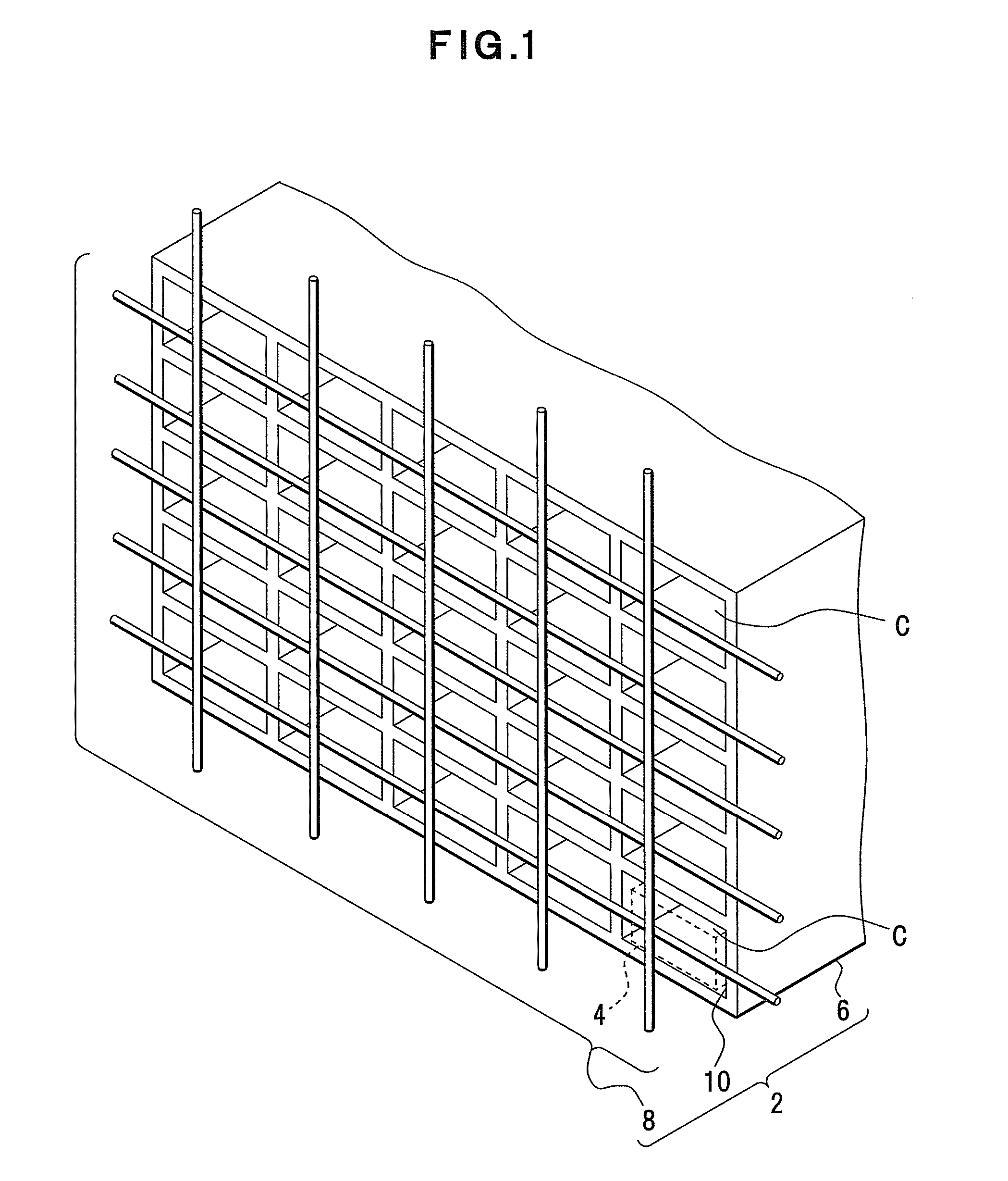

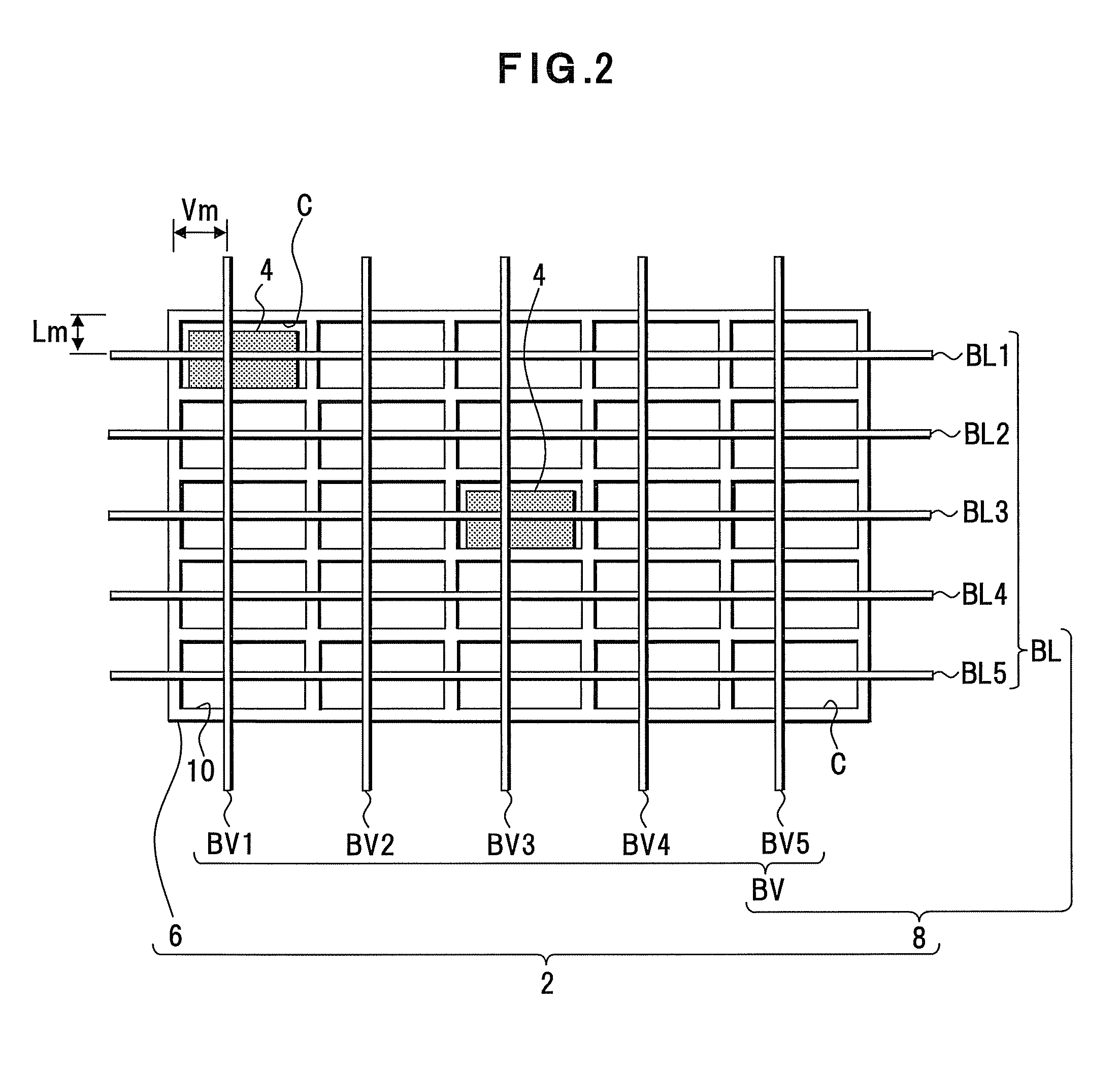

Touch sensor integrated type display device

ActiveUS20140168537A1Prevent in touch sensitivityIncrease parasitic capacitanceNon-linear opticsInput/output processes for data processingDisplay devicePhysics

A touch sensor integrated type display device includes gate lines and data lines; a plurality of pixel electrodes respectively formed in pixel areas defined by crossings of the gate and data lines; a first electrode formed between first pixel electrodes and in parallel with a first gate line of the gate lines, the first pixel electrodes being adjacent to each other with the first gate line interposed therebetween; second electrodes formed between second pixel electrodes and arranged in a line in parallel with a second gate line adjacent to the first gate line, the second pixel electrodes being adjacent to each other with the second gate line interposed therebetween; and third electrodes, each of which is formed in parallel with the data lines and contacts the second electrodes, at least a portion of each of the third electrodes overlapping the first and second pixel electrodes.

Owner:LG DISPLAY CO LTD

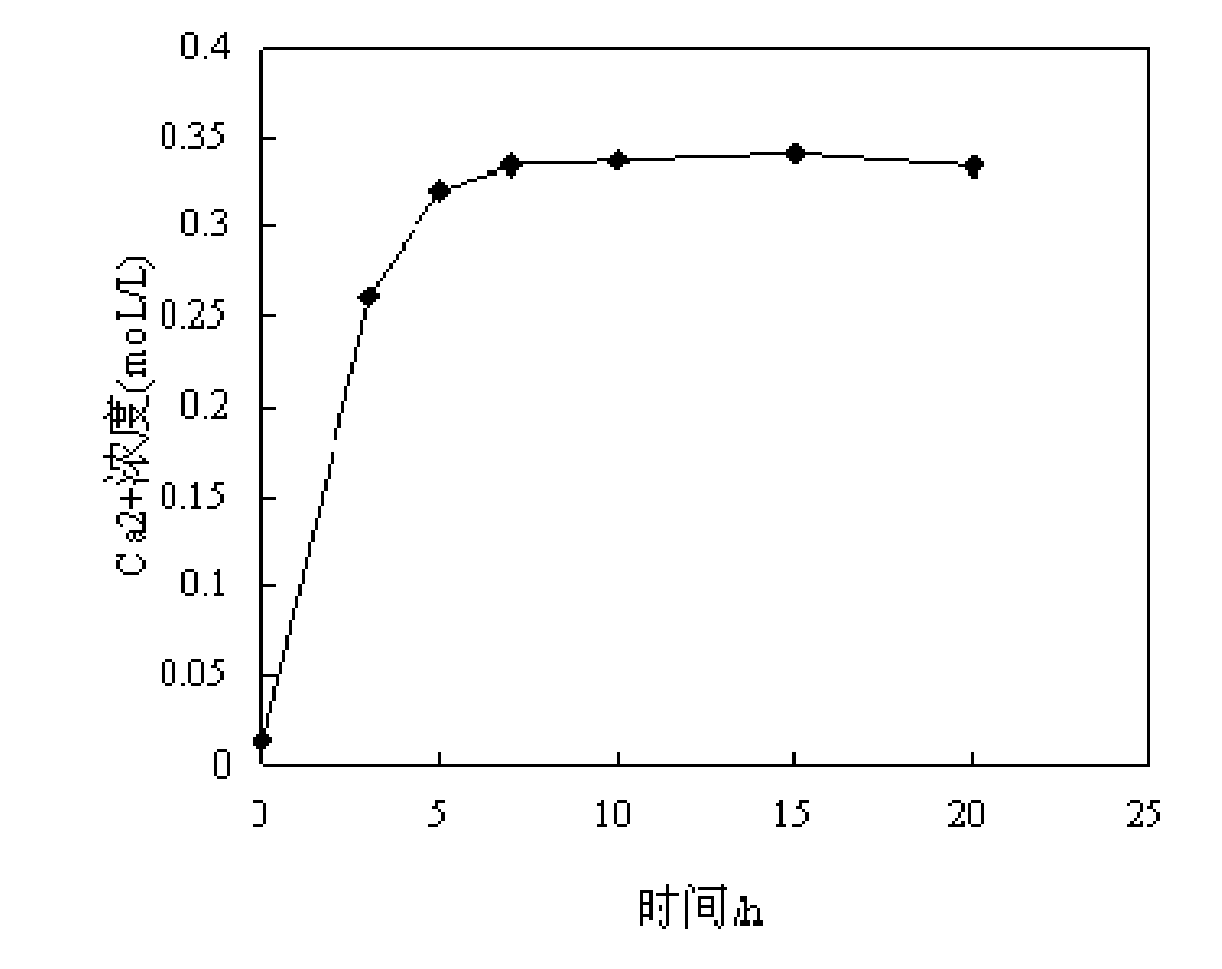

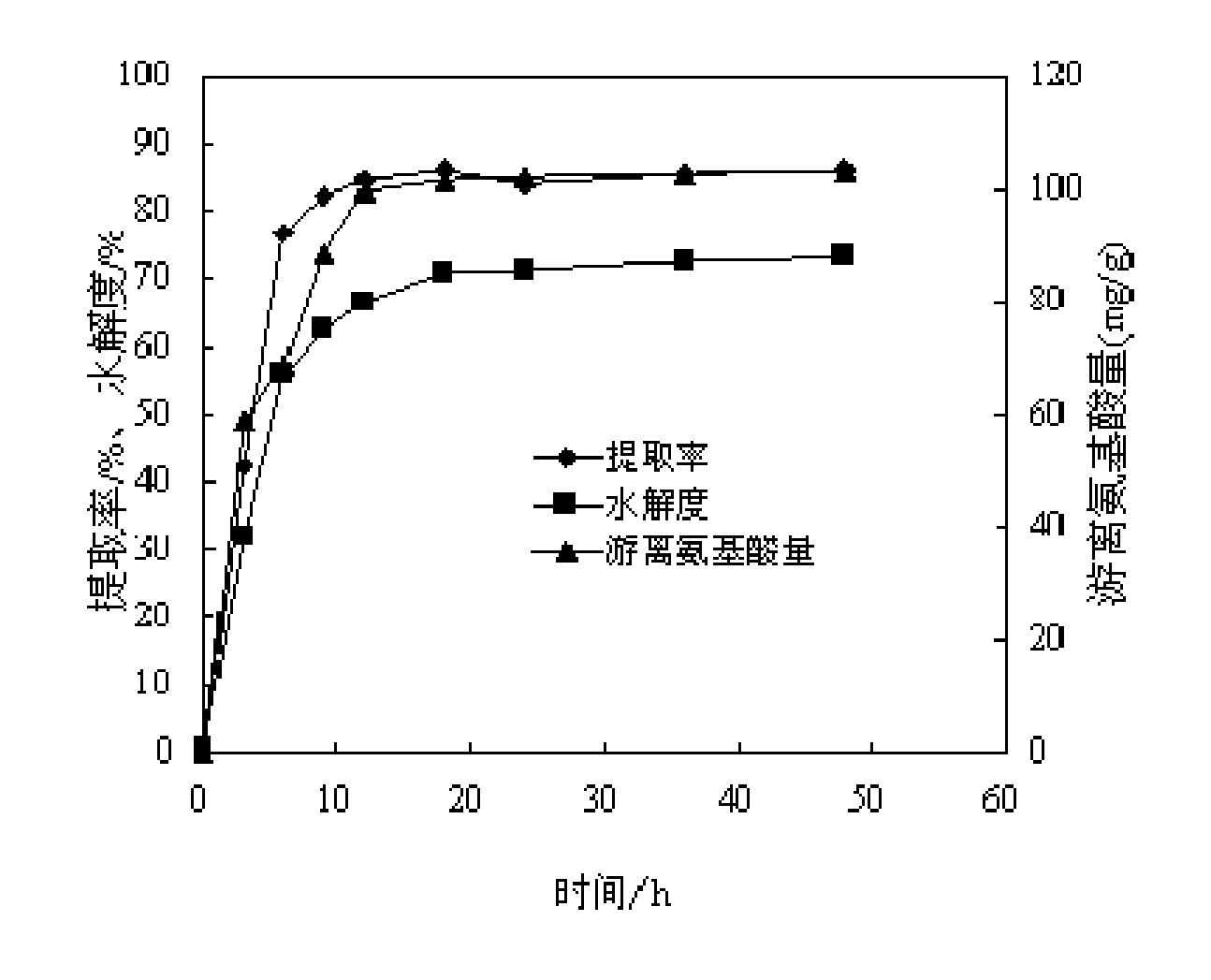

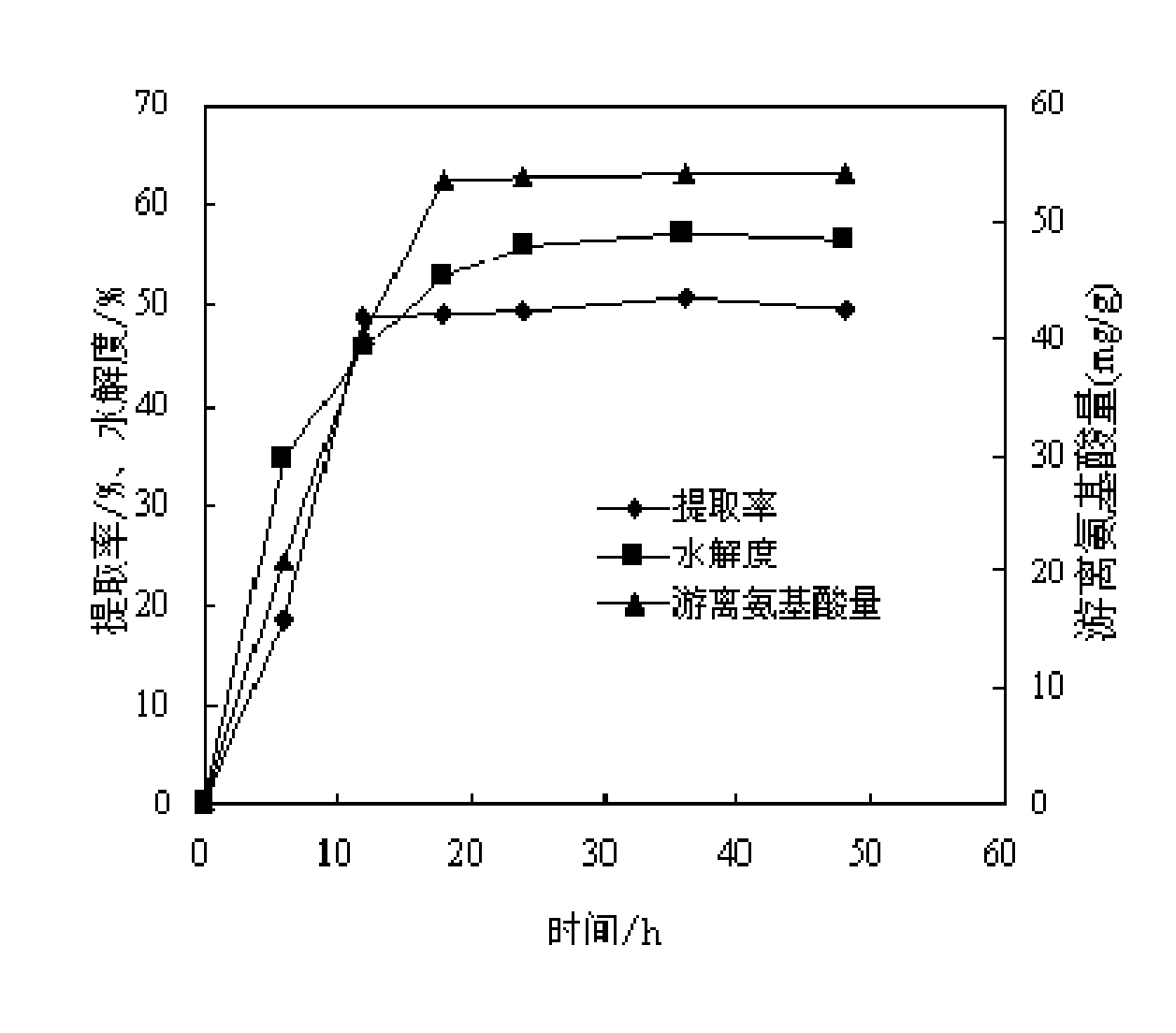

Method for preparing collagen peptide from fish scales

The invention discloses a method for preparing collagen peptide from fish scales, which is characterized by comprising the following steps of: 1, taking the fish scales and immersing hydrochloric acid to remove calcium; washing to be neutral, drying and crushing; 2, adding the calcium-removed, dried and crushed fish scales obtained by the step 1 into an enzyme reactor; adding water and mixed protease to extract the collagen peptide; after the extraction, carrying out enzyme deactivation and centrifuging to obtain an enzymolysis solution, wherein the mixed protease is a mixture of neutral protease, papain and flavored protease; and 3, carrying out film concentration on the enzymolysis solution obtained by the step 2; and freezing and drying a concentrated solution to obtain fish scale collagen peptide powder. According to the fish scale collagen peptide obtained by the invention, the neutral protease, the papain and the flavored protease are used for extracting the fish scale collagen peptide by an enzymic method at one step, so that not only can the enzymolysis time (9 hours)be reduced, but also the extracting rate (72.72%) of the collagen peptide is improved, and solves the special flavor problem of bitter taste of the collagen peptide and the like.

Owner:WENZHOU UNIVERSITY

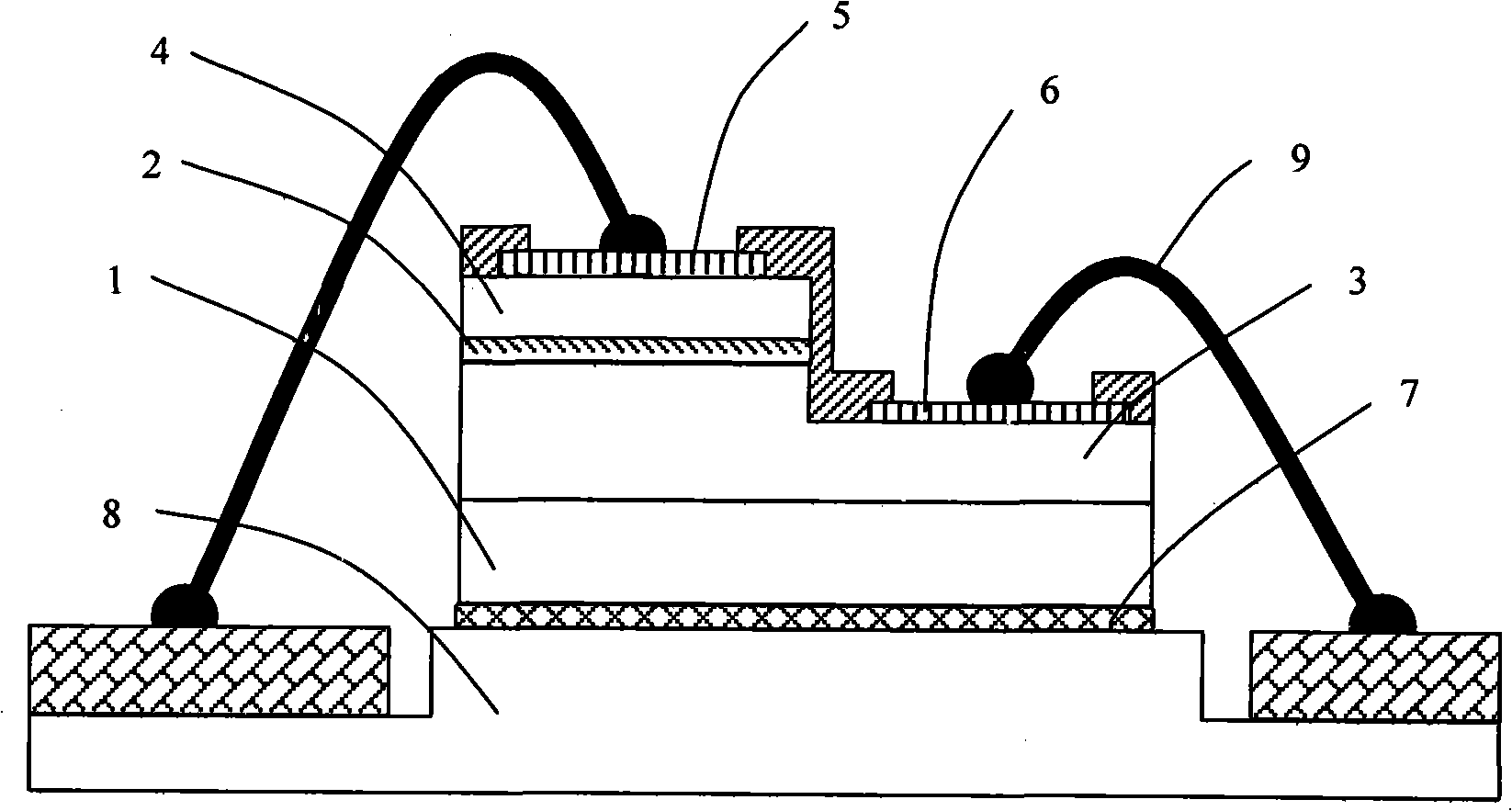

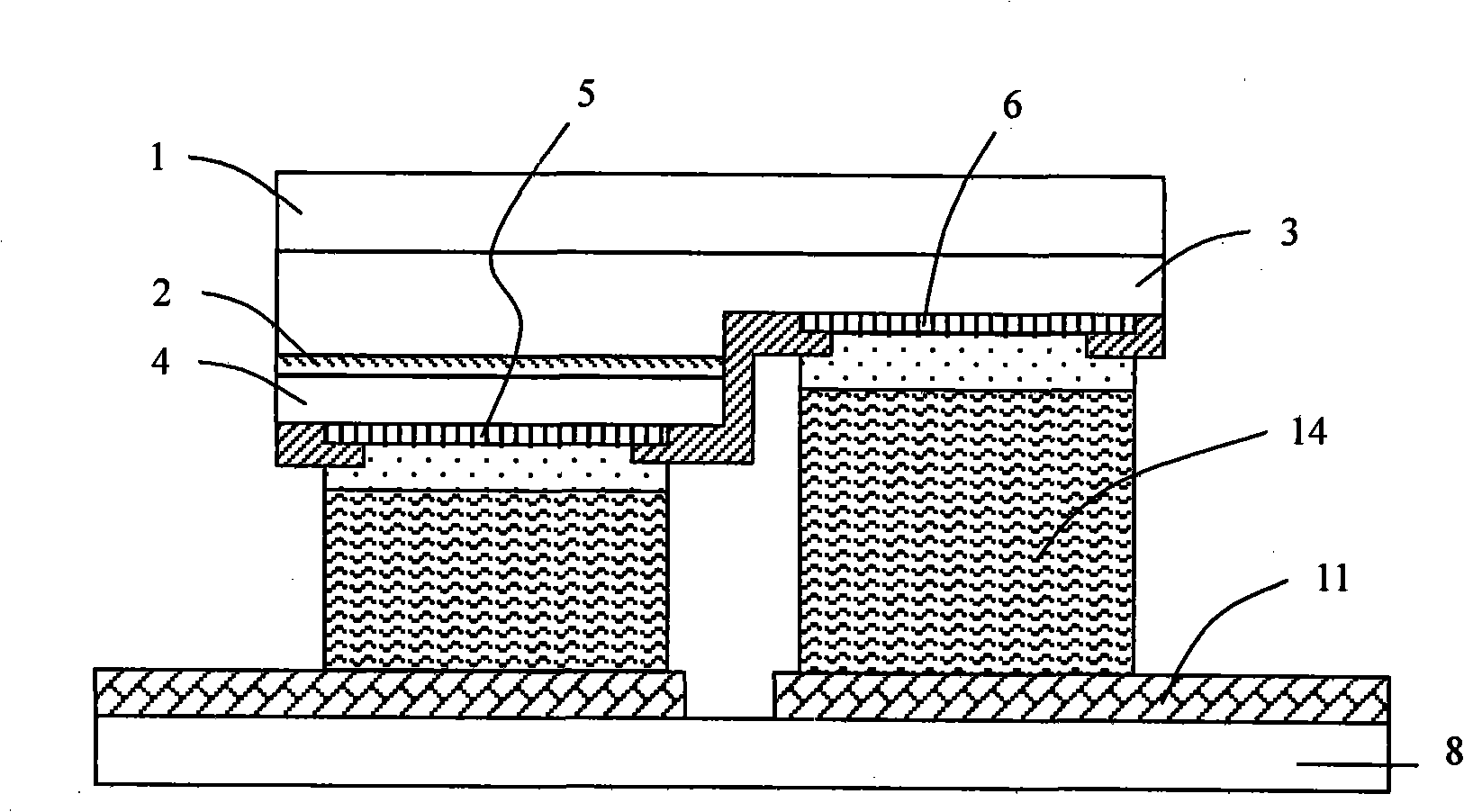

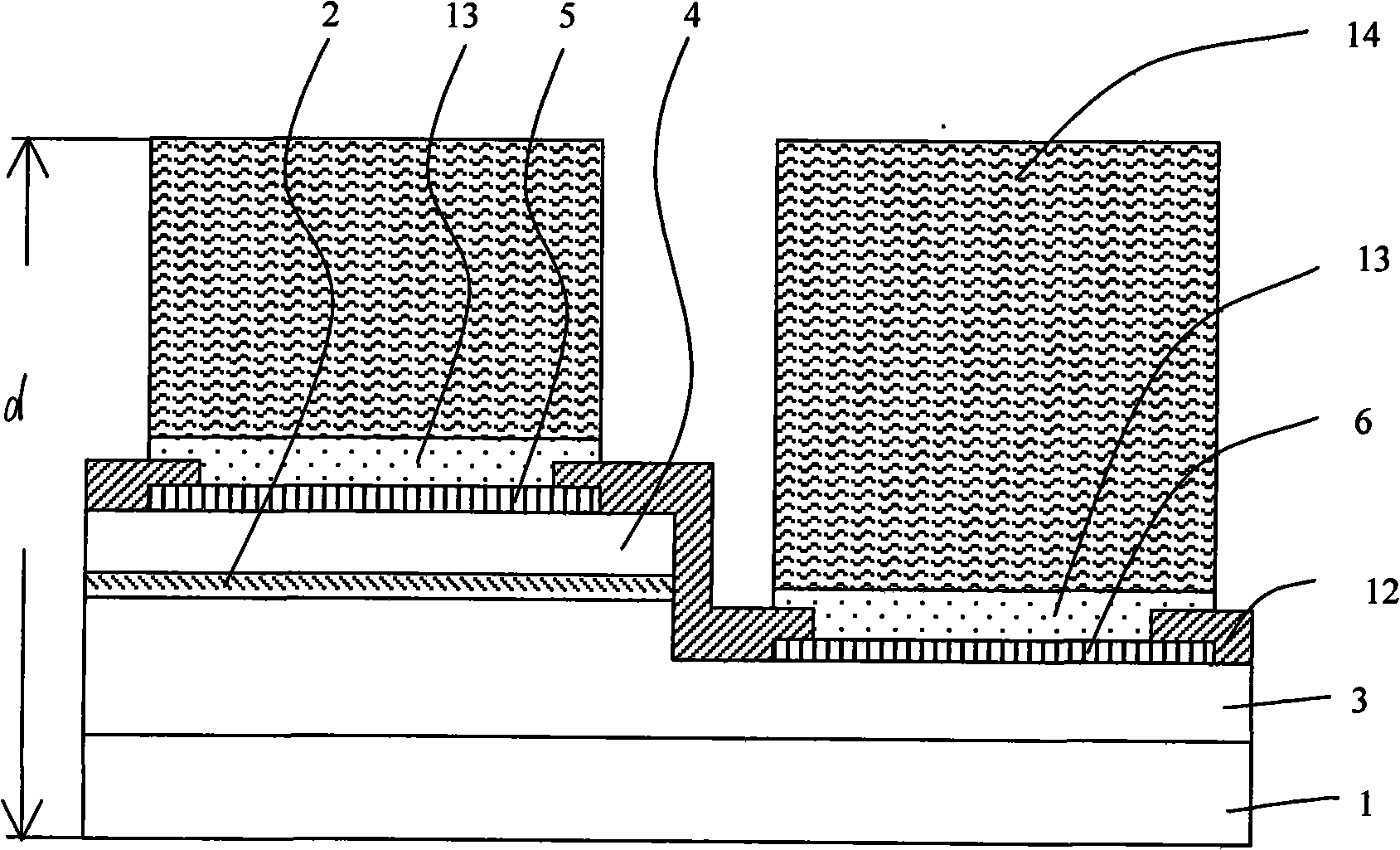

Salient point LED and manufacturing method thereof

ActiveCN101350381ASolve the problem of centralized heat dissipationRelaxed machining accuracy requirementsSemiconductor/solid-state device detailsSolid-state devicesMiniaturizationDie bonding

The invention relates to a protruding point luminescent diode, wherein a protruding point lower metal is plated on an electrode of a protruding point luminescent diode chip, metallic protruding points are grown on the upper portion of the protruding point lower metal, a passivation layer is grown on the surface of the upper portion of the luminescent diode chip excepting the surface of an electrode, a welding pad is made on a packing support, the metallic protruding points of the protruding point luminescent diode are inversely welded on the welding pad of the packing support. The method for preparing the diode comprises the following steps: making the passivation layer, sputtering a metal sacrificial layer, making a photoresist mask, forming the metallic protruding points, removing the photoresist mask, removing the metal sacrificial layer, reducing, cutting into separated chips and inversely welding on an SMD support, and then forming an inversely welded LED die set. The method enables the chip of the luminescent diode to be without the gold wire bonding and the die bond technique, directly switches a circuit and assembles the chip on a base plate or a metallic support, realizes the miniaturized package and the die set with multiple chips, and successfully solves the problem of the heat dissipation of the luminescent diode.

Owner:APT ELECTRONICS

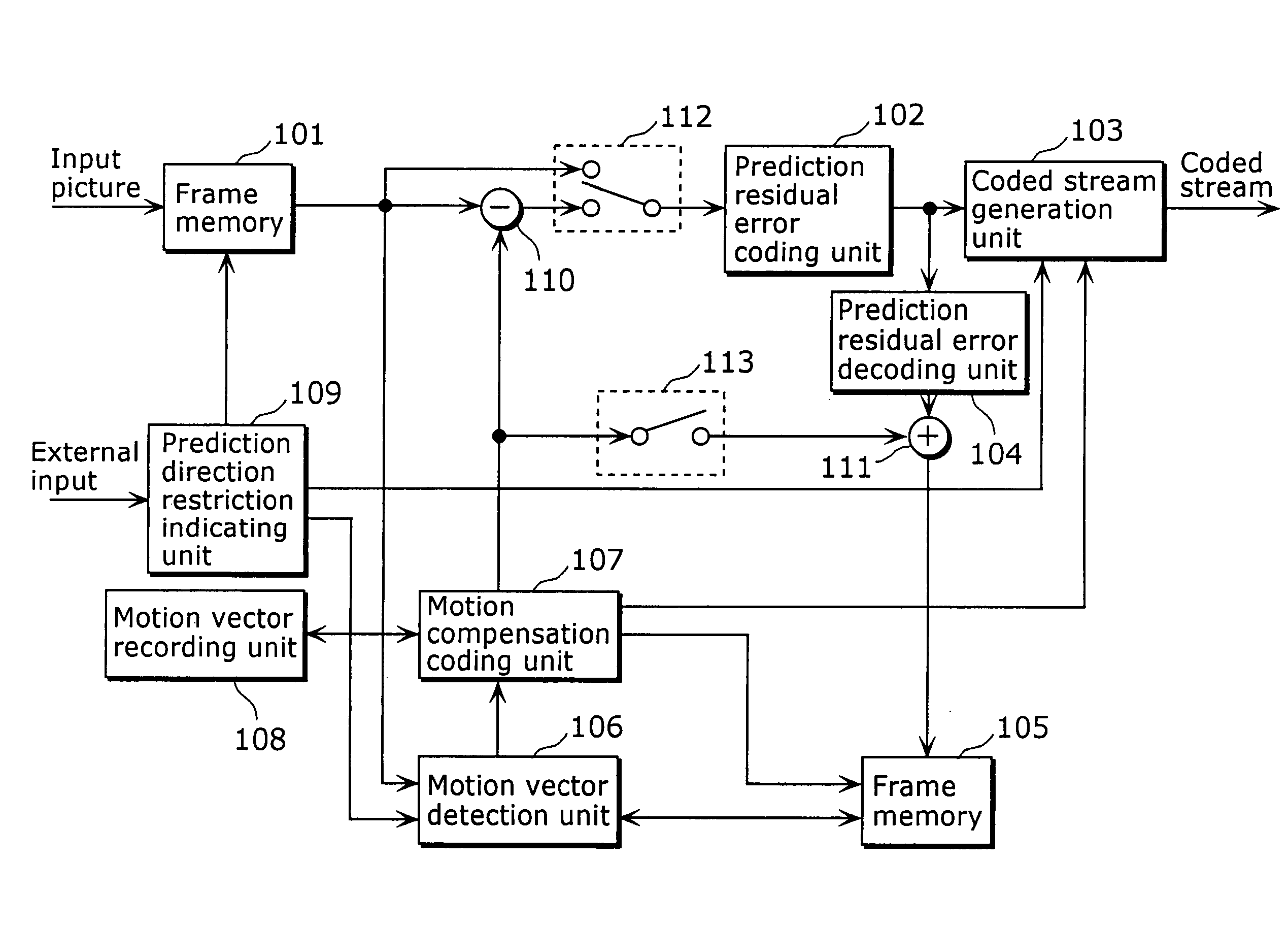

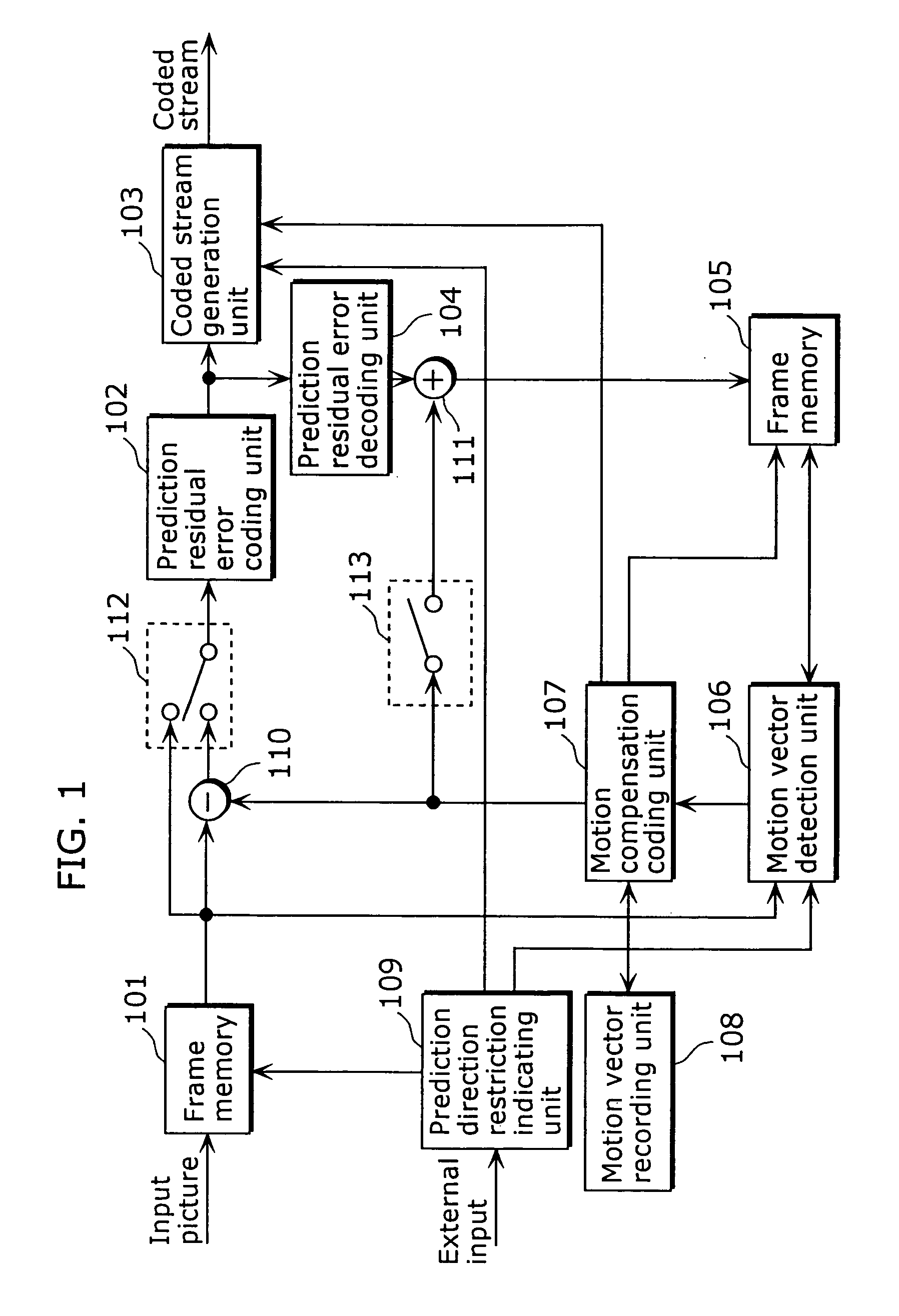

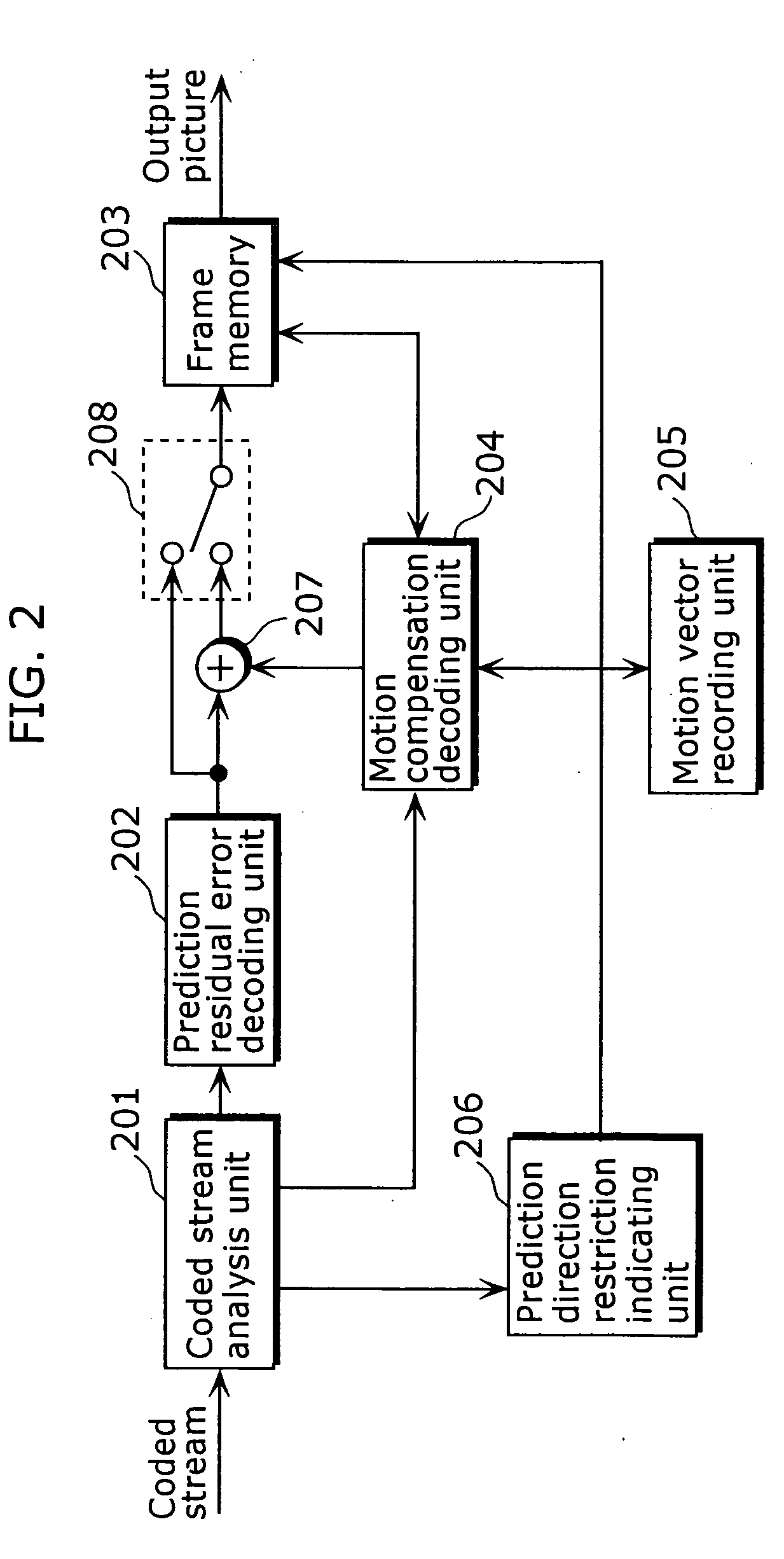

Moving picture coding method, decoding method, data stream, data recording medium and program

InactiveUS20050117642A1Minimize temporal delayReduce the amount of processingColor television with pulse code modulationColor television with bandwidth reductionDecoding methodsData stream

In the coding method of the present invention, by adding an identification signal for indicating that there is no need to reorder coded pictures in the case where no picture coded by referring to a single or two pictures in the backward direction in display order is included in the sequence data, a restriction on pictures not to refer to any picture except the pictures that are positioned in the temporally forward direction is imposed and pictures are coded in the same order as the display order. Also, in the decoding method, only pictures that are positioned in the temporally forward direction are referred to according to the above-mentioned identification signal and these coded pictures are decoded in the same order as the display order.

Owner:PANASONIC CORP

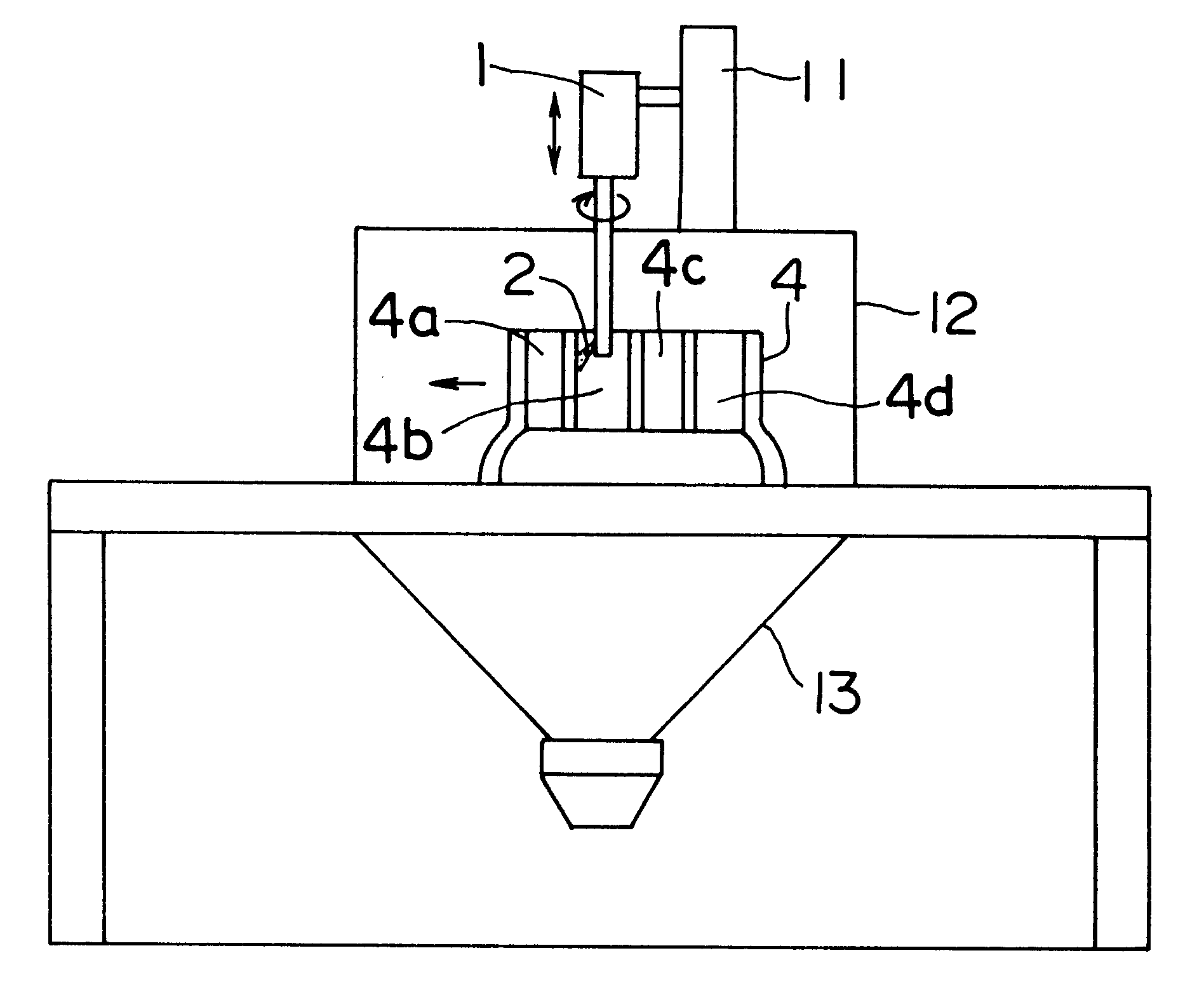

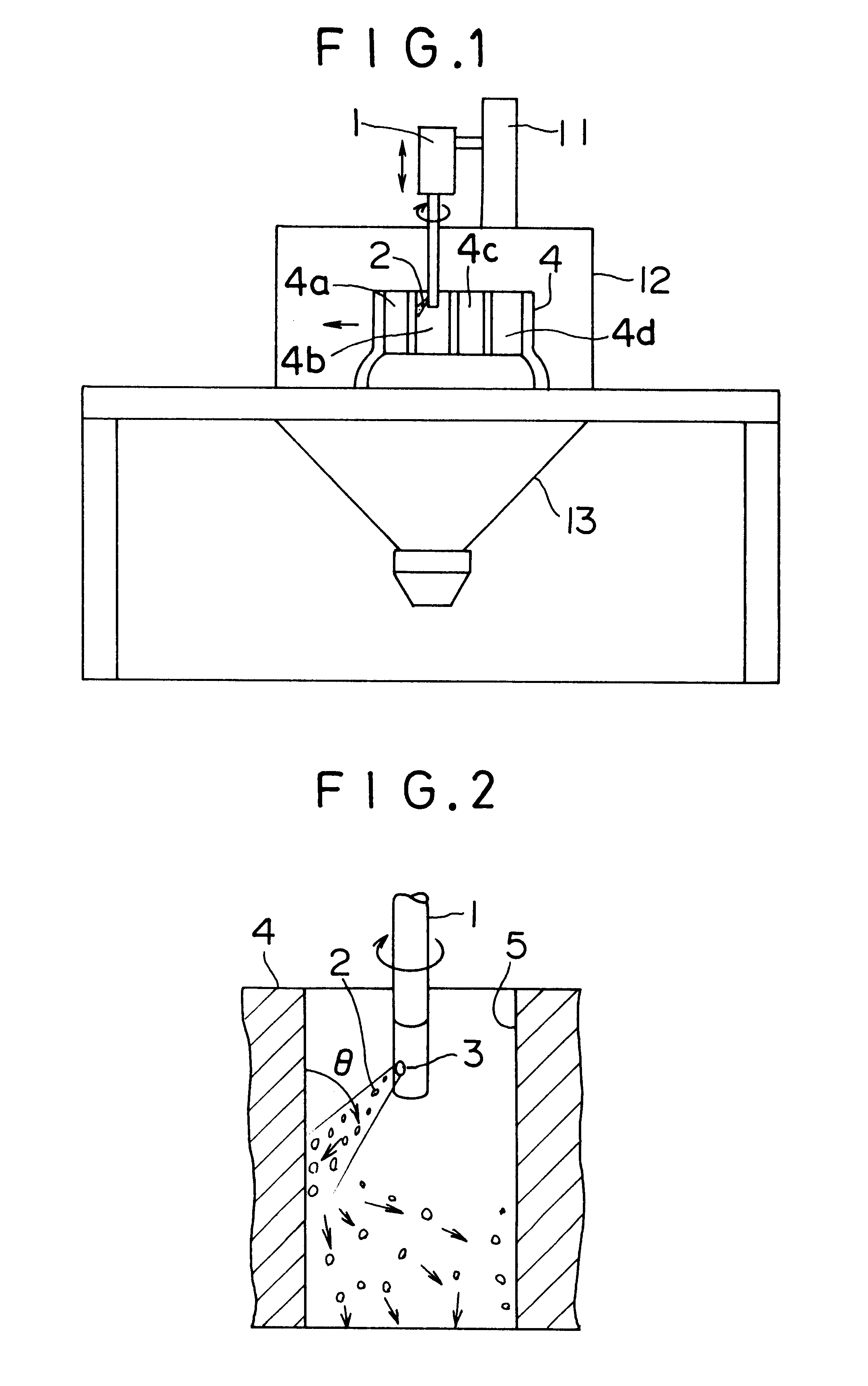

Method for blasting an inside surface of a cylinder

InactiveUS6244934B1Uniform surfaceFine surfaceAbrasive machine appurtenancesAbrasive blasting machinesRough surfaceCylinder head

The present invention provides a method for blasting an inside surface of a cylinder, in which a steady rough surface is always obtained efficiently in the whole region of inside surface of cylinder for an internal combustion engine. For this purpose, a blast gun 1, which is provided so as to be moved vertically by a traverser 11 and capable of rotating around the axis thereof, has a blast nozzle 3 for blowing blast particles 2 in the vicinity of the lower end thereof. The blowing direction of the blast nozzle 3 is slant downward. A cylinder block 4 is placed upright so that the axis of each cylinder is vertical with a cylinder head mating surface 4e on the upper side, and is isolated from the surrounding space by a cabinet 12. The blast gun 1 blows the blast particles 2 while lowering in each cylinder of the cylinder block 4, by which the inside surface 5 of cylinder is blasted. A blast particle recovering reservoir 13 is provided under the apparatus to recover the blast particles 2.

Owner:SUZUKI MOTOR CORP

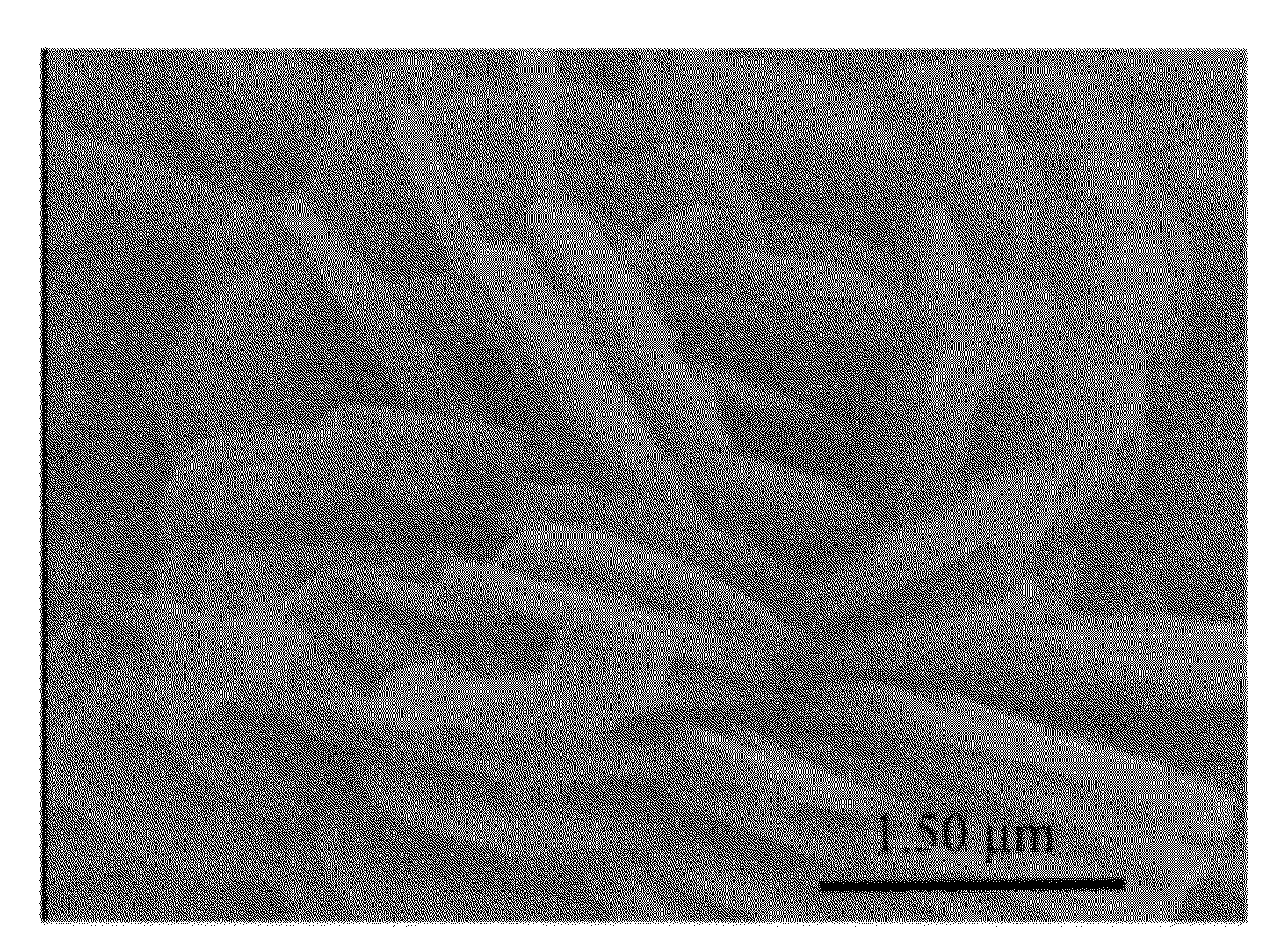

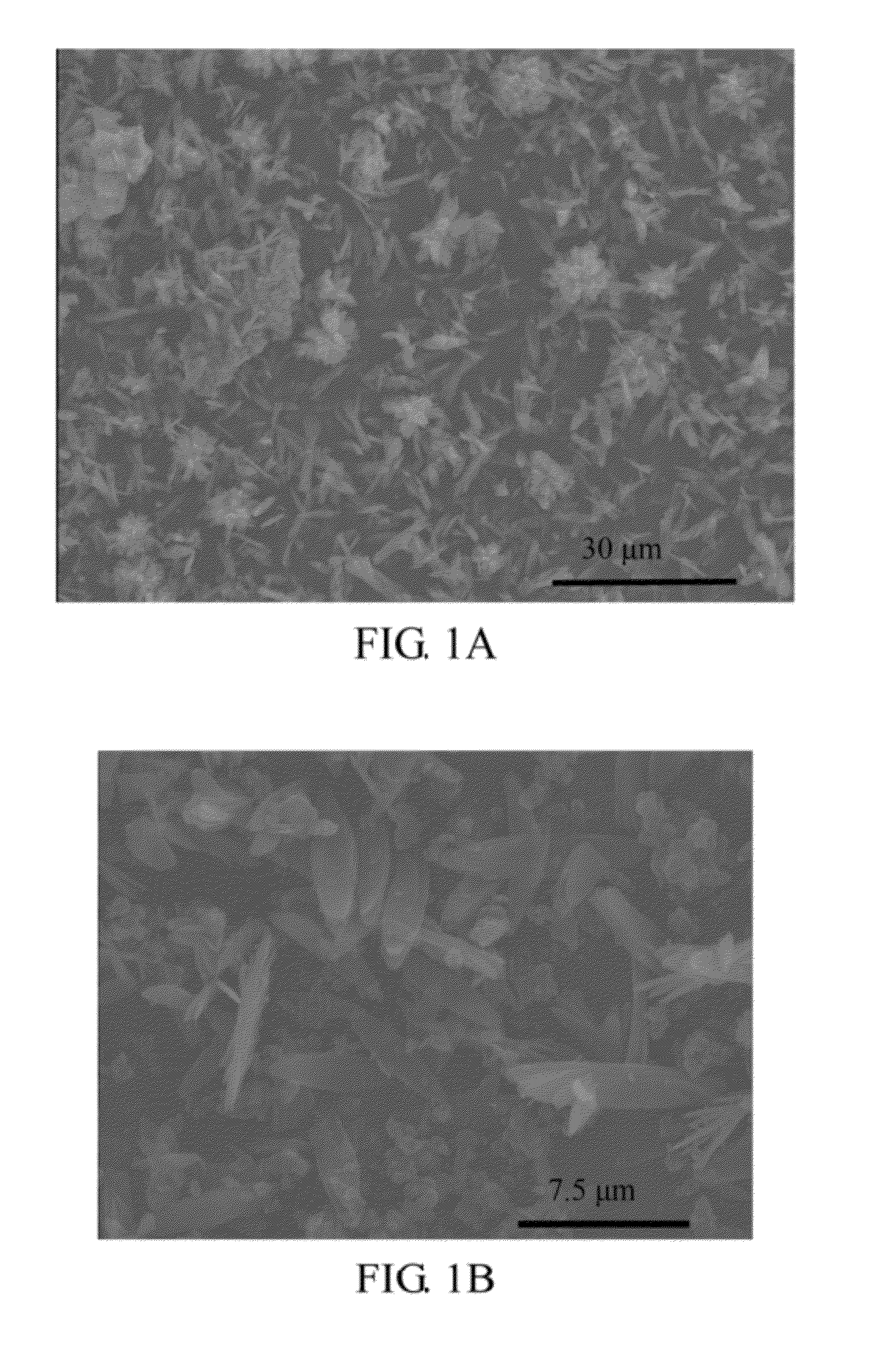

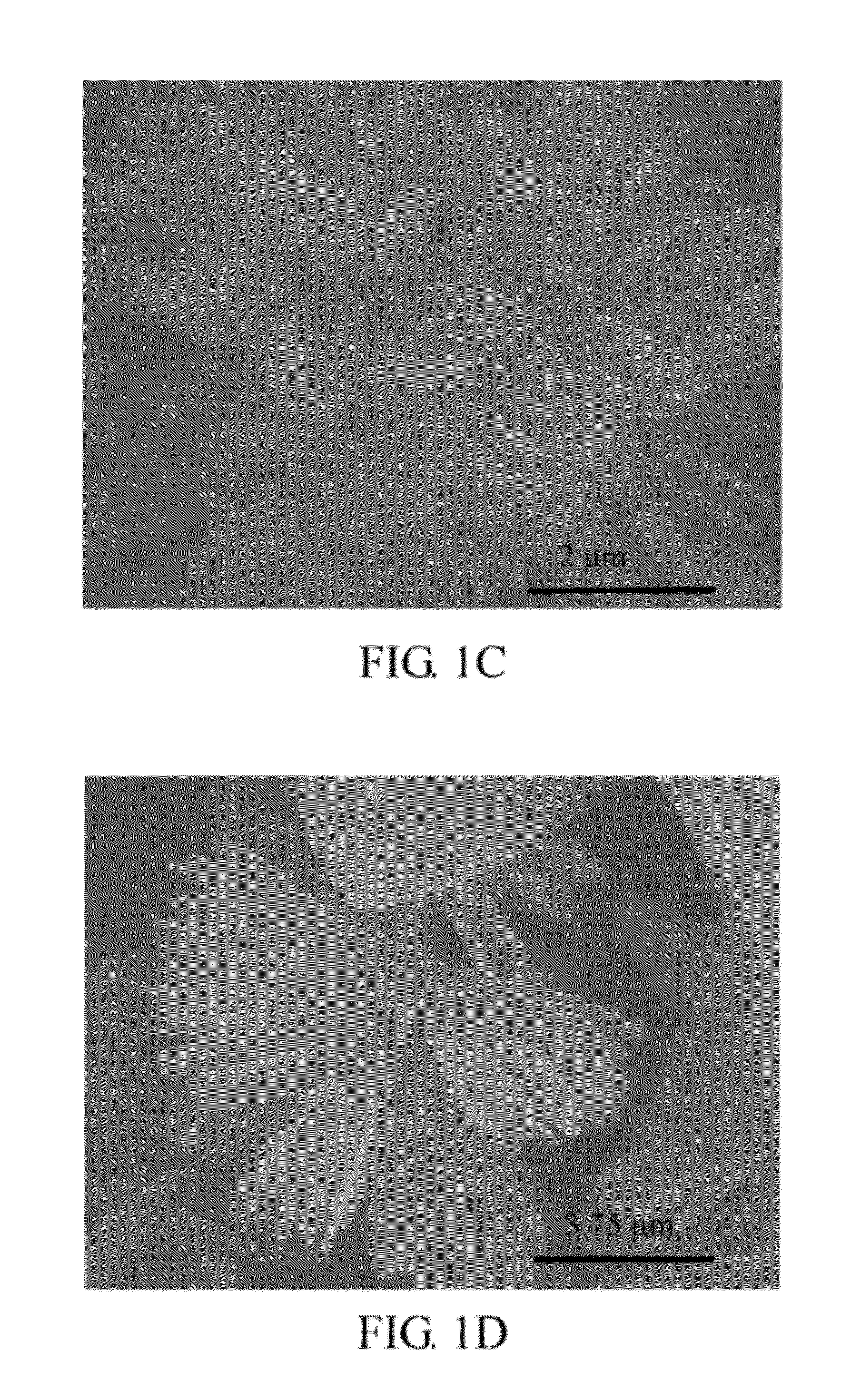

Ferrous phosphate (II) powders, lithium iron phosphate powders for li-ion battery, and methods for manufacturing the same

ActiveUS20120321958A1Uniform and small grain sizeUniform and small sizePhosphatesConductive materialLithium iron phosphatePhosphate

Ferrous phosphate (II) (Fe3(PO4)2) powders, lithium iron phosphate (LiFePO4) powders for a Li-ion battery and methods for manufacturing the same are provided. The ferrous phosphate (II) powders are represented by the following formula (I):Fe(3-x)Mx(PO4)2.yH2O (I)wherein, M, x, and y are defined in the specification, the ferrous phosphate (II) powders are composed of plural flake powders, and the length of each of the flake powders is 0.5-10 μm.

Owner:NATIONAL TSING HUA UNIVERSITY +1

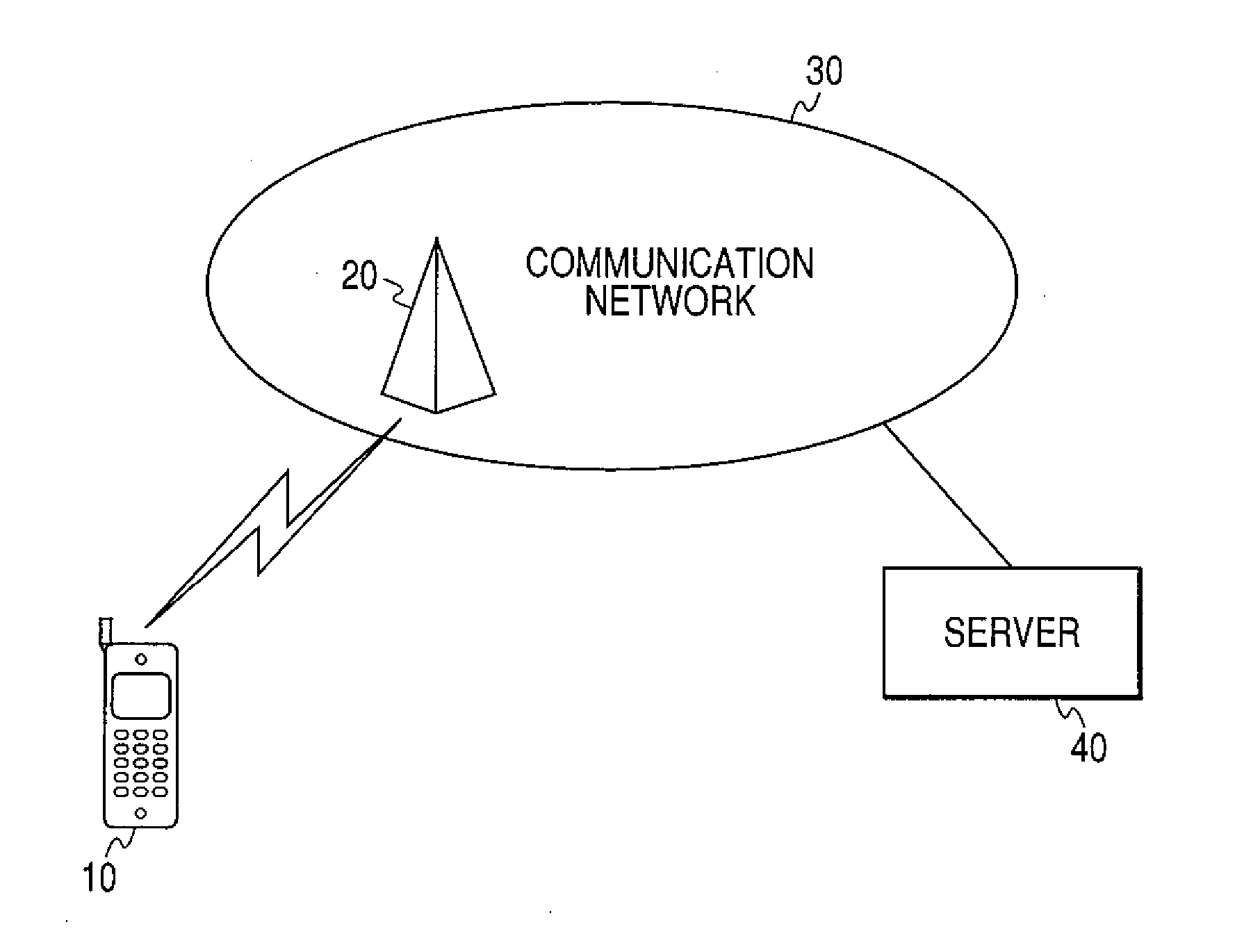

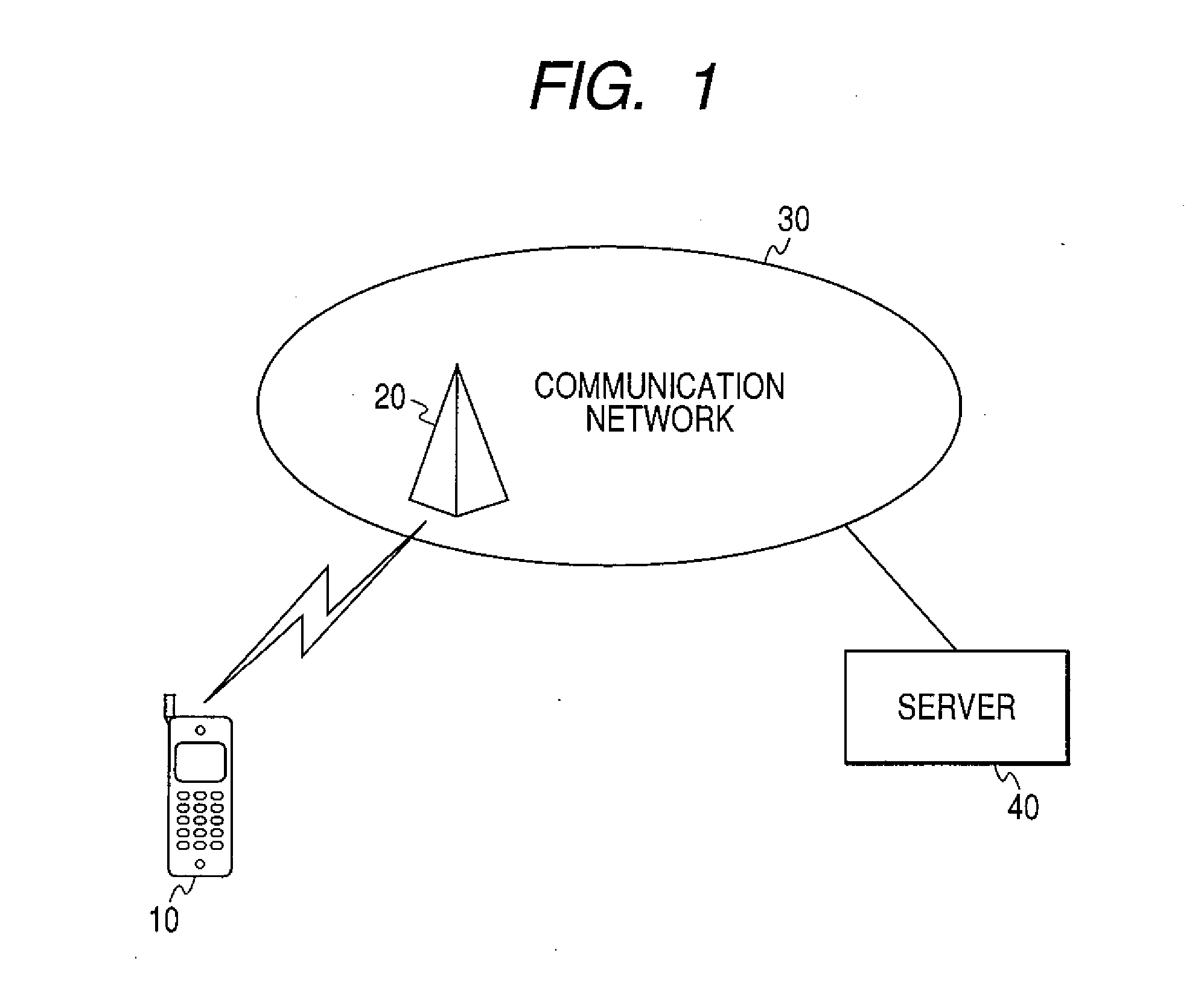

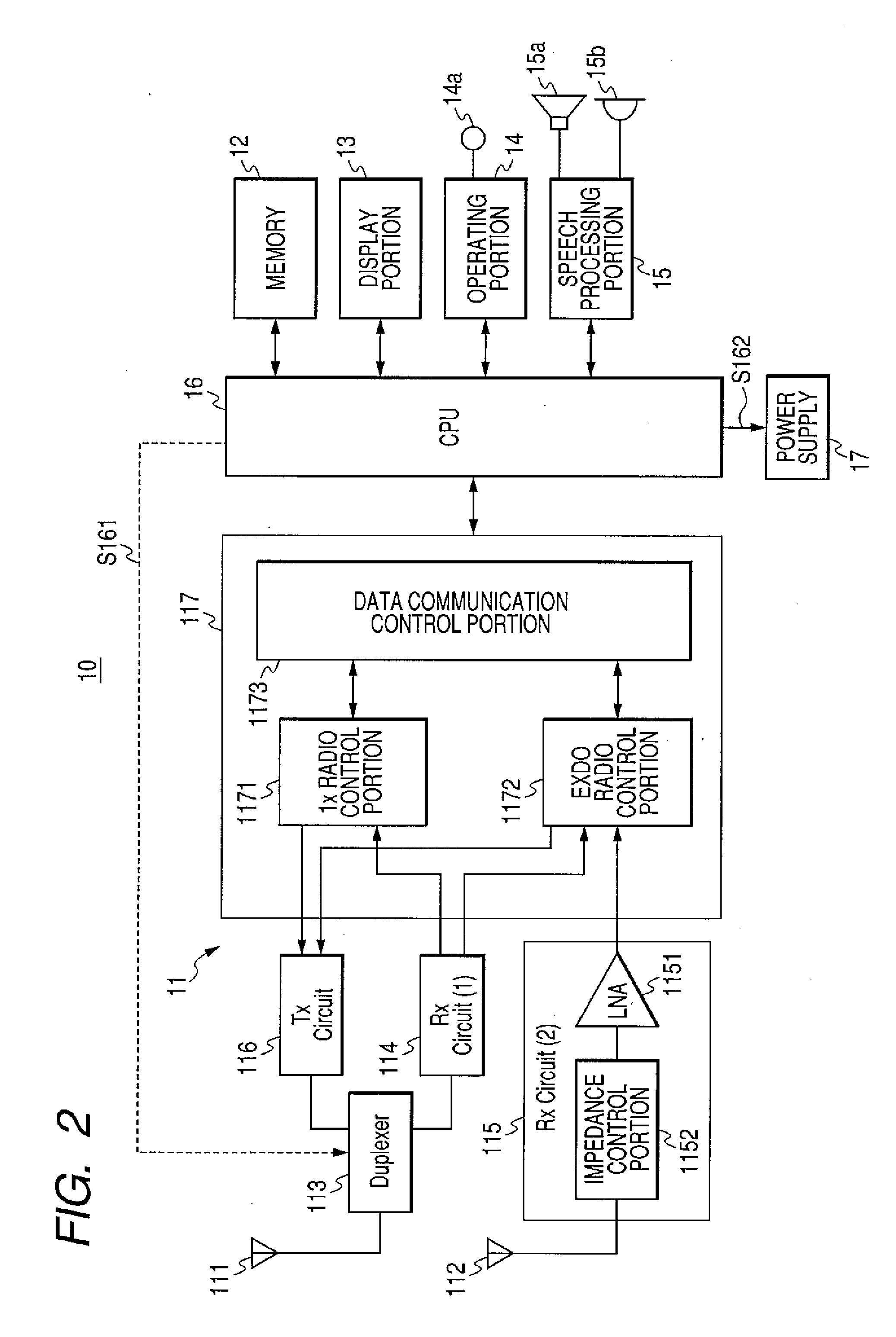

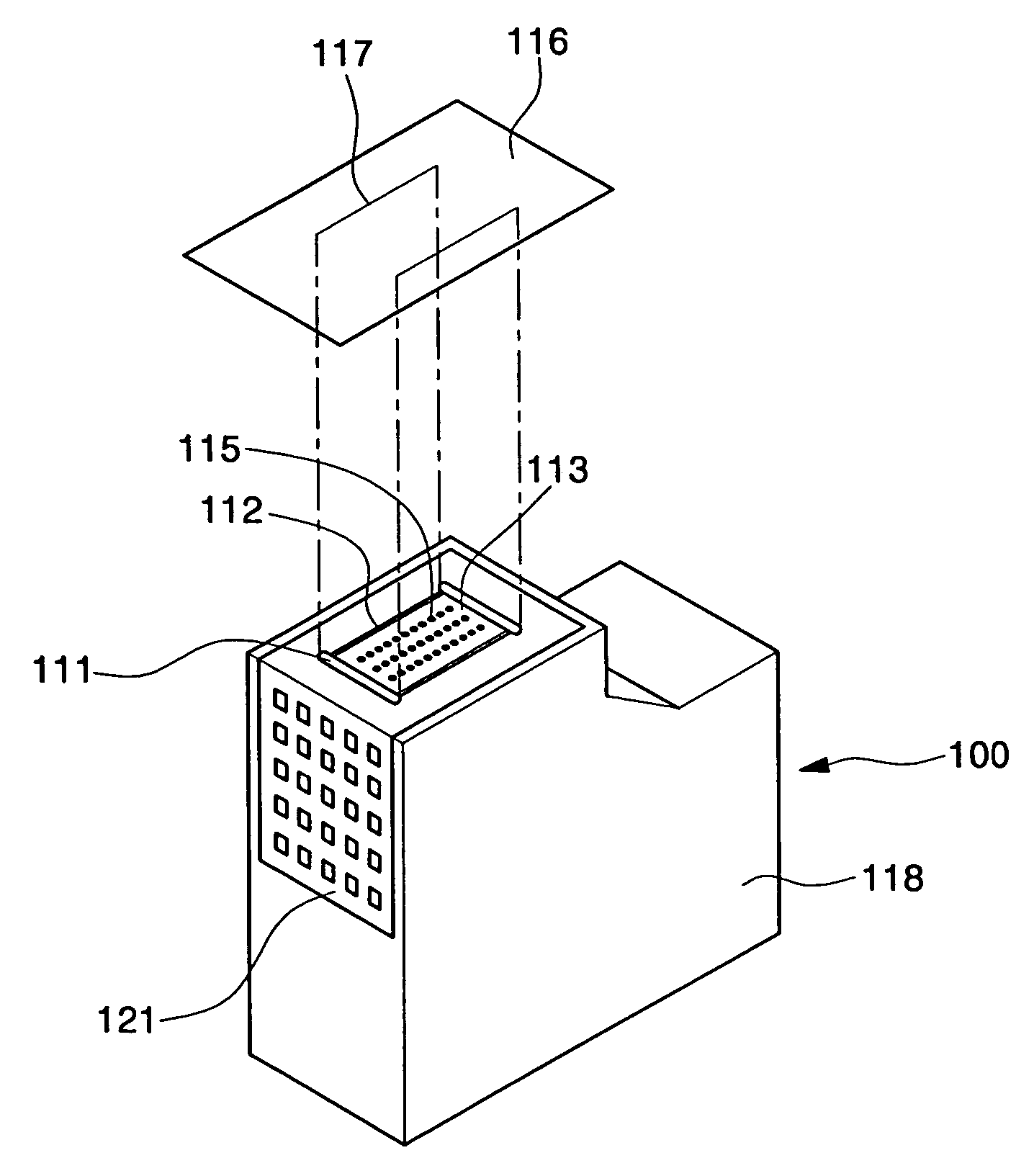

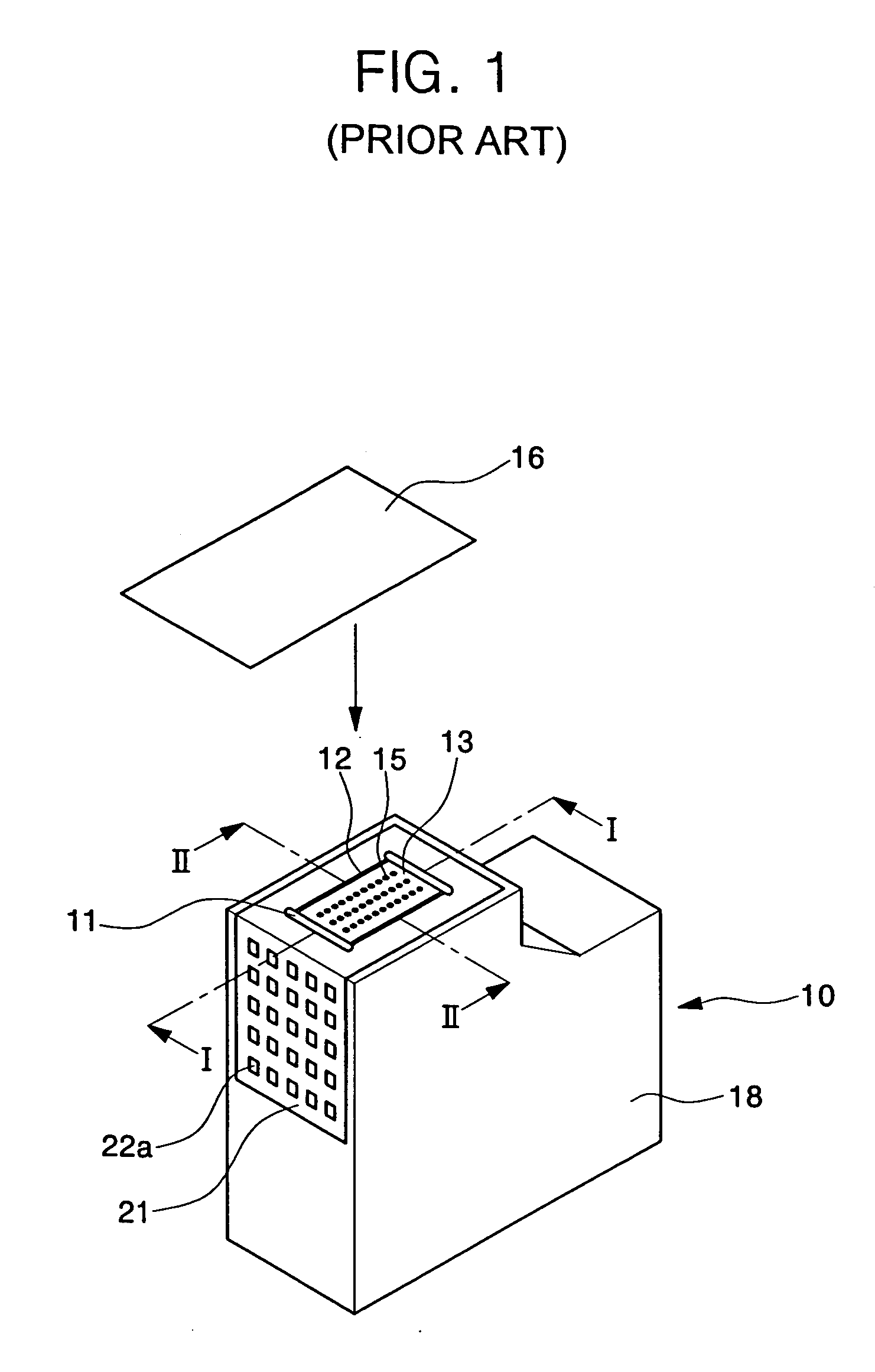

Communication Terminal and Communication Method Thereof

InactiveUS20070178874A1Shorten the timeOmit processVolume/mass flow measurementMultiple digital computer combinationsCommunications systemCommunication control

It is a communication terminal including an EVDO radio control portion 1172 adapted to perform a radio communication control operation according to an EVDO communication system. When a data link is released by issuing a power-supply-off instruction during an EVDO communication, the EVDO radio communication portion 1172 is not caused to release a communication session. When the release of a data link is not based on a power-supply-off instruction, the EVDO radio control portion 1172 is caused to release a communication session and to perform reestablishment of a communication session.

Owner:KYOCERA CORP

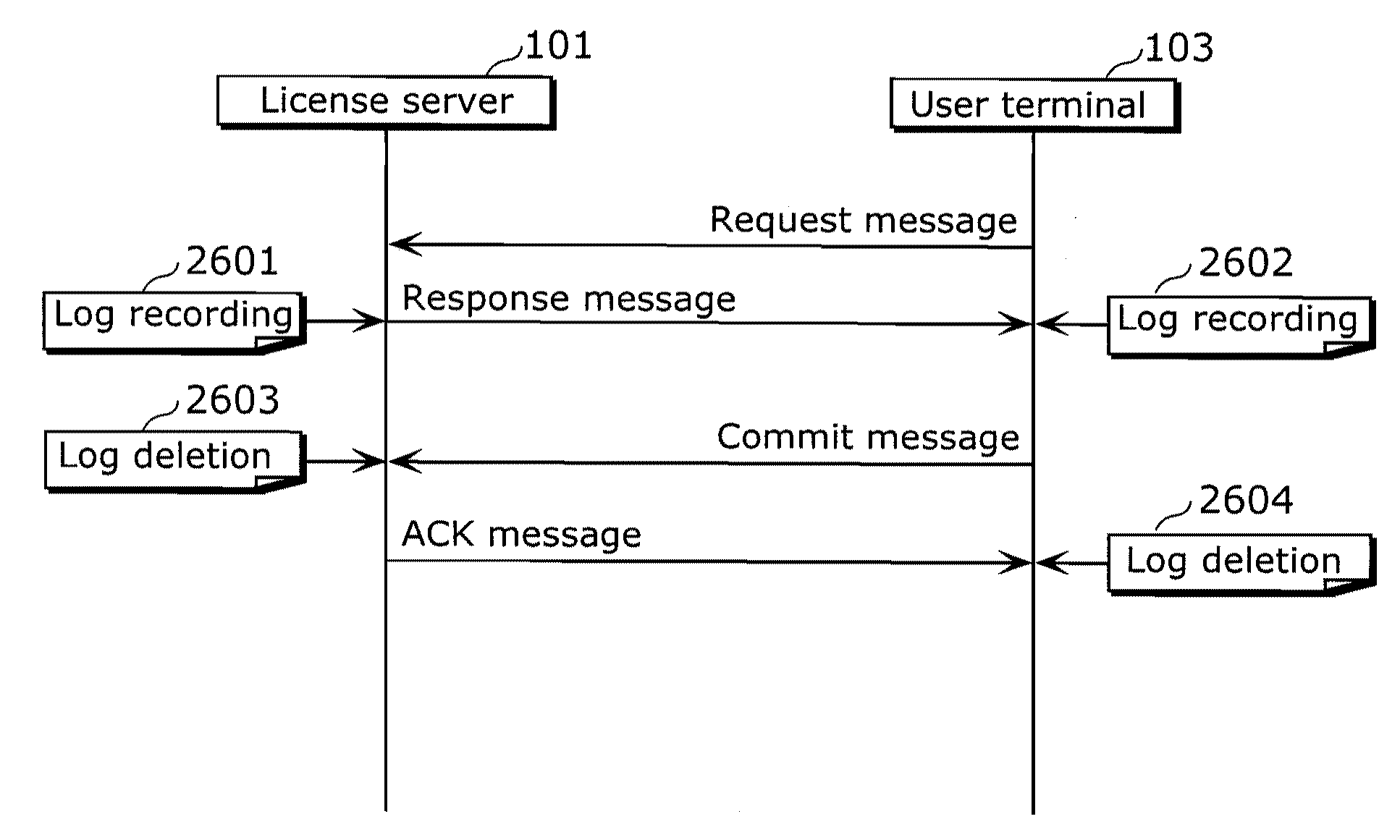

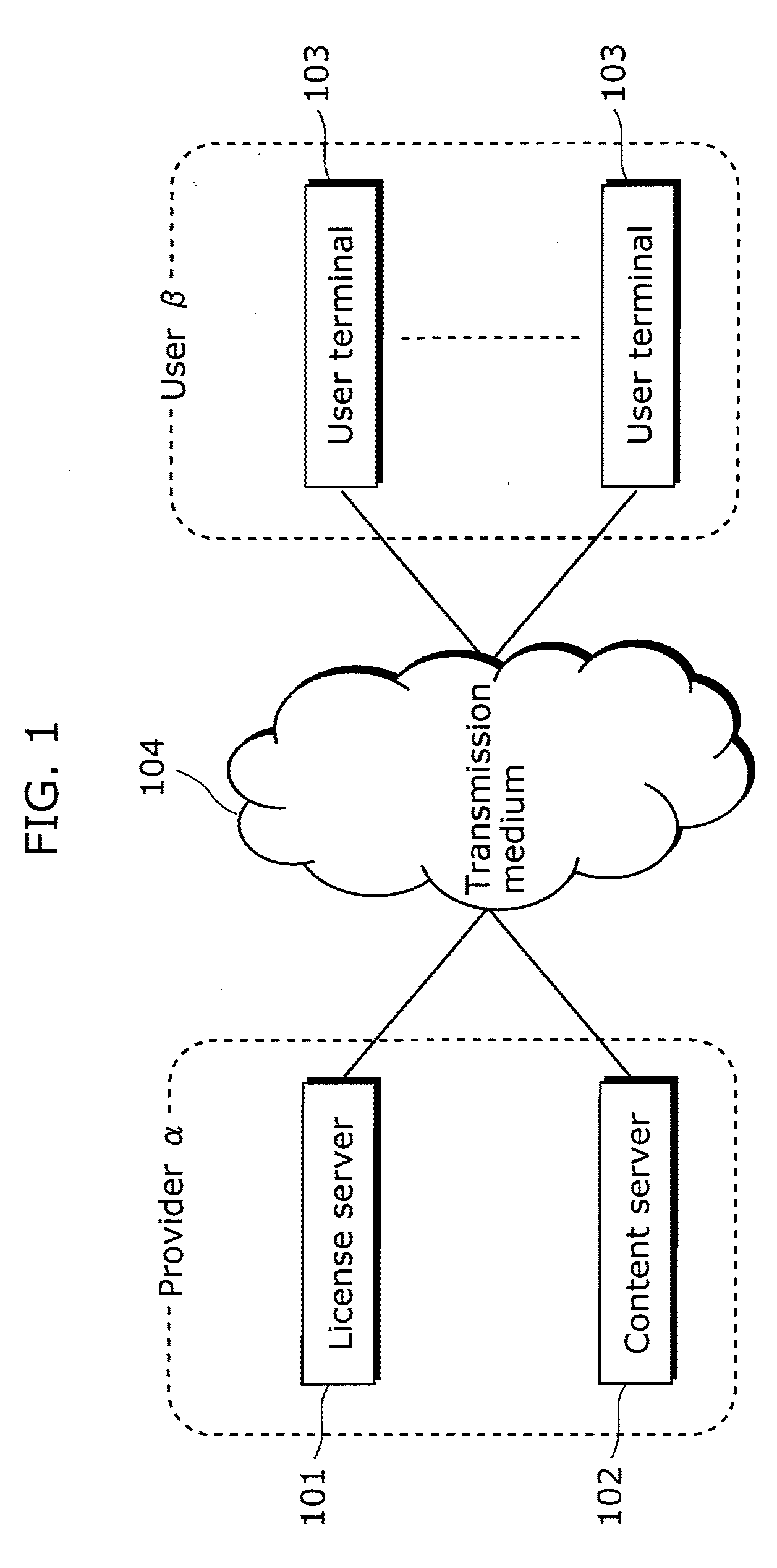

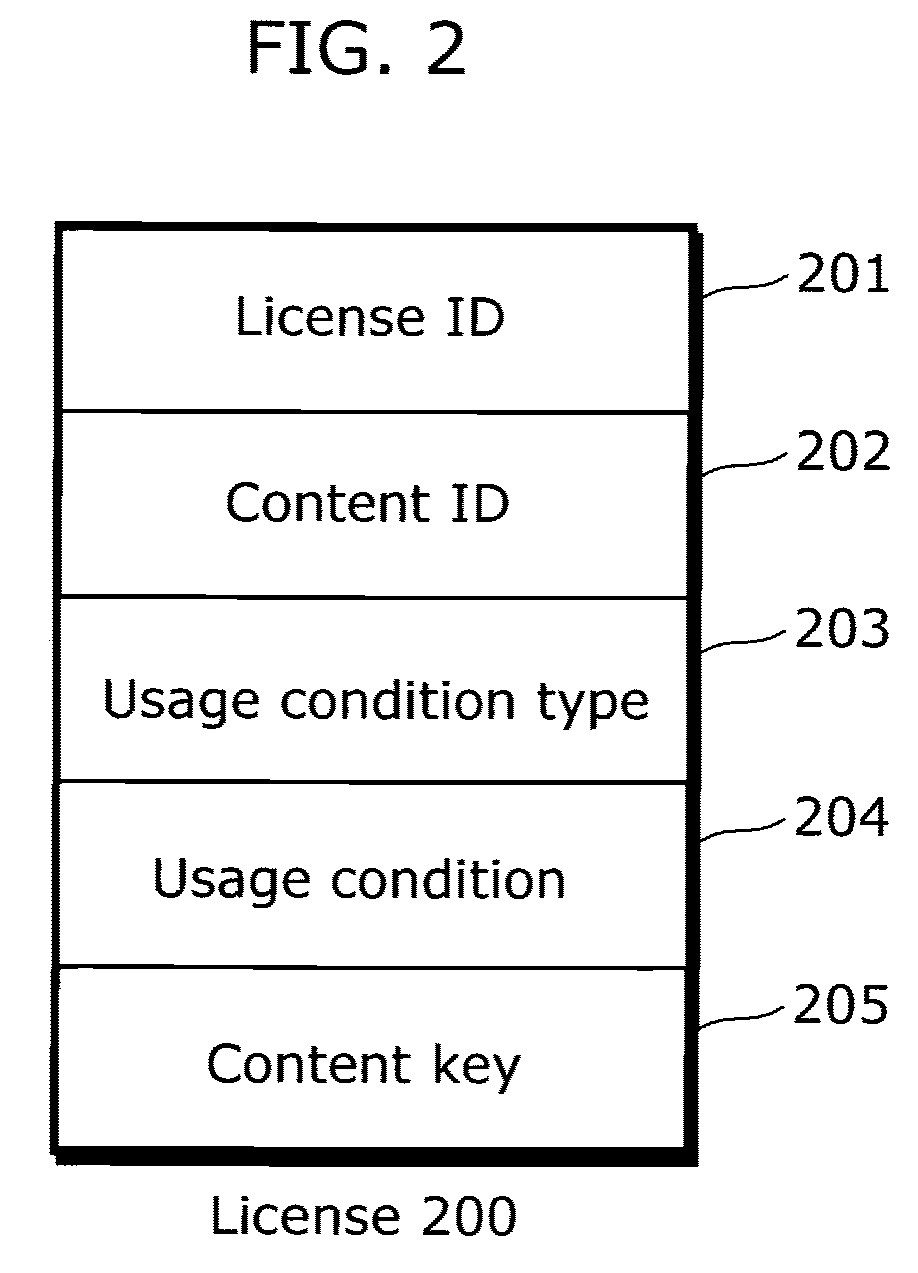

Terminal Apparatus, Server Apparatus, and Digital Content Distribution System

InactiveUS20090010439A1Reduced memory writing frequencyOmit processKey distribution for secure communicationDigital data processing detailsDistribution systemCountermeasure

To reduce a frequency of recording communication management information for communication disconnection countermeasure. A digital content distribution system includes a license server (101) that issues a license, and a user terminal (103) that controls use of content based on the issued license. The license server (101) judges, according to the license to be issued, whether or not the communication management information for the communication disconnection countermeasure needs to be recorded, and notifies the user terminal of a result of the judgment. This enables the user terminal (103) to reduce the frequency of recording the communication management information.

Owner:INTERTRUST TECH CORP

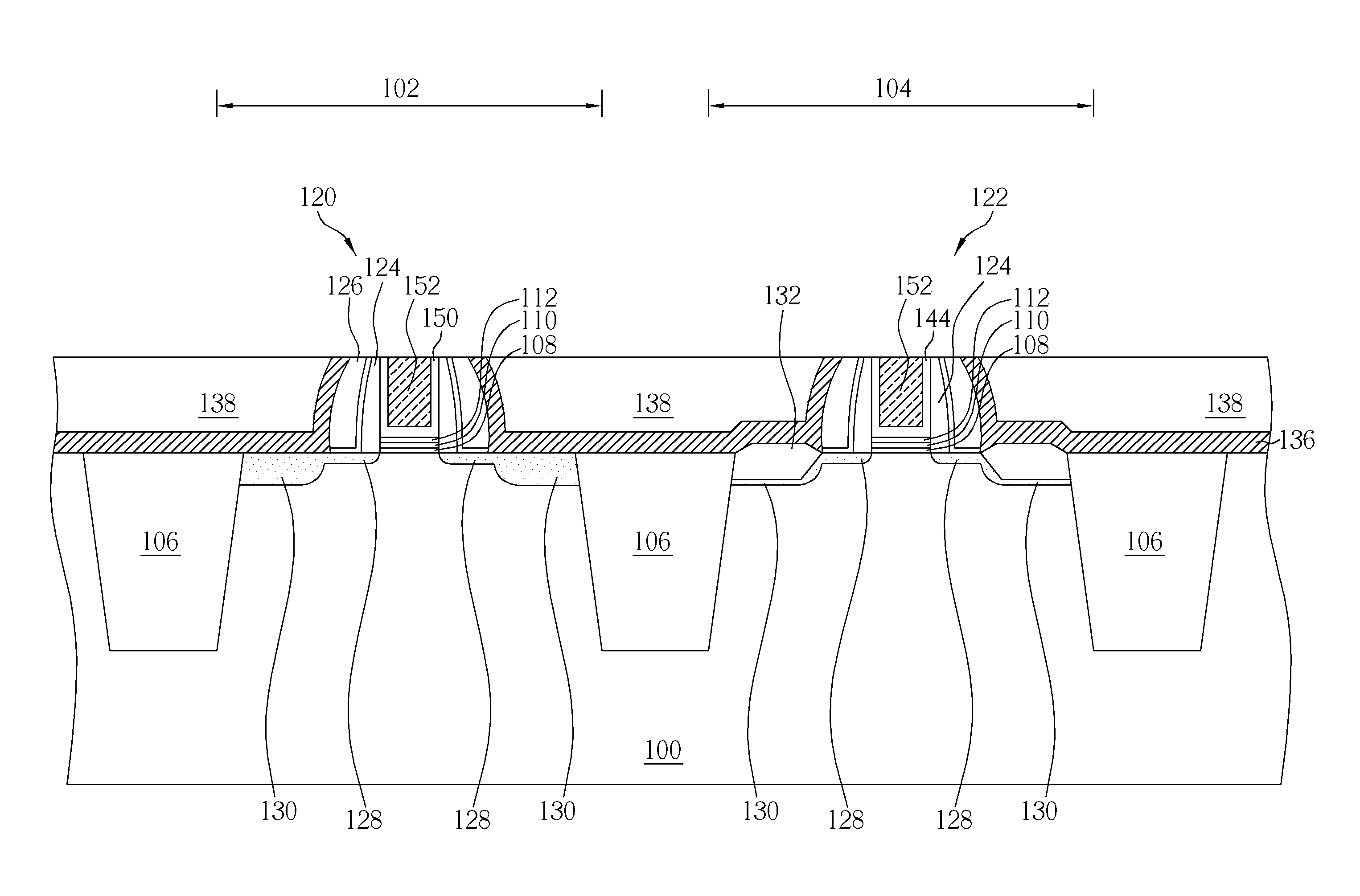

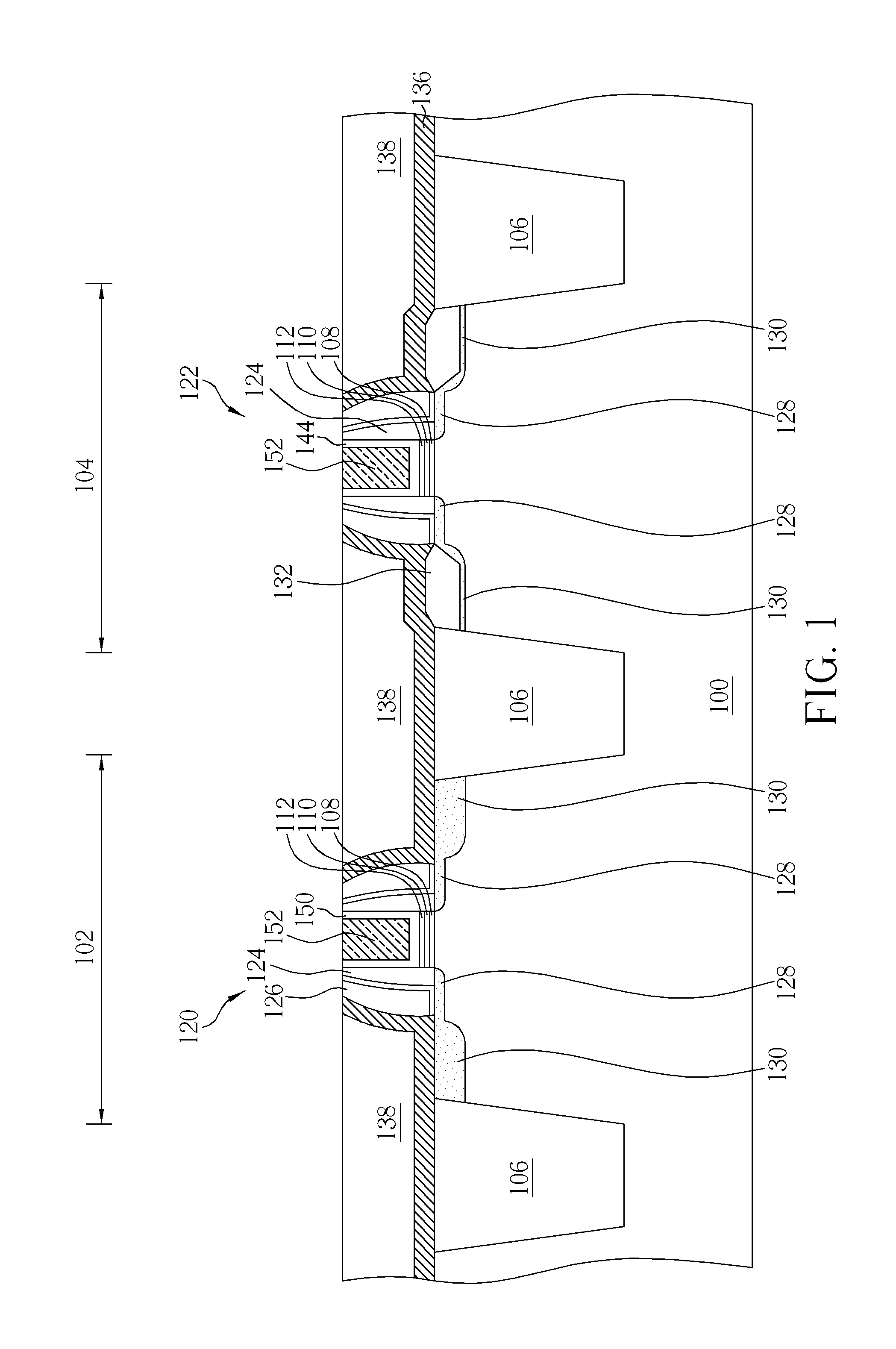

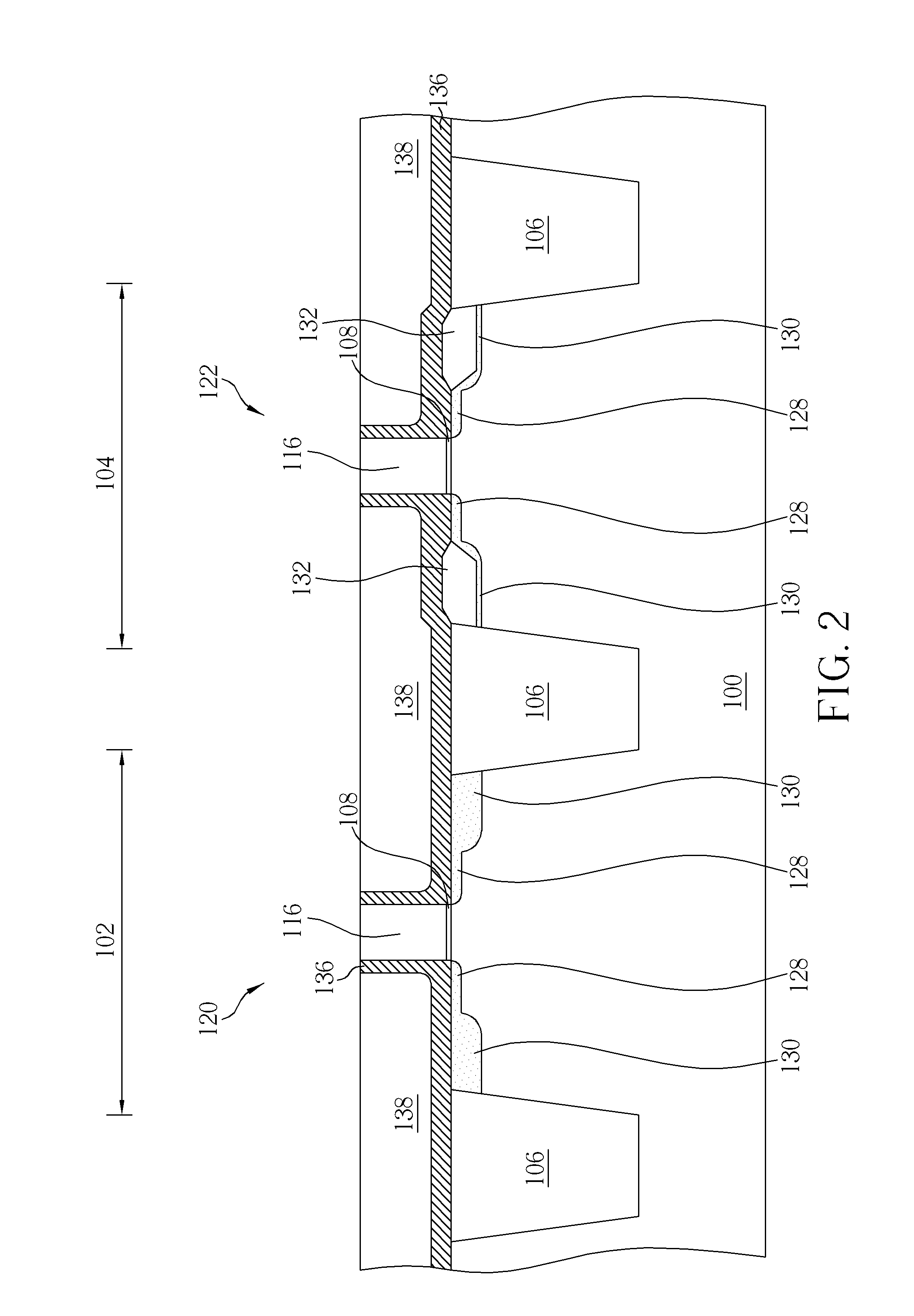

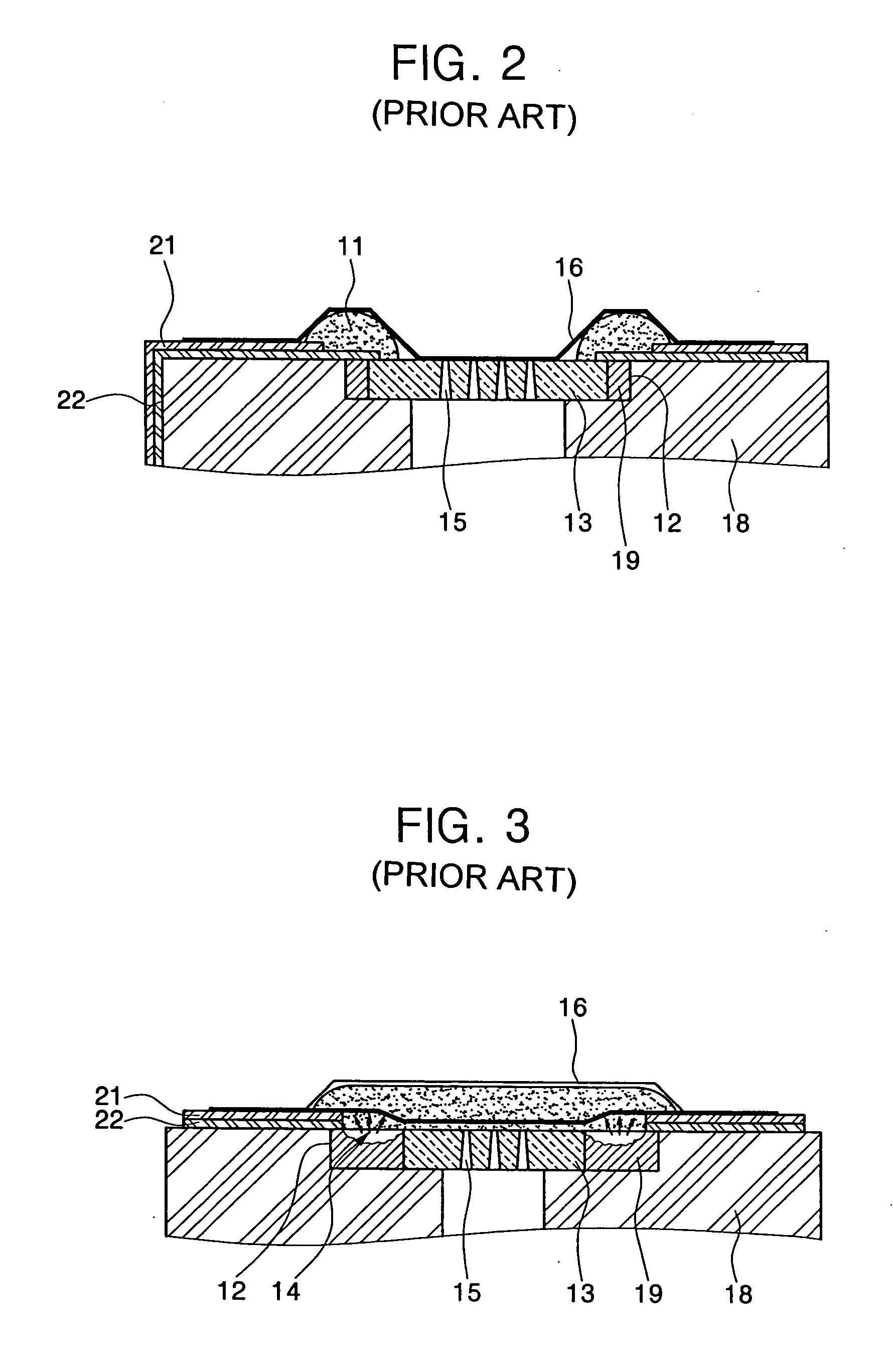

Structure of electrical contact and fabrication method thereof

ActiveUS20130193577A1Simplify the manufacturing processSave budgetSemiconductor/solid-state device detailsSolid-state devicesInsulation layerMetal silicide

A method of fabricating an electrical contact comprises the following steps. A substrate having at least a silicon region is provided. At least an insulation layer is formed on the substrate, wherein the insulation layer comprises at least a contact hole which exposes the silicon region. A metal layer is formed on sidewalls and bottom of the contact hole. An annealing process is performed to form a first metal silicide layer in the silicon region nearby the bottom of the contact hole. A conductive layer covering the metal layer and filling up the contact hole is then formed, wherein the first metal silicide layer is transformed into a second metal silicide layer when the conductive layer is formed.

Owner:UNITED MICROELECTRONICS CORP

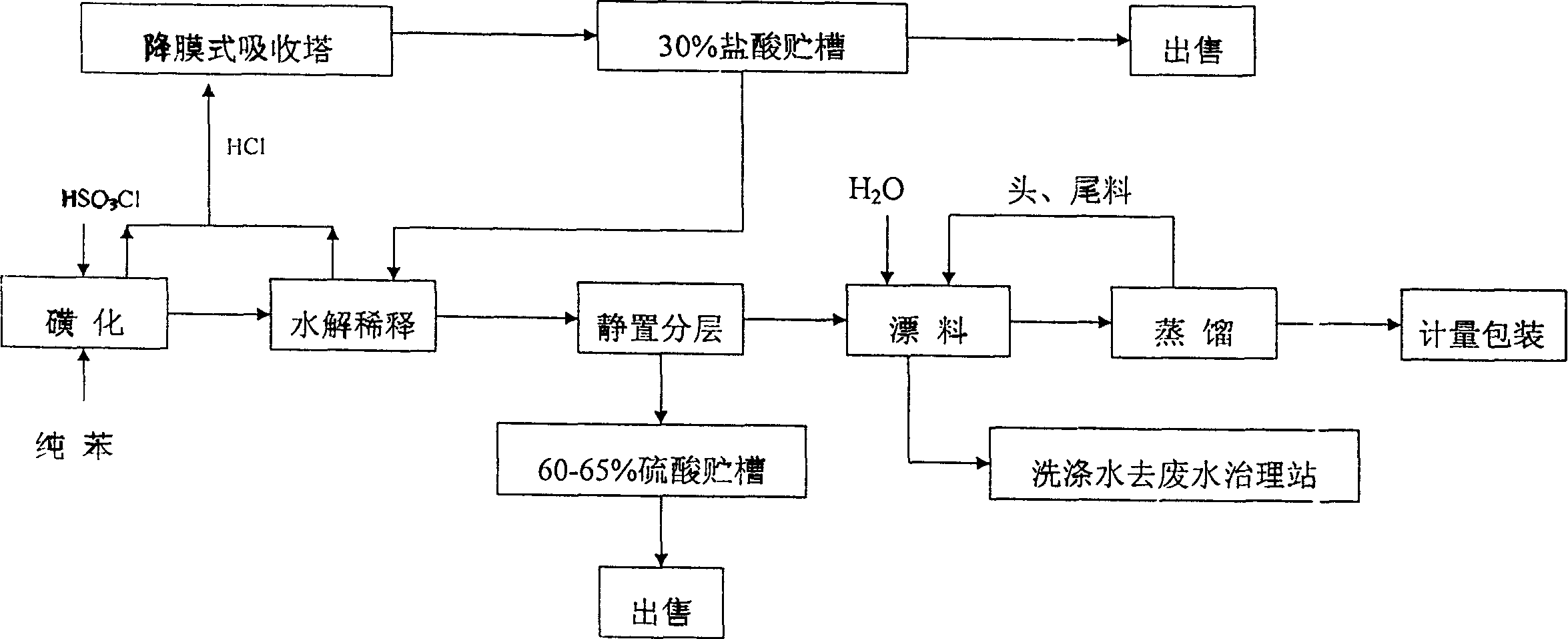

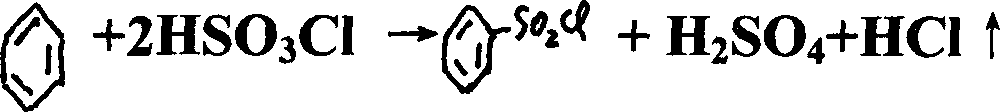

Production technology of phenyl sulfuryl chloride

The present invention provides a production method of benzenesulfonyl chloride. It is characterized by that said invention uses benzene and chlorosulfonic acid as raw material, and makes them undergo the processes of sulfonation reaction, hydrolytic dilution, standing still and layer separation and reduced pressure distillation so as to obtain the invented product. Said invention also provides the concrete steps of every process and its concrete requirements.

Owner:江苏康祥实业集团有限公司

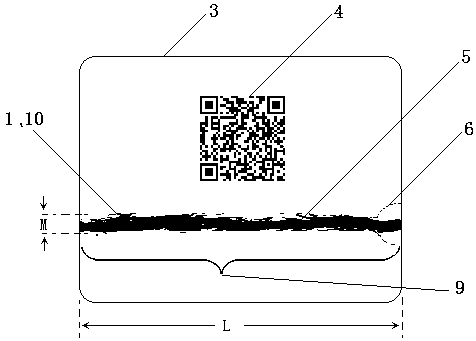

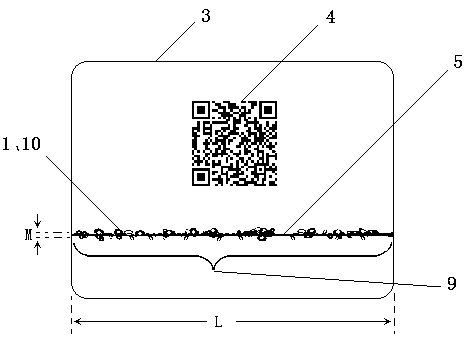

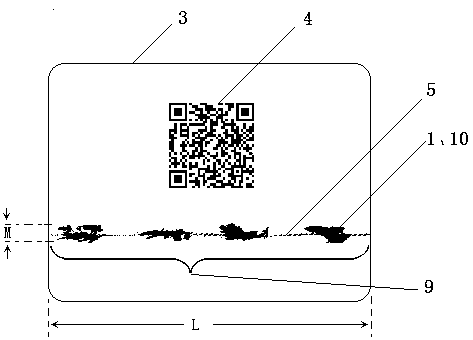

Hand-tear texture anti-counterfeiting method and its product and material

ActiveCN109215493BOvercoming the disadvantages of distinguishing true and false texturesAvoid circulationStampsRecord carriers used with machinesPattern recognitionFiber

A hand-tear texture anti-counterfeit method and a product and a material thereof are provided. Fancy yarn is embedded in printed matters and substrates, fancy yarn and its individual element are squeezed and shaped into a flat texture string. Personality information of flat texture strings is collected and stored as texture information files in the database of anti-counterfeit checking system. Themethod overcomes the drawbacks of needle pick fiber (texture), achieves the purpose of manual texture detection, can facilitate the public to discriminate the true and false texture by hand, avoids the trouble of anti-counterfeit application of needle pick texture, simplifies the production of texture paper, and avoids the residual fibers from polluting the production workshop environment of ordinary white paper.

Owner:HAINAN PAIPAIKAN INFORMATION TECH CO LTD

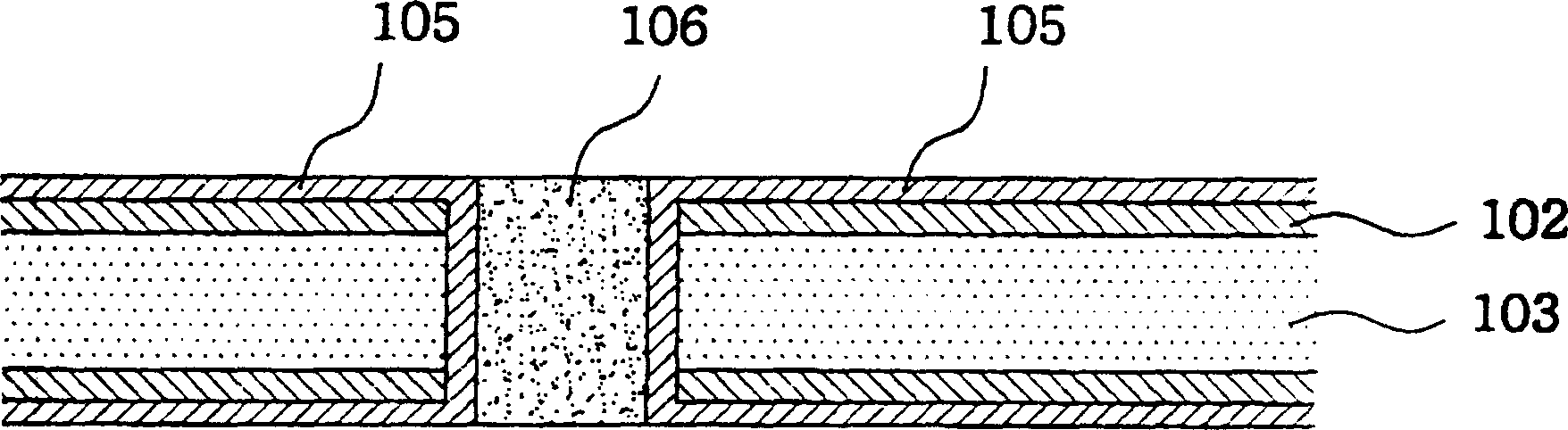

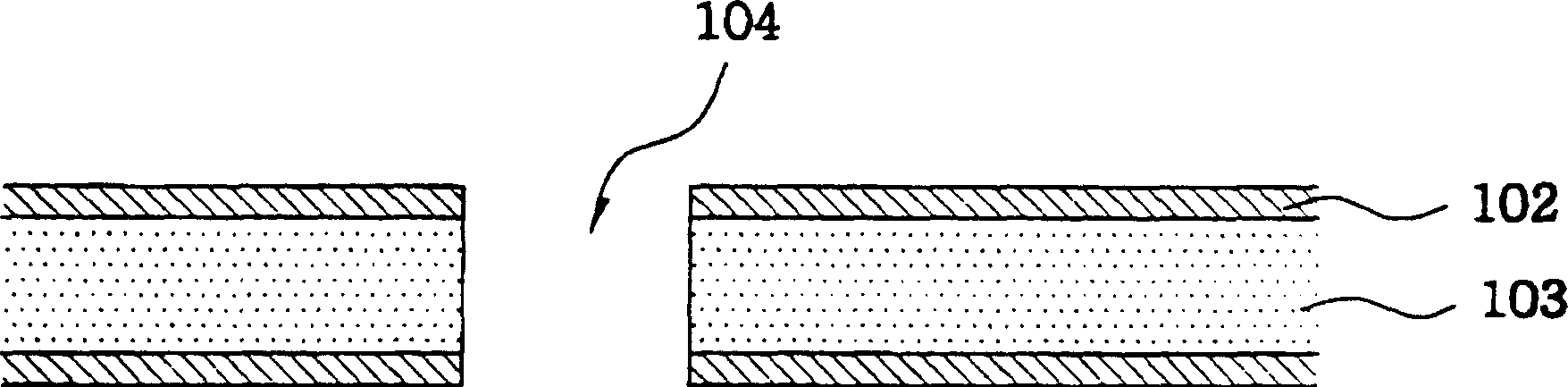

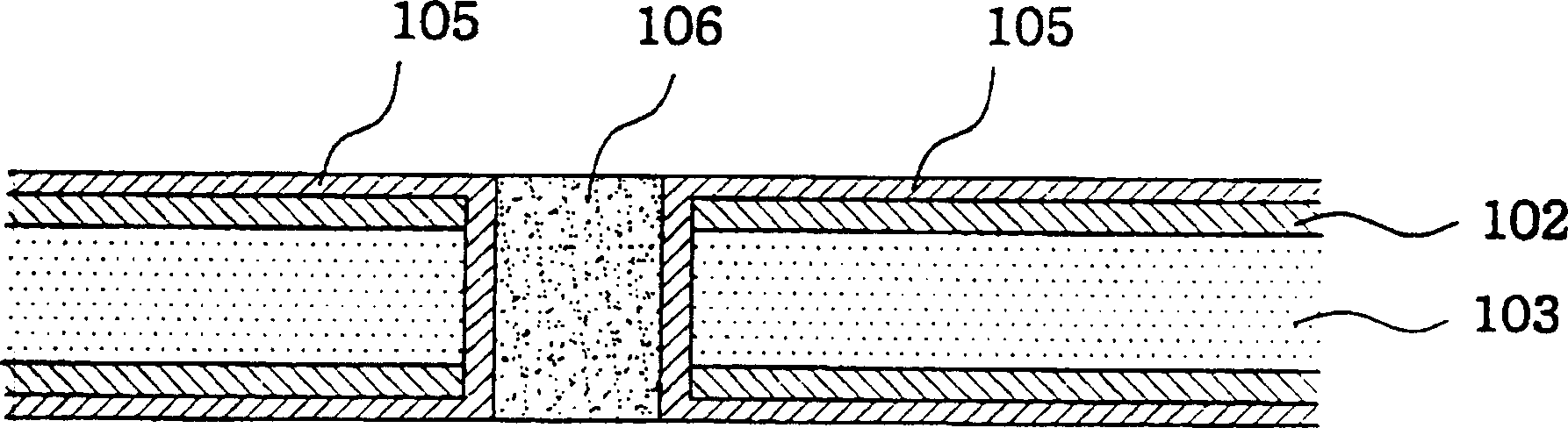

Manufacturing method of multilayer printed circuit board

InactiveCN1535106AShorten production timeMinimize Defective RatioPrinted circuit aspectsMultilayer circuit manufactureCopper platingPrinted circuit board

Disclosed is a method of fabricating a multi-layered PCB, wherein a plurality of circuit layers on which circuit patterns are constructed and insulating layers which are alternately positioned between the circuit layers to insulate the circuit layers from each other are severally fabricated according to different processes, and then layered with each other at once. The present invention provides a method of fabricating a multi-layered PCB, in which a copper clad laminate is drilled to create via holes therethrough in such a way that a diameter of each via hole is relatively small, and then plated with copper to plug the via holes with the copper, thereby omitting the plugging process of the via holes using paste. The insulating layers are formed in such a way that semi-hardened (b-stage) thermosetting resin layers are layered on both sides of a completely hardened (c-stage) thermosetting resin layer, thereby improving impedance balance of the insulating layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Lithium ion battery assembly method and lithium ion battery

InactiveCN110690506AImprove securityImprove cycle performanceFinal product manufactureElectrolyte accumulators manufacturePhysical chemistryBattery cell

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery assembly method which comprises the following steps: baking a positive plate, anegative plate and a diaphragm to obtain a baked positive plate, a baked negative plate and a baked diaphragm; laminating and / or winding the baked positive plate, the baked negative plate and the baked diaphragm; welding a tab to obtain a bare battery cell; soaking the bare battery cell in an electrolyte to obtain a battery cell soaked in the electrolyte; putting the battery cell soaked in the electrolyte into a shell, and performing packaging; and forming and re-packaging the packaged battery cell to obtain the lithium ion battery. According to the method, the bare battery cell is directly soaked in the electrolyte, so that the battery pole piece and the diaphragm are fully soaked by the electrolyte; then the liquid supplementing procedure is added according to the designed weight, so that the electrical consistency among battery batches can be ensured; and the standing time of a battery after liquid injection can be shortened, and the production efficiency is improved. The lithium ion battery prepared by the method disclosed by the invention is high in safety performance and good in cycle performance.

Owner:汇洋世纪新能源科技有限公司

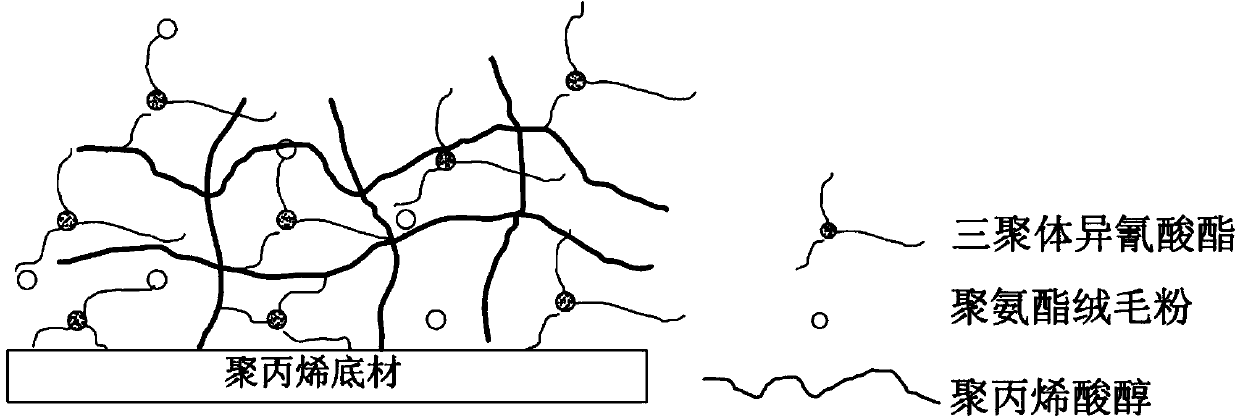

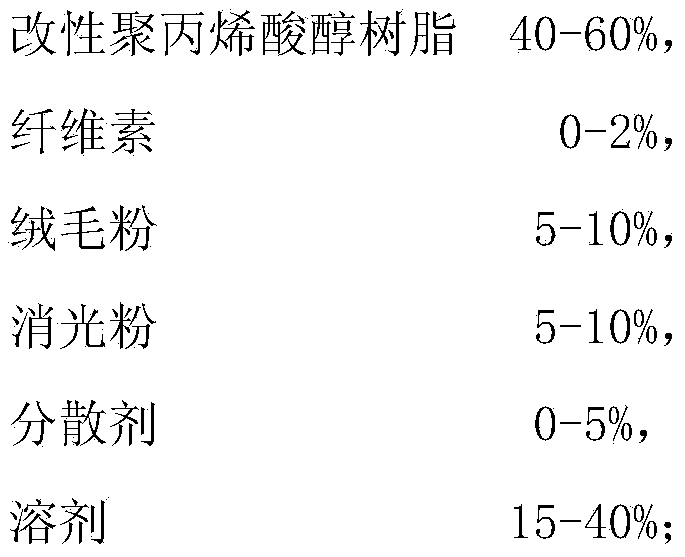

Mist surface hand feeling scratch-resistant coating paint and preparation method thereof

The invention discloses a mist surface hand feeling scratch-resistant coating paint and a preparation method thereof. The mist surface hand feeling scratch-resistant coating paint is composed of a component A and a component B, wherein the part ratio of the component A to the component B is equal to 100: (1-5); the component A comprises the following components in mass percentage: 40-60 percent of modified poly-acrylic acid alcohol resin, 0-2 percent of cellulose, 5-10 percent of tomentum powder, 5-10 percent of extinction powder, 0-5 percent of dispersing agent and 15-40 percent of solvent; the component B is a hardening agent. Due to the adoption of the manner, the mist surface hand feeling scratch-resistant coating paint can meet scratch-resistant property, improves the coating texture and the decoration effect, has a special hand feeling and meets different decoration requirements.

Owner:昆山大世界油墨涂料有限公司

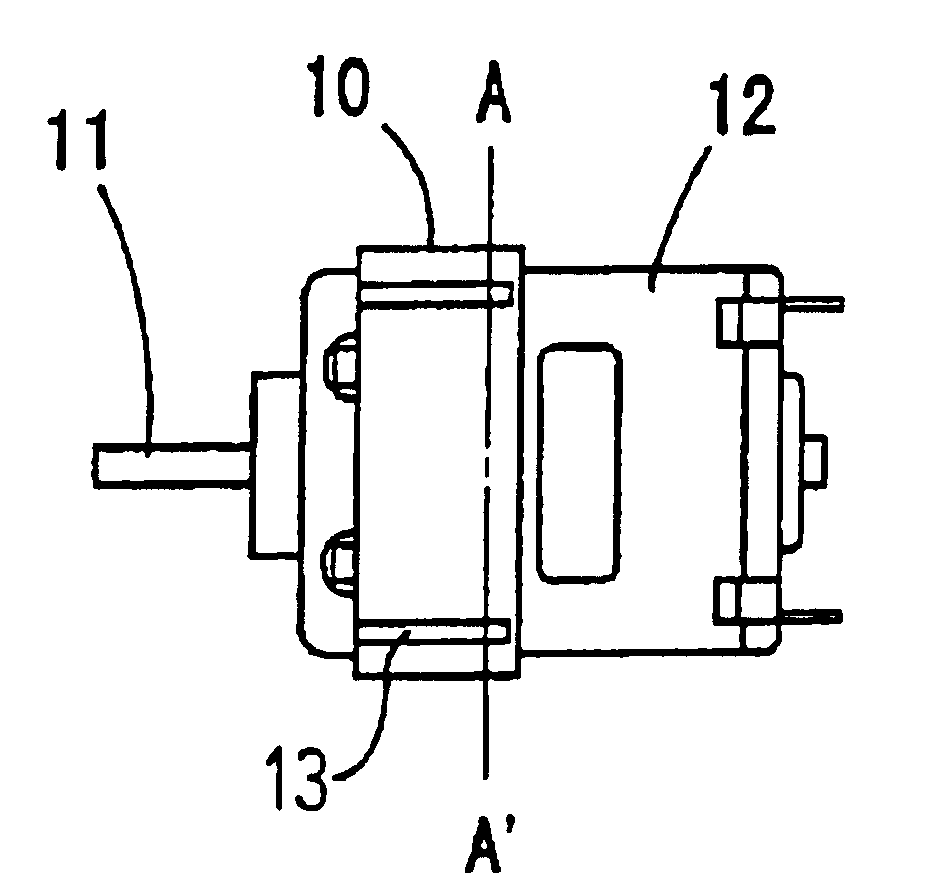

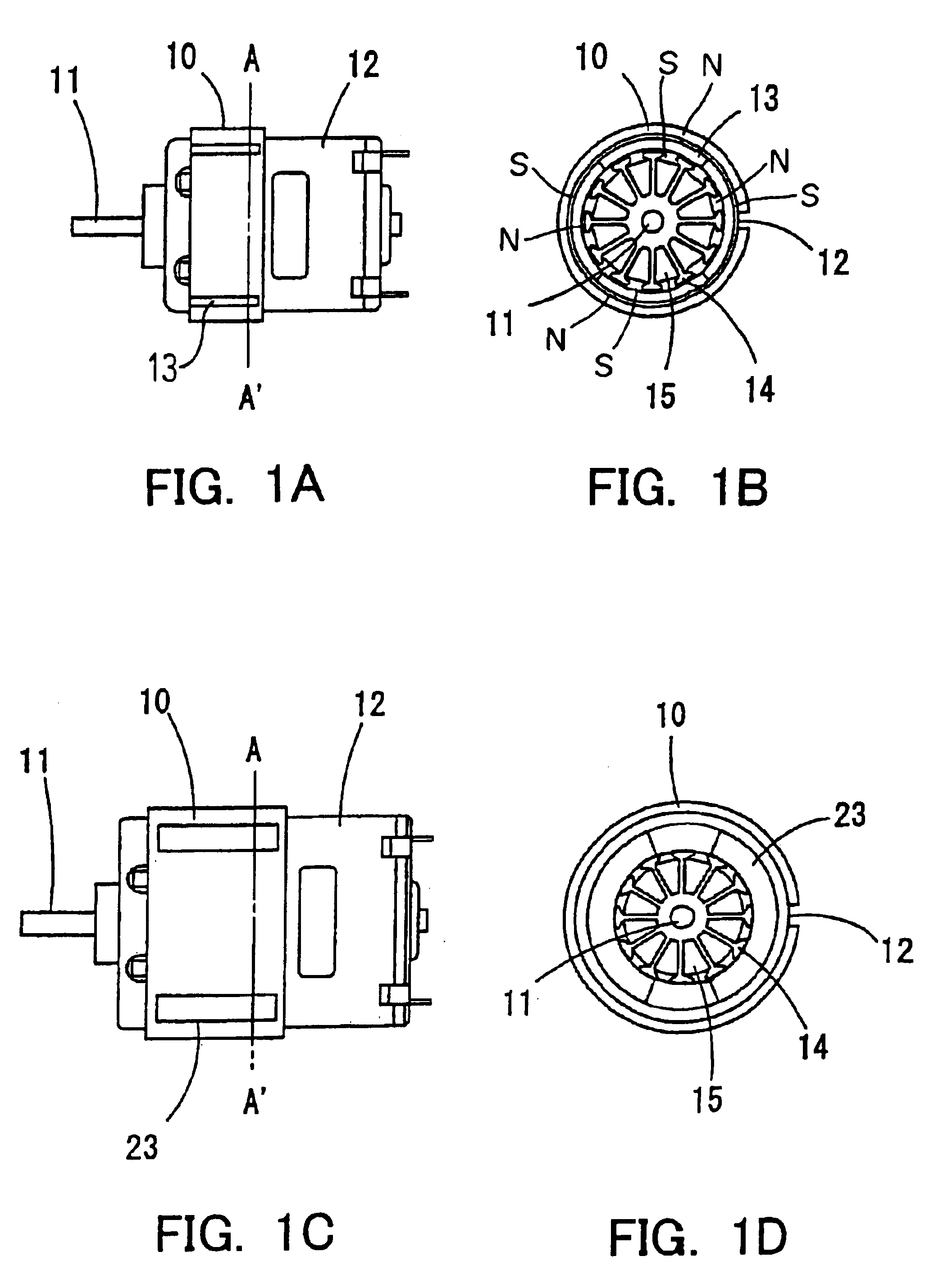

DC brush motor and permanent magnet used therein

InactiveUS6917132B2Lower the volumeSmall sizePermanent magnetsMagnetic circuit stationary partsMiniaturizationControl theory

The challenge to be solved by the present invention is the miniaturization of a 1-300 W class of motor. This can be achieved by using a hollow-cylinder shaped anisotropic bonded magnet magnetized in a 4-pole configuration. The anisotropic bonded magnet has a maximum energy product approximately 4 times greater than the conventional sintered ferrite magnets. The use of a 4-pole configuration shortens the magnetic path length of the individual magnetic circuits and the magnetic force contributing to the torque is increased. When the torque is kept the same as in the conventional motor, the length of the electromagnetic rotor core and the axial magnet length can be reduced. In this fashion, 1-300 W class motors can be reduced in size.

Owner:AICHI STEEL

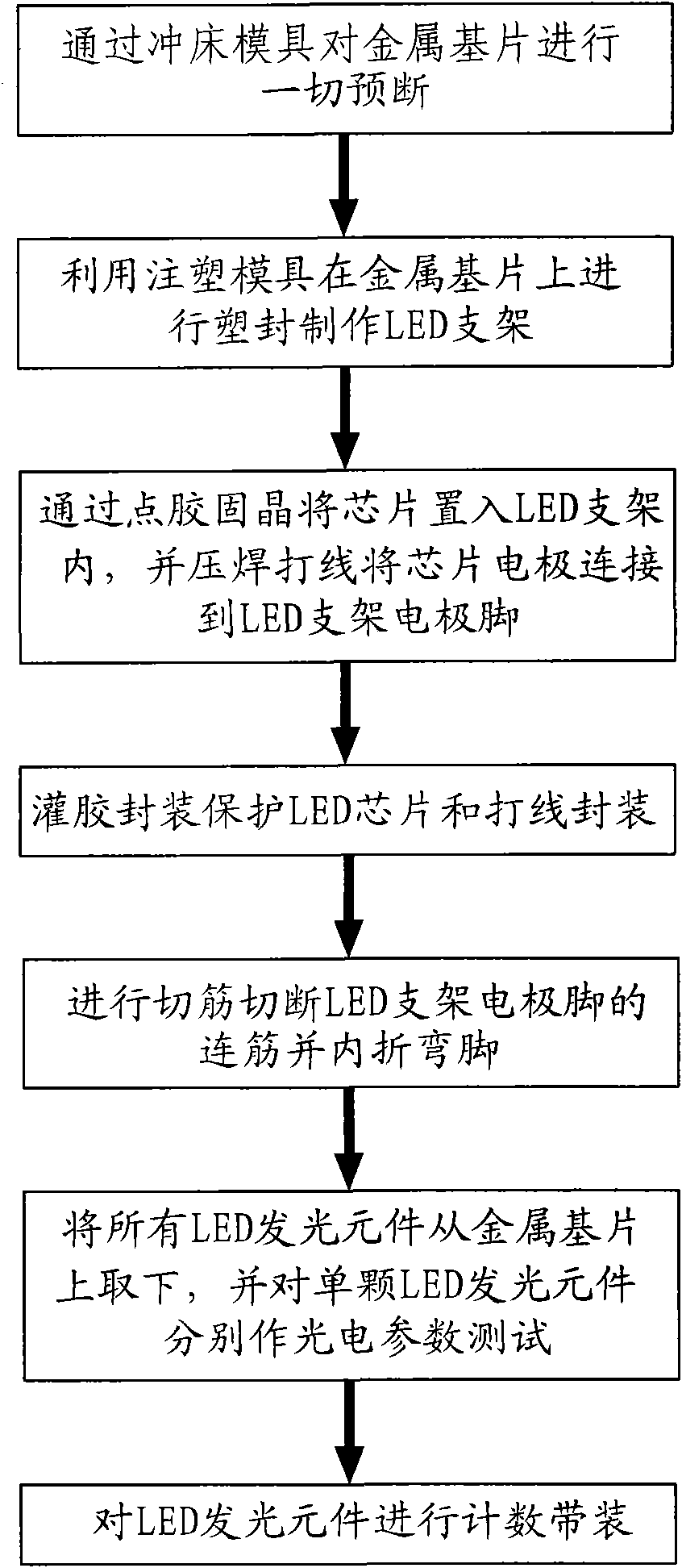

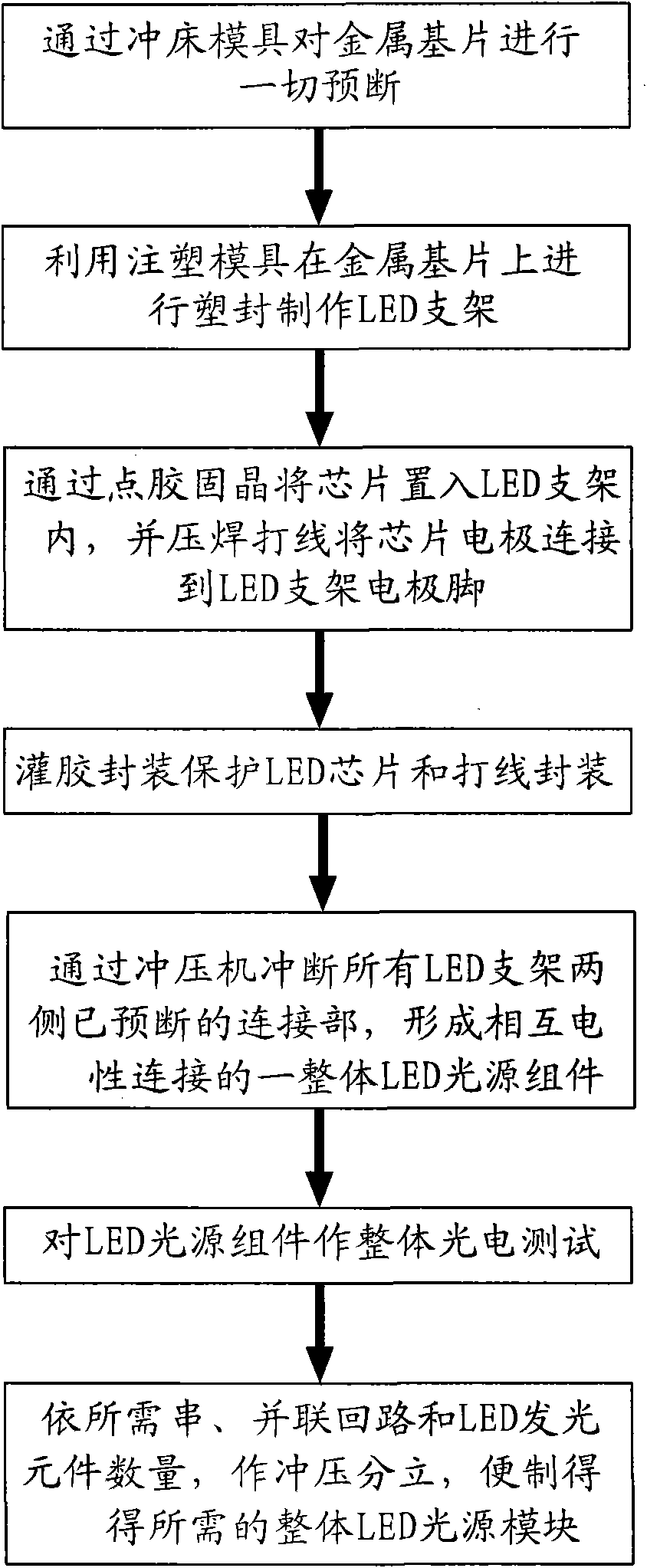

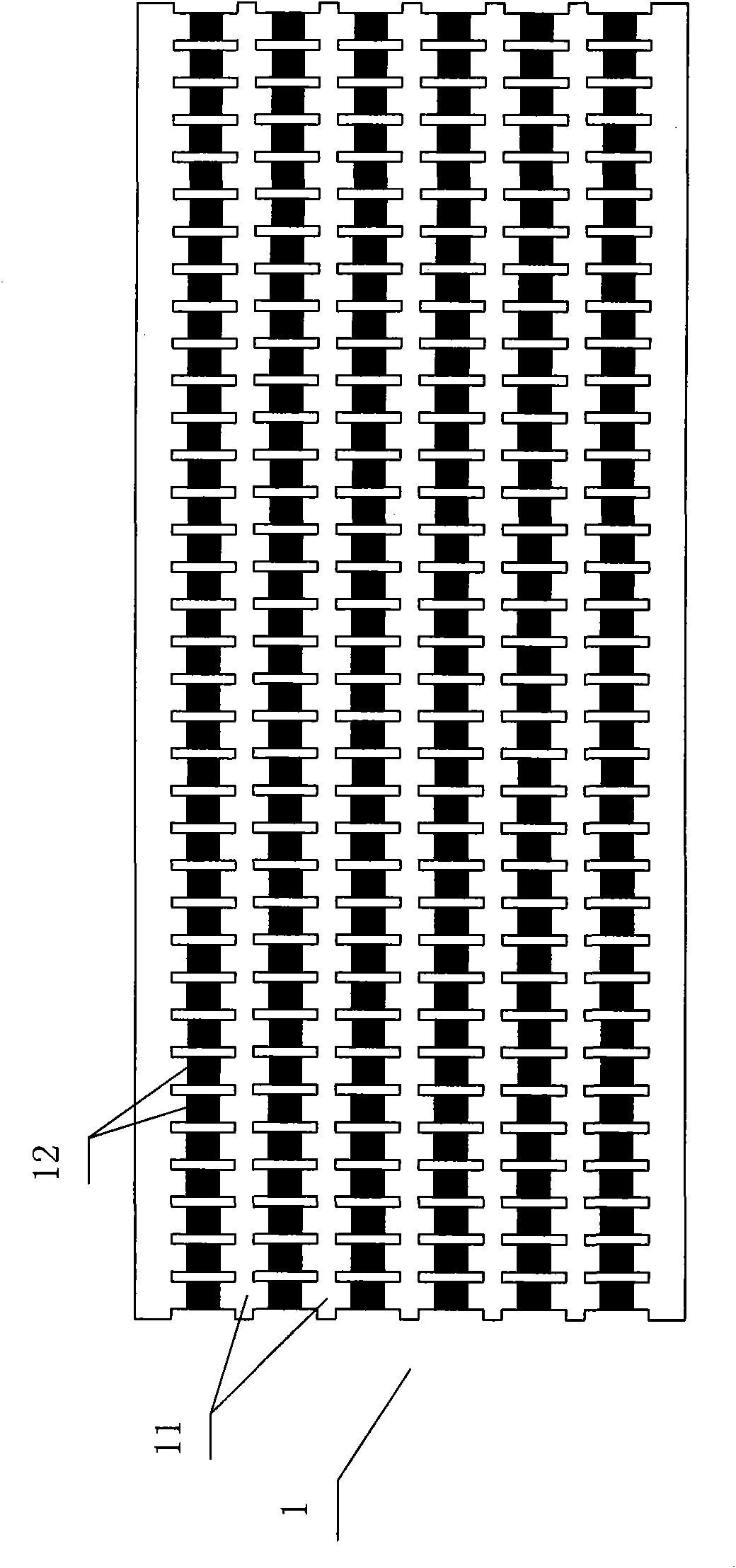

Manufacturing method for integral LED light source module

InactiveCN101793352AEasy to carrySimple processPoint-like light sourceLighting support devicesComputer moduleEngineering

The invention relates to a manufacturing method for an integral LED light source module. The manufacturing method comprises the following technological steps that: a metal substrate is precut; an LED support is manufactured on the metal substrate through plastic encapsulation; chips are placed in the LED support one by one through adhesive dispensing and die bonding, and the electrodes of the chips are connected with the electrode pin of the LED support through pressure welding and routing; adhesive is injected to encapsulate and protect the LED chips and the routing; precut connecting parts on the two sides of the LED support are punched to be cut to form an integral LED light source assembly; an integral test is conducted to all LED light emitting elements; and finally punching discretion is conducted to obtain the required integral LED light source module according to the required series and parallel circuits and the number of the LED light emitting elements. The invention properly uses the metal substrate as the base material, uses high-reflectivity plastics to be combined with the metal substrate for series and parallel circuit connection to manufacturing the integral LED light source module, omits the manufacturing process of pin bending and semi-discretion and the tape armoring and the manufacturing process of the existing SMT on the basis of the existing SMD manufacturing process, and greatly shortens the manufacturing process of the elements.

Owner:林柏廷

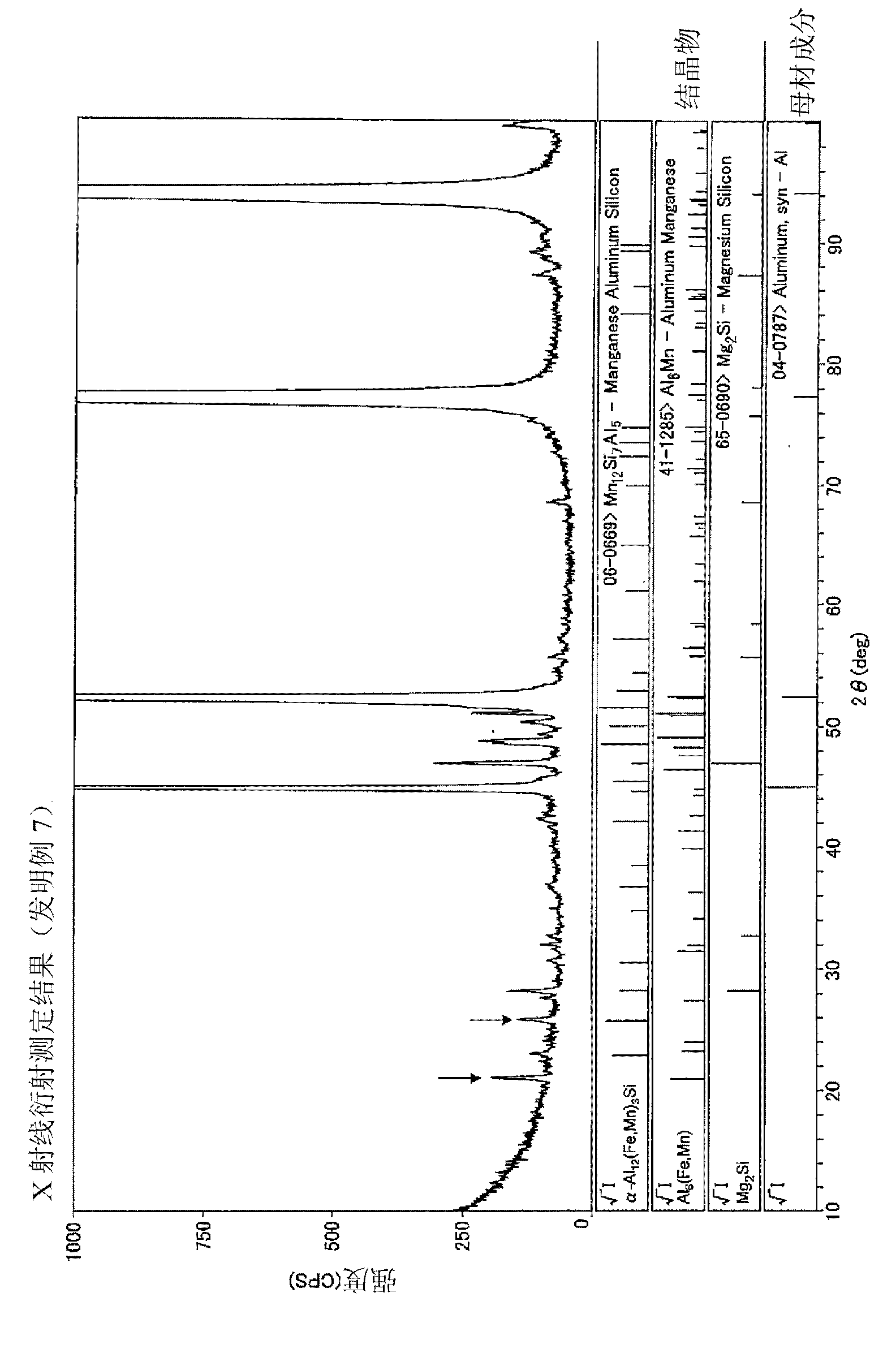

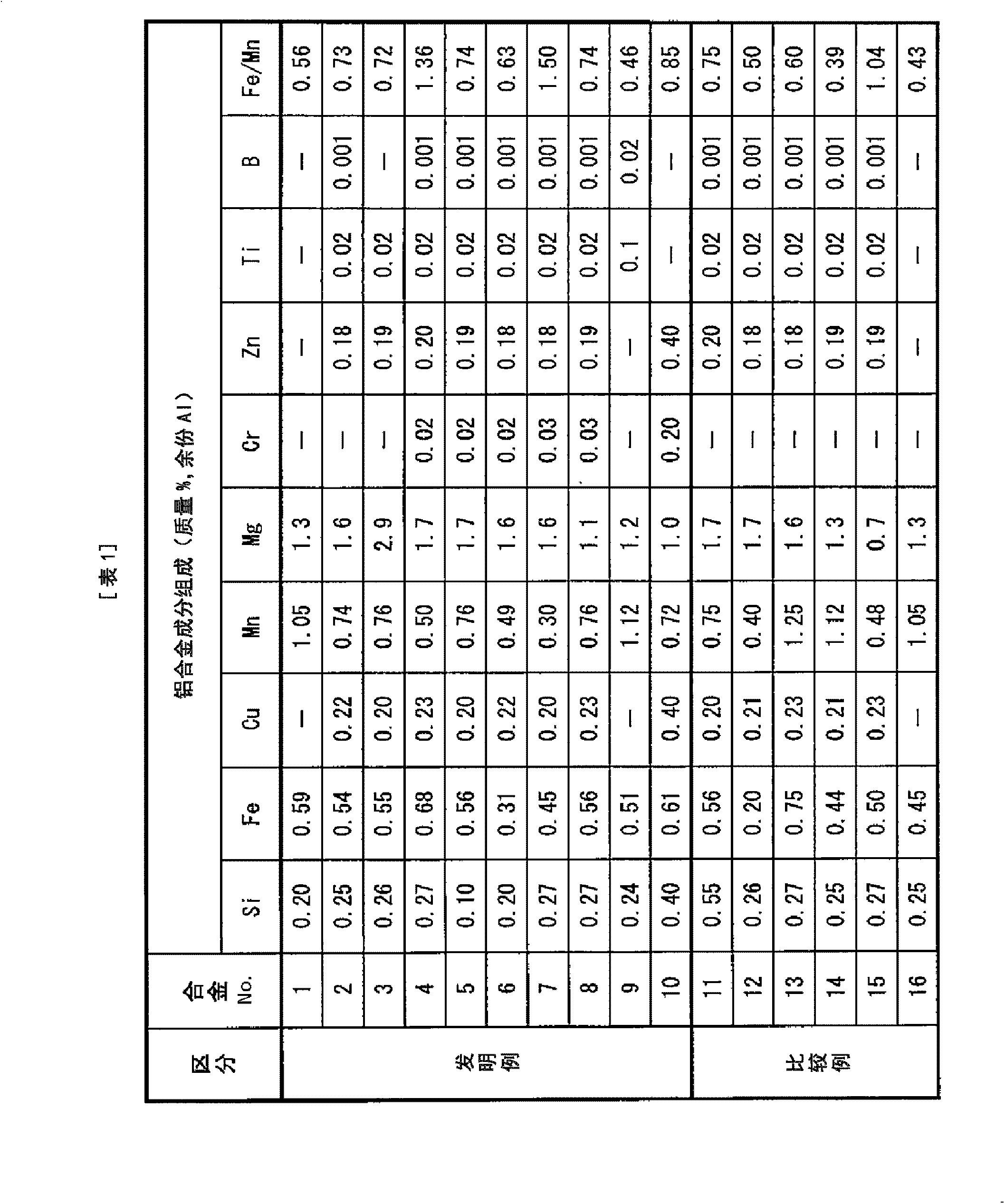

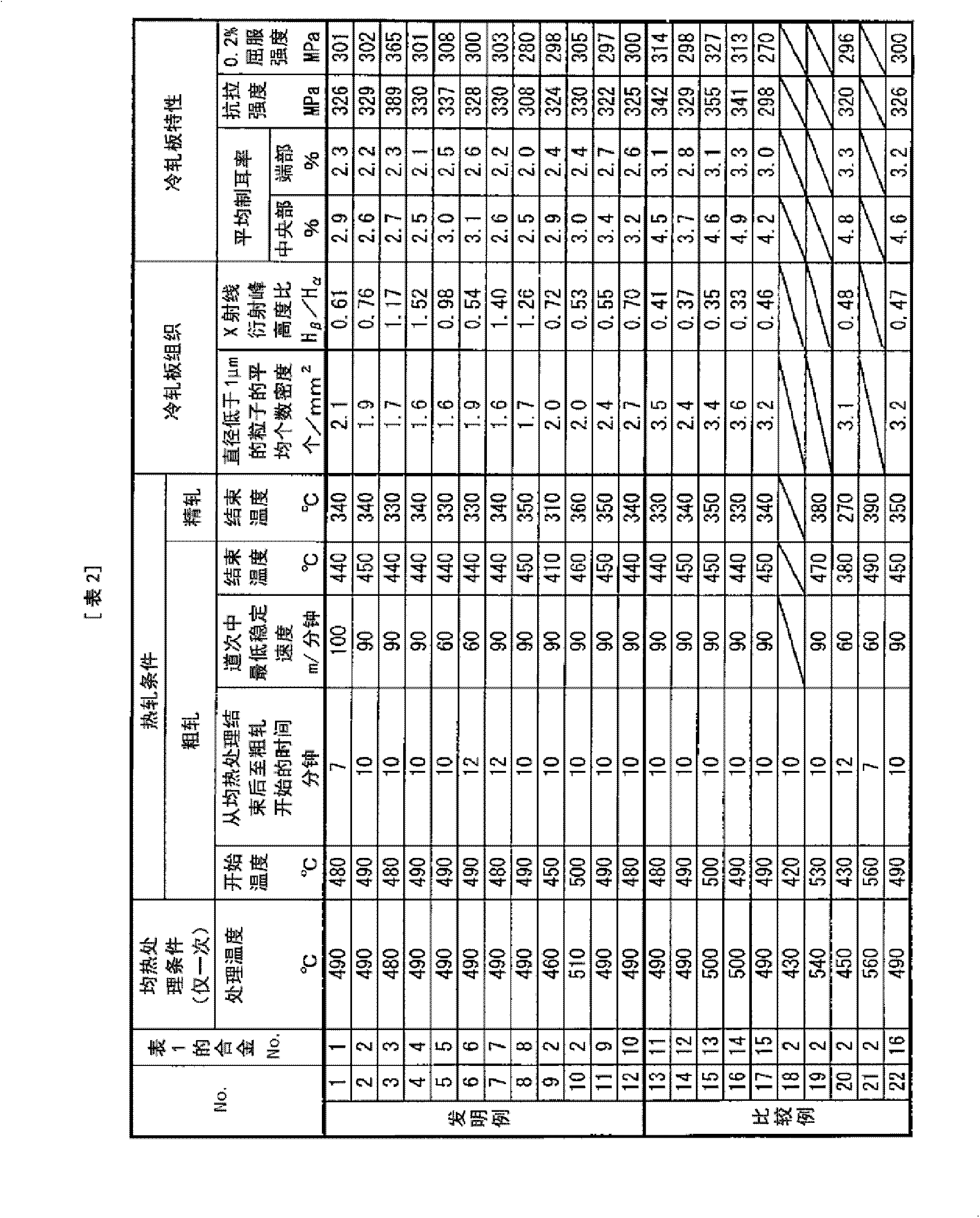

Cold-rolled aluminum alloy sheet for bottle can

The present invention reduces the cost of production of a cold-rolled aluminum alloy sheet to be used as a material for bottle cans and reduces the width-direction unevenness of earing. This cold-rolled aluminum alloy sheet for bottle cans has a specific composition and has a structure which contains a small amount of dispersed particles having a center-of-gravity diameter less than 1 [mu]m, which represent an a phase, and in which the ratio of the amount of the ss phase that is an Al6(Fe,Mn)-based intermetallic compound to the amount of the a phase that is an Al-Fe-Mn-Si-based intermetallic compound is 0.50 or more in terms of the ratio of the maximum height Hss of the X-ray diffraction peaks and the maximum height Ha of the X-ray diffraction peaks, Hbeta / Halpha. Thus, the hot-rolled sheet in the invention has an even degree of recrystallization in the sheet-width direction, and the cold-rolled aluminum alloy sheet has low width-direction unevenness of earing.

Owner:KOBE STEEL LTD

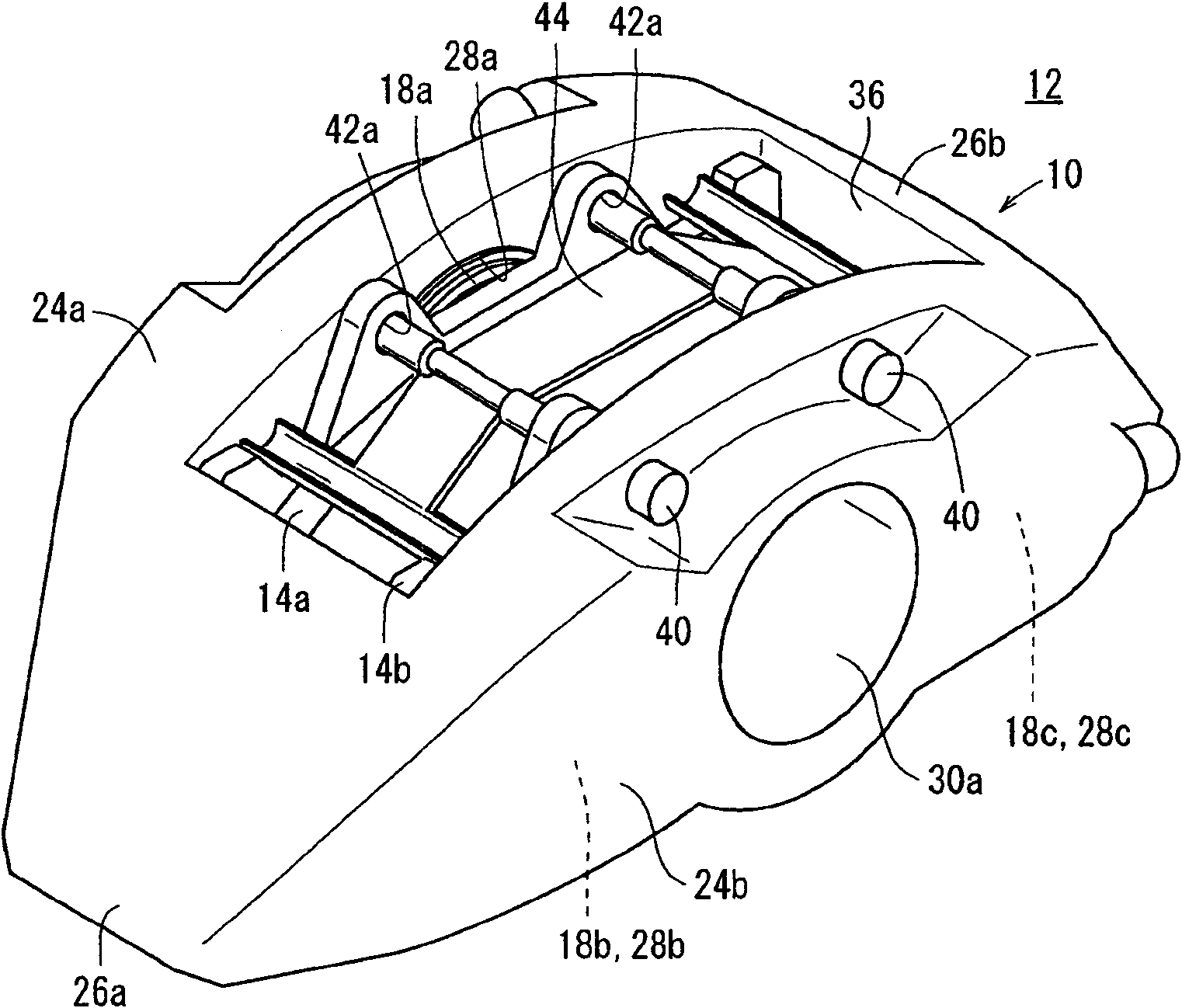

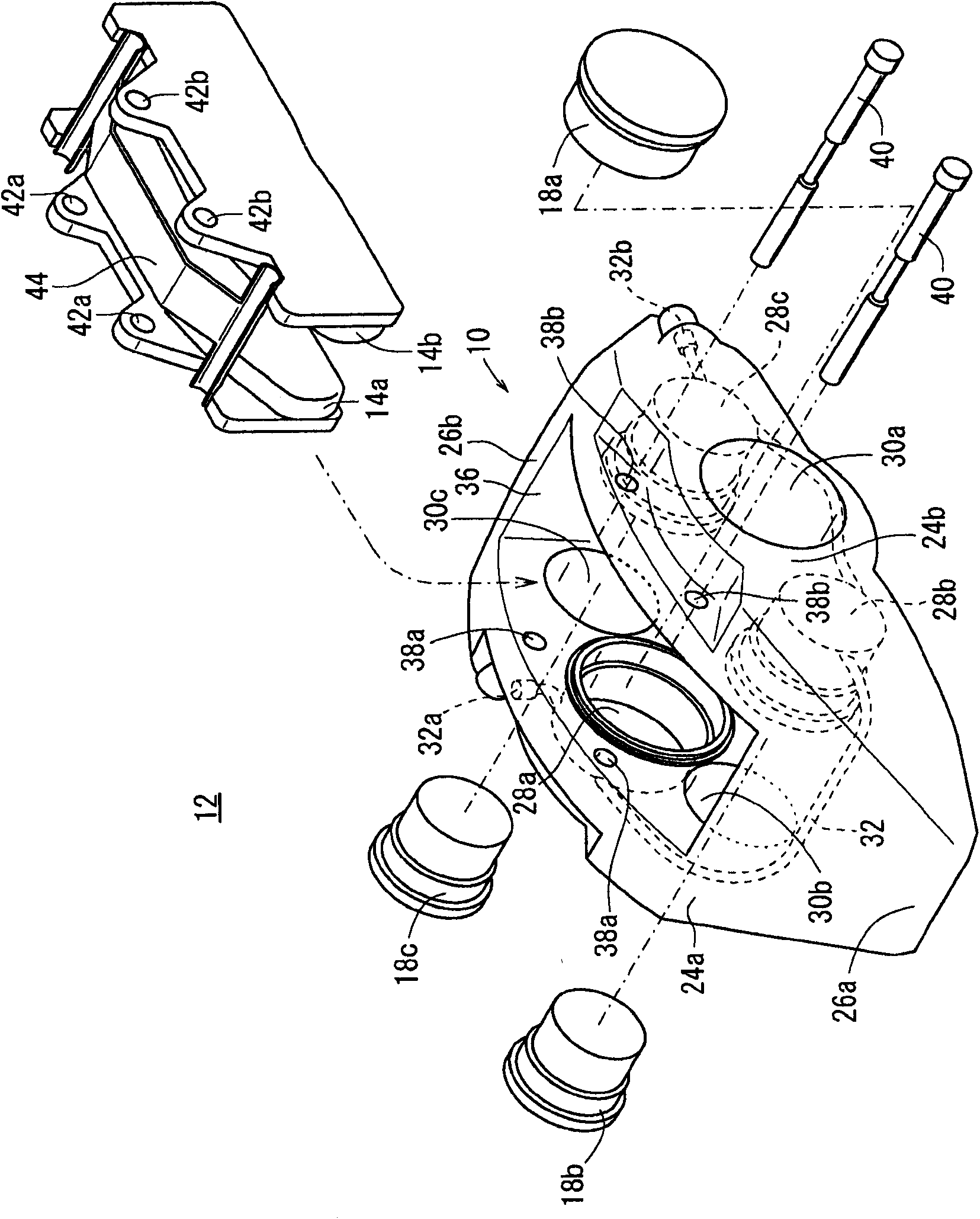

Opposite plug type pliers

InactiveCN101929513AOmit processReduce the numberAxially engaging brakesBraking membersEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

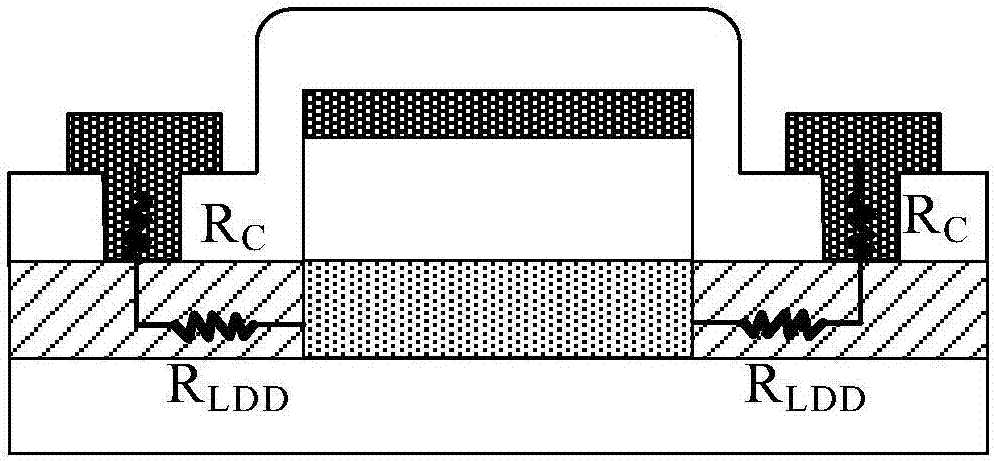

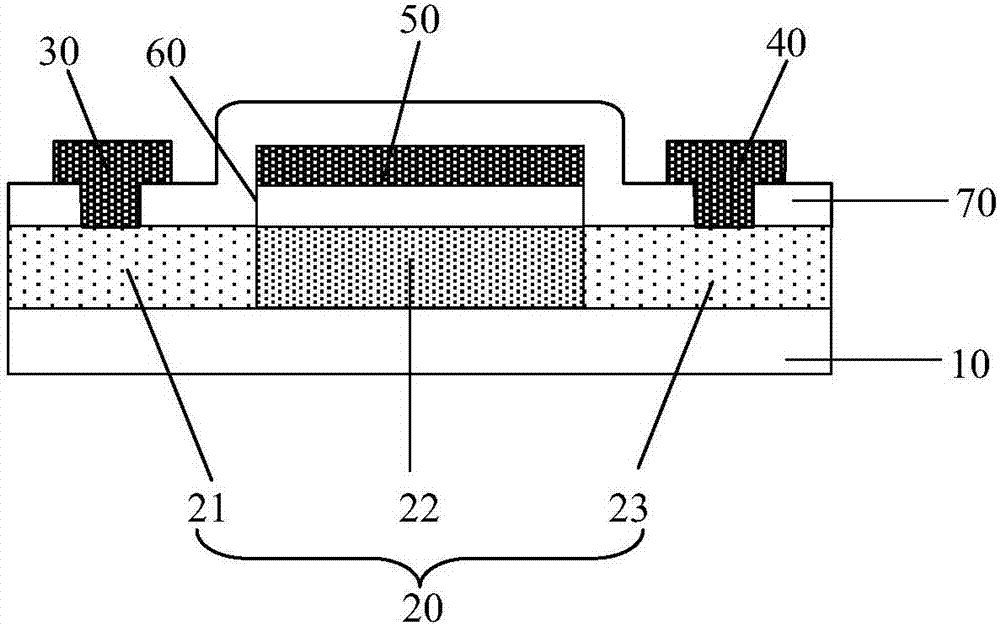

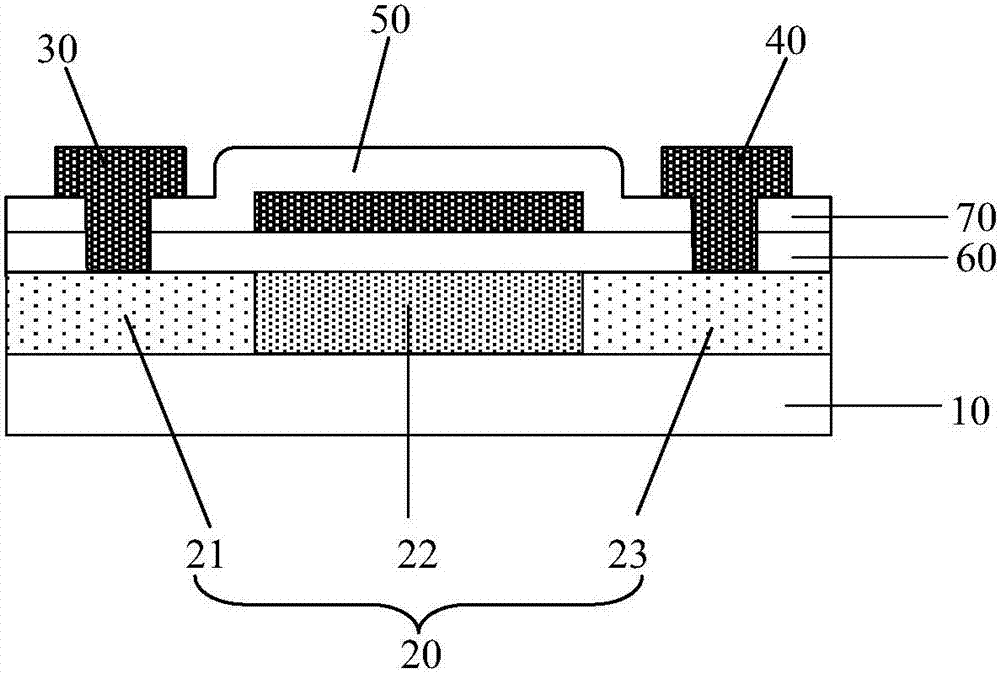

Thin film transistor and preparation method thereof and array substrate

ActiveCN106935658AImprove mobilityImprove stabilityTransistorSemiconductor/solid-state device manufacturingInsulation layerSemiconductor materials

The invention provides a thin film transistor and a preparation method thereof and an array substrate, relates to the technical field of display and can reduce parasitic resistance between source and drain electrodes and an active region. The thin film transistor comprises an active layer arranged on a substrate, the source electrode, the drain electrode, a grid electrode and a gate insulation layer. The active layer comprises a source region, a drain region and the active region. The source region and the drain region are mainly made of metal; and the active region is made of a semiconductor material, the semiconductor material being formed by oxide of the metal.

Owner:BOE TECH GRP CO LTD

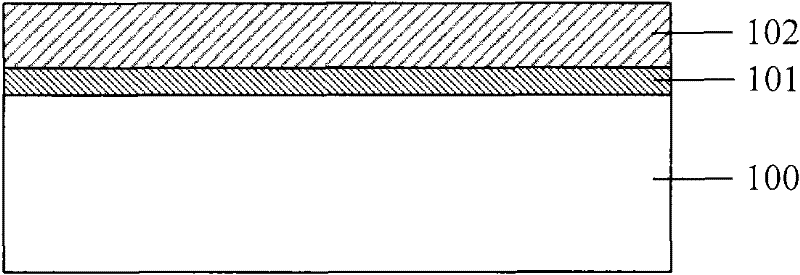

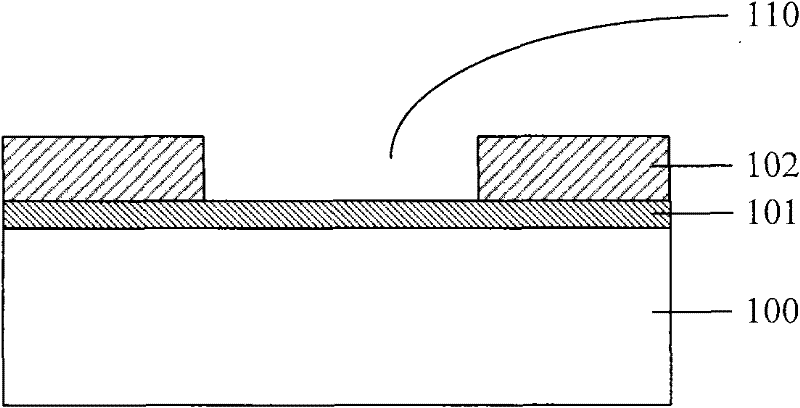

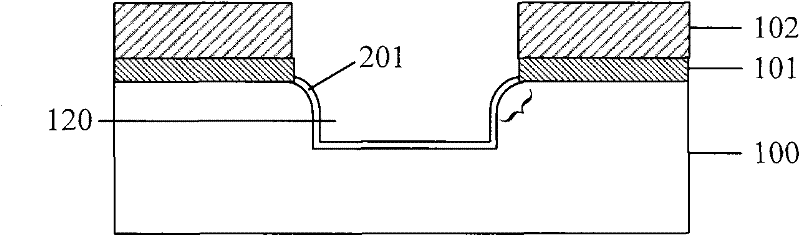

Manufacturing method of shallow trench isolation

ActiveCN102222636AImprove uniformityAchieve smoothSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention provides a manufacturing method of shallow trench isolation, which comprises the steps of: providing a semiconductor substrate with a masking structure covered on a surface, wherein an opening for exposing the semiconductor substrate is formed on the masking structure; etching a trench corresponding to the opening on the semiconductor substrate by taking the masking structure as a mask; forming lining oxidizing layers on sidewalls and the bottom of the trench; annealing under an argon atmosphere; and filling an insulating medium in the trench to form the shallow trench isolation. The manufacturing method provided by the invention can ensure that corners on the top of the trench are smoothened; and in addition, compared with the prior art, the manufacturing method has the advantages of simplifying process steps and lowering process cost.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

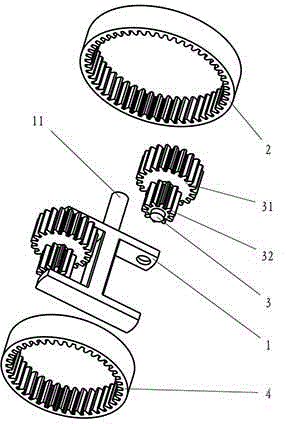

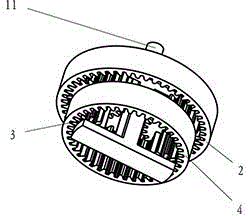

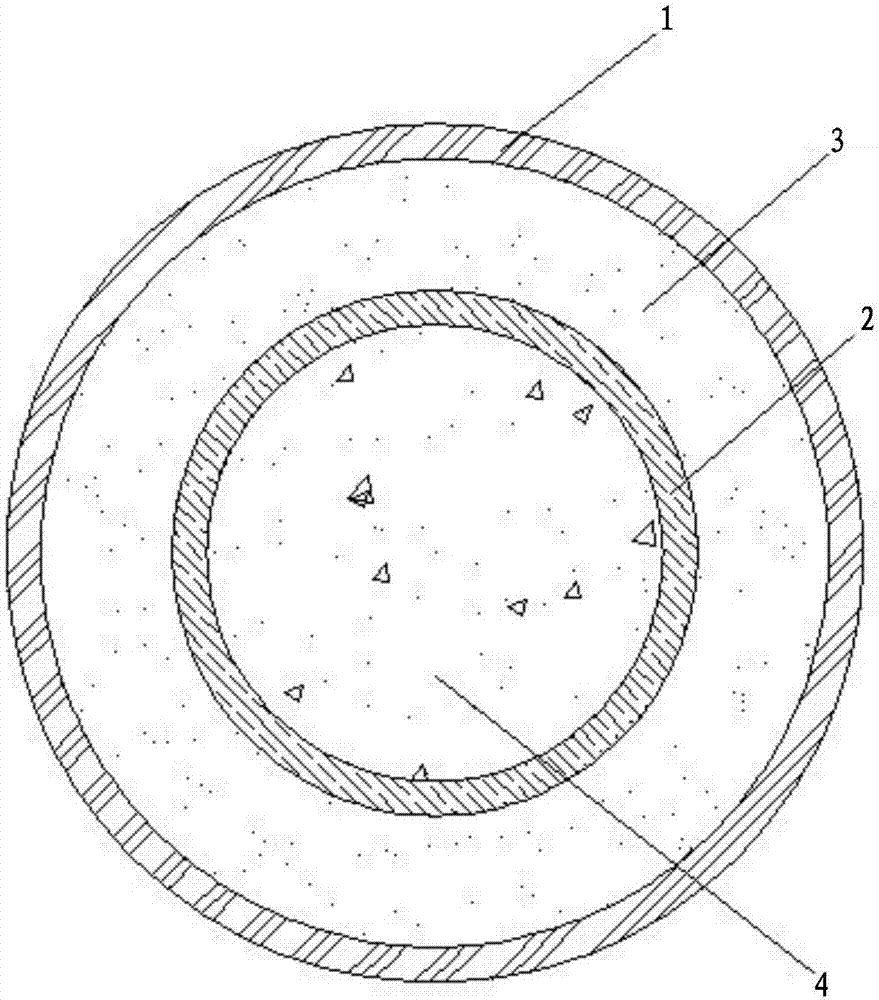

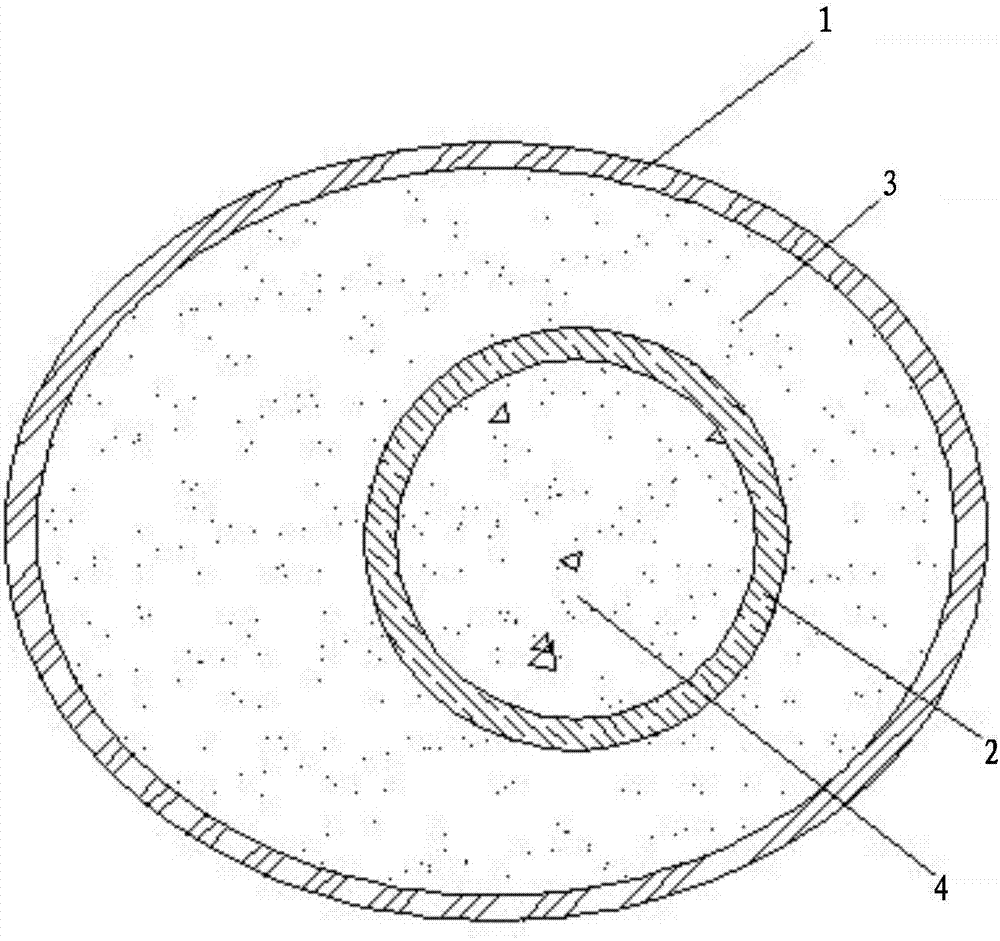

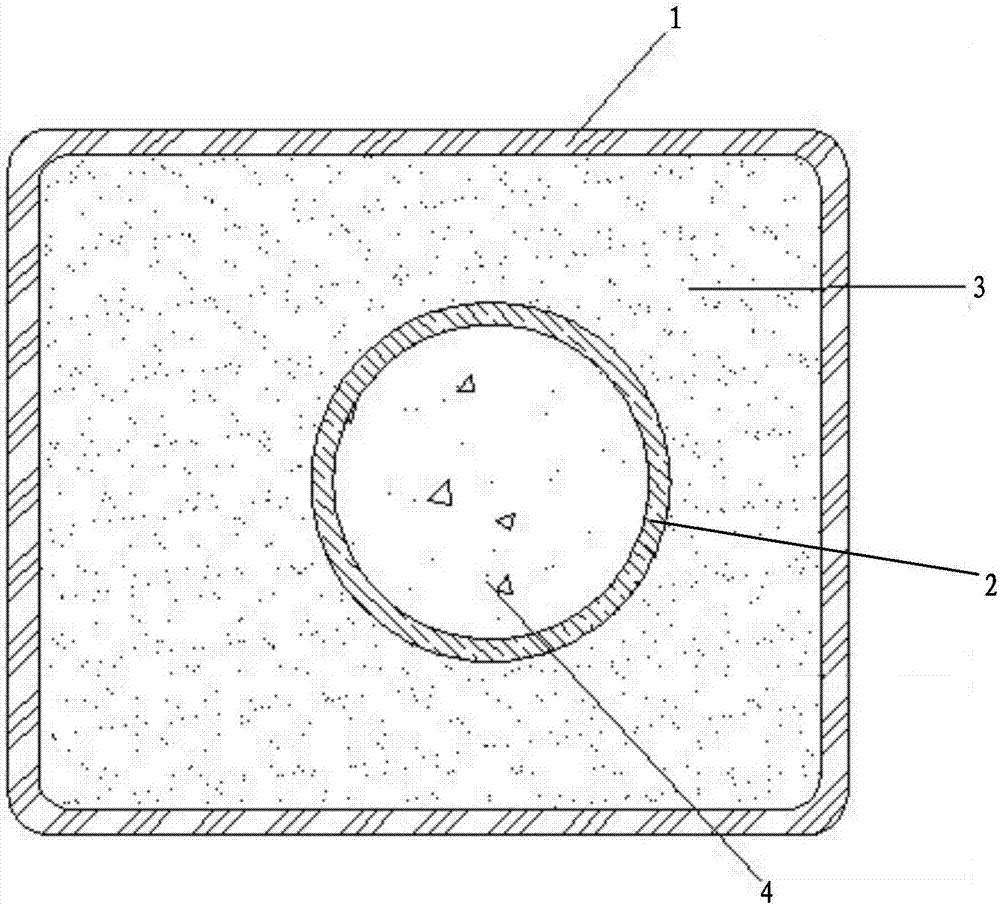

Wheel diameter difference member speed reducer

InactiveCN103982600AReduce restrictionsHigh output torqueToothed gearingsGearing detailsEngineeringReducer

The invention discloses a wheel diameter difference member speed reducer. The wheel diameter difference member speed reducer comprises a wheel diameter difference member frame, a fixing main casing wheel, wheel diameter difference members and a differential motion casing wheel; the wheel diameter difference members are fixed inside the wheel diameter difference member frame in a rotary mode; the wheel diameter difference members are in transmission enragement with the fixing main casing wheel and the differential motion casing wheel; the wheel diameter difference member frame and the differential motion casing wheel can be input and output shafts; the wheel diameter difference member frame, the fixing main casing wheel and the differential motion casing wheel are arranged coaxially. The wheel diameter difference member speed reducer difference member speed reducer has the advantages of being simple in structure, low in machining difficulty, large in output power, strong in shock resistant capability and large in speed reducing range.

Owner:张小龙 +1

Concrete column with sea sand concrete and core rubber concrete

PendingCN107035071AAvoid odorExpand the applicable field of engineeringStrutsPillarsFiberFresh water

The invention discloses a concrete column with sea sand concrete and core rubber concrete. The concrete column with the sea sand concrete and the core rubber concrete comprises an outer-layer FRP pipe, an FRP-steel composite pipe, the sea sand concrete and the rubber concrete, the FRP-steel composite pipe is arranged in the outer-layer FRP pipe, and the position between the FRP-steel composite pipe and the outer-layer FRP pipe is filled with the sea sand concrete; the FRP-steel composite pipe is filled with the rubber concrete; and the FRP-steel composite pipe comprises a steel pipe body and FRP fiber cloth covering the external surface of the steel pipe body. According to the concrete column with the sea sand concrete and the core rubber concrete, original sea sand which is not subjected to desalting treatment can be directly used, the fresh water resource is saved, the desalting working procedure is omitted, and the utilization rate of the sea sand is greatly increased. In addition, the defects that a rubber concrete column is low in compressive strength, and peculiar smell is released are overcome, the engineering application fields of the rubber concrete are expanded, the utilization rate of rubber is greatly increased, and the concrete column with the sea sand concrete and the core rubber concrete has the beneficial effects of being high in bearing capacity, good in shock resistance and damping capacity, excellent in seismic performance and environmentally friendly.

Owner:GUANGDONG UNIV OF TECH

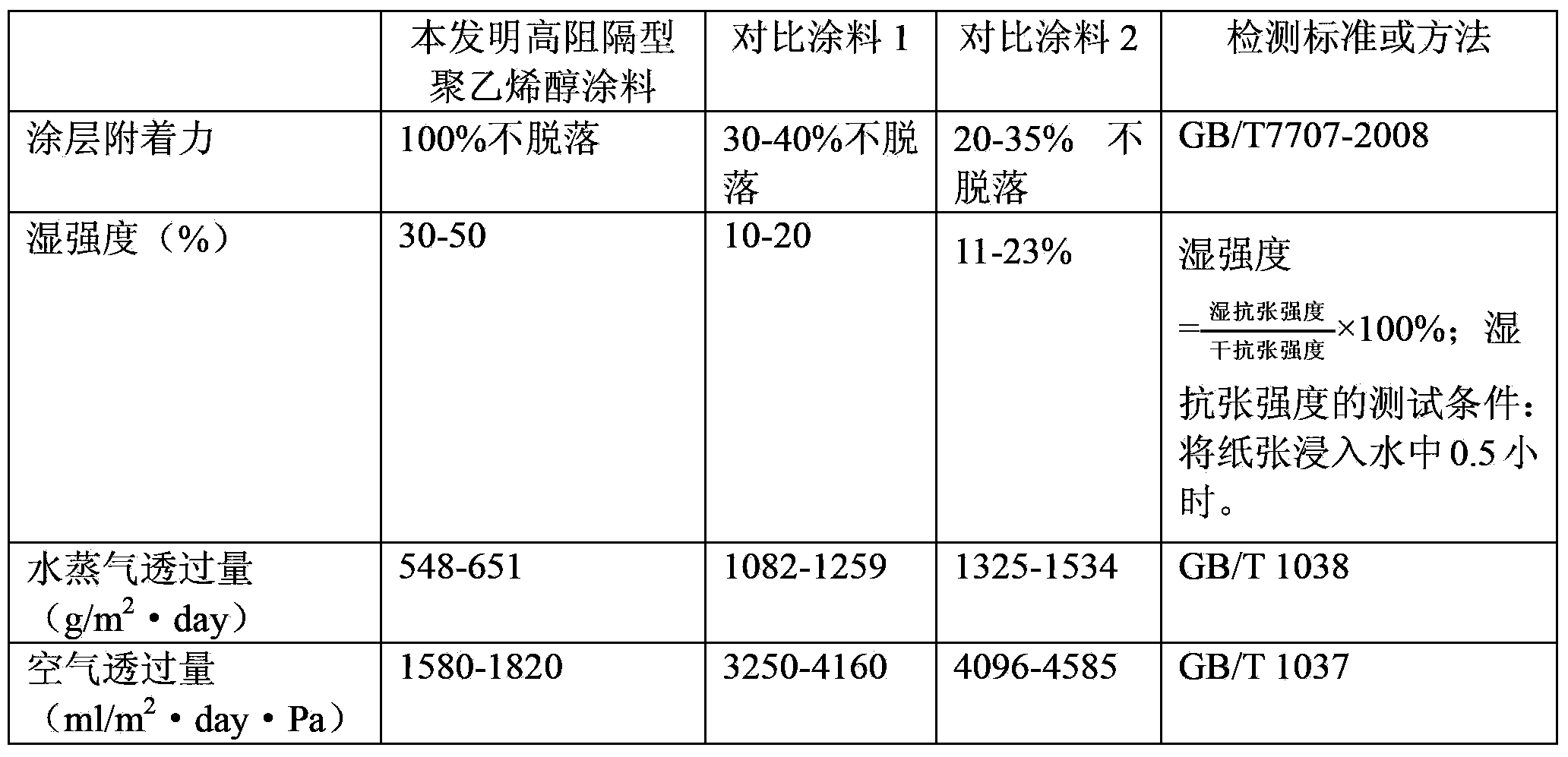

High-barrier polyving akohol coating for coating lined paper and preparation method thereof

ActiveCN103382677ASolve the problem of prone to paper breaksImprove wet strengthDefoamers additionPaper coatingHigh resistanceWet strength

The invention relates to high-barrier polyving akohol coating for coating lined paper. The coating comprises the following raw materials of, by weight, 12-16% of polyving akohol, 2.1-3.8% of amino resin, 0.01-0.015% of catalysts, 0.05-0.3% of wet strength agents, 2-4% of xylan, 0.1-0.25% of anti-blocking agents, 0.005-0.01% of antifoaming agents and 78-83% of deionized water. The invention further provides a preparation method of the high-resistance polyving akohol coating for coating the lined paper. The coating is directly coated on a lined paper substrate of 45-80g / m<2>, and has good adhesive force and barrier property. After the coated lined paper is wetted or soaked into the water, the tensile strength of the coated lined paper is higher than 30%. Trial results show that the coated lined paper can be completely applied to high-speed presses and packing machines.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

High hardness, high wear resistant and non-polished iron based microcrystalline glass ceramic composite plate and preparation method thereof

The invention discloses a high hardness, high wear resistant and non-polished iron based microcrystalline glass ceramic composite plate and a preparation method thereof. The preparation method includes: applying ground glaze to a ceramic green body, then applying frit dry granules, and conducting firing so as to obtain the composite plate. The high hardness, high wear resistant and non-polished iron based microcrystalline glass ceramic composite plate provided by the invention has the characteristics of high hardness, high wear resistant and no polishing at the same time, the ceramic green body has enough strength, and has suitable firing temperature and thermal expansion coefficient. The preparation method disclosed by the invention is convenient for making, and is easy to realize normalized, large-scale and standardized production.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL +1

Nozzle tape used with inkjet cartridge

A nozzle tape for an inkjet cartridge is attached to the inkjet cartridge including a head chip, a cartridge body provided with a head chip-mounting portion spaced apart from edges of the head chip by a predetermined extent, and at least one bead member protruded along the edges of the head chip, wherein the nozzle tape is provided with at least one communication portion in fluid communication with a spaced gap between the head chip and the head chip-mounting portion to make the air trapped under the nozzle tape communicate with external air through the communication portion, thereby tightly attaching the nozzle tape to the nozzles, regardless of changes of an external environment.

Owner:S PRINTING SOLUTION CO LTD

Apparatus, method and program for protecting accommodated item such as cartridge

InactiveUS8359986B2Function increaseOmit processDigital data processing detailsBuilding locksMagnetic tapeEngineering

Owner:FUJITSU LTD

Method of Producing Mixed Powder Comprising Noble Metal Powder and Oxide Powder, and Mixed Powder Comprising Noble Metal Powder and Oxide Powder

ActiveUS20110114879A1Inhibit aggregationAvoid grain growthOther chemical processesHydrazine compoundNitrogen

Provided are a method of producing mixed powder comprising noble metal powder and oxide powder, wherein powder of ammonium chloride salt of noble metal and oxide powder are mixed, the mixed powder is subsequently roasted, and ammonium chloride is desorbed by the roasting process in order to obtain mixed powder comprising noble metal powder and oxide powder, and mixed powder comprising noble metal powder and oxide powder, wherein chlorine is less than 1000 ppm, nitrogen is less than 1000 ppm, 90% or more of the grain size of the noble metal powder is 20 μm or less, and 90% or more of the grain size of the oxide powder is 12 μm or less. Redundant processes in the production of noble metal powder are eliminated, and processes are omitted so that the inclusion of chlorine contained in the royal water and nitrogen responsible for hydrazine reduction reaction is eliminated as much as possible. Consequently, the present invention aims to omit the drying process at a high temperature and thereby prevent grain growth and aggregation, and further eliminate the pulverization and classification processes in order to considerably reduce the production cost.

Owner:JX NIPPON MINING& METALS CORP

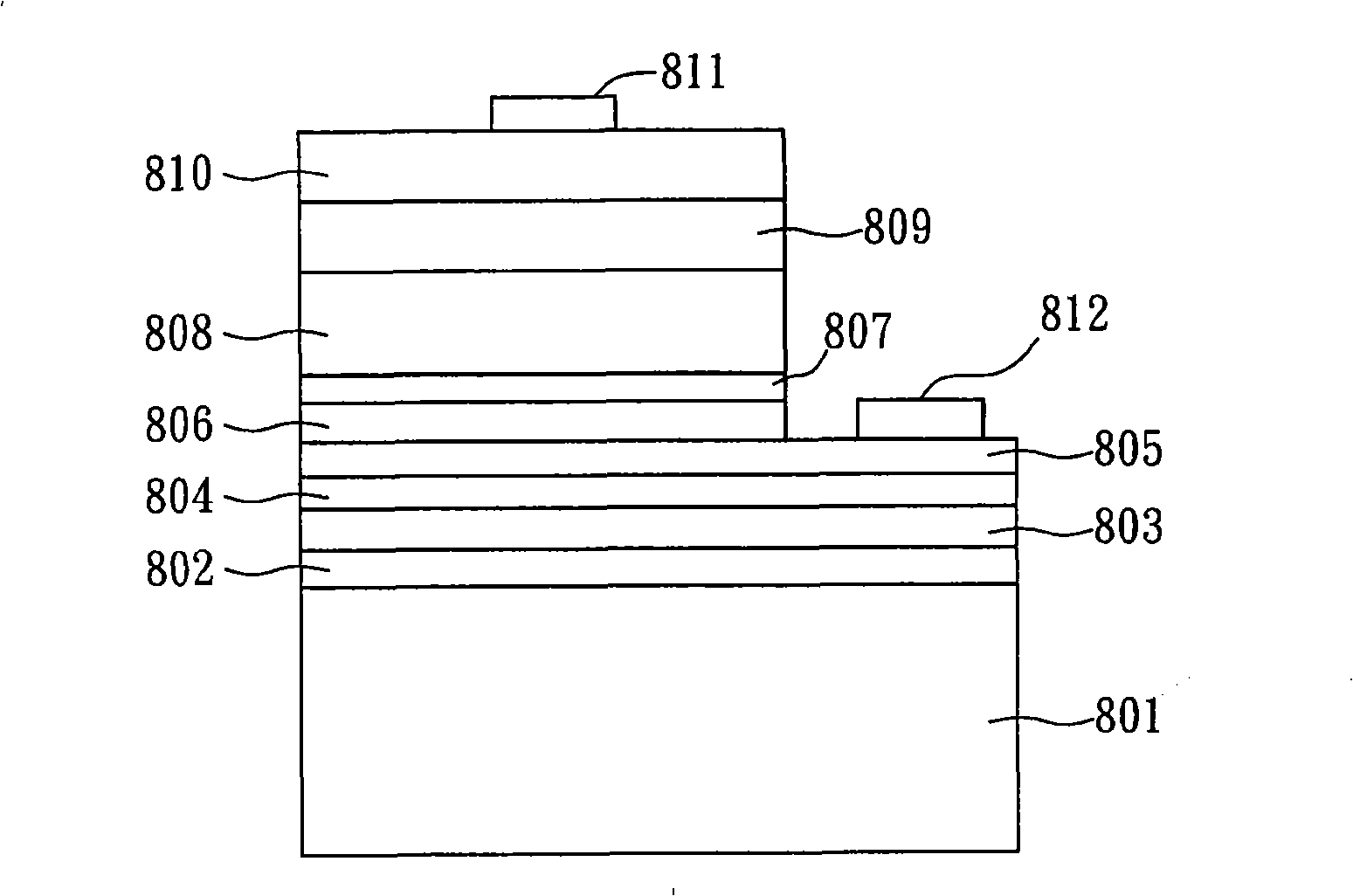

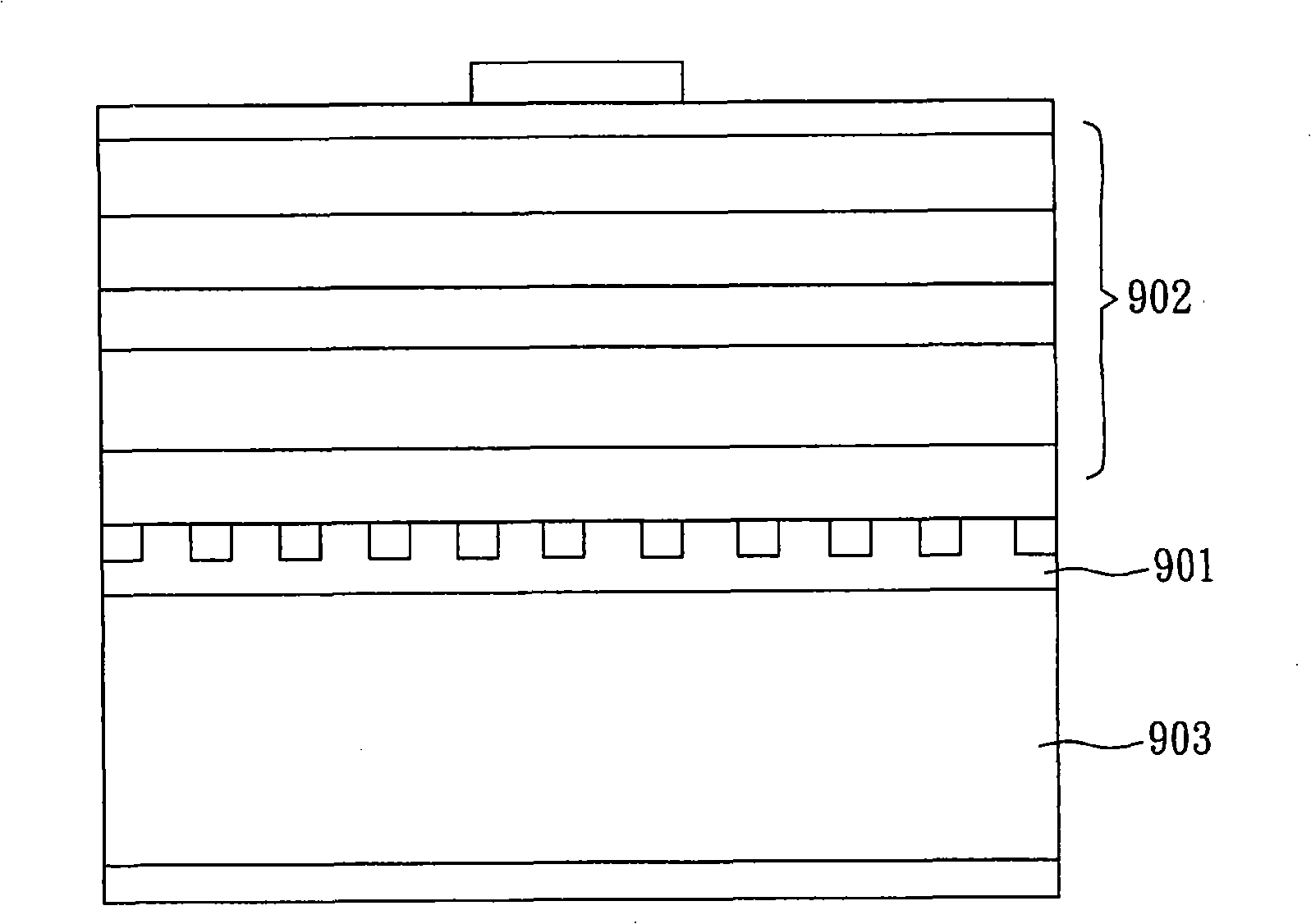

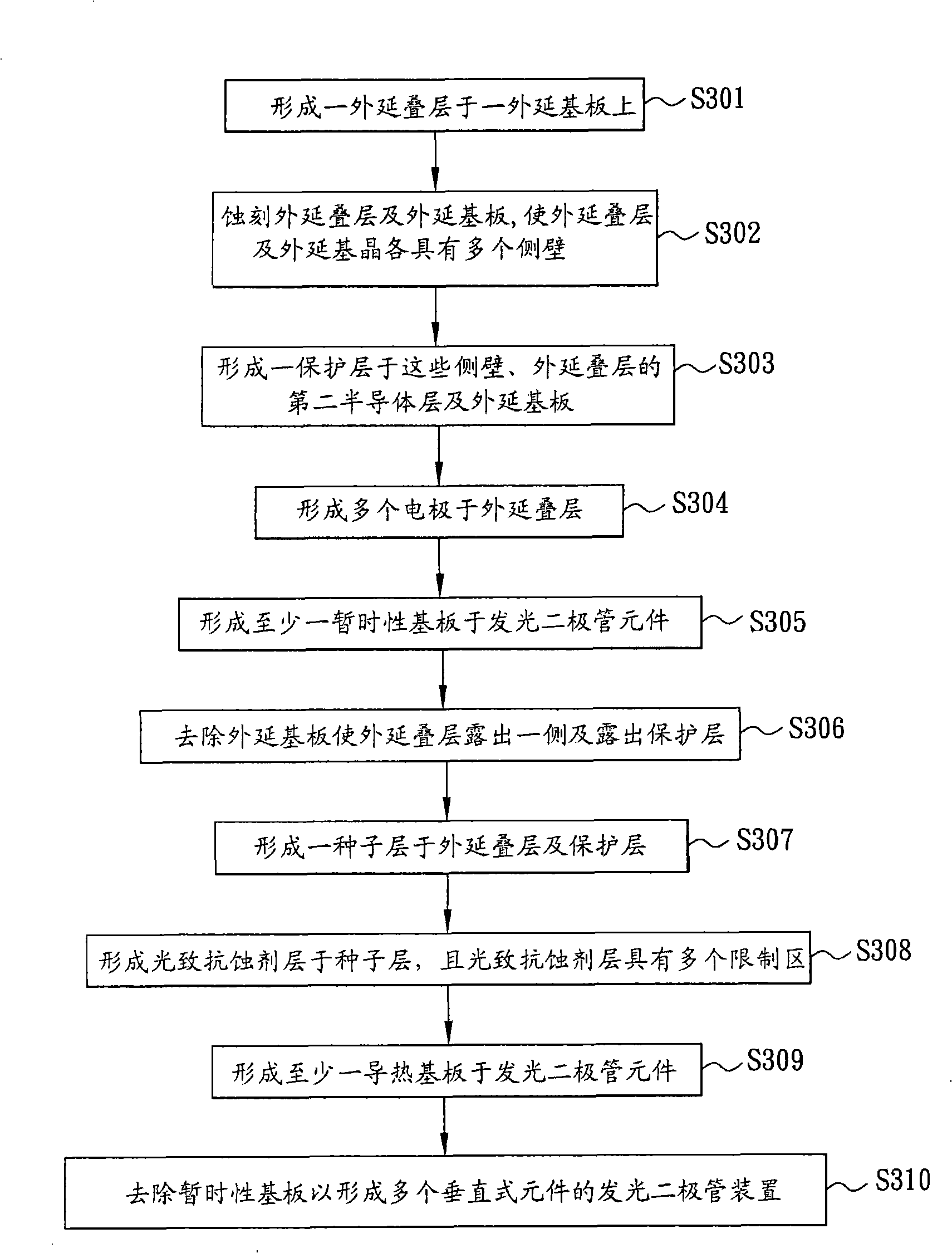

LED device and its preparing process

ActiveCN101345276AReduce residual stressReduce corrosionSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorEngineering

The invention discloses an LED device and a preparation method thereof; the LED device comprises an external extension lamination layer, a heat conduction substrate and a seed layer. The external extension lamination layer is sequentially provided with a first semiconductor layer, a luminescent layer and a second semiconductor layer; the heat conduction substrate and the fist semiconductor layer are arranged correspondingly to each other; the seed layer is arranged between the first semiconductor layer and the heat conduction substrate; wherein, the first semiconductor is an N-typed external extension layer; furthermore, the second semiconductor layer is a P-typed external extension layer. The preparation method of the invention comprises the steps as follows: a temporary substrate is formed on the LED element; at least one heat conduction substrate is formed on the LED element. The material of the temporary substrate comprises a solidified polymer material.

Owner:DELTA ELECTRONICS INC

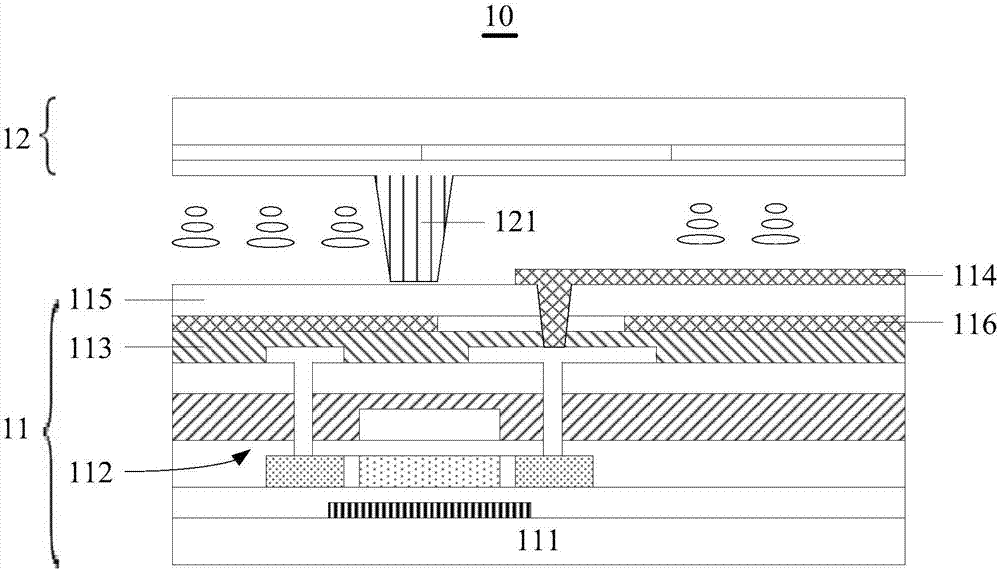

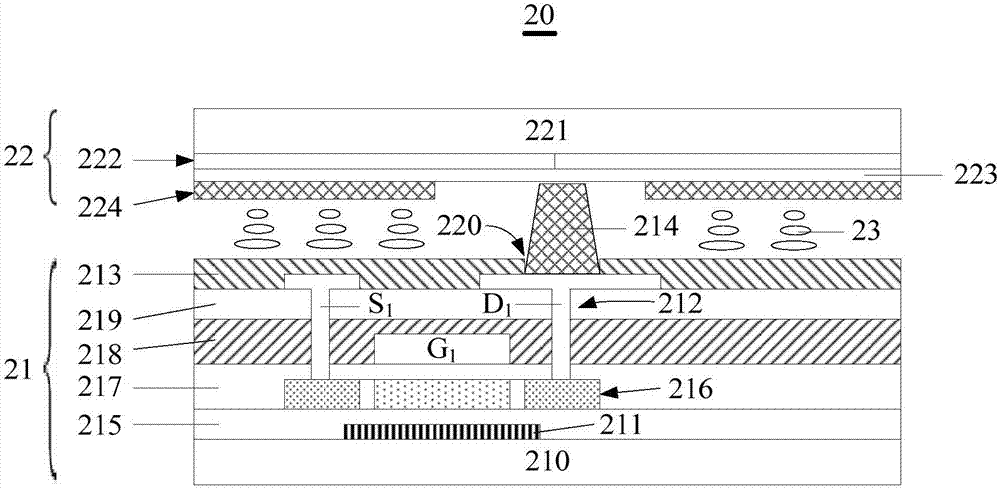

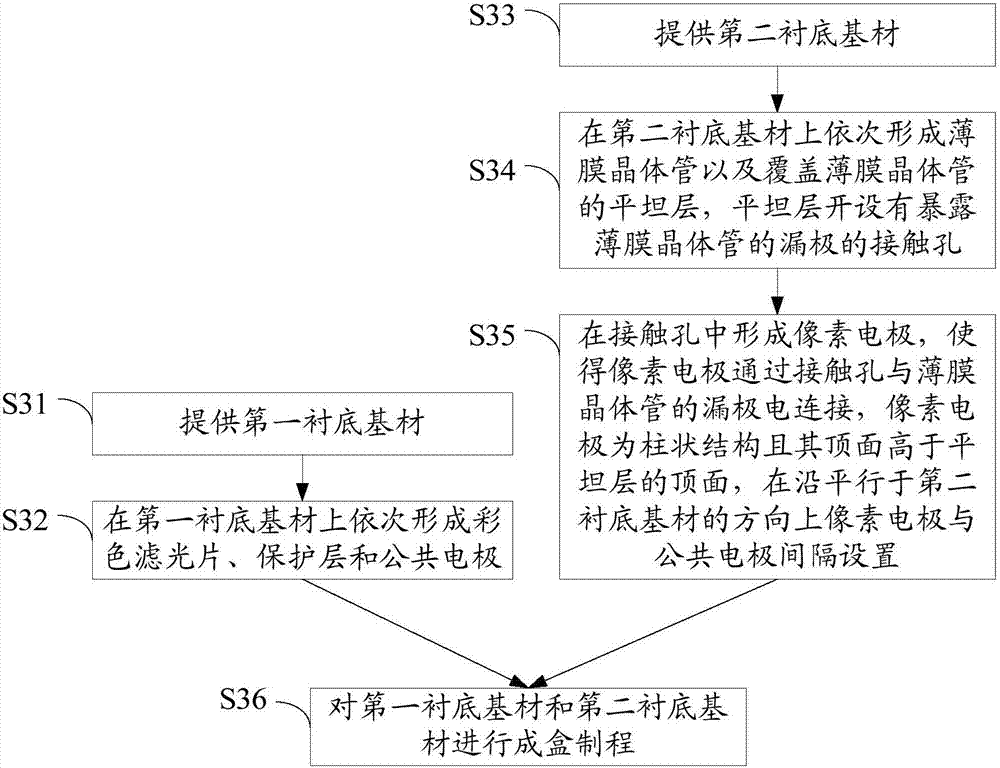

Liquid crystal display panel and manufacturing method thereof as well as array substrate

The invention discloses a liquid crystal display panel and a manufacturing method thereof as well as an array substrate. Common electrodes are arranged at one side of a color film substrate; pixel electrodes are formed in contact holes in a flat layer of the array substrate and are electrically connected with a drain of a thin-film transistor through the contact holes; the pixel electrodes are of a columnar structure and the top surfaces of the pixel electrodes are higher than that of the flat layer; and the pixel electrodes and the common electrodes are arranged at an interval along the direction parallel to the array substrate. Therefore, the manufacture procedure of the liquid crystal display panel can be simplified, the light transmissivity is improved and the influence of an electric field between the adjacent pixel electrodes is reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com