High-barrier polyving akohol coating for coating lined paper and preparation method thereof

A polyvinyl alcohol, high-barrier technology, applied in paper coating, papermaking, coating, etc., can solve the problems of low wet strength, inability to protect moisture and fragrance, and the coating of inner lining paper is easy to fall off, etc., to achieve The effect of enhancing wet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] First, add 12 kg of polyvinyl alcohol into 81.5 kg of deionized water, start stirring at a speed of 200 rpm, raise the temperature to 85°C and keep it for 1.5 hours to completely dissolve; then cool down to 65°C, add 0.01 kg of ethanol, 0.005 kg Phosphoric acid, 0.01 kg of maleic acid and 2.2 kg of methyl etherified melamine resin were reacted for 2 hours; the temperature was lowered to 38°C again, and the stirring speed was raised to 800 rpm, and 2.19 kg of xylan and 1.6 kg of methyl etherified melamine resin were added. The melamine resin was completely reacted after 0.8 hours; finally, 0.235 kg of ethyleneimine and 0.25 kg of silicon dioxide were added, stirred thoroughly for 2 hours, left to stand, cooled, and discharged.

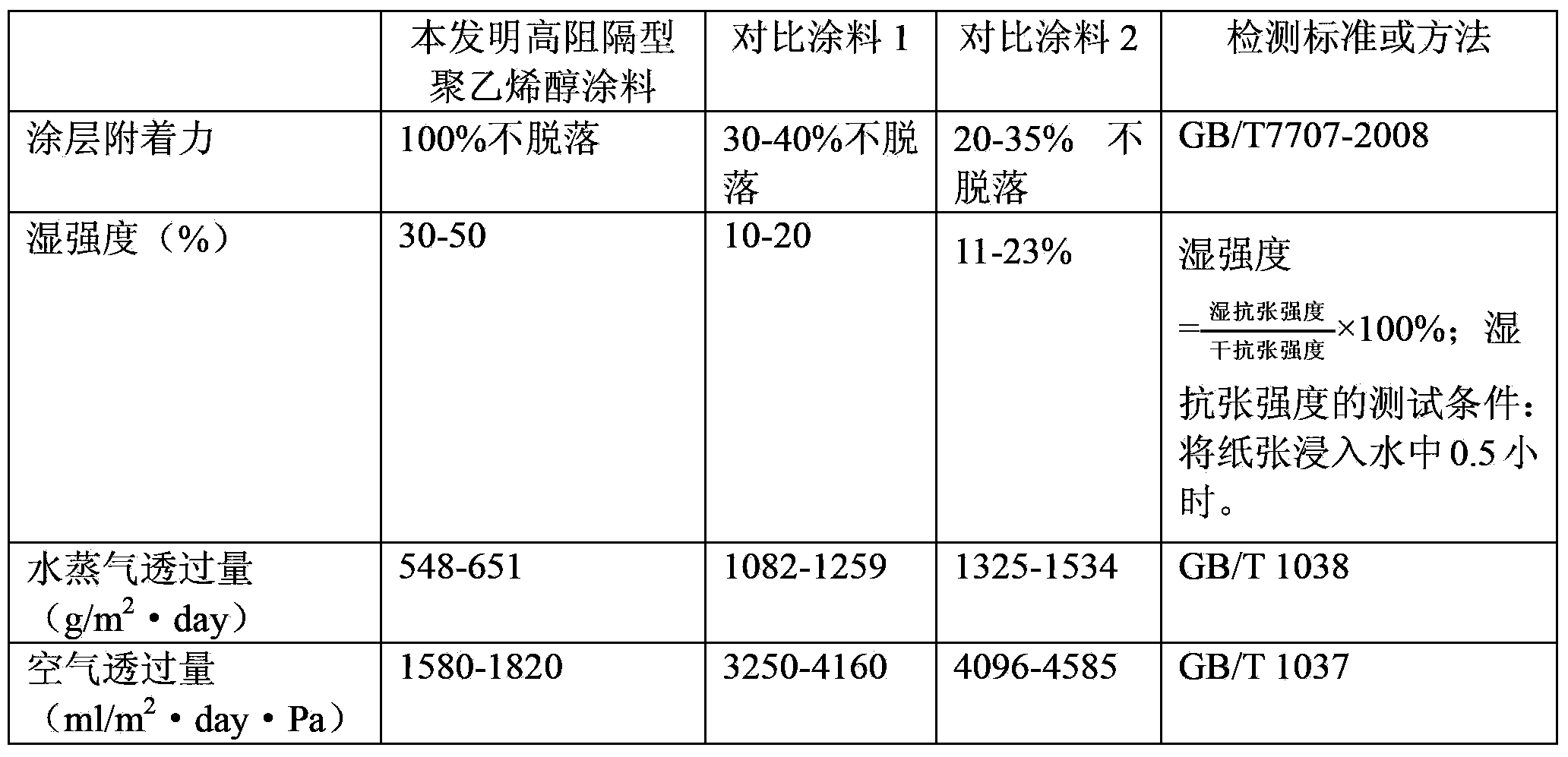

[0027] The coating test was carried out on a 45g / ㎡ inner lining paper substrate. The coating coating amount was 1.5g / ㎡. 602g / m 2 ·day, the air permeability is 1795ml / m 2 · day · Pa.

Embodiment 2

[0029] First, add 14 kg of polyvinyl alcohol into 80.68 kg of deionized water, start stirring at a speed of 300 rpm, raise the temperature to 95°C and keep it for 1.7 hours to completely dissolve; then cool down to 68°C, add 0.008 kg of ethanol, 0.003 kg Citric acid, 0.007 kg of p-toluenesulfonic acid and 2 kg of methyl etherified urea-formaldehyde resin were reacted for 2.4 hours; the temperature was lowered to 38°C again, and the stirring speed was raised to 500 rpm, and 2 kg of xylan and 0.8 kg of formaldehyde were added Etherification of urea-formaldehyde resin, the reaction is complete after 0.5 hours; finally add 0.3 kg of ethyleneimine and 0.2 kg of silicon dioxide, stir thoroughly for 1.5 hours, let stand, cool, and discharge.

[0030] The coating test was carried out on a 45g / ㎡ inner lining paper substrate. The coating amount was 1.0g / ㎡. 548g / m 2 ·day, the air permeability is 15800ml / m 2 · day · Pa.

Embodiment 3

[0032] First, add 13 kg of polyvinyl alcohol into 79.76 kg of deionized water, start stirring at 230 rpm, raise the temperature to 88°C and keep it for 1 hour to completely dissolve; then cool down to 66°C, add 0.005 kg of ethanol, 0.005 kg Citric acid, 0.007 kg of maleic acid, 0.5 kg of methylated melamine resin, 1.5 kg of methylated urea-formaldehyde resin were reacted for 3 hours; the temperature was lowered to 40°C again, and the stirring speed was raised to 700 rpm, and 4 kg of Xylan, 0.3 kg of methyl etherified melamine resin, 0.7 kg of methyl etherified urea-formaldehyde resin, the reaction is complete after 0.5 hours; finally add 0.1 kg of ethyleneimine, 0.12 kg of silicon dioxide, fully stir for 1 hour, stand still, and cool ,Discharge.

[0033]The coating test was carried out on a 50g / ㎡ inner lining paper substrate. The coating coating amount was 2.2g / ㎡. 580g / m 2 ·day, the air permeability is 1740ml / m 2 · day · Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com