Patents

Literature

75results about How to "High defective rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

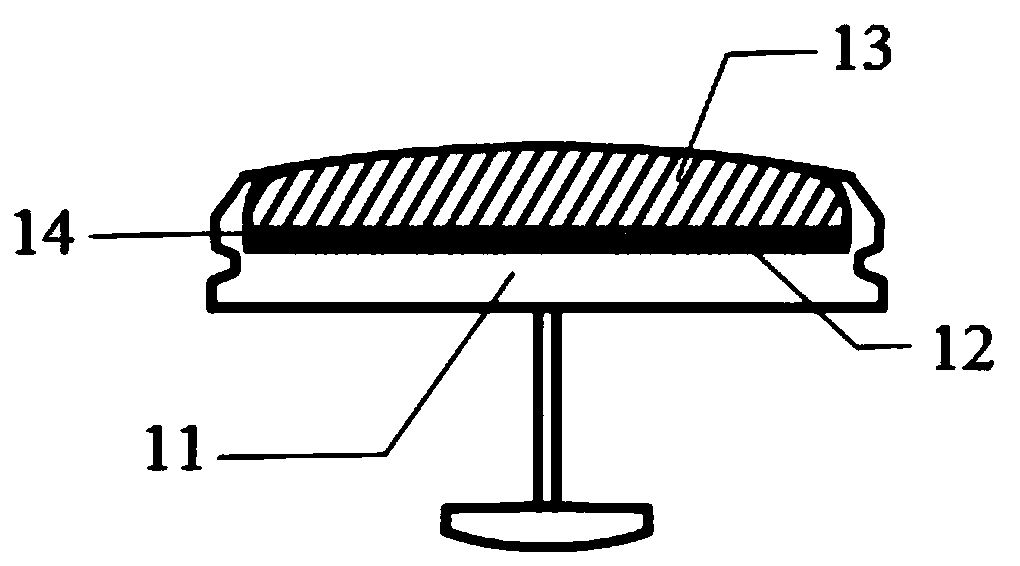

Production method of ball valve core

InactiveCN101362281AHigh defective rateImprove reliabilityPlug valvesManufacturing technologyUltimate tensile strength

The invention provides a method for producing the core of a ball valve, which belongs to the technical field of valve production, and solves the problems of a large amount of material, high cost and high defective rate in the prior art. The production method of the core of the ball valve is realized through the following steps: firstly, an outer ball shell is produced; secondly, an inner straight pipe is installed; and thirdly, surface treatment is carried out. Through the production method, the material is greatly saved, and the cost for the core of the ball valve is reduced; the precision, the thickness and the integrity of the produced core of the ball valve can be guaranteed, and the intensity of the valve handle connecting seat and the valve handle connecting part is enhanced; the reliability of the production method is good, and the rate of finished products is high; the technological process of the production method is simplified, the appearance of the produced core of the ball valve is beautiful, and the core is comparatively perfect; if stainless steel material is selected to produce the core of the ball valve, galvanization is not needed, therefore, the environment protection property is good.

Owner:黄勇

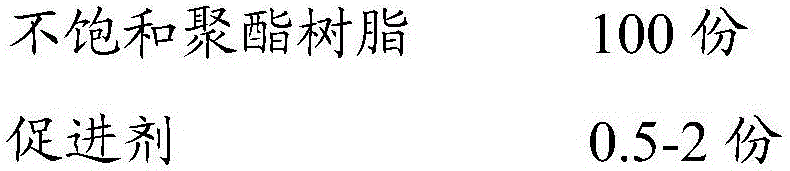

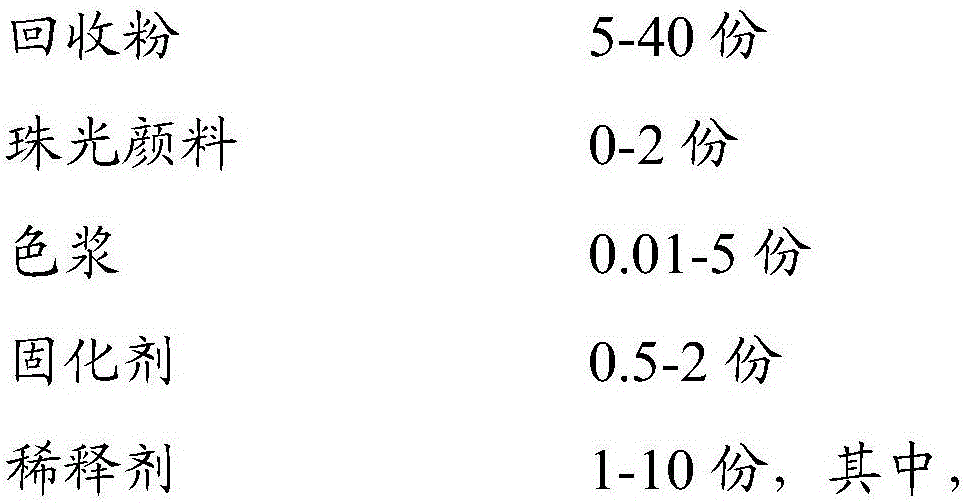

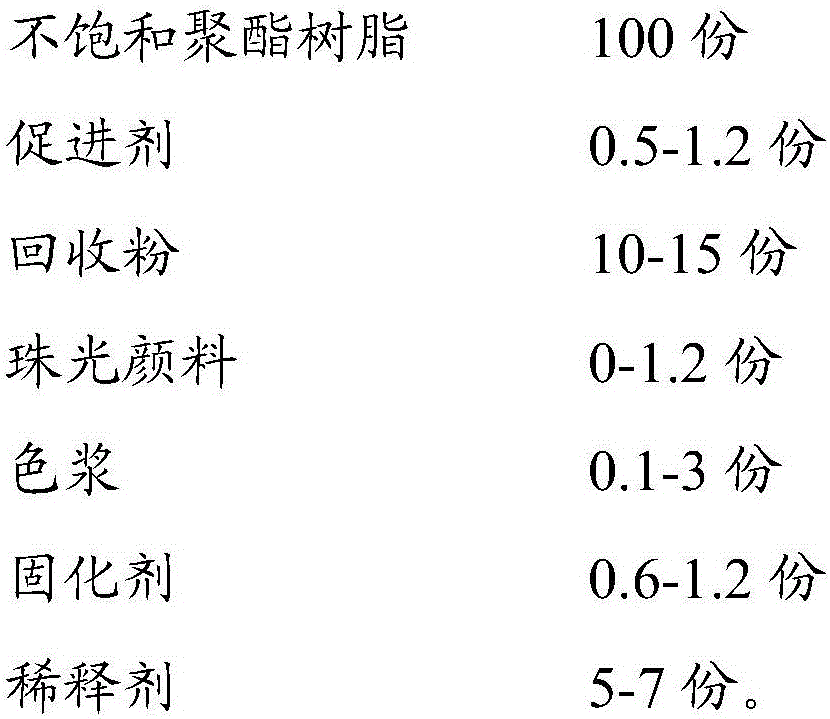

Environment-friendly unsaturated polyester resin button and preparation method thereof

The invention relates to an environment-friendly unsaturated polyester resin button and a preparation method thereof. The environment-friendly unsaturated polyester resin button is prepared from raw materials in parts by weight as follows: 100 parts of unsaturated polyester resin, 0.5-2 parts of an accelerant, 5-40 parts of recycle powder, 0-2 parts of pigments, 0.01-5 parts of color paste, 0.5-2 parts of a curing agent and 1-10 parts of a diluent, wherein the recycle powder contains powder of leftover materials and / or waste rejected products of the unsaturated polyester resin button, and the grain size of the powder is 100-200 meshes. According to the resin button, the leftover materials and the waste rejected products are recycled, so that waste emission in the production process of the resin button is effectively reduced, the use amount of resin is also reduced, resources are saved, the environment-friendly unsaturated polyester resin button is low in cost, and the quality can meet the national standard requirement.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

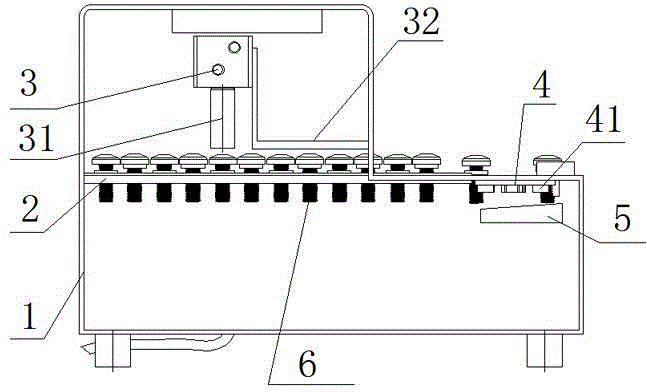

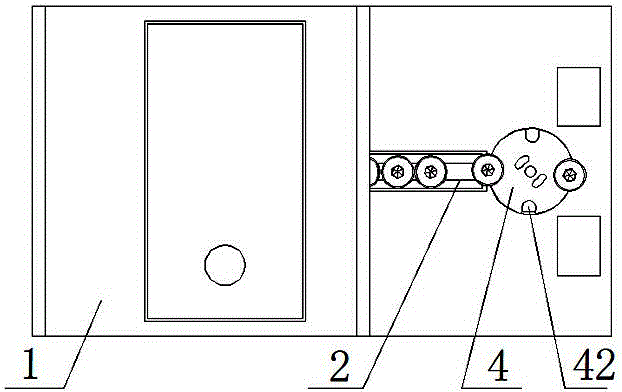

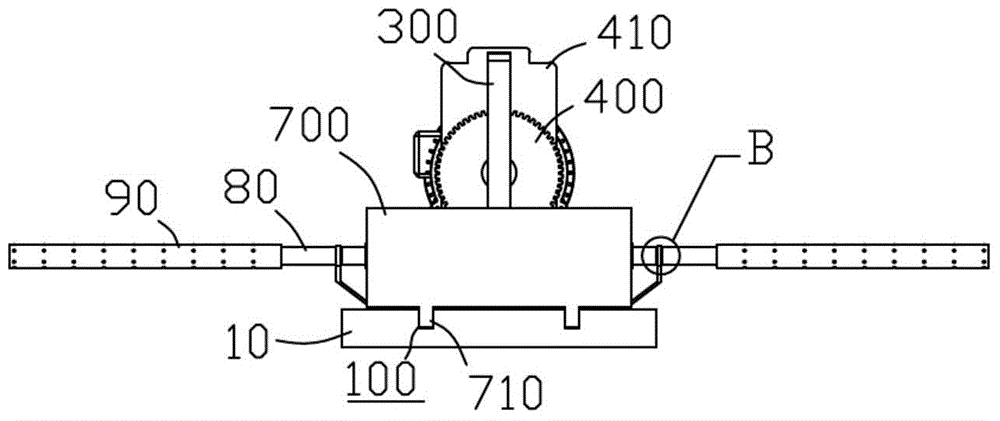

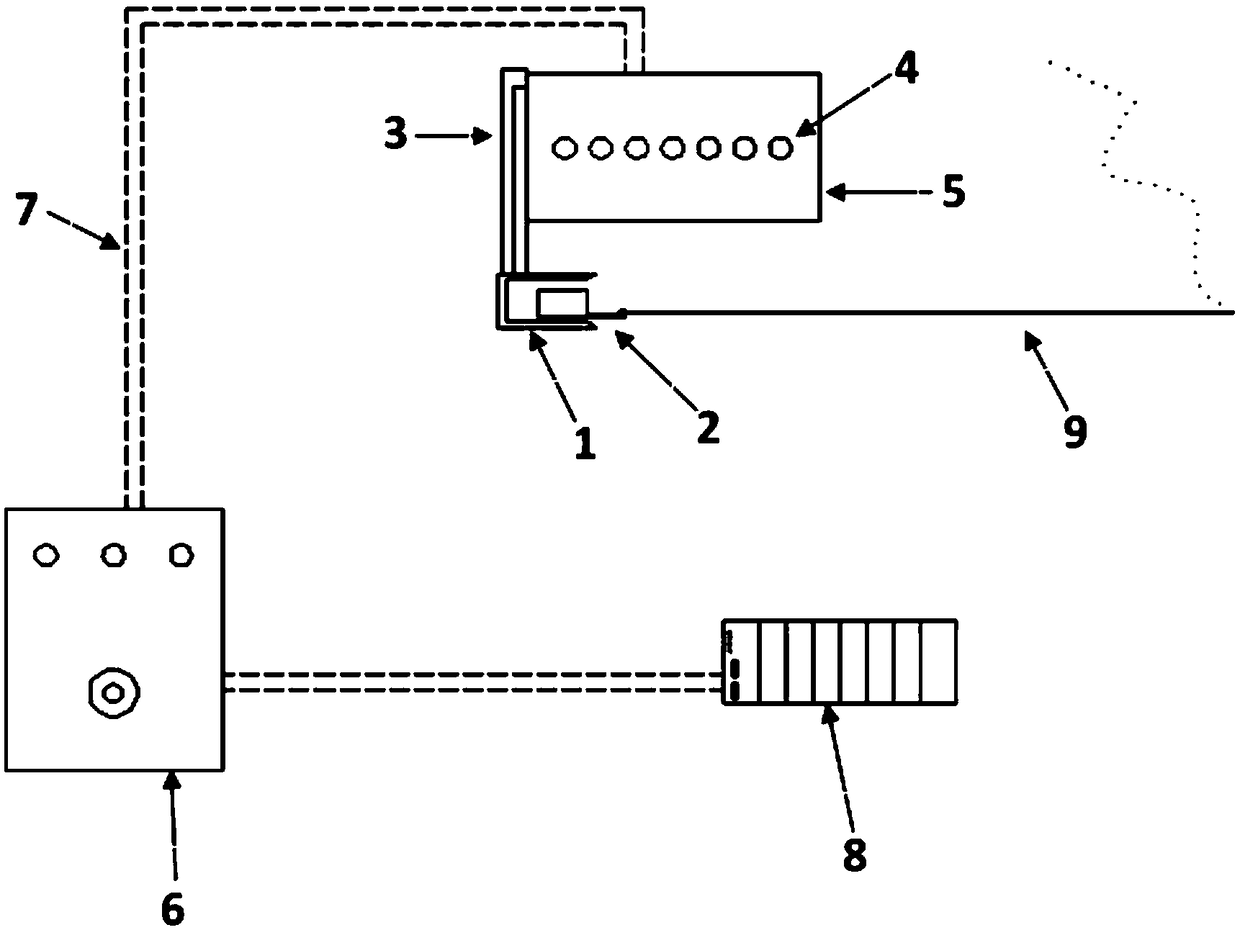

Screw supplying device

The invention discloses a screw supplying device. The screw supplying device comprises a machine box, a conveying guide rail, a screw, a height limiting frame, a flattening air cylinder, a pressing needle, a turn plate, a limiting hole, a protecting block, limiting holes and a heightening block. The designed flattening air cylinder and the pressing needle can be used for flattening the screw so as to prevent a screw gasket from being blocked on a screw rod so as to cause deflection of the screw during a conveying process, and a screw cap and the screw gasket are enabled to be tightly jointed and conveyed; by arranging the height limiting frame, defective products can be screened out; the protecting block is arranged and matched with the turn plate in use; the protecting block and the turn plate are respectively provided with limiting holes which are the same in diameter to locate the screw, so that deflection is prevented when the screw is arranged; a heightening plate is also arranged for upwards-pushing the screw during circumferential motion of the screw, so that the screw can be separated from the turn plate after being conveyed and heightened; convenience is provided for a mechanical arm to suck the screw; the screw supplying device is high in accuracy, high in screw supplying efficiency, high in intelligent level, simple in structure, low in cost and capable of satisfying high requirements of industrial development.

Owner:DONGGUAN OKATA ELECTRONICS & TECH

Printed and embroidered seamless wall fabric and manufacturing method thereof

ActiveCN105804345ALow viscosityEvenly dispersedCovering/liningsDyeing processBiochemical engineeringMembranous layer

The invention belongs to the technical field of facing decoration materials and particularly relates to printed and embroidered seamless wall fabric and a manufacturing method thereof. The wall fabric comprises a cloth layer, a glue film layer and a raw paper layer or non-woven layer, wherein the glue film layer is located between the cloth layer and the raw paper layer; the surface, making contact with the glue film layer, of the cloth layer is a smooth surface, and the other surface of the cloth layer is provided with printed patterns; and embroidered patterns are arranged on the cloth layer, and the cloth layer is soaked or coated with a waterproof and mouldproof agent. The wall fabric is formed by conducting printing and embroidering on base cloth and then conducting shaping. The wall fabric manufactured through the manufacturing method has the advantages of being easy to stick, not prone to wrinkles, various in style and long in service life.

Owner:ZHEJIANG LIANXIANG EMBROIDERY CO LTD

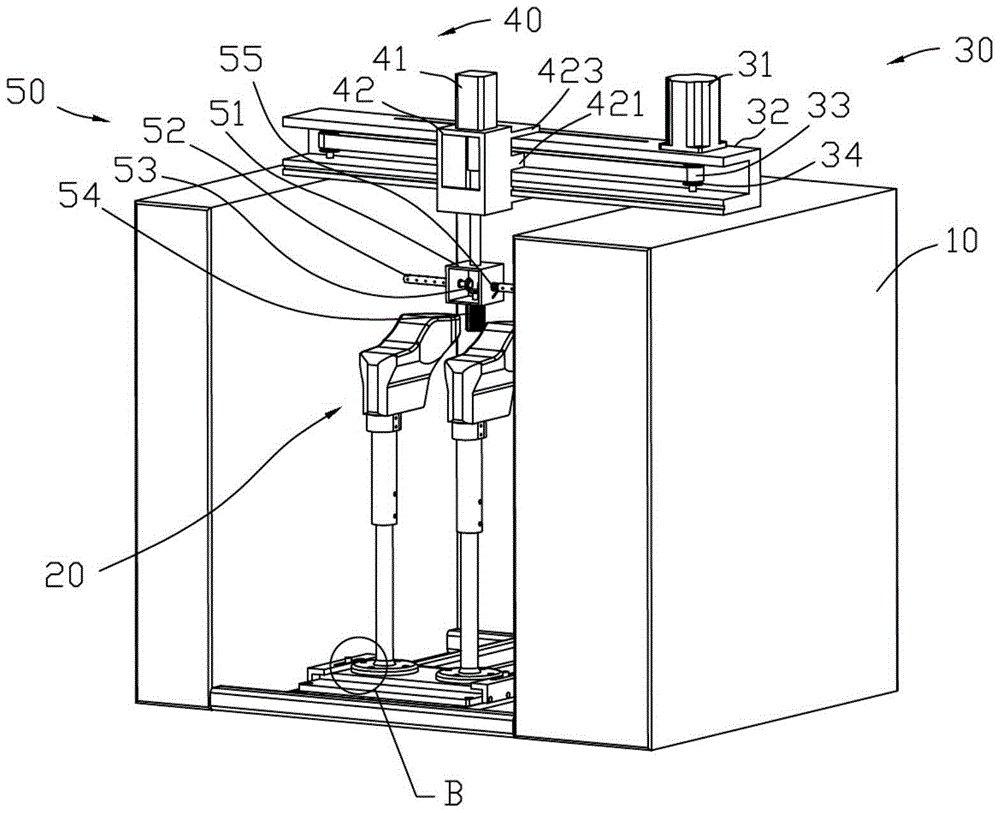

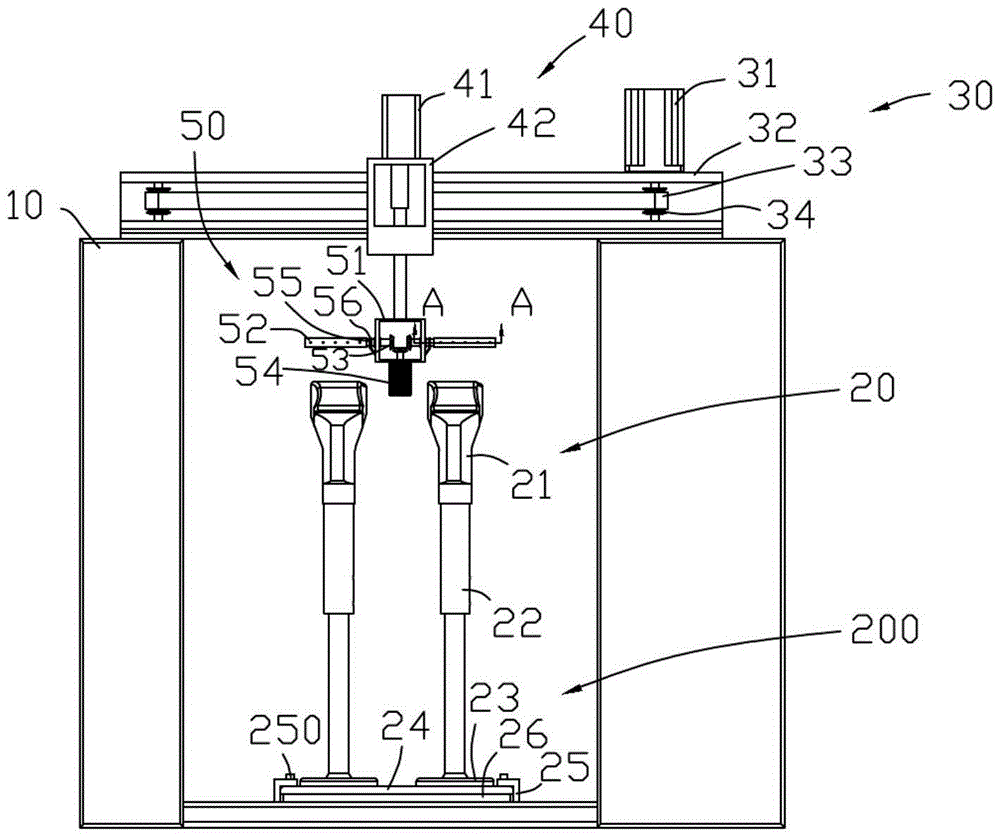

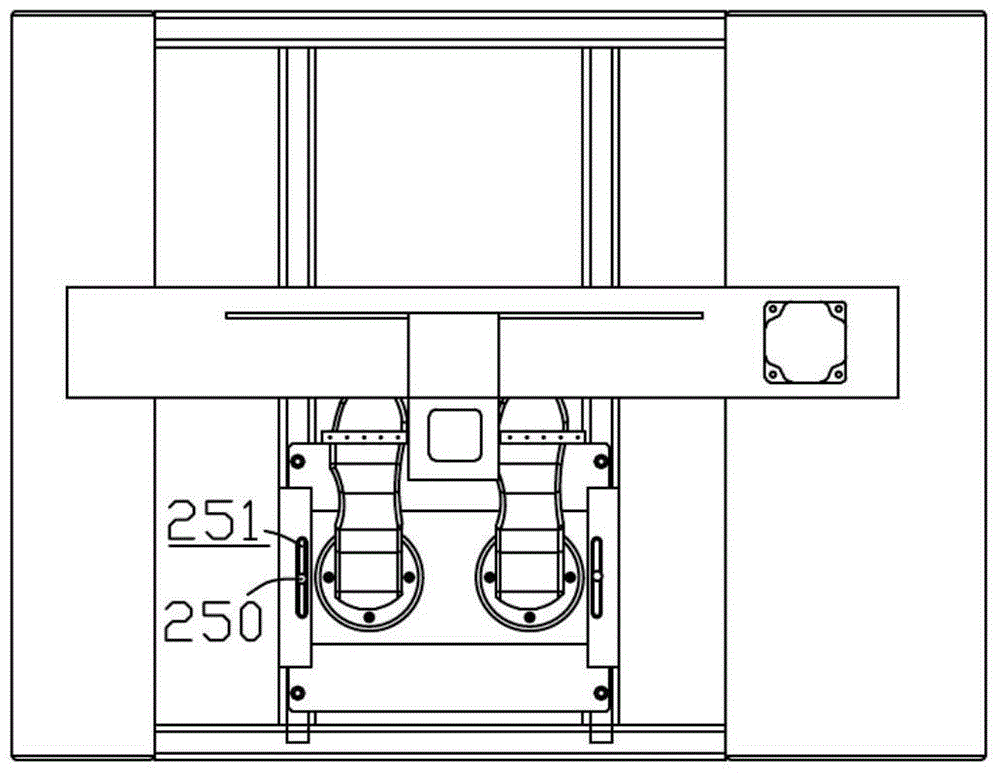

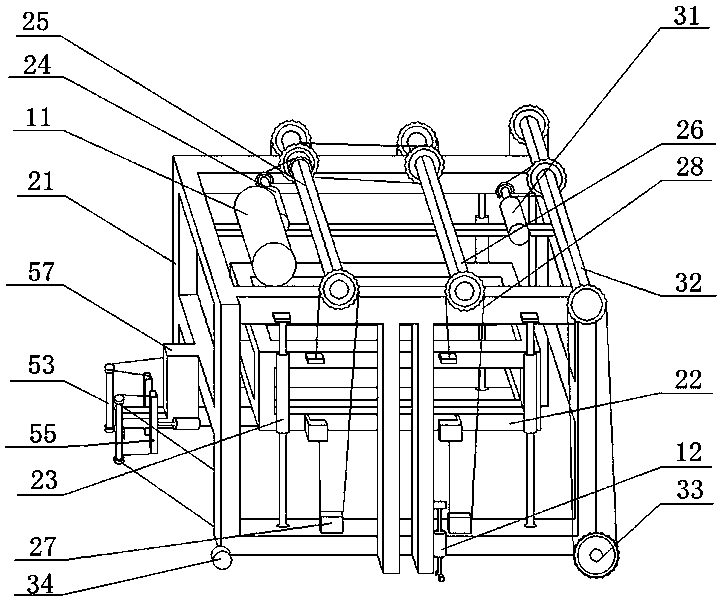

Full-automatic sole grinding machine

ActiveCN105193006AThe grinding process is inefficientHigh defective rateShoemaking devicesGrinding machinesEngineering

The invention discloses a full-automatic sole grinding machine comprising a frame, a shoe mold component, a cross adjustment component, a vertical adjustment component and a grinding component, wherein the shoe mold component is positioned between two frame plates; the grinding component is arranged above the shoe mold component and comprises two horizontal grinding rods and a vertical grinding motor; the upside of the grinding component is connected to the vertical adjustment component; the vertical adjustment component comprises a cylinder and a cylinder base, and the cylinder base is connected to an adjusting rack of the cross adjustment component in a sliding manner; and the cross adjustment component comprises an adjusting motor, two synchronous belt wheels and a synchronous belt. The cross adjustment component can be used for adjusting the horizontal position of the grinding component, and the vertical adjustment component can be used for adjusting the vertical position of the grinding component.

Owner:海门市创豪工业设计有限公司

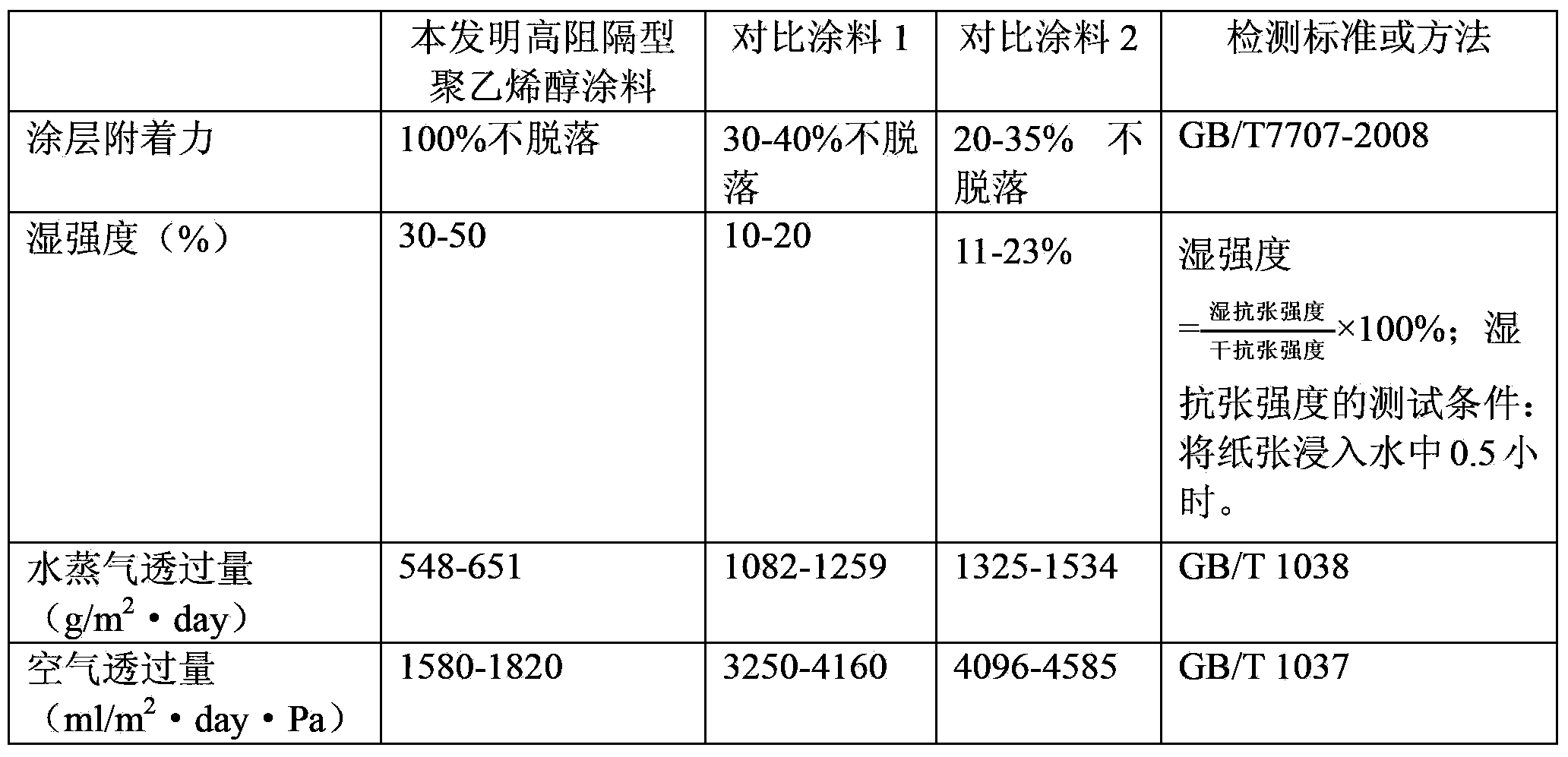

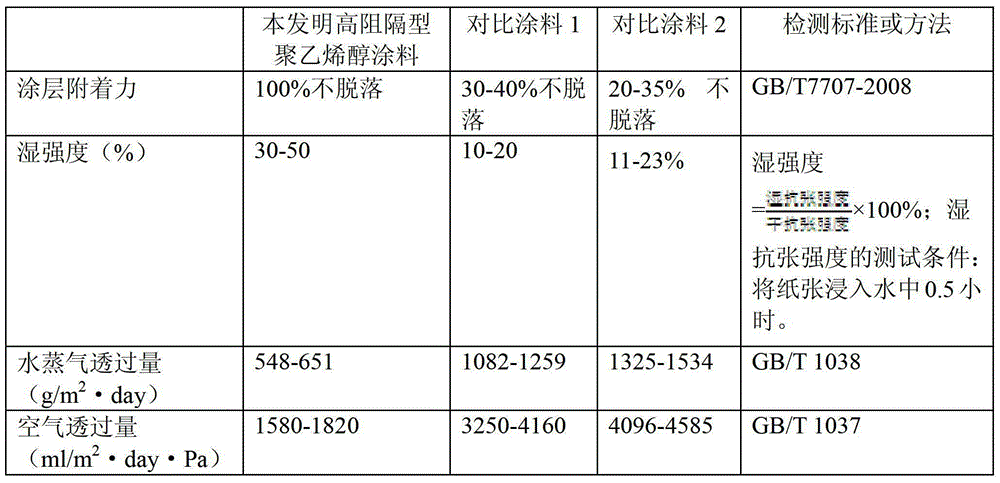

High-barrier polyving akohol coating for coating lined paper and preparation method thereof

ActiveCN103382677ASolve the problem of prone to paper breaksImprove wet strengthDefoamers additionPaper coatingHigh resistanceWet strength

The invention relates to high-barrier polyving akohol coating for coating lined paper. The coating comprises the following raw materials of, by weight, 12-16% of polyving akohol, 2.1-3.8% of amino resin, 0.01-0.015% of catalysts, 0.05-0.3% of wet strength agents, 2-4% of xylan, 0.1-0.25% of anti-blocking agents, 0.005-0.01% of antifoaming agents and 78-83% of deionized water. The invention further provides a preparation method of the high-resistance polyving akohol coating for coating the lined paper. The coating is directly coated on a lined paper substrate of 45-80g / m<2>, and has good adhesive force and barrier property. After the coated lined paper is wetted or soaked into the water, the tensile strength of the coated lined paper is higher than 30%. Trial results show that the coated lined paper can be completely applied to high-speed presses and packing machines.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

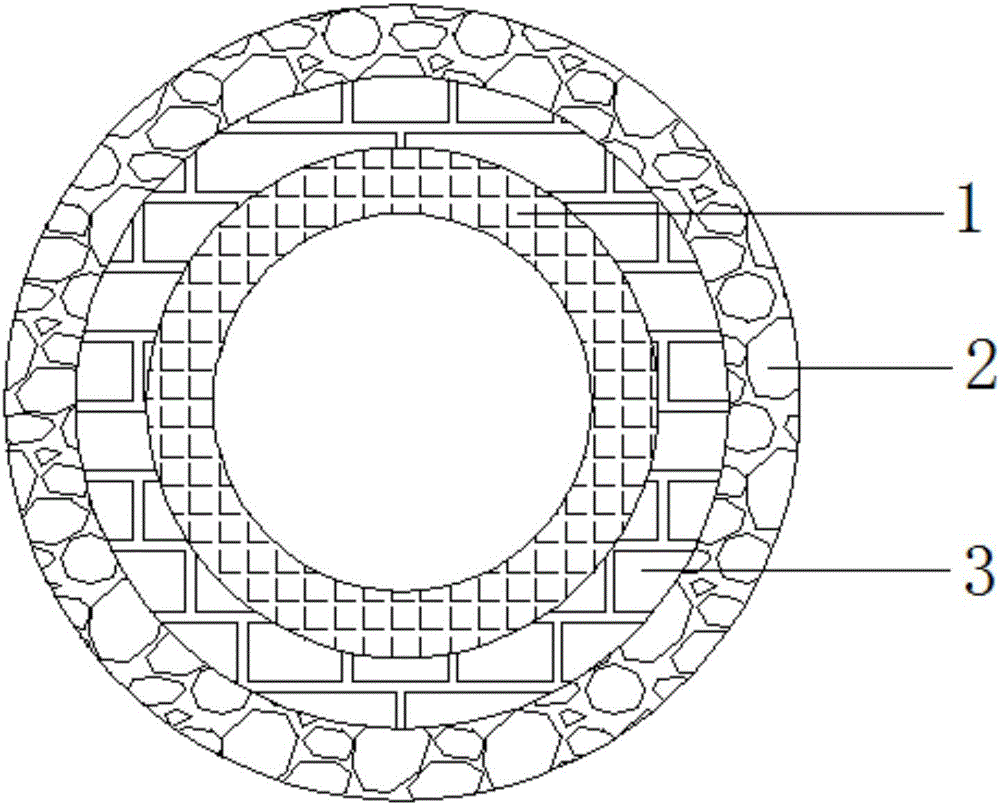

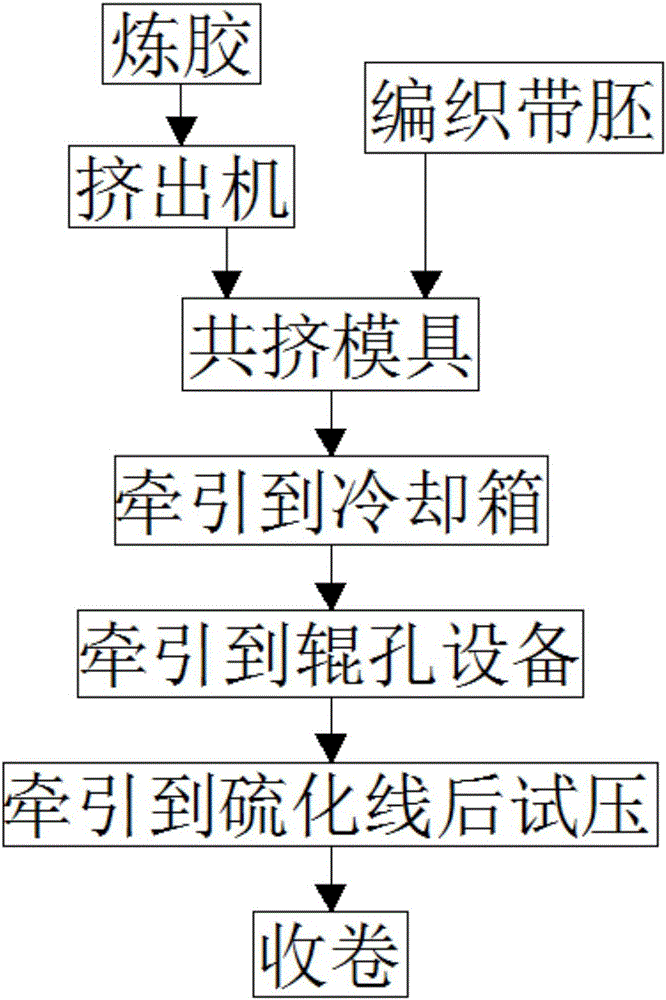

One-time formed rubber double-face rubber hose and process thereof

InactiveCN106626426AOvercoming the phenomenon of uneven wall thickness in stretchingOvercoming uneven wall thicknessTubular articlesRubber materialVulcanization

The invention discloses a one-time formed rubber double-face rubber hose and a process thereof in the technical field of rubber pipelines. The one-time formed rubber double-face rubber hose comprises an inner rubber layer. A reinforcement layer is arranged on the outer wall of the inner rubber layer. An outer rubber layer is arranged on the outer wall of the reinforcement layer. Through one or two extruders and a co-extrusion die, the inner rubber layer and the outer rubber layer are extruded on a strip blank once, the procedures that inner pipe extrusion is conducted, an inner pipe penetrates into the strip blank, outer pipe extrusion is conducted, and an outer pipe penetrates into a rolled hollow semi-finished product are completed, and the procedure of strip overturning is omitted; and then the one-time extruded semi-finished product is pulled to pass a cooling water tank area and hole rolling equipment and is pulled to a vulcanization area for vulcanization, and after vulcanization, direct pressure testing and rolling are conducted. The automation degree and production efficiency are high, the productivity is large, the defective rate is low, and the defect of nonuniform partial stretching wall thickness of a rubber hose due to pipe penetrating is overcome. Due to the fact that through the process, the inner rubber layer and the outer rubber layer are extruded once, rubber materials are extruded from outside to inside, the inner rubber layer and the outer rubber layer are connected with each other in strip blank gaps through rubber threads, the integration is high, and the service life is long.

Owner:ZHONG YU HOSES TECH CO LTD

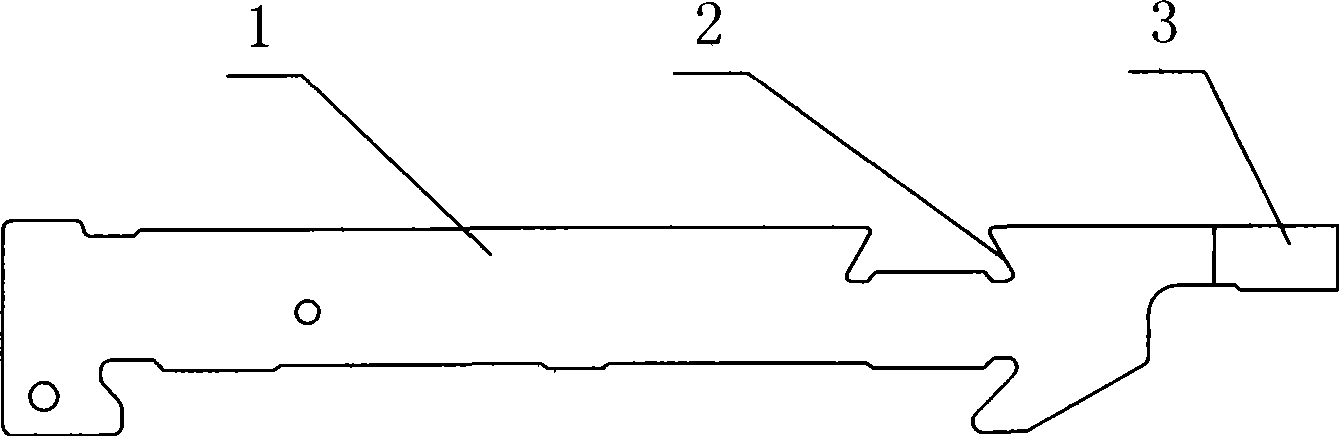

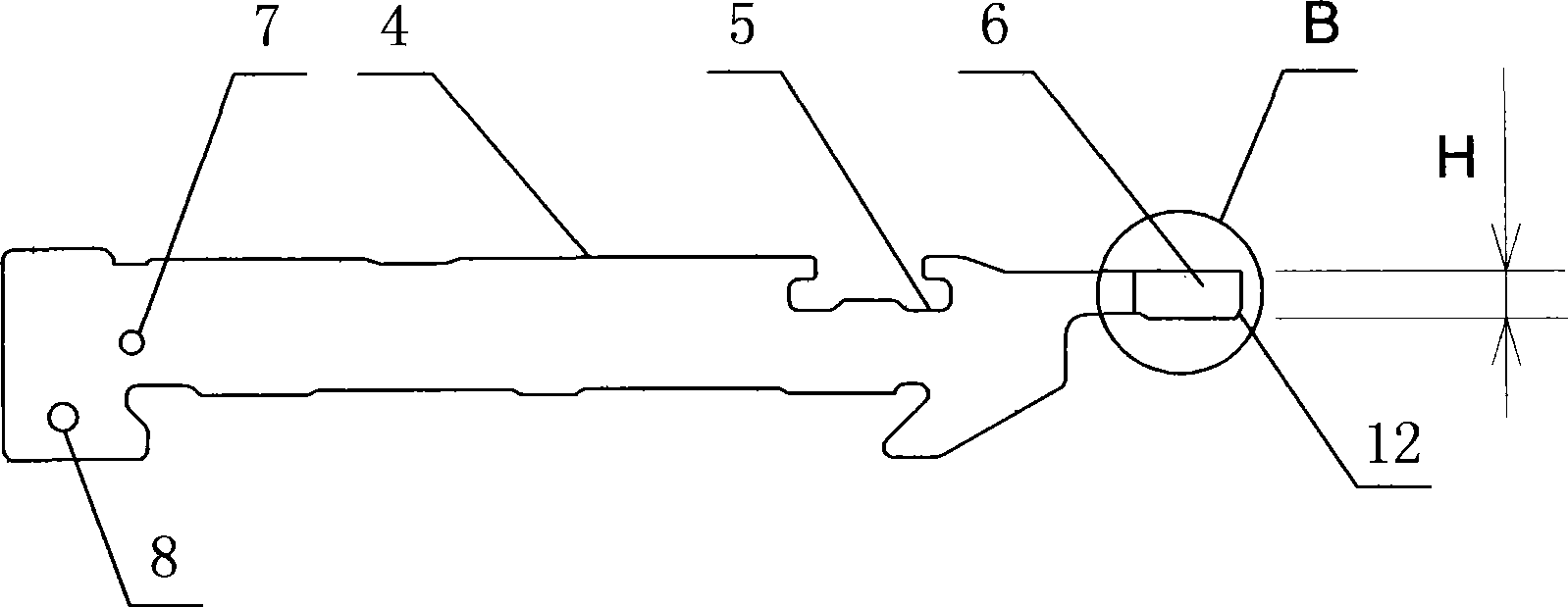

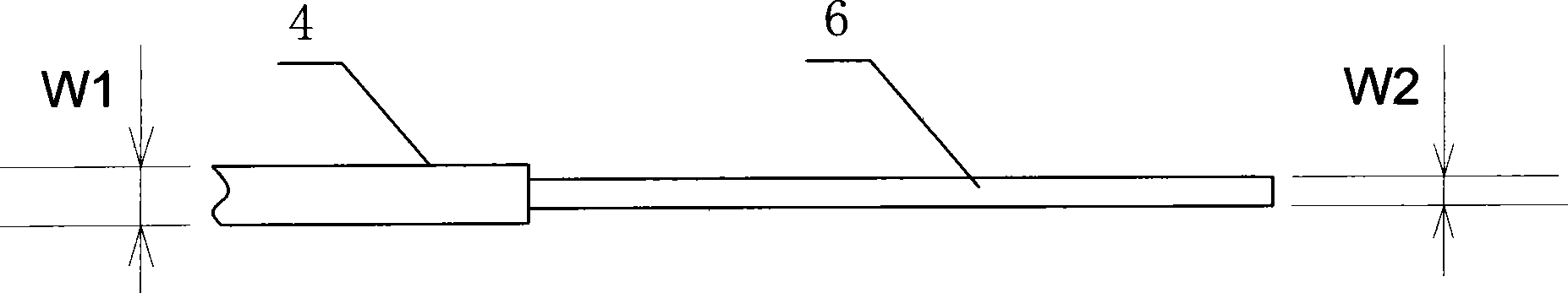

Needle bed inlaid piece and method of processing the same

InactiveCN101435132AEasy Press NeedleReduce generationWeft knittingWarp knittingPunchingBiochemical engineering

The invention discloses a neilsbed splice piece and a processing method thereof, belonging to the technical field of computer glove knitting machine spare and accessory parts. The neilsbed splice piece comprises a body, the upper end of which is provided with a groove with straight flanges; furthermore, the body is made by using SK5 carbon tool steel. The processing method of the neilsbed splice piece comprises the following steps of: blanking, stamping, notching, punching, wheel head grinding and head decorating. The neilsbed splice piece has high precision and high quality, the processing method of the neilsbed splice piece has simple working procedure, high work efficiency, low cost, and high product precision and quality.

Owner:SHAOXING QIANGSHENG PRECISION MACHINERY

Holding ageng for Chinese sauerkraut material and its use method

The invention discloses a uniting agent for vegetarian stuffing and a use method thereof, which relate to a uniting agent for stuffing and a use method thereof. The invention solves the problems that in the prior uniting agent for the vegetarian stuffing, the single use of egg white can improve the defective rate of products, and the use of edible gum affects the taste of consumers and the flavor of food. The uniting agent for the vegetarian stuffing consists of powder glue stuff and egg white; and the use method of the uniting agent for the vegetarian stuffing comprises the following steps: the powder glue stuff is added first and stirred, and then the egg white is added and stirred to obtain the vegetarian stuffing added with the uniting agent. The uniting agent for the vegetarian stuffing has the advantages of reducing the defective rate of the products and not affecting the flavor of stuffing and the taste of the consumers after the uniting agent is added.

Owner:HARBIN MAOMAO FOOD

Sole grinding machine

InactiveCN101518382ASame sanding qualityIncrease productivityShoemaking devicesPulp and paper industryGrinding wheel

The invention relates to a sole grinding machine which is characterized by comprising a stand. The stand is provided with a shoe clip fixed desk; a plurality of sole fixed clips are fixed on a desktop of the shoe clip fixed desk; and a sole grinding device is fixed on the stand and is positioned above the sole fixed clips. The shoe fixed clips are formed by brackets, shoe sleeves and fixed clips. Shoe sleeve heads and shoe sleeve heels are connected together through a length adjustment device; the shoe sleeve heels and the brackets are connected together through a height adjustment device. The fixed clips are fixed on the brackets, the fixed clips are provided with shoe clip fixed rods and clip sleeves, and the shoe sleeves are arranged on the middle of the fixed clips. An upper lifting cylinder and a lower lifting cylinder are respectively arranged on both sides of the bracket of the grinding device of the shoe sole grinding machine, and the top end of a cylinder shaft supports against the lower end of a movable bracket. The lower end of the movable bracket is connected with a controller, and the lower end of the controller is connected with a plurality of electric grinding wheels. The grinding machine can grind a plurality of soles at the same time, realizes mechanized grinding of soles, enhances the production efficiency and ensures that the grinding quality of all shoes are same.

Owner:沈刚 +1

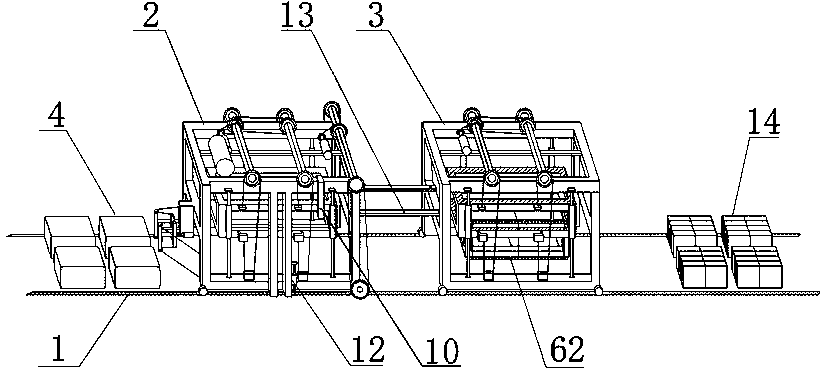

Integral movable cutting device with adjustable interval between cutting wires

PendingCN107696299AAvoid operating errorsIncrease productivityMetal working apparatusStone-like material working toolsEngineeringManufacturing line

The invention provides an integral movable cutting device with the adjustable interval between cutting wires. The integral movable cutting device comprises two sliding rails arranged in parallel, a first cutting machine, a second cutting machine and a connecting rod, wherein the first cutting machine is used for cutting upper and lower end faces and side end faces of self-heat-preserving buildingblock blanks and carries out slitting in the parallel direction of the side end faces, and the second cutting machine is used for cutting front and rear end faces of the self-heat-preserving buildingblock blanks and carries out slitting in the parallel direction of the third end face. The two ends of the connecting rod are fixedly connected with the first cutting machine and the second cutting machine correspondingly. According to the movable cutting device, a wetting method is adopted for cutting, one traveling mechanism can be shared, the production efficiency is improved greatly, the laborcost is reduced, the labor intensity is low, the interval between the cutting wires is adjustable, and practicability and operability of the production line are improved greatly. According to the movable cutting device, one-person operation can be achieved completely, moreover, no dust is generated in the production process, and the movable cutting device is consistent with the aim of enterprisesto build green environment-friendly factories.

Owner:许昌五星实业有限责任公司

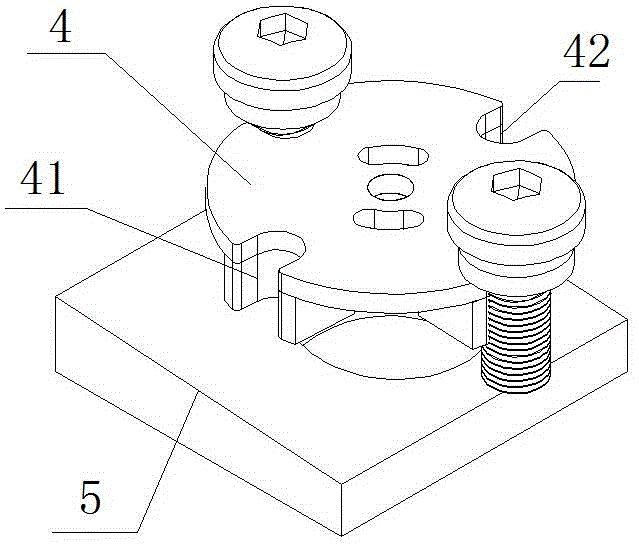

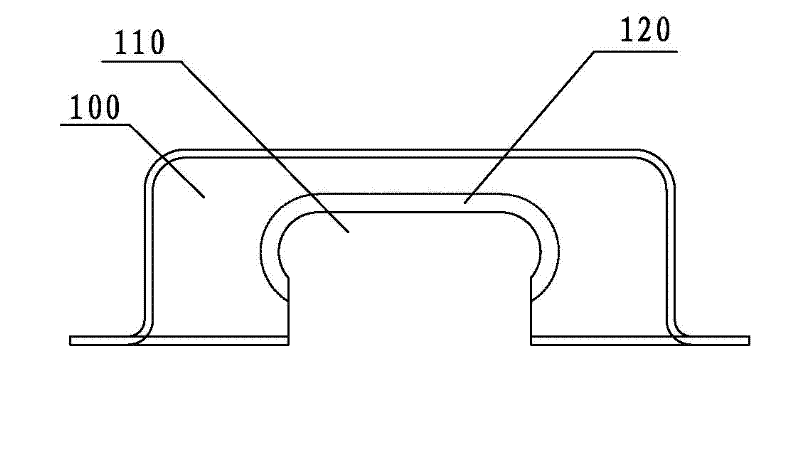

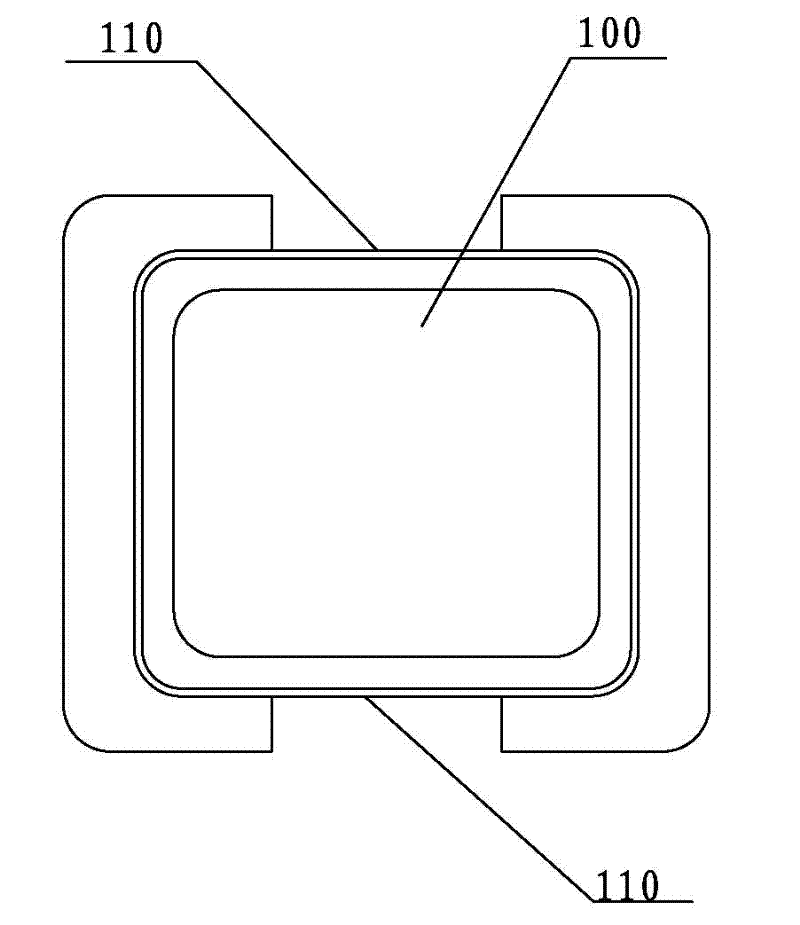

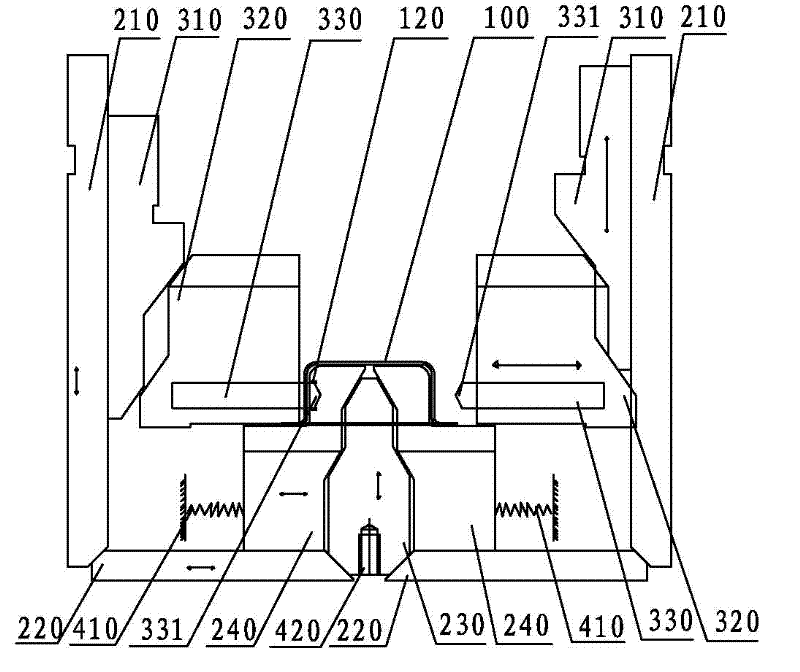

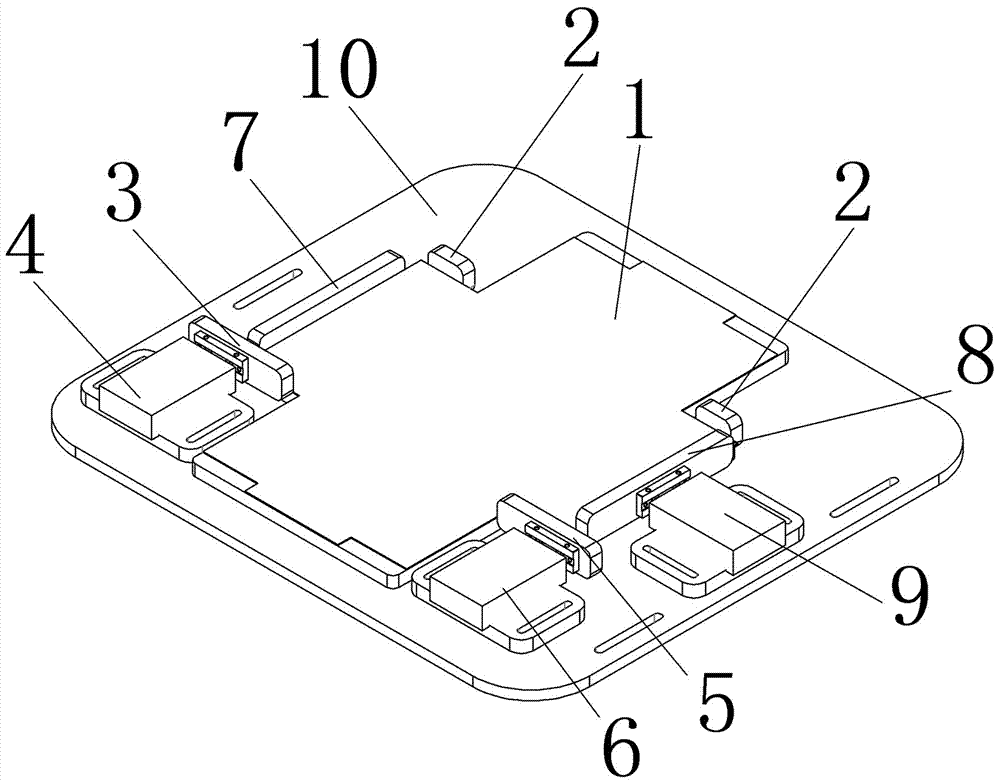

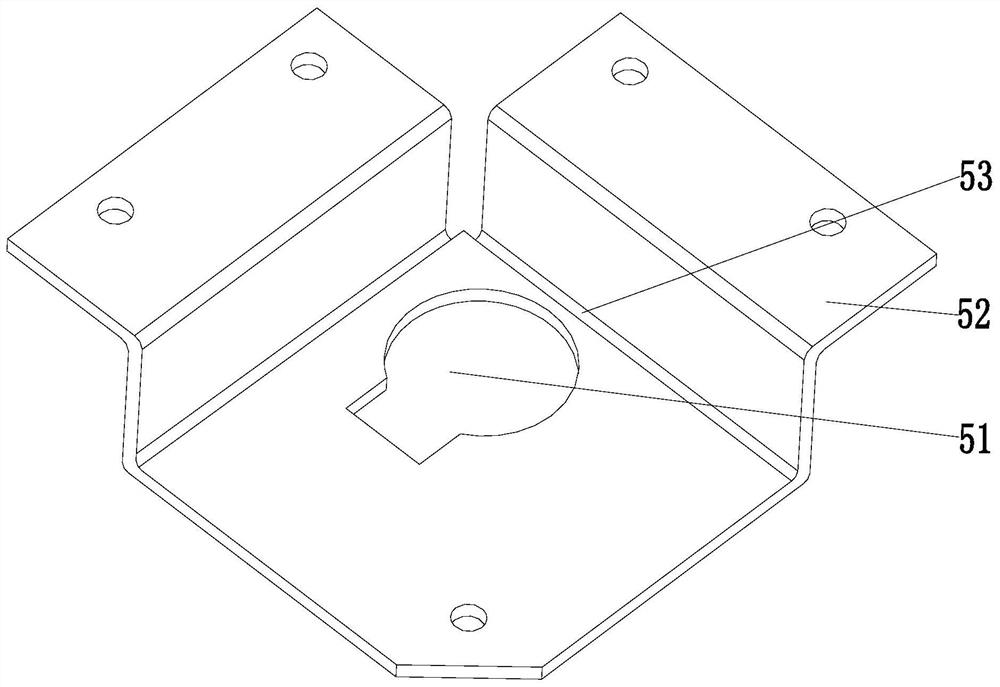

Integrated structure of double-side punching and double-side hole flanging of progressive die for double-hole shielding cover

ActiveCN102266890AReduce one stationReduce design and manufacturing costsShaping toolsPerforating toolsPunchingStructural engineering

The invention relates to the technical field of moulds and in particular relates to a double side punching-hole and double side punching-hole flange integrated structure for a double-hole shielding cover progressive mould, and the integrated structure provided by the invention comprises through holes, flanged discharging slide blocks, flanged discharging slide block limiting plates and flanged discharging slide block resetting devices respectively arranged on two sides of a discharging plate in turn, wherein slide block third-level punches in lower flanged moulds pass through the through holes; the flanged discharging slide blocks are correspondingly arranged inside the flanged discharging slide block punches; side flanged punches are arranged on the flanged discharging slide blocks; the ends, which are close to the shielding cover, of the side flanged punches are of a blade-shaped structure; side flanged punching-holes are formed on the flanged discharging slide block limiting plates; and the side flanged punching-holes are matched with the side flanged punches. Double side punching-hole and double side punching-hole flange are finished in a same process, thereby reducing a station on the mould, lowering the designing and manufacturing cost of the mould, promoting the production efficiency and reducing the defective percentage.

Owner:DONGGUAN DAZHONG ELECTRONICS

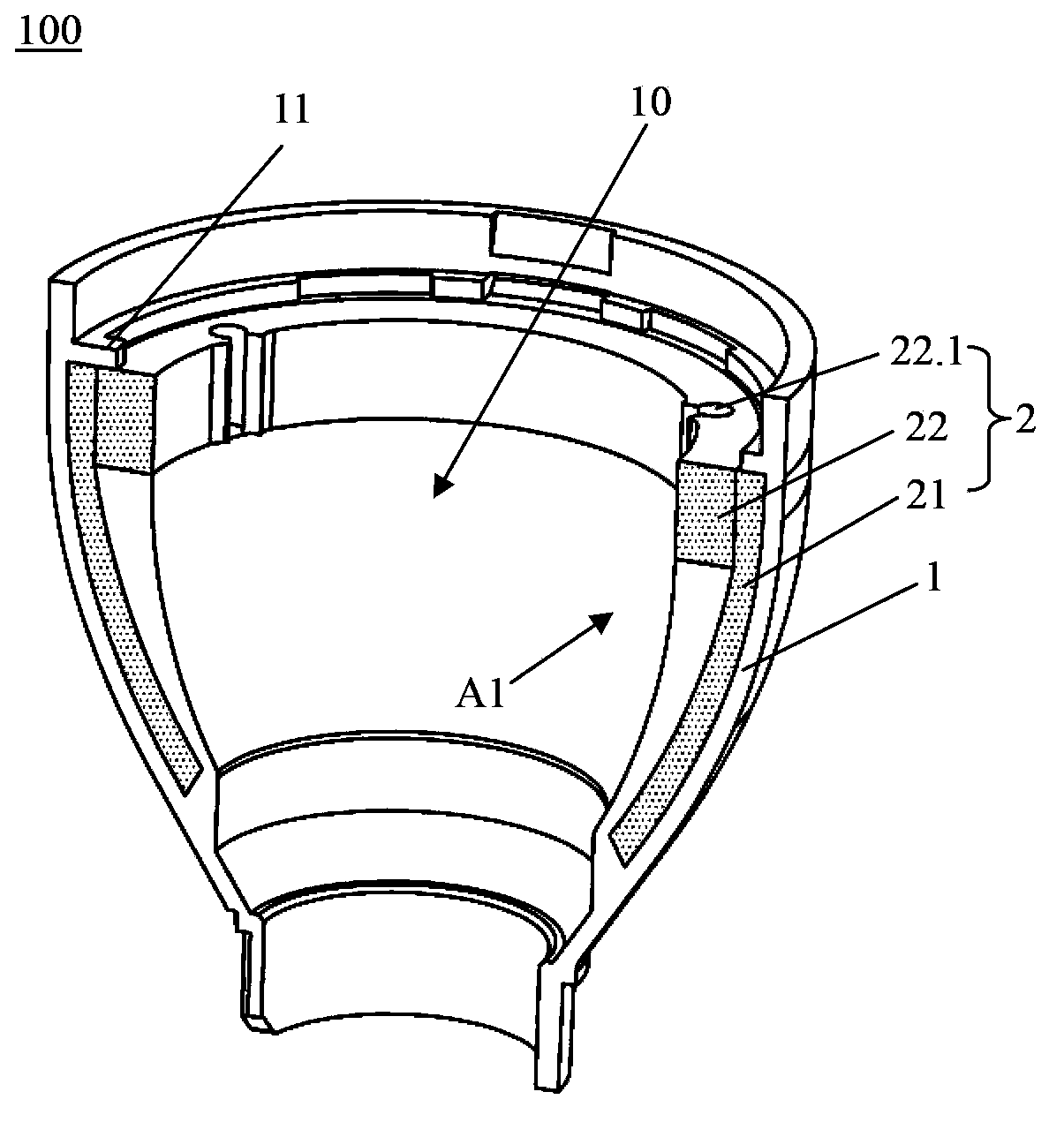

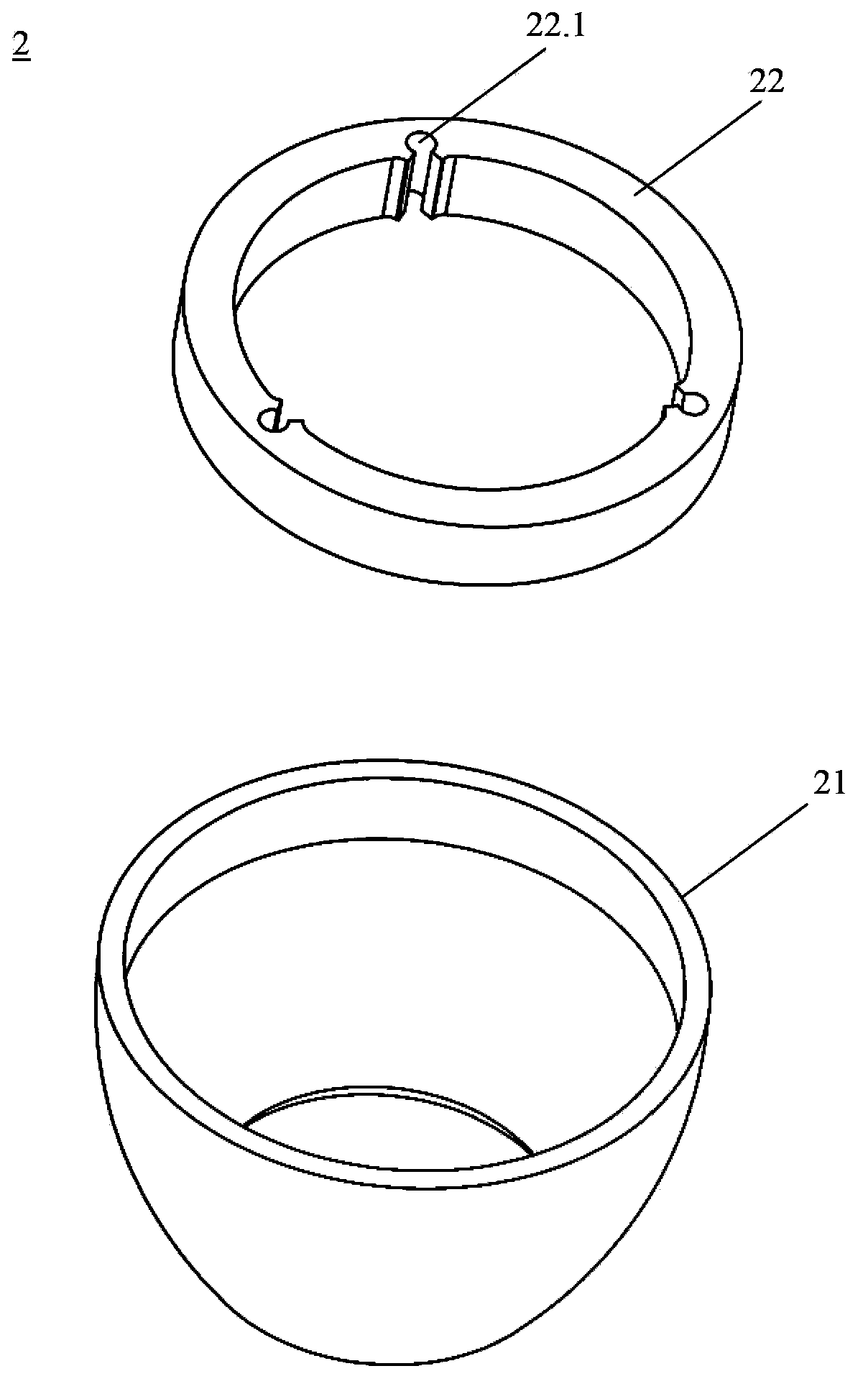

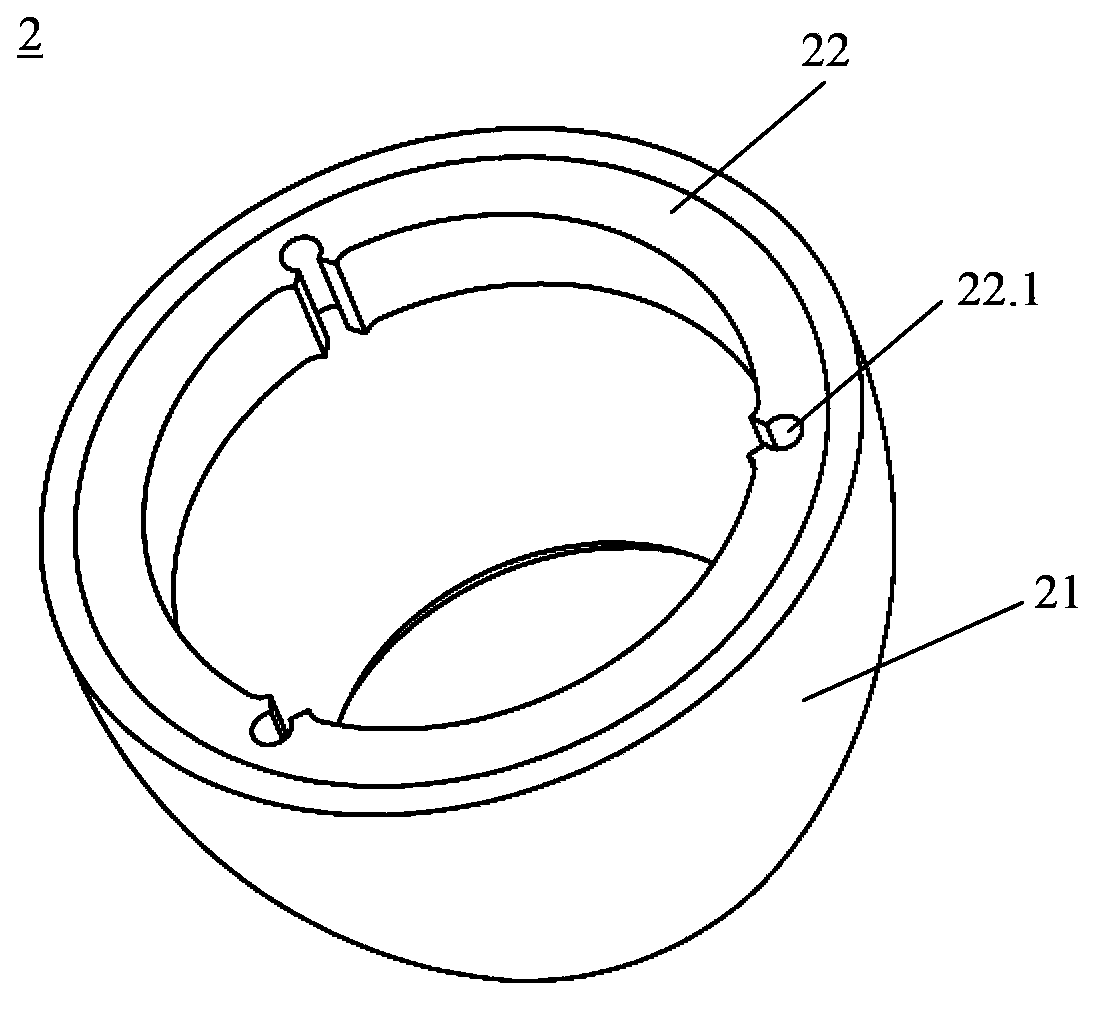

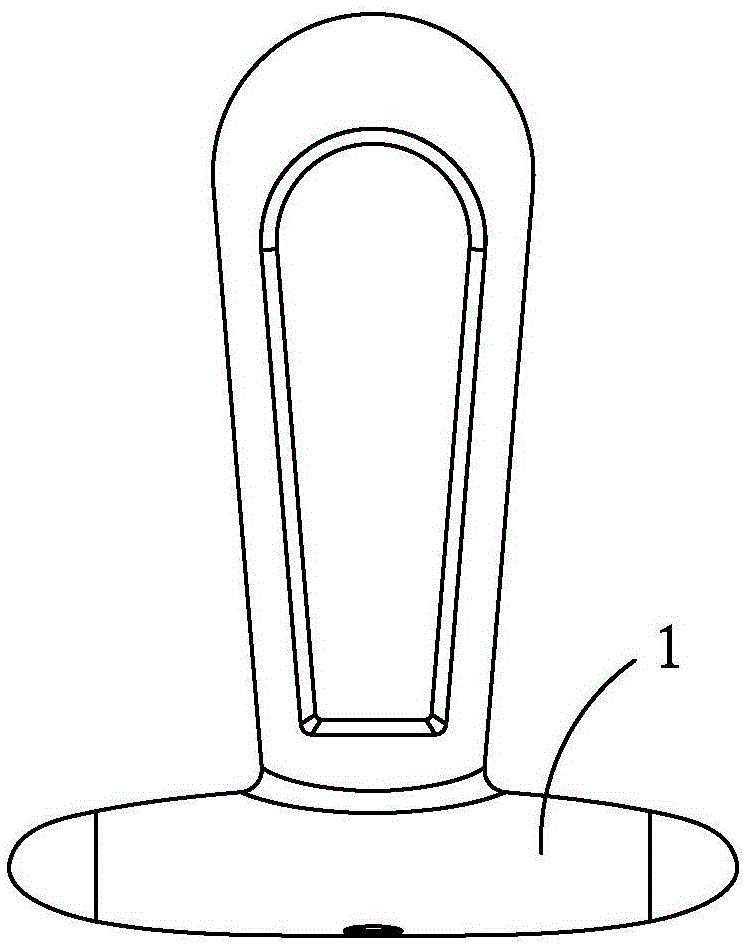

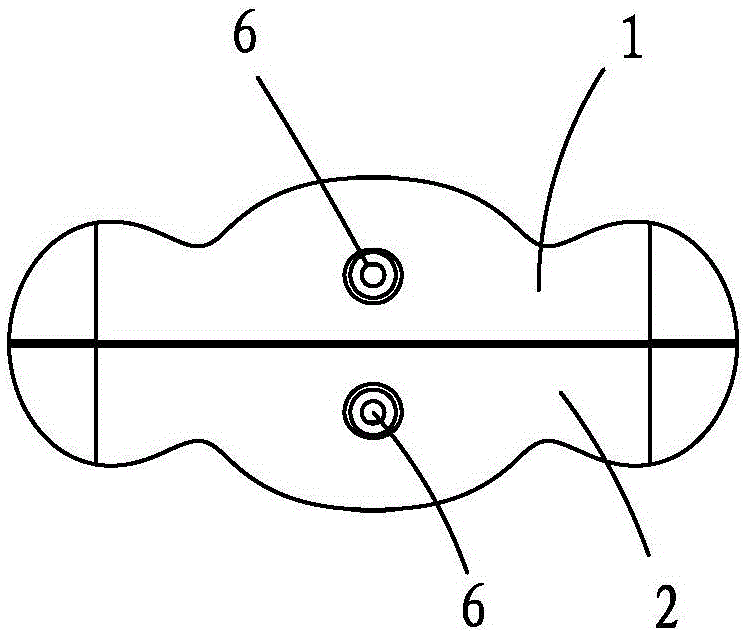

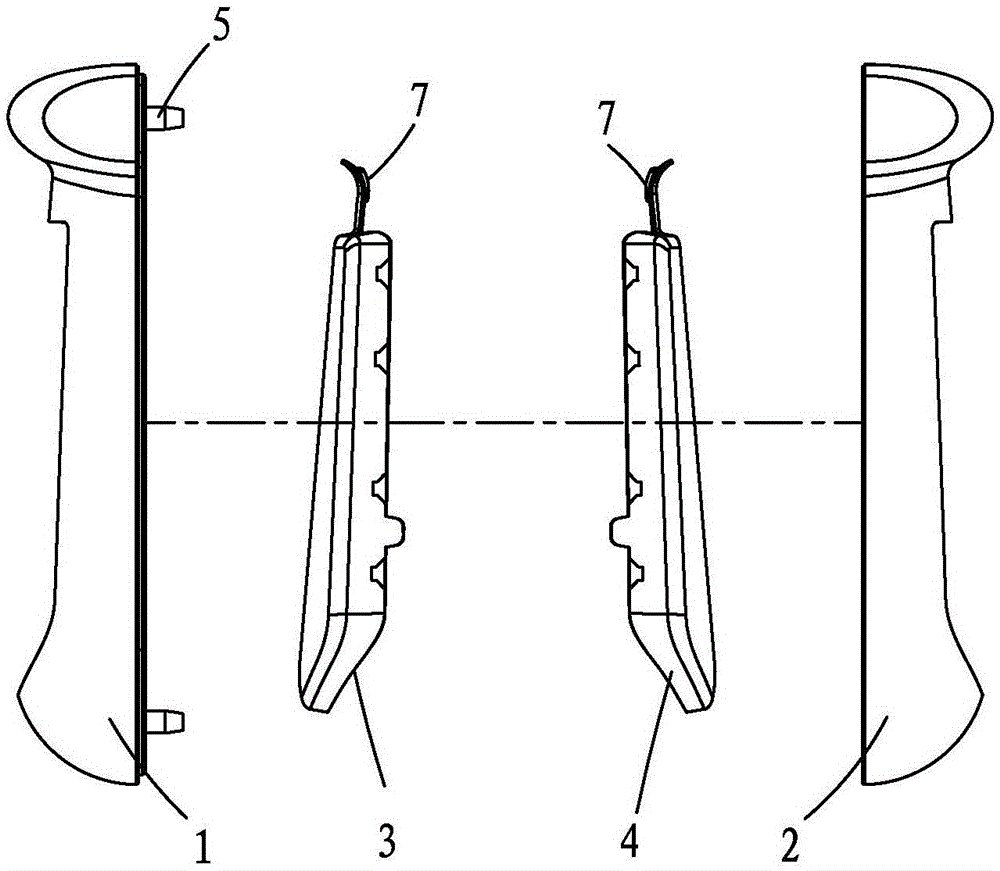

Lamp shell, manufacturing method thereof and lighting device with lamp shell

ActiveCN104235748AGuaranteed thermal conductivityMeet the requirements of the applicationLighting heating/cooling arrangementsProtective devices for lightingEffect lightLamp shell

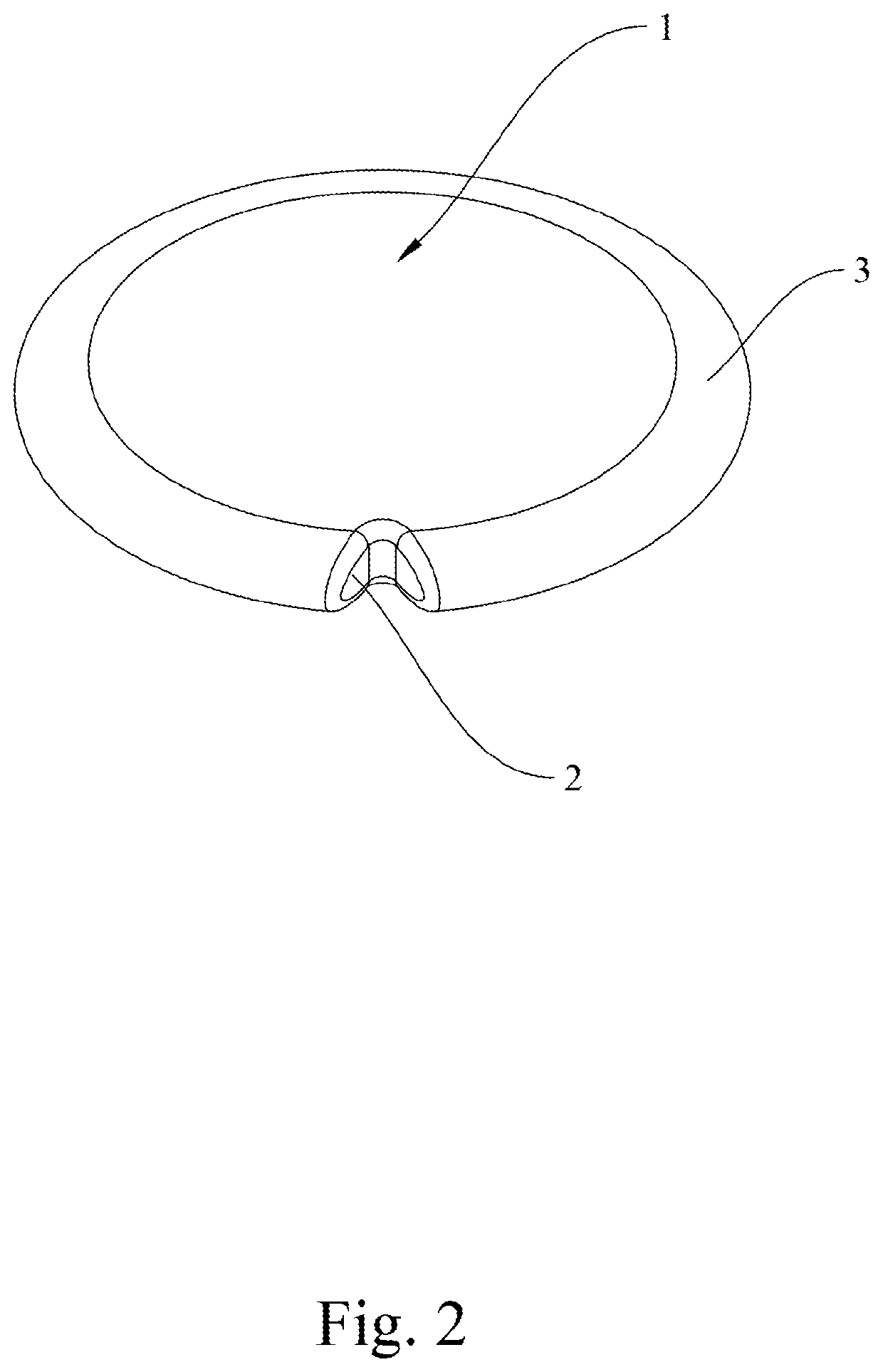

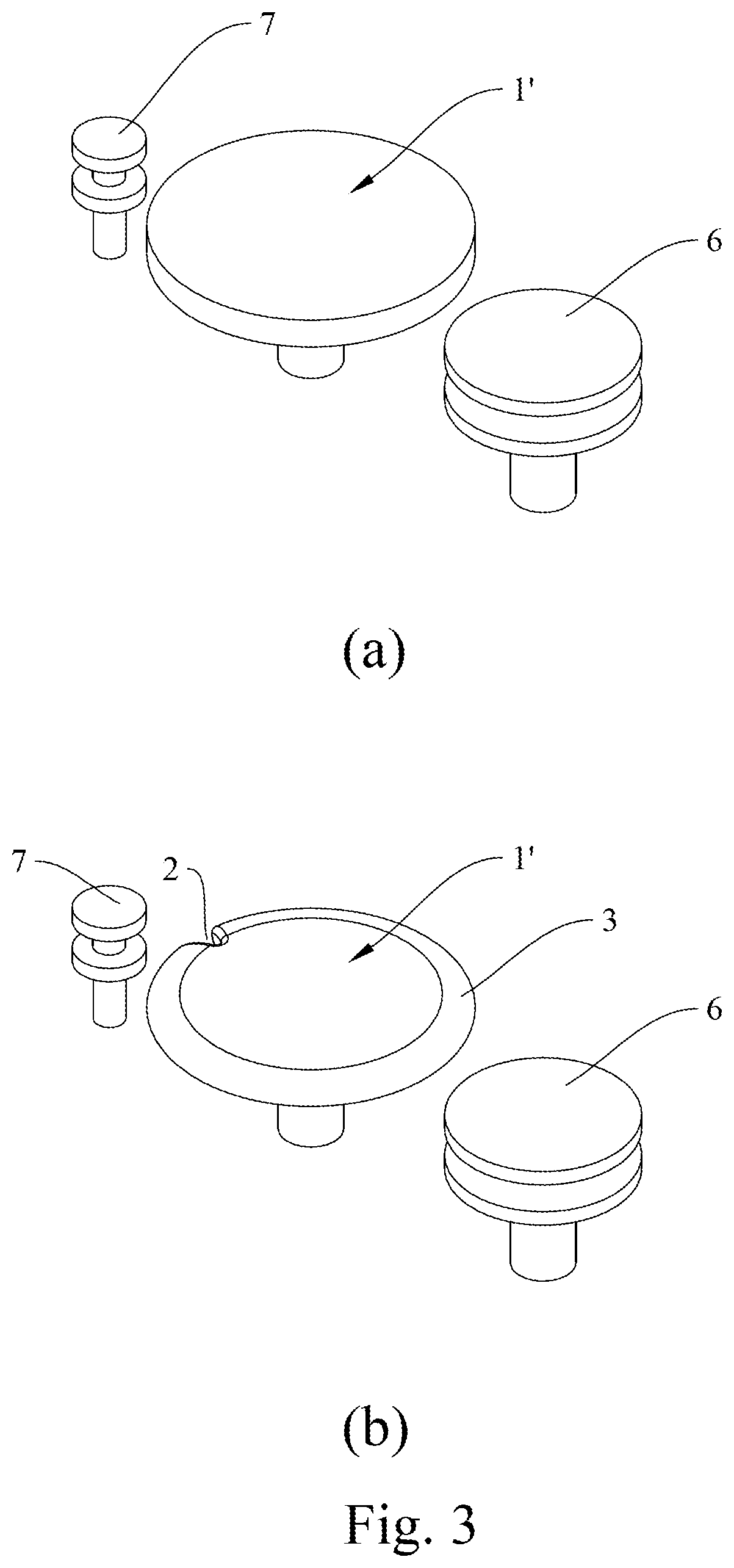

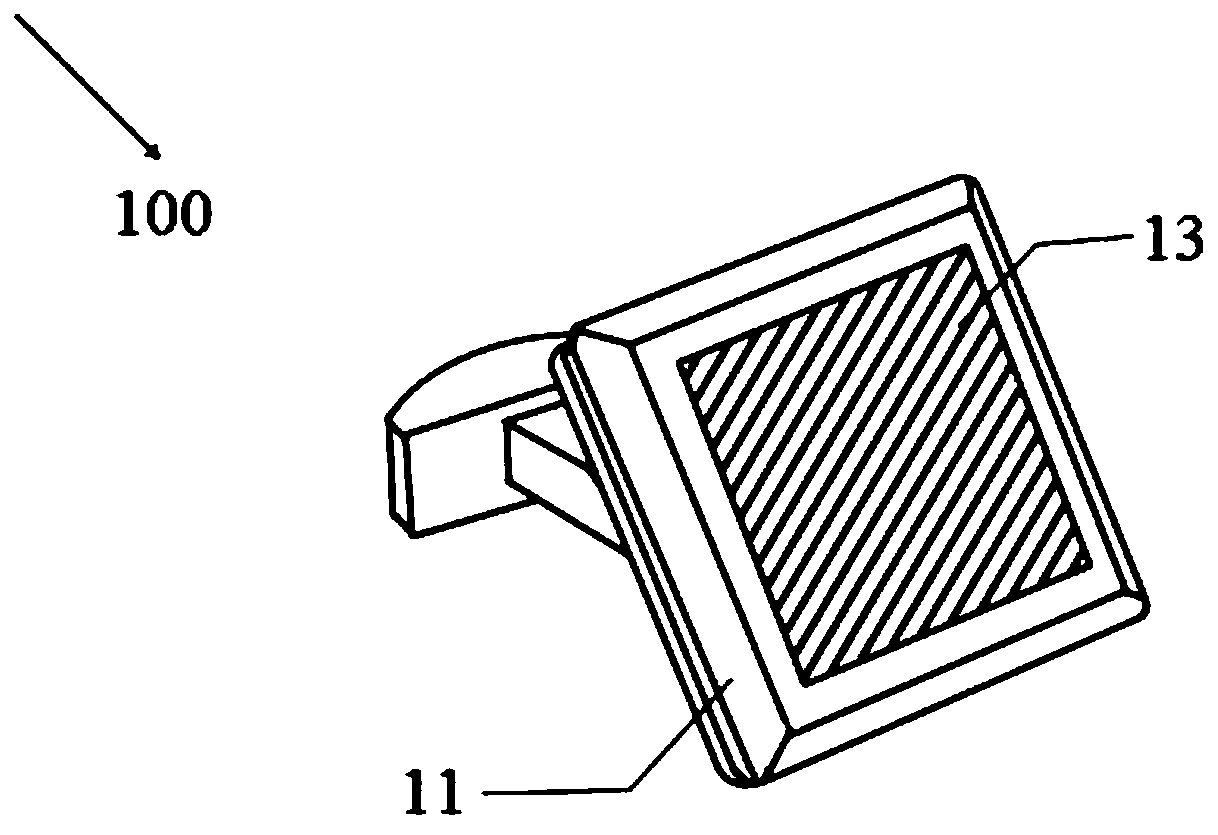

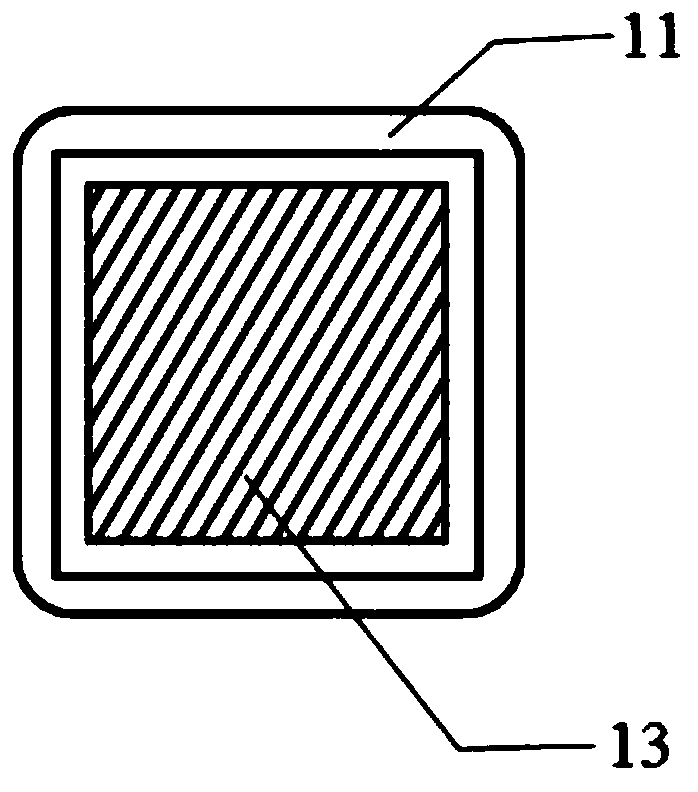

The invention relates to a lamp shell (100) of a lighting module. The lamp shell (100) comprises a first shell body (1) and a second shell body (2) which are made by different materials. The lamp shell (100) is characterized in that the second shell body (2) comprises a body part (21) and an assembling part (22) which are in heat contact, the second shell body (2) is integrally embedded into the first shell body (1) and in heat contact with the same, and the assembling part (22) and the body part (21) are mounted together. In addition, the invention further relates to a manufacturing method of the lamp shell and a lighting device with the lamp shell.

Owner:LEDVANCE GMBH

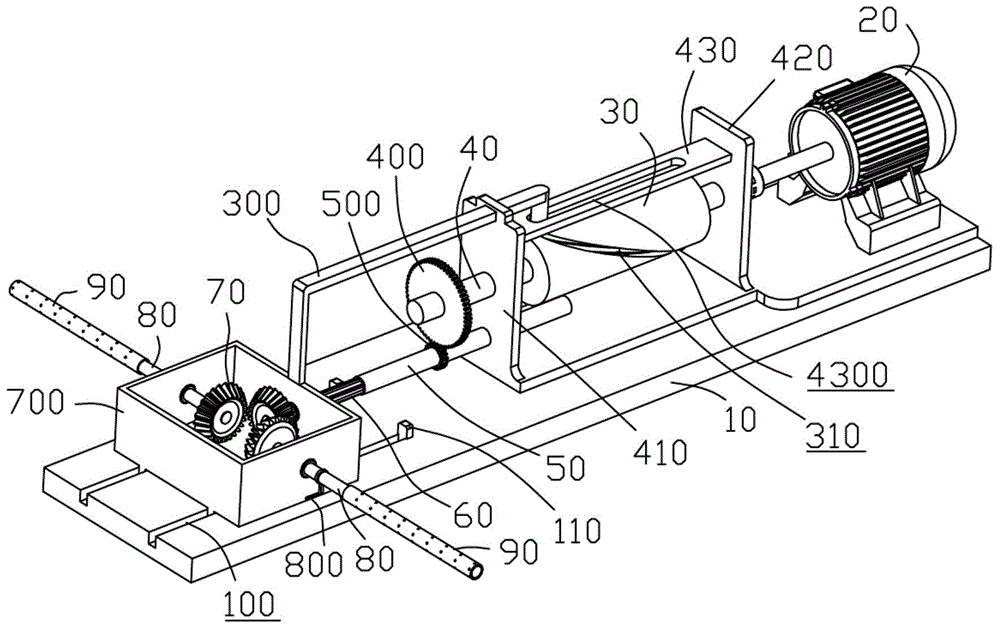

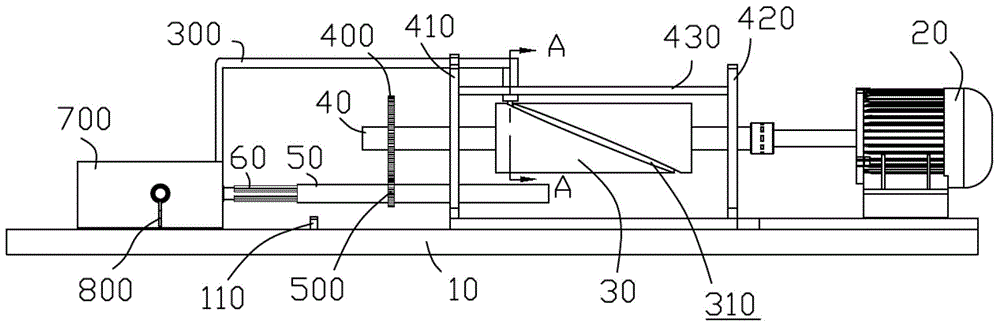

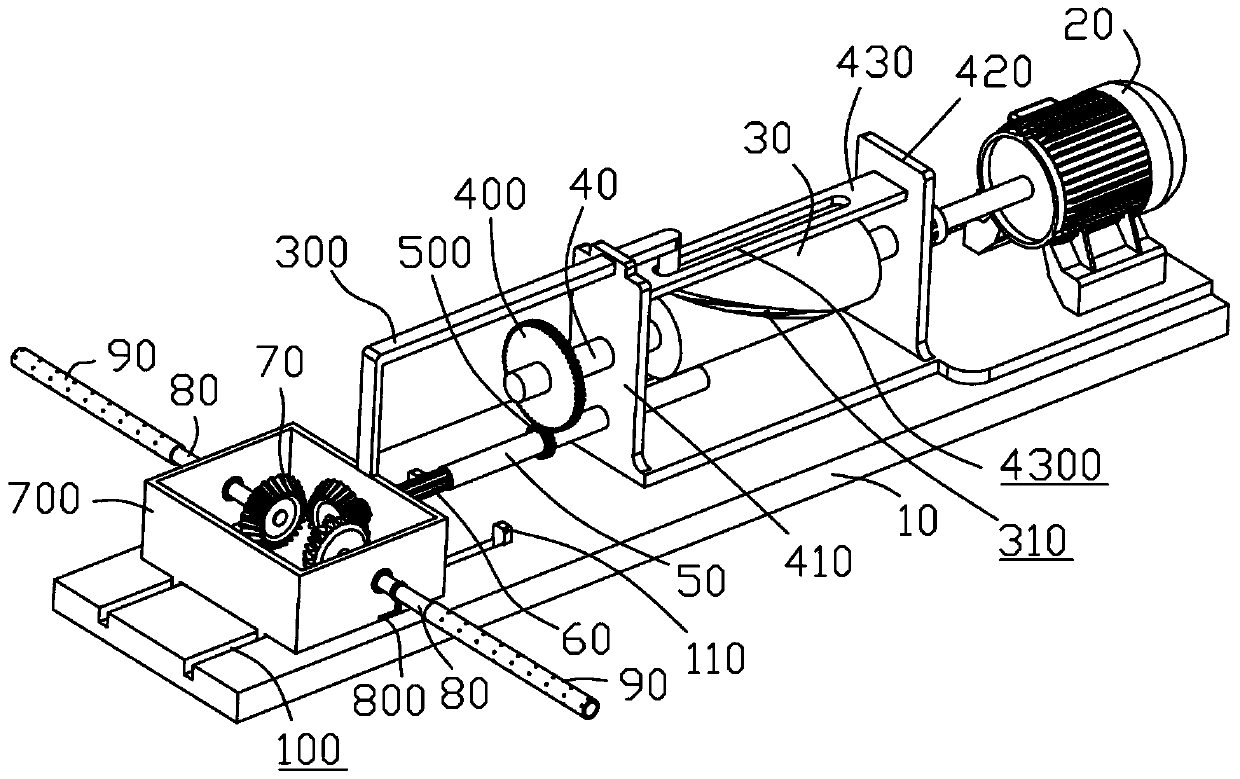

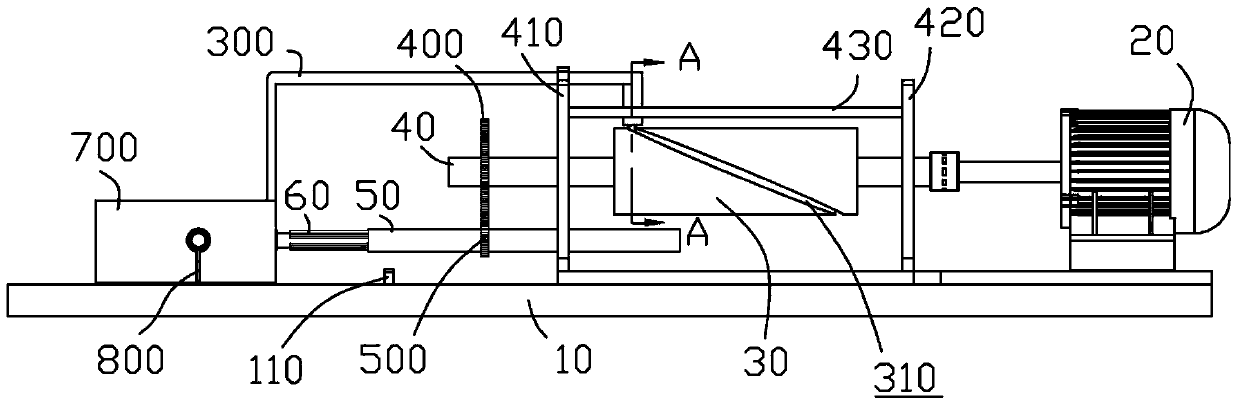

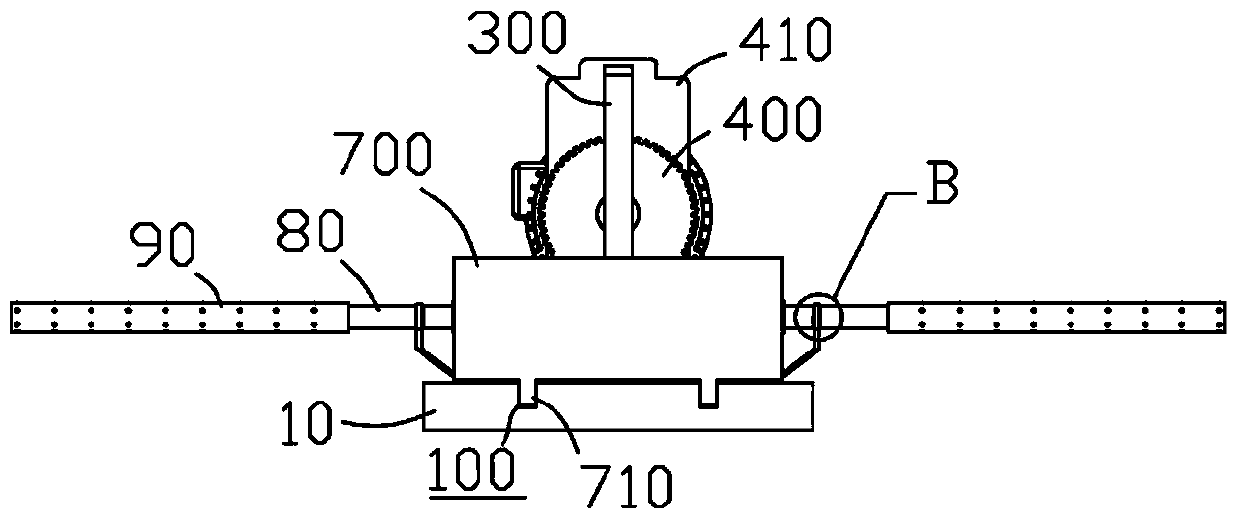

Sole grinding machine

ActiveCN105193007AThe grinding process is inefficientHigh defective rateShoemaking devicesGrinding machinesGear wheelEngineering

The invention discloses a sole grinding machine comprising a base, a motor, a rotary drum, a rotary drum shaft, an inner spline shaft, an outer spline shaft, a box body, grinding rods and grinding rod shafts, wherein base is positioned at the very bottom of the equipment, and the other components are positioned on the base; the motor is arranged at a tail part above the base and is connected with the rotary drum shaft; the rotary drum sleeves outside the rotary drum shaft; a rotary groove is formed on the surface of the rotary drum and is a closed circular arc notch; one end of a connecting rod is inserted into the rotary groove, and the other end of the connecting rod is connected to the box body; the inner spline shaft is positioned below the rotary drum shaft, and a small gear wheel is arranged on the inner spline shaft; a big gear wheel is arranged on the rotary drum shaft; a bevel gear is arranged at the tail end of the outer spline shaft; and the grinding rod shafts are arranged by penetrating two sides of the box body, and the grinding rods are fixed outside one ends of the two grinding rod shafts. The sole grinding machine disclosed by the invention is simple and compact in structure and high in transmission efficiency, and can be used for automatically grinding two pairs of soles at the same time.

Owner:永州远威运动鞋业有限公司

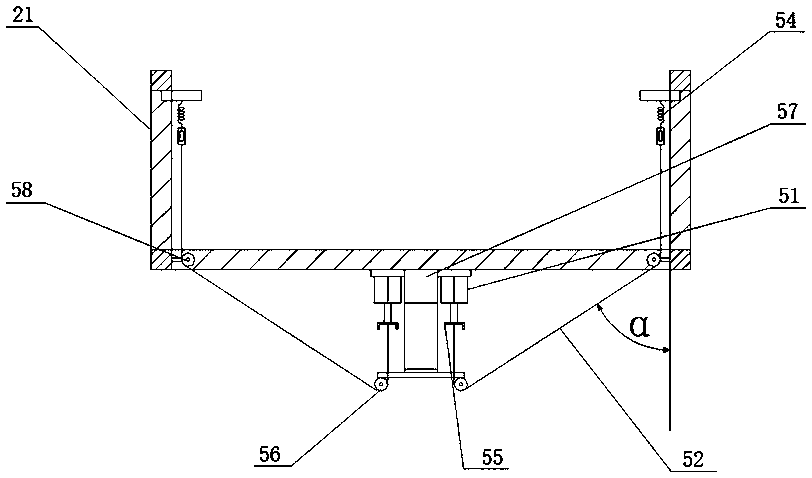

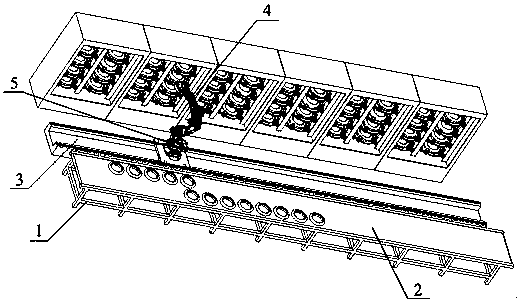

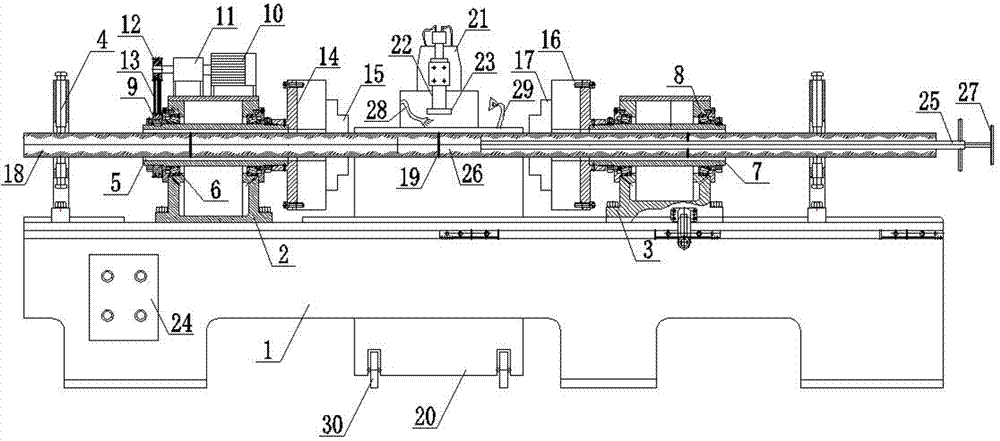

Automatic vulcanization line and vulcanization method for tires

The invention discloses an automatic vulcanization line for tires, belongs to the technical field of tire production and mainly relates to the automatic vulcanization line and a vulcanization method for the tires. The automatic vulcanization line for the tires comprises an assembly line, a robot feeding / discharging system and a vulcanizing machine, wherein the assembly line comprises a supportingdevice and a transmitting device arranged at the upper part of the supporting device; the robot feeding / discharging system comprises a ground walking track, a tire clamping mechanism and a robot body;green tires on the transmitting device are transferred to the vulcanizing machine through the tire clamping mechanism for vulcanizing. The invention also discloses the vulcanization method for the tires. The vulcanization method comprises three steps of a green tire feeding step, a gripping feeding step and a vulcanizing step. The automatic vulcanization line disclosed by the invention has the advantages of high repeated positioning precision, flexible joint, higher adaptability, compact structure, low cost, easiness in maintenance and high yield; the requirements of equipment on the positionof the vulcanizing machine and the ground levelness are reduced.

Owner:江苏金猫机器人科技有限公司

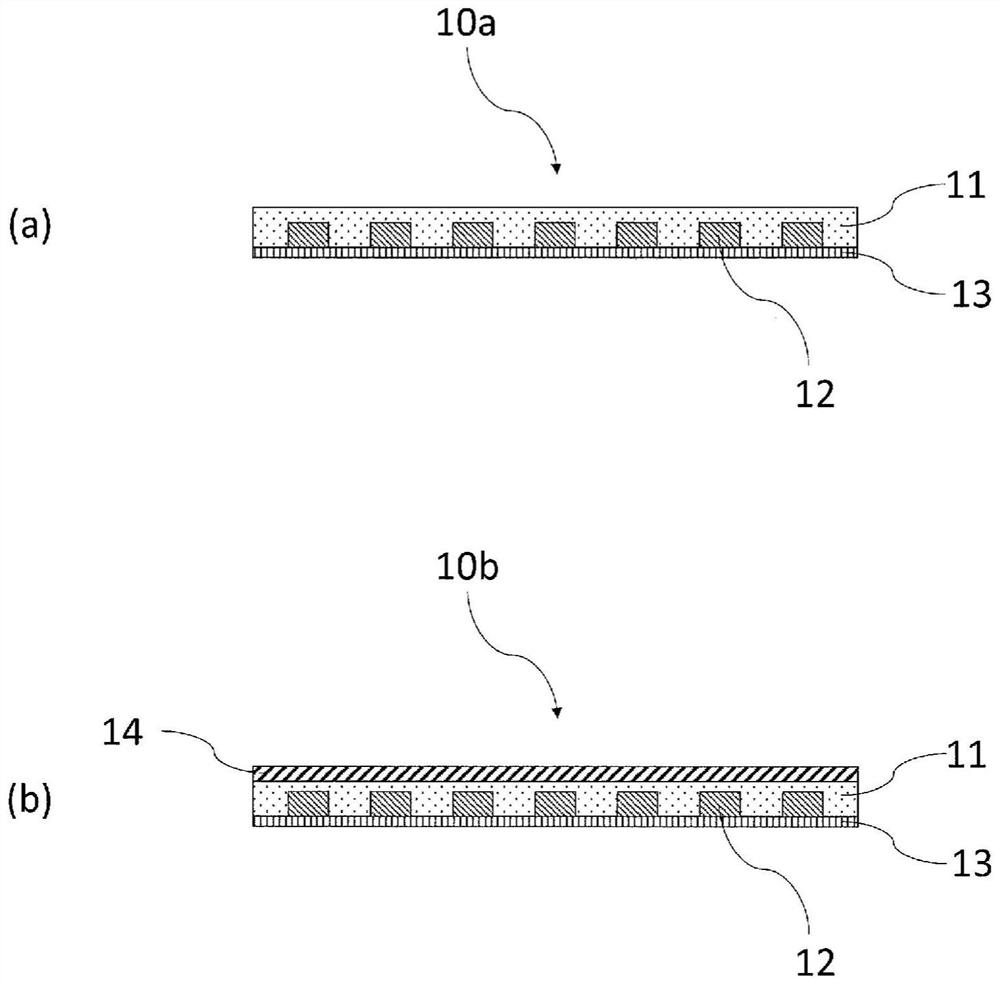

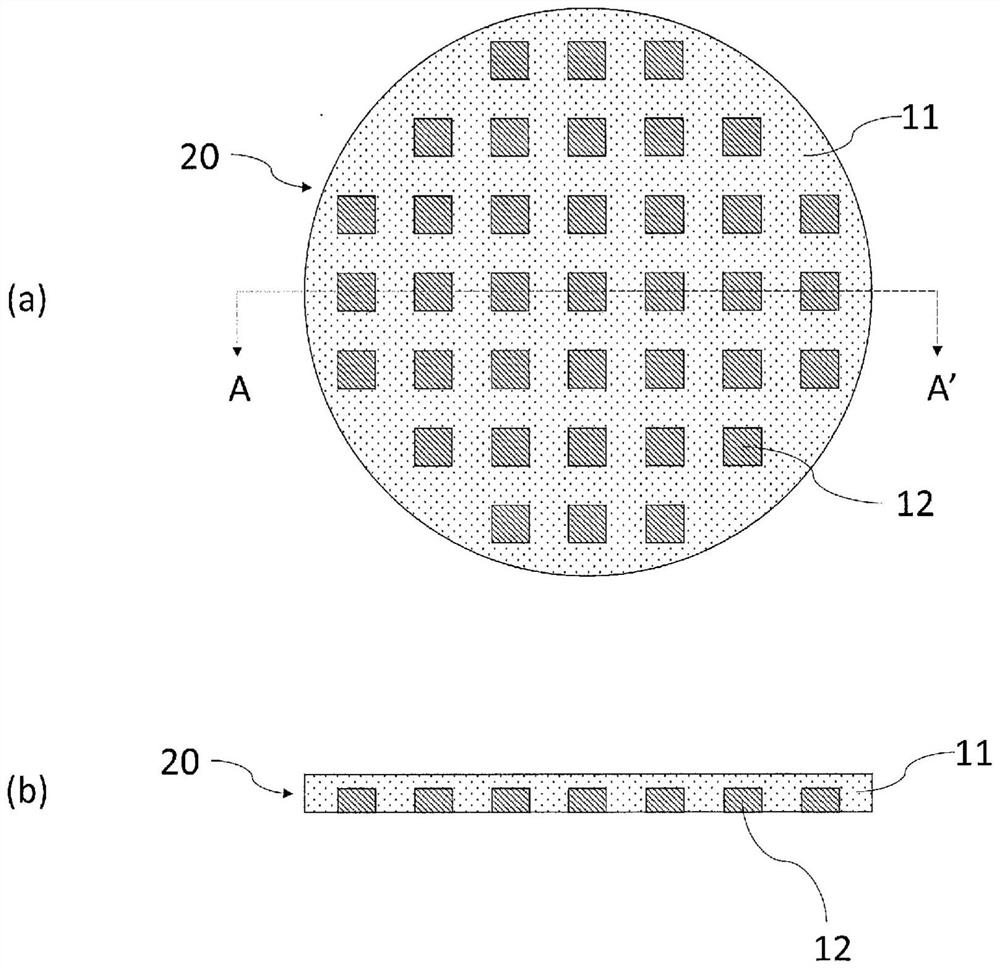

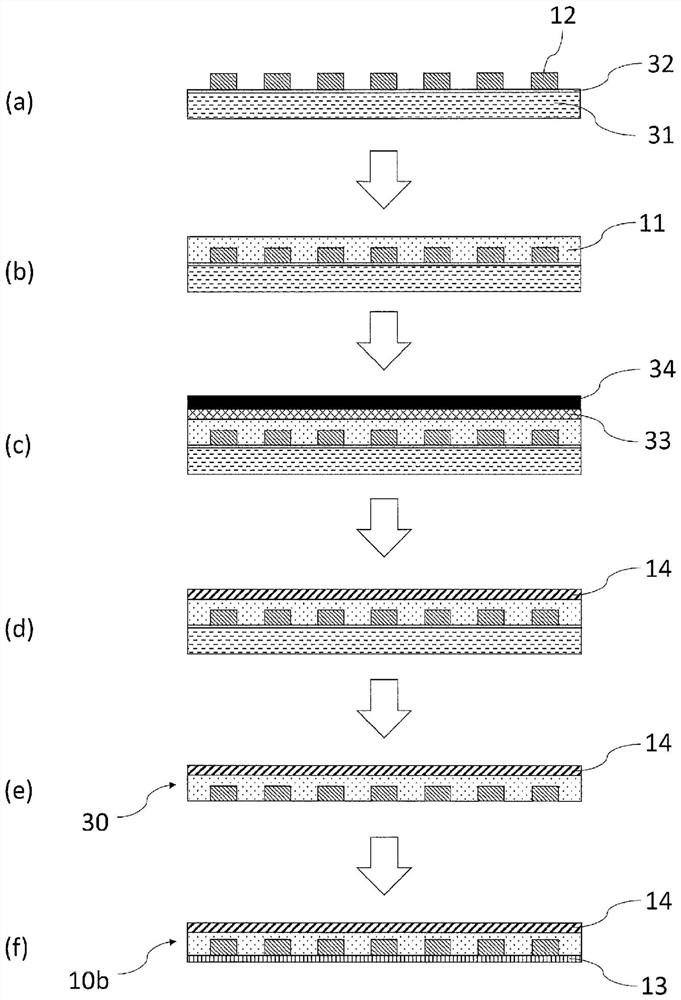

Curable film

PendingCN113330560ANot easy to produceLow coefficient of linear expansionSemiconductor/solid-state device detailsSolid-state devicesPorous sheetPolymer chemistry

The purpose of the present invention is to provide: a curable film for forming an anti-warping layer on the reverse surface of a semiconductor package, the curable film being such that it is possible to form a cured product having a low linear expansion coefficient even when the inorganic filler content of the curable film is low, to effectively form a via, and to form an anti-warping layer in which scum is not readily produced after formation of the via; a semiconductor package provided with an anti-warping layer; and a method for producing the semiconductor package. This curable film is used for forming, on the reverse surface of a semiconductor package, an anti-warping layer that prevents warping of the semiconductor package, wherein: the curable film has a configuration in which pores in a porous sheet-form support, which comprises a material having a linear expansion coefficient of 20 ppm / K or less, are filled with a curable composition; and the glass transition temperature of a cured product of the curable film is 100 DEG C or less. This semiconductor package provided with an anti-warping layer has an anti-warping layer comprising a cured product of the curable film described above on the reverse surface of the semiconductor package.

Owner:DAICEL CHEM IND LTD

A kind of high-barrier polyvinyl alcohol coating for lining paper coating and preparation method thereof

ActiveCN103382677BSolve the problem of prone to paper breaksImprove wet strengthDefoamers additionPaper coatingHigh resistancePolyvinyl alcohol

The invention relates to high-barrier polyving akohol coating for coating lined paper. The coating comprises the following raw materials of, by weight, 12-16% of polyving akohol, 2.1-3.8% of amino resin, 0.01-0.015% of catalysts, 0.05-0.3% of wet strength agents, 2-4% of xylan, 0.1-0.25% of anti-blocking agents, 0.005-0.01% of antifoaming agents and 78-83% of deionized water. The invention further provides a preparation method of the high-resistance polyving akohol coating for coating the lined paper. The coating is directly coated on a lined paper substrate of 45-80g / m<2>, and has good adhesive force and barrier property. After the coated lined paper is wetted or soaked into the water, the tensile strength of the coated lined paper is higher than 30%. Trial results show that the coated lined paper can be completely applied to high-speed presses and packing machines.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Equipment for improving uniformity of dyeing of fabric

PendingCN108842352ATo achieve the purpose of preheatingMake up for the disadvantage that the temperature is not as high as the middle position of the clothHeating/cooling textile fabricsEngineeringProduction quality

The invention discloses equipment for improving the uniformity of dyeing of fabric. The equipment comprises a chain rail and a needle board respectively arranged on two sides of the front end of a drying room; a heating device is arranged at the front end of the drying room; the heating device is arranged above the chain rail; the heating device comprises a clamp holder, infrared heating tubes andan infrared heating lamp cover; the infrared heating tubes are arranged on the clamp holder; and the infrared heating tubes are arranged above the chain rail and directly opposite to the two sides ofweaving fabric. The heating device arranged at the front end of the drying room is used for preheating the two sides of the woven fabric. The woven fabric is first passed through the heating device such that two ends of the woven fabric are rapidly heated. Before entering the drying room, the woven fabric exhibits a temperature distribution state in which the temperature at the two ends is high and the intermediate temperature is low, thereby achieving the purpose of preheating the two ends of the woven fabric. After the woven fabric heated by the heating device on the two sides enters the drying room, the defects that the temperature on both sides of the woven fabric is not as high as that of a middle position of the fabric is compensated, so that the styling effect on the two sides of the woven fabric is closer to that of the middle position, the color of a product is more uniform, and the production quality of the product is greatly Improved.

Owner:GUANGDONG TIANHAI LACE

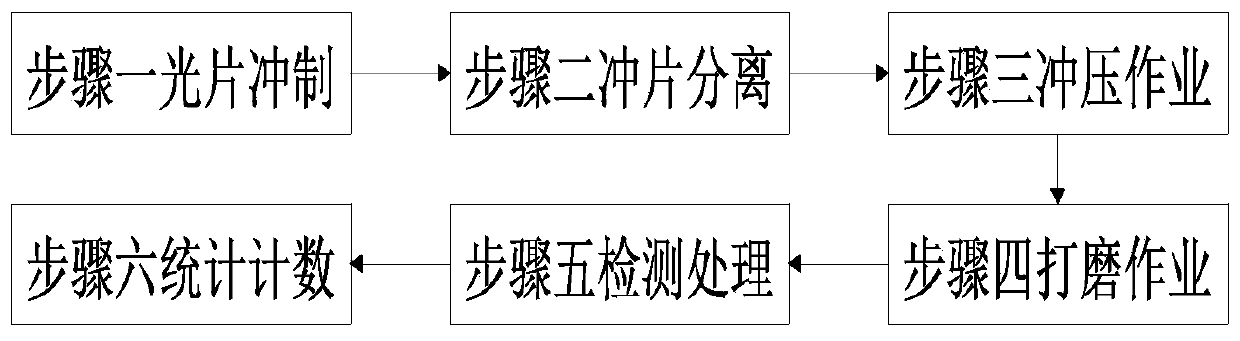

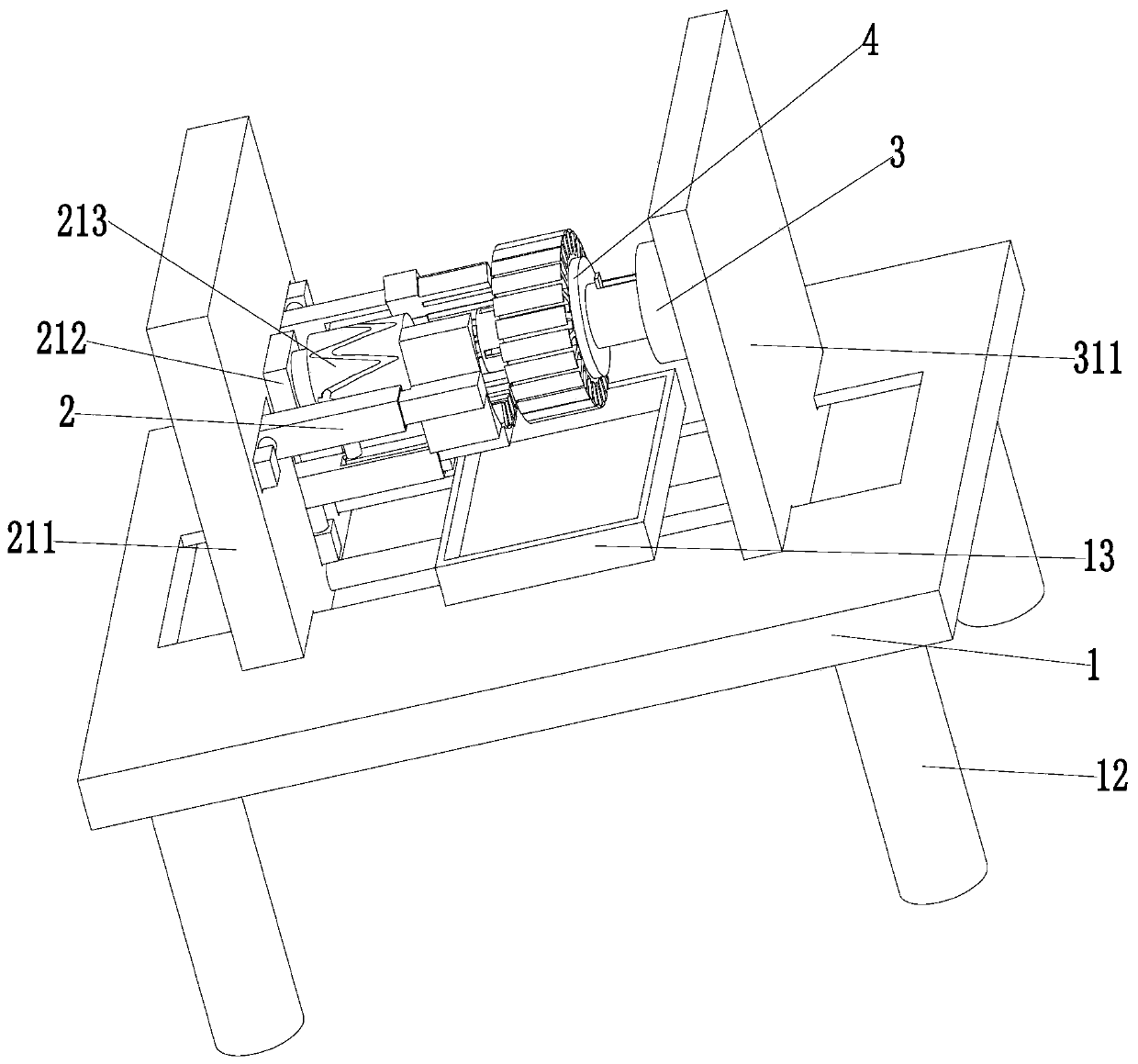

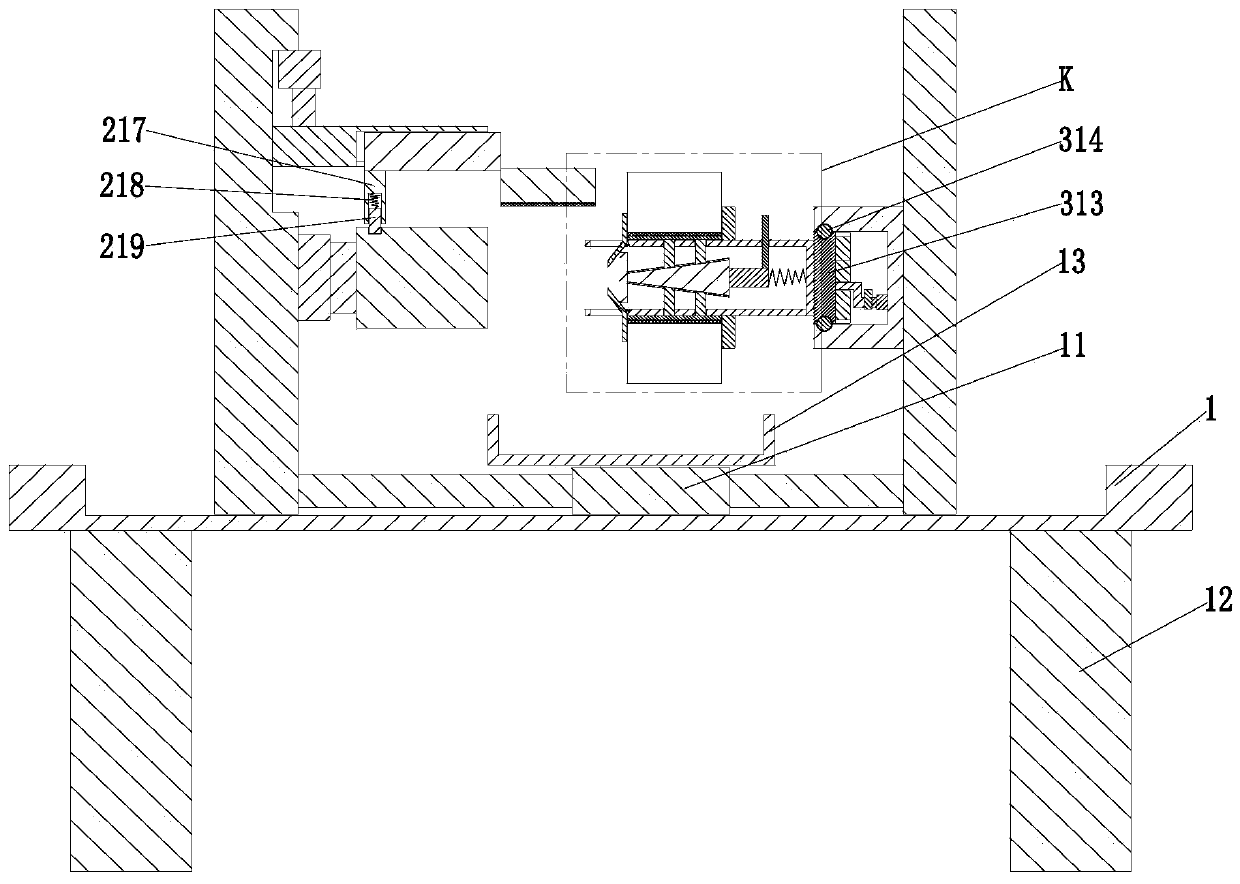

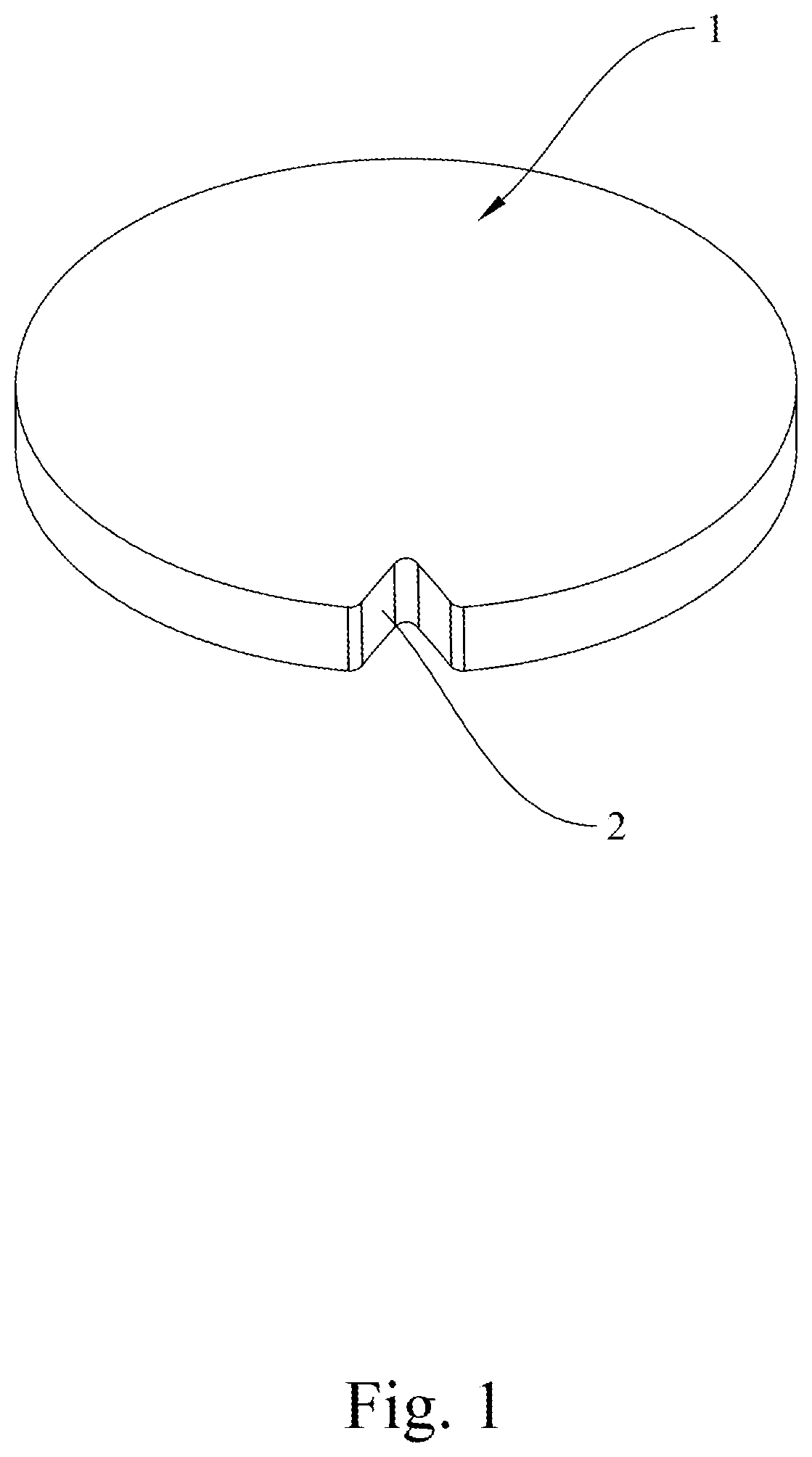

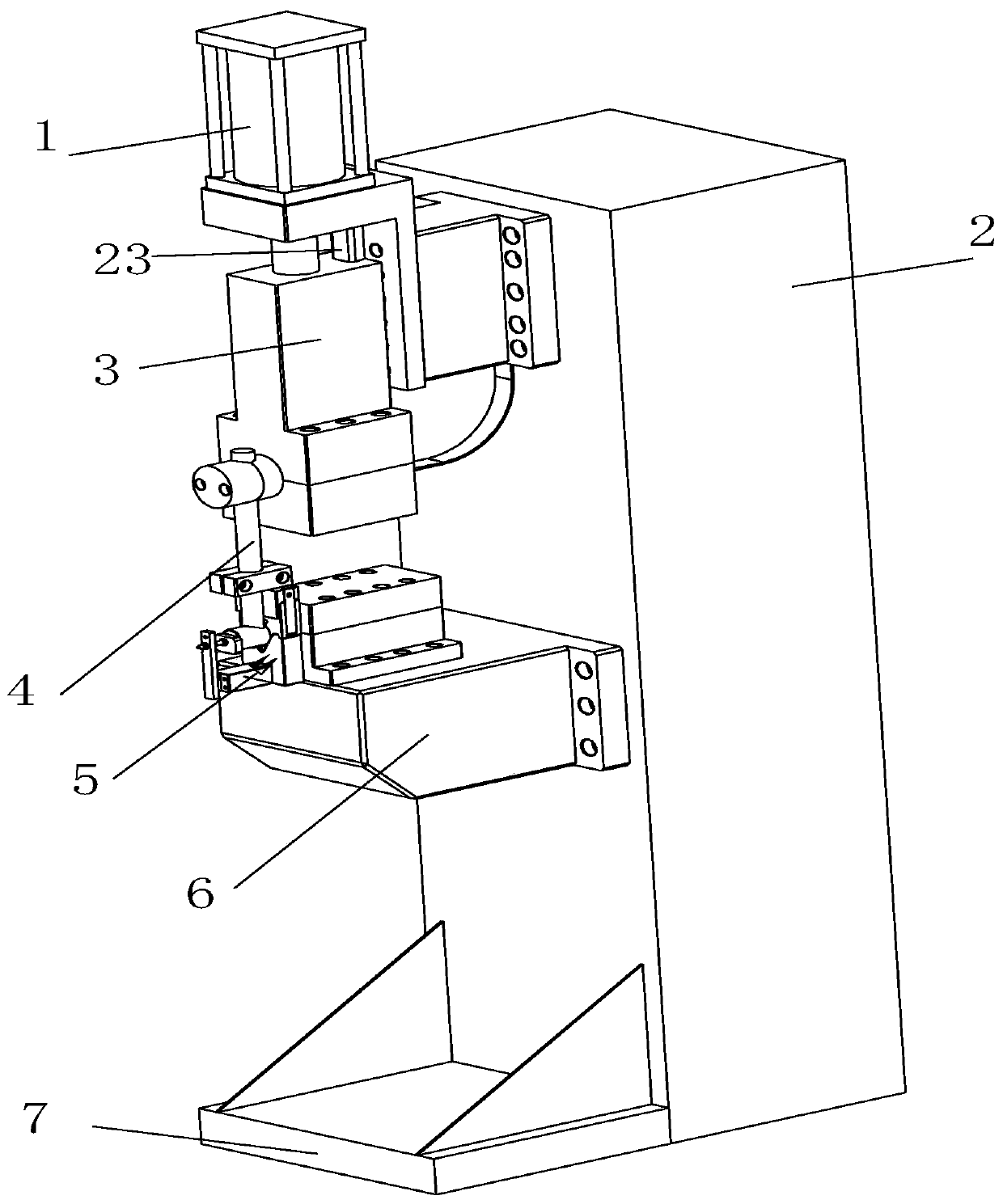

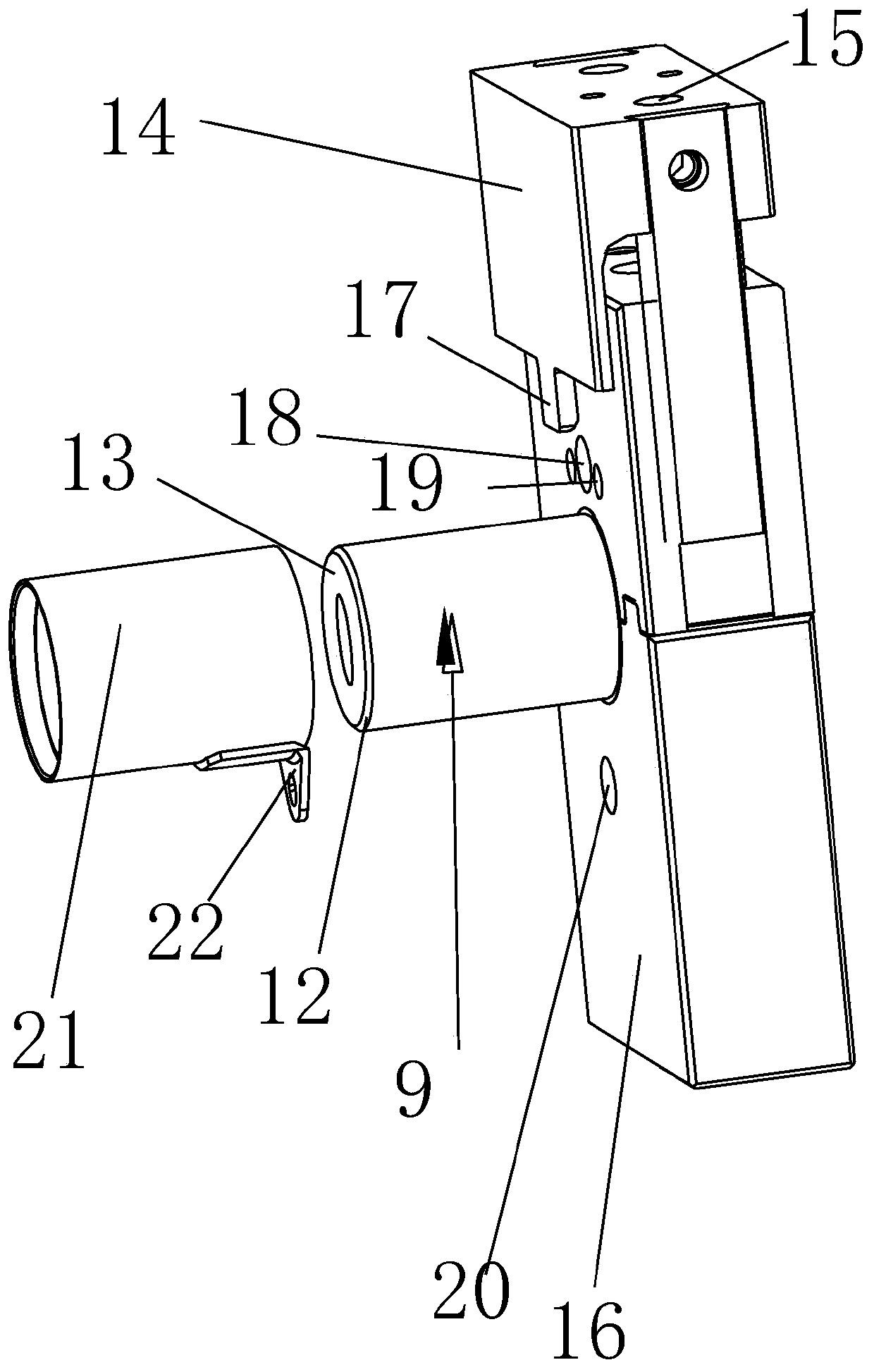

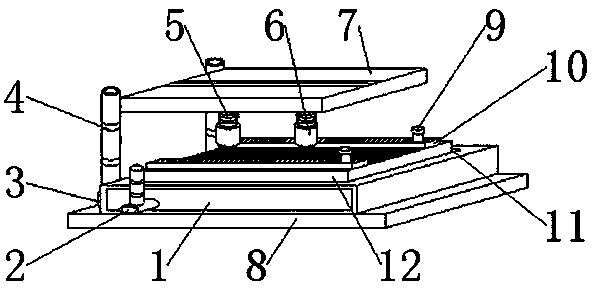

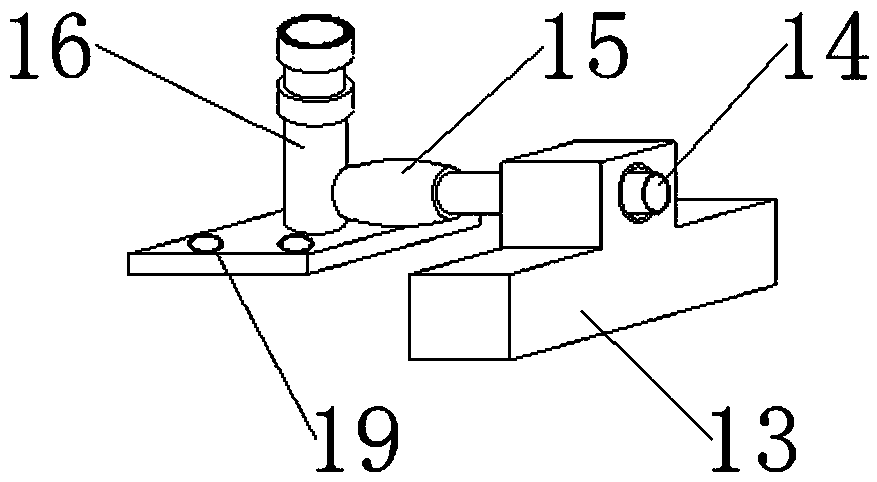

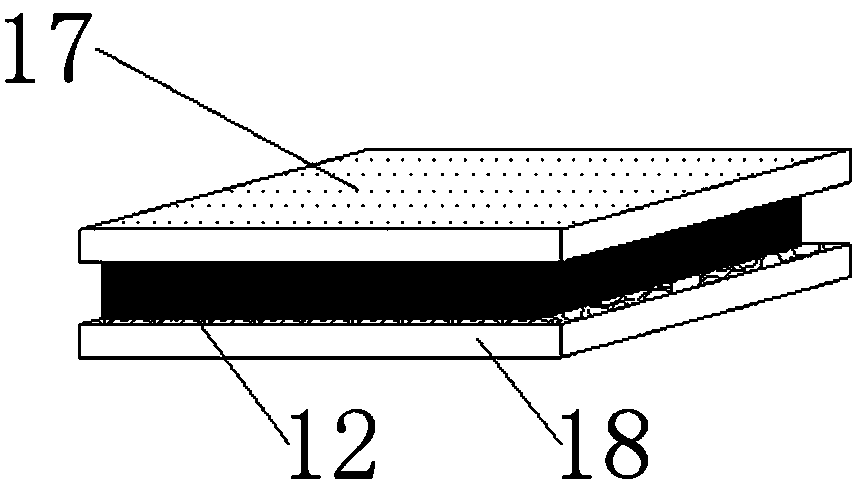

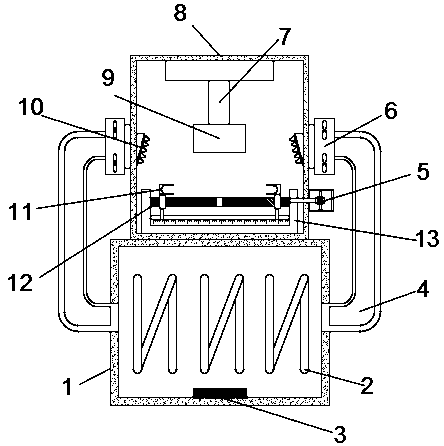

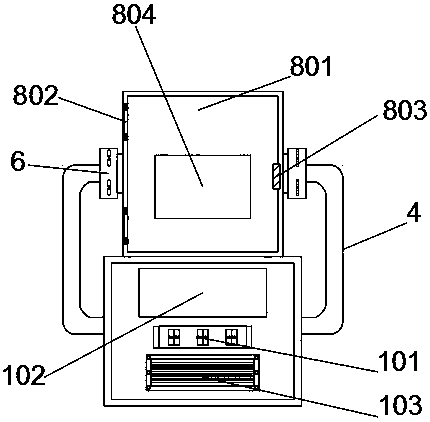

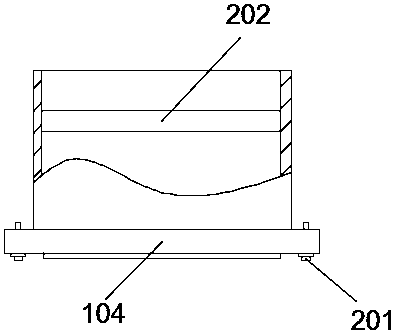

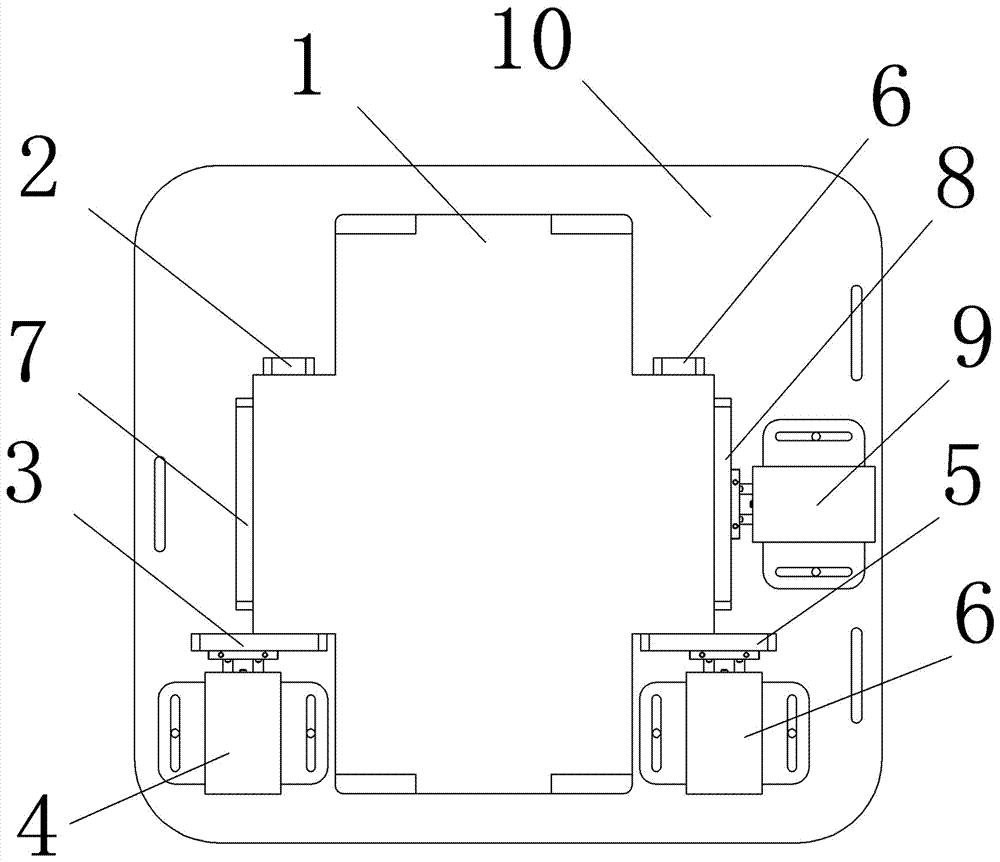

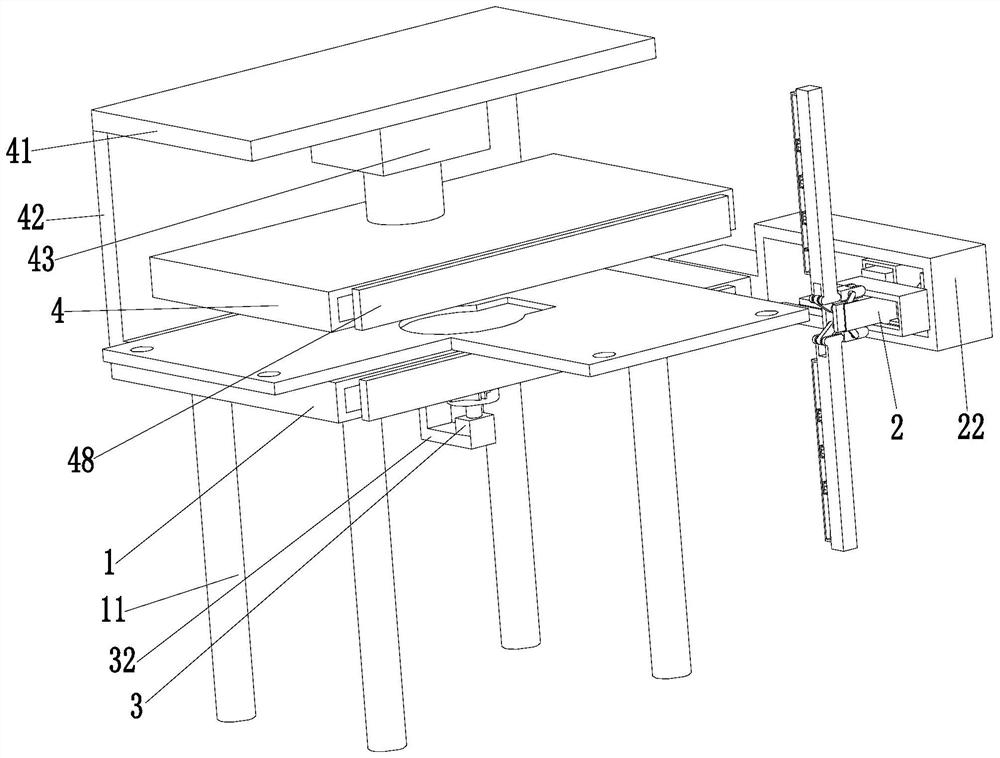

Machining method for manufacturing motor rotor punching sheet

ActiveCN111130283AAvoid product qualityReduce grinding efficiencyGrinding drivesGrinding machinesPunchingElectric machine

The invention relates to a machining method for manufacturing a motor rotor punching sheet. The method mainly comprises the following steps of polished section punching, punched sheet separation, punching operation, polishing operation, detection processing, statistical counting and the like. Used rotor punching sheet grinding equipment comprises a bottom plate, a grinding device, a rotary positioning device and a clamping device. The machining method can be used to solve the following problems existing in grinding of an existing rotor punching sheet: a, a grinding machine is commonly used forgrinding the rotor punching sheet at present, a phenomenon that a slotted hole is not ground or excessive grinding occurs easily when the grinding machine grinds, and production quality of the rotorpunching sheet is reduced, and cost is wasted; and b, only a single rotor punching sheet can be ground when the traditional rotor punching sheet is ground, grinding efficiency is low, a defective rateof products is high, polishing conditions of the rotor punching sheets are inconsistent, and the rotor punching sheets are extremely easy to scrap. A yield of the rotor punching sheets and the grinding efficiency of the rotor punching sheets can be improved.

Owner:福州中研电机有限公司

Method for making aluminum nitride wafer and aluminum nitride wafer made by the same

ActiveUS20210287996A1High mechanical strengthCorrosion resistanceSemiconductor/solid-state device detailsSolid-state devicesWaferingDielectric permittivity

The present invention provides an aluminum nitride wafer and a method for making the same. The method includes forming at least one alignment notch in or at least one flat alignment edge on a periphery of the aluminum nitride wafer. The alignment notch and the flat alignment edge can prevent the aluminum nitride wafer from being in a poor state during the semiconductor manufacturing process and makes it possible to position the aluminum nitride wafer precisely so that the fraction defective can be lowered. The aluminum nitride wafer of the present invention has advantages of effective insulation, efficient heat dissipation, and a high dielectric constant, and can be used in semiconductor manufacturing processes, electronic products, and semiconductor equipment.

Owner:HONG CHUANG APPLIED TECH CO LTD

Jewelries inlaid with Jianzhan ceramic tiles and production method thereof

The invention provides jewelries inlaid with Jianzhan ceramic tiles and a production method thereof. The production method comprises the following steps: 1, selecting ceramic tiles with ornamental values and complete patterns from a Jianzhan defective product; 2, cutting the Jianzhan defective product into small differently-shaped ceramic tiles which retain original patterns; 3, polishing the cutceramic tiles with corundum, then repolishing the edges with sandpaper until rounded corners of 0.5-1 mm appear, then polishing, measuring the edges of the ceramic tiles by using a minimum micrometerafter completion of polishing, continuing polishing when measurement results are not less than 5% of original lengths until the measurement results are less than 5% of the original lengths, and then stopping polishing to obtain the treated Jianzhan ceramic tiles; and 4, according to different treated Jianzhan ceramic tiles and different jewelries, through an adhesive or clamping claws on bottom supports formed by downwardly sinking the tops of metal main bodies, fixing the Jianzhan ceramic tiles to the bottom supports so as to obtain the jewelries. The jewelries are produced by the productionmethod.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A shoe sole grinding machine

ActiveCN105193007BThe grinding process is inefficientHigh defective rateShoemaking devicesGrinding machinesSanderEngineering

Owner:永州远威运动鞋业有限公司

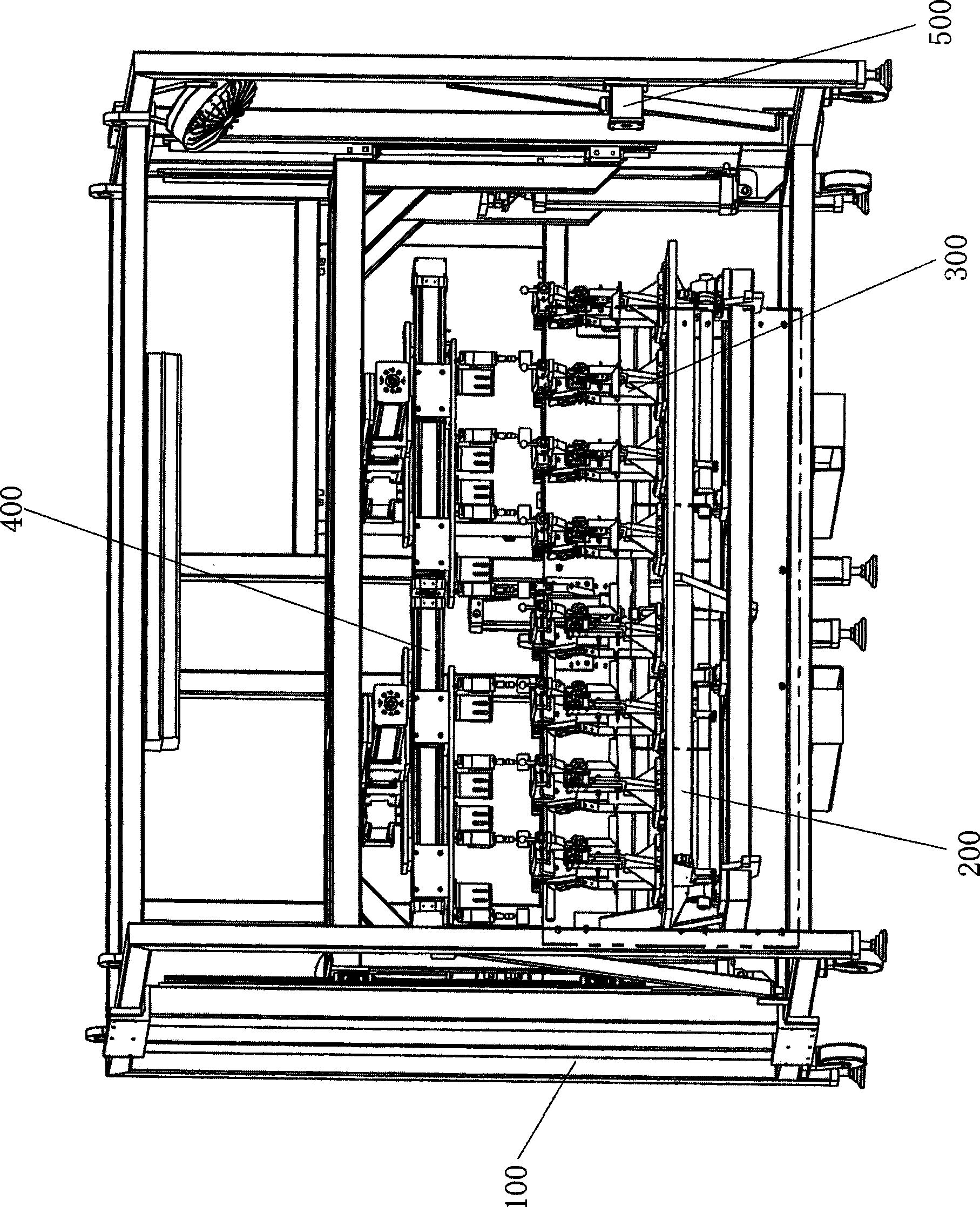

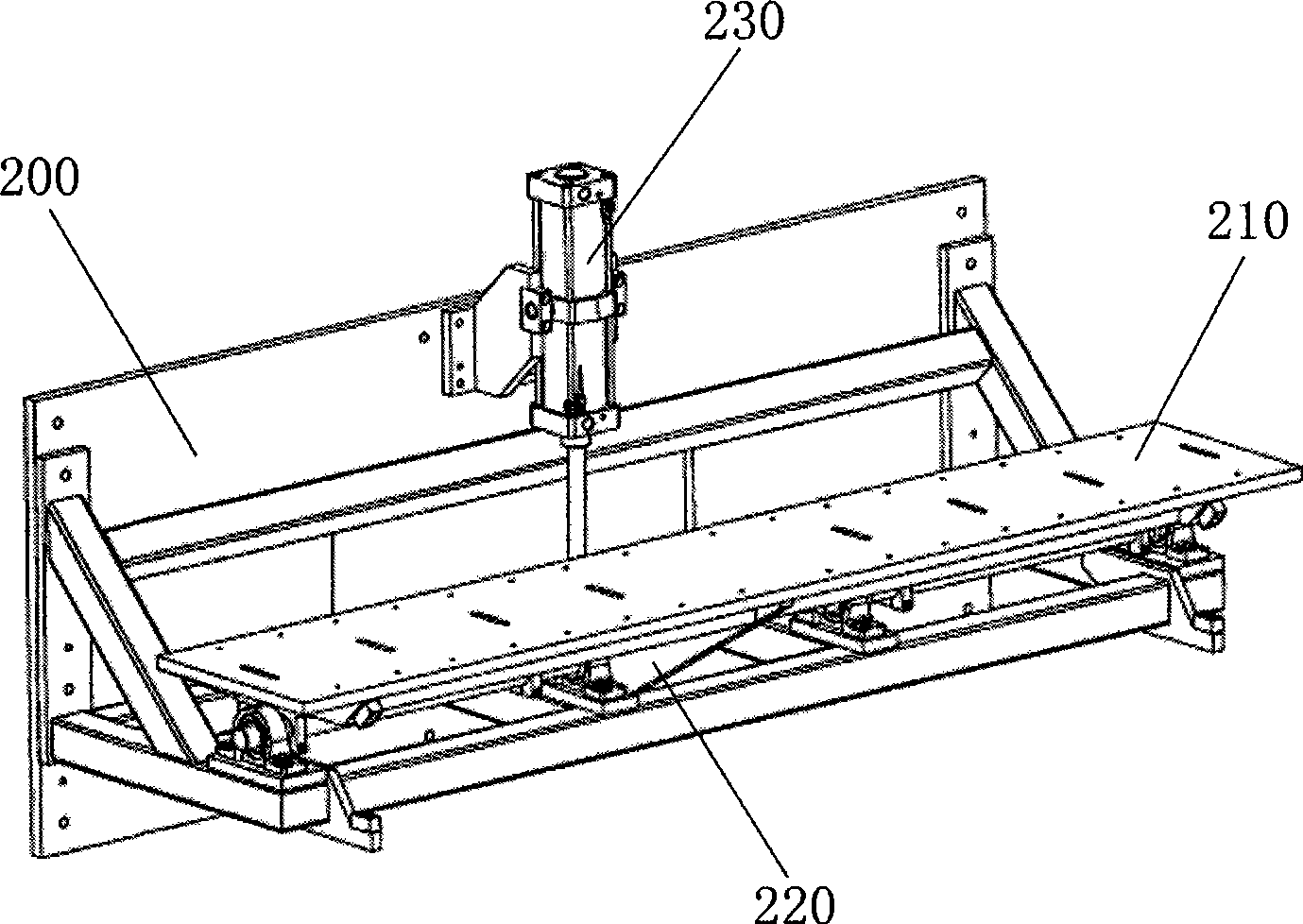

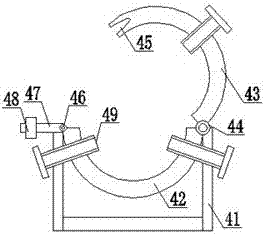

Screw pump metal stator welding whole-set equipment system

InactiveCN107309548AEasy dockingEasy to fixLaser beam welding apparatusReduction driveThermal deformation

The invention relates to a screw pump metal stator welding whole-set equipment system. A front support frame and a rear support frame are separately arranged at the front and the rear of the surface of a machining tool body; clamping positioning racks are symmetrically arranged on two sides of the machining tool body; a first sleeve and a second sleeve are movably mounted in the middles of the front support frame and the rear support frame separately in the transverse direction through a first bearing and a second bearing; a motor is mounted on the top of the front support frame; an output end of the motor is connected with a driving belt pulley through a speed reducer; a first rotating plate and a second rotating plate are separately mounted on opposite side surfaces of the front support frame and the rear support frame; a first chuck and a second chuck are separately arranged on the first rotating plate and the second rotating plate; a welding rack is arranged at a position which is close to the middle of the machining tool body; and a laser welding machine is further mounted on the top of the welding rack. By the technical scheme, the screw pump metal stator welding whole-set equipment system which is accurate in welding and positioning, high in welding speed, high in depth, small in weld joint thermal stress and small in thermal deformation can be provided.

Owner:YANCHENG SHIHONG PETROLEUM EQUIP

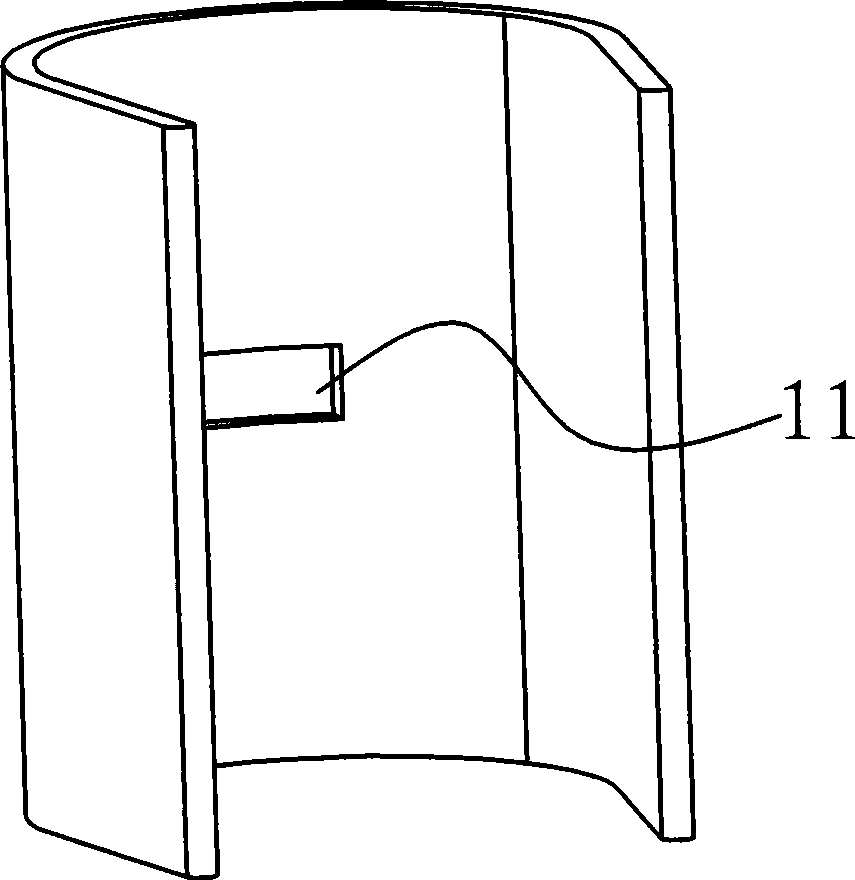

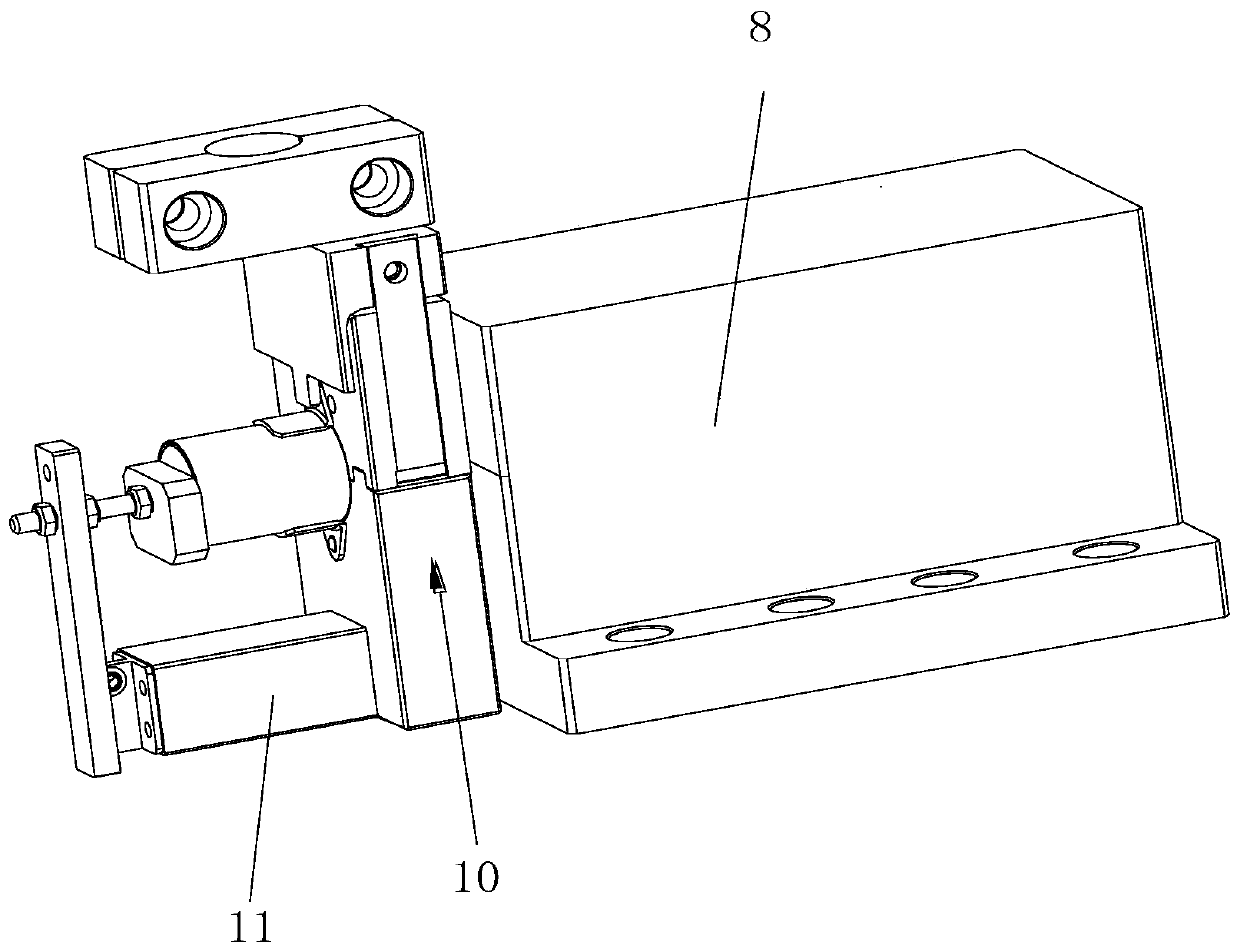

Circular shell welding device

PendingCN110328473AAppearance detectionIncrease production costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention relates to a circular shell welding device. The circular shell welding device comprises a cylinder, a welding machine, a sliding block, a welding joint, a rotary welding module, a workbench and a engine base, wherein the engine base is connected with the lower end of the welding machine; the workbench is connected with the middle of the side face of the welding machine; the rotary welding module is connected with the workbench; the cylinder is connected with the upper end of the welding machine; the cylinder is connected with the sliding block; the sliding block is connected withthe welding joint; the rotary welding module includes a servo motor, a mandrel, a guide block and a fixed cylinder; the servo motor passes through the guide block to be connected with the mandrel; and the fixed cylinder is arranged at the bottom of the guide block and connected with the guide block. The welding device achieves the automatic welding process of a circular shell, so that the production efficiency is greatly improved without manual operation in the whole process; and the welding effect is good, so that the product scrap rate is low, and the enterprise cost is reduced.

Owner:苏州神本精密机械有限公司

Graphene heating film welding fixing device

PendingCN108758769APrevent deviationHigh defective rateLighting and heating apparatusElectric heating systemGrapheneElectric wire

The invention relates to the technical field of fixing devices, in particular to a graphene heating film welding fixing device. The graphene heating film welding fixing device comprises a device body,a PIC type graphene heating film and a convex plate; the lower end of the PIC type graphene heating film is fixedly connected with a frosted plate, metal current carrying strips are clamped on the front side and the rear side of the upper end of the PIC type graphene heating film, rivets are arranged at the right ends of the metal current carrying strips in a penetrating mode, the rivets are buckled on the metal current carrying strips, the upper ends of the metal current carrying strips are fixedly connected with a waterproof plate, a rocker is movably connected to the left end of a cross rod, and a user can fix the PIC type graphene heating film through the frosted plate and weld the PIC type graphene heating film into a groove, so that the PIC type graphene heating film is prevented from sliding in the groove; and the rivets on the metal carrying strips are used, and the rivets are connected with electric wires, so that the PIC type graphene heating film is connected to a power supply; and the water-proof plate is used for preventing the PIC type graphene heating film from entering water, so that the PIC type graphene heating film is damaged.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

Special glass laminating protector

PendingCN111497419AThe lamination process went smoothlyEasy to organizeDispersed particle filtrationLaminationHydraulic cylinderElectric machine

The invention discloses a special glass laminating protector comprising an electric heating box. A heating disc is arranged in the electric heating box; a temperature sensor is fixedly mounted at thebottom of an inner cavity of the electric heating box; a working box body is arranged at the upper end of the electric heating box; air ducts are arranged at two ends of the outer side of the electricheating box; the other end of each air duct penetrates through an exhaust fan and is fixedly connected with a working box body; and an air nozzle is arranged at the part, embedded in the inner cavityof the working box body, of each air duct. A base is arranged at the bottom of the inner wall of the working box body and transversely connected with a threaded rod in a threaded mode, a motor is installed on the outer side wall of the working box body, the power output end of the motor penetrates through the working box body and the base and is connected with the threaded rod, a glass clamping block is fixedly installed on the threaded rod, and a hydraulic cylinder is fixedly connected to the upper end of the inner wall of the working box body. Glass with different widths is heated and wellarranged and fixed, the situation that glass laminating work cannot be conducted is prevented, the production efficiency is reduced, the practical effect is good, and the glass laminating protector isworthy of application and popularization in the existing market.

Owner:湖南衡波特种玻璃科技有限公司

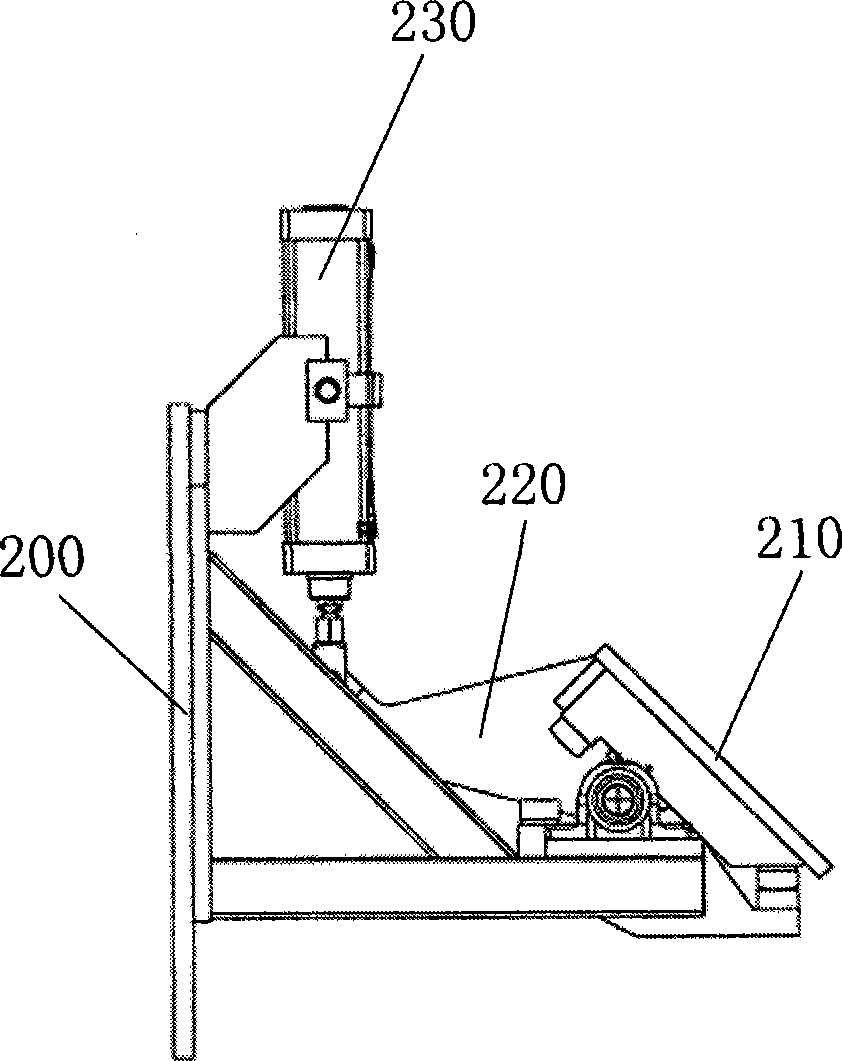

Accurate adjusting device before gelatinizing skin paper of paper box and gelatinizing system and gelatinizing method

InactiveCN106864156ASolve the inaccurate gluing positionReduce defective ratePaper-makingBox making operationsEngineeringFlange

The invention discloses an accurate adjusting device before gelatinizing skin paper of a paper box and a gelatinizing system and a gelatinizing method. The accurate adjusting device comprises a base plate matched with the skin paper in shape, wherein a group of flange A and a group of flange B perpendicular to the base plate are arranged on the periphery of the base plate; the working faces of the group of flange A and the group of flange B are towards the internal direction of the base plate and are higher than the surface of the base plate; the working face of the group of flange A is perpendicular to that of the group of flange B; a telescopic adjusting mechanism A and a telescopic adjusting mechanism B corresponding to the group of flange A and the group of flange B are arranged on the periphery, corresponding to the group of flange A and the group of flange B in position, of the base plate; each of the telescopic adjusting mechanism A and the telescopic adjusting mechanism B comprises a push plate in front and a telescopic component at back; and the working face of each push plate is towards the internal direction of the base plate and is higher than the surface of the base plate. The gelatinizing system comprises coarse adjusting device, a fine adjusting device, a silk-screen gelatinizing device and a transferring device; and the gelatinizing method utilizes the accurate adjusting device and the gelatinizing system to accurately adjust the skin, so that the problem that the gelatinizing position of the skin paper is not accurate is solved, and the defective rate can be greatly reduced to increase the rate of finished products.

Owner:河南圣昌自动化设备有限公司

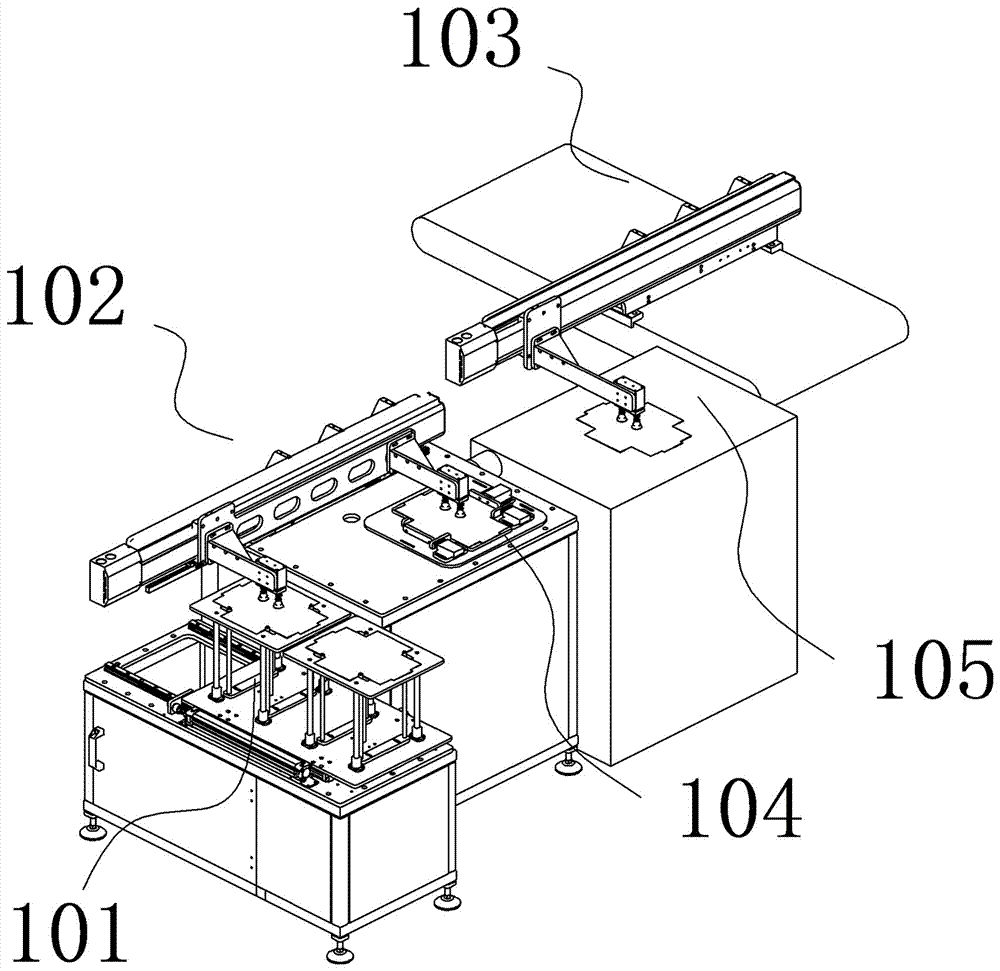

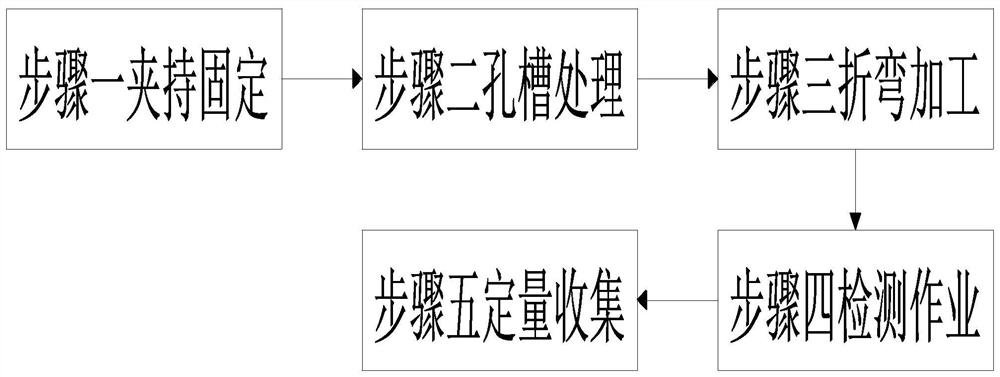

A method of bending and forming a sheet metal part after stamping

ActiveCN111036740BReduce production efficiencyHigh defective rateMetal-working feeding devicesOther manufacturing equipments/toolsStructural engineeringSheet metal stamping

The invention relates to a bending forming method of a sheet metal part after stamping, which mainly includes the following steps, including clamping and fixing, hole groove processing, bending processing, detection operation, quantitative collection and other processes, and the sheet metal parts used after stamping The bending and forming equipment includes a bottom plate, a clamping and rotating device, an intermittent rotating device and a clamping device. The present invention can solve the following problems in the bending and forming of existing sheet metal parts. a. At present, the sheet metal parts are processed into angled It is necessary to bend sheet metal parts. In mass production, bending machines are often used, but the bending machine is not easy to adjust the bending angle of sheet metal parts. It often needs to be stopped. Bending operations waste a lot of time, reduce production efficiency, and waste the time for manual machine adjustment; b. When the bending machine bends sheet metal parts, the bending effect is not stable due to the unstable bending process. Poor, the product defective rate is high.

Owner:佛山市广浩科技有限公司

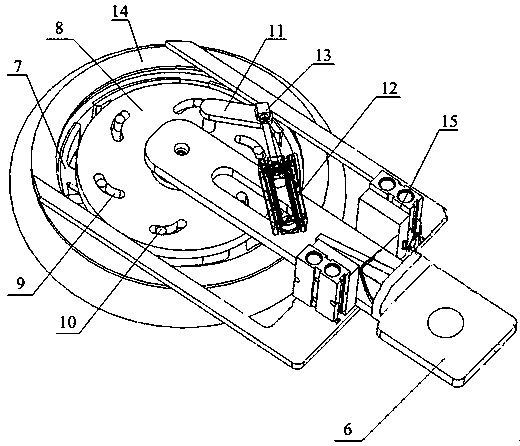

Cavity electrode

ActiveCN105147285ALow costImprove conductivityInternal electrodesDiagnostic recording/measuringConductive materialsEngineering

A cavity electrode comprises an upper casing, a lower casing, an upper electrode and a lower electrode, wherein the upper casing and the lower casing are made of an insulating material and provided with windows; and the upper electrode and the lower electrode are made of a conductive material. The conductive material of the upper electrode and the lower electrode is made of metal parts. The upper casing and the lower casing are fixedly assembled into a hollow geometry structure through a locating device. The upper electrode and the lower electrode are embedded in the upper casing and the lower casing respectively, and part of surfaces of the upper electrode and the lower electrode are exposed through the windows of the upper casing and the lower casing. Through holes are formed in the end faces of tail ends of the upper casing and the lower casing respectively, the end faces of tail ends of the upper electrode and the lower electrode are provided with bosses, a conductive connecting device connected with a signal line of a test instrument is inserted in the through holes, penetrates a locating hole of the locating device, and abuts against the bosses to form elastic deformation close fit. The conductive performance of the cavity electrode is greatly improved, the manufacturing cost is low, and the working reliability is high.

Owner:福州仁馨医疗科技有限公司

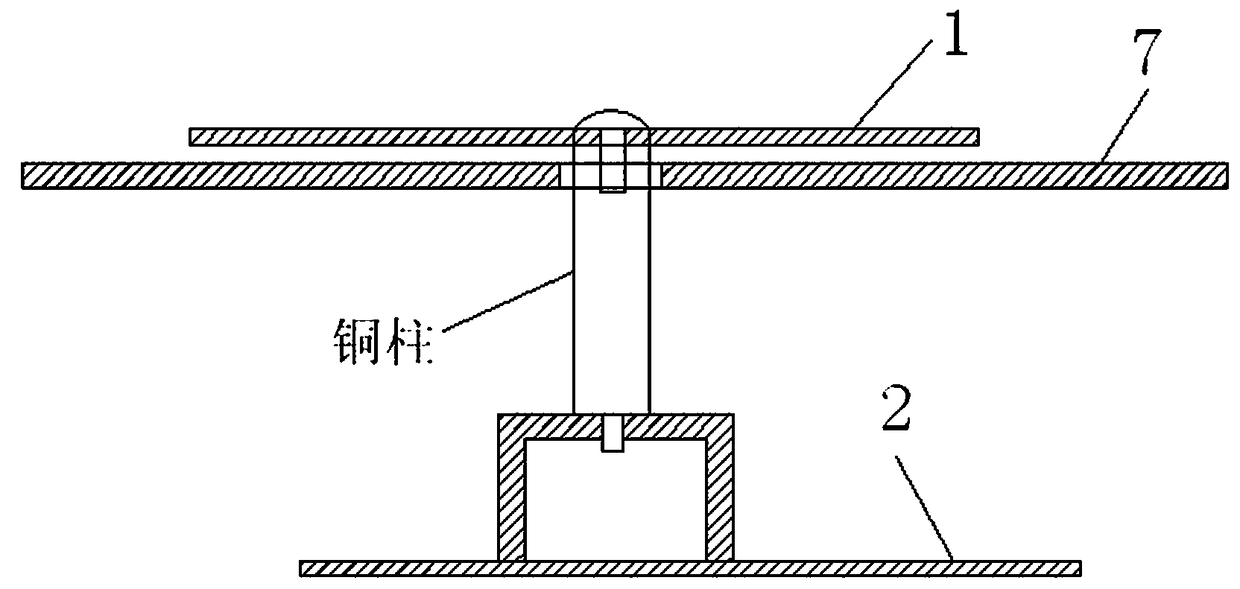

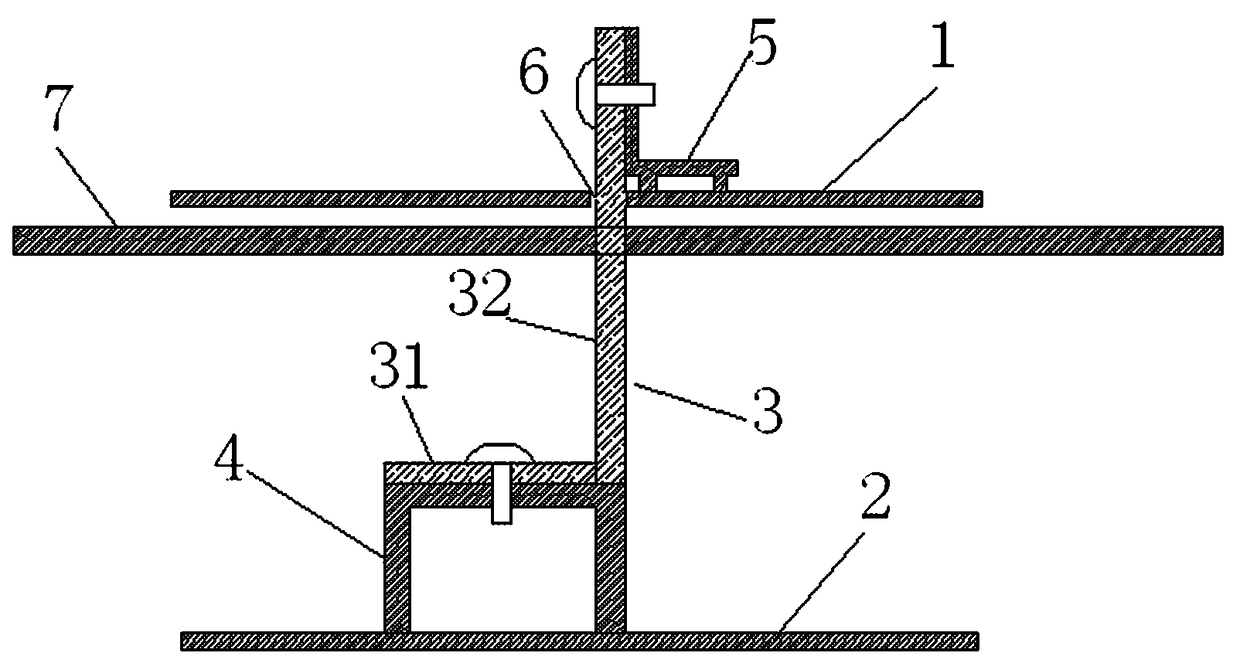

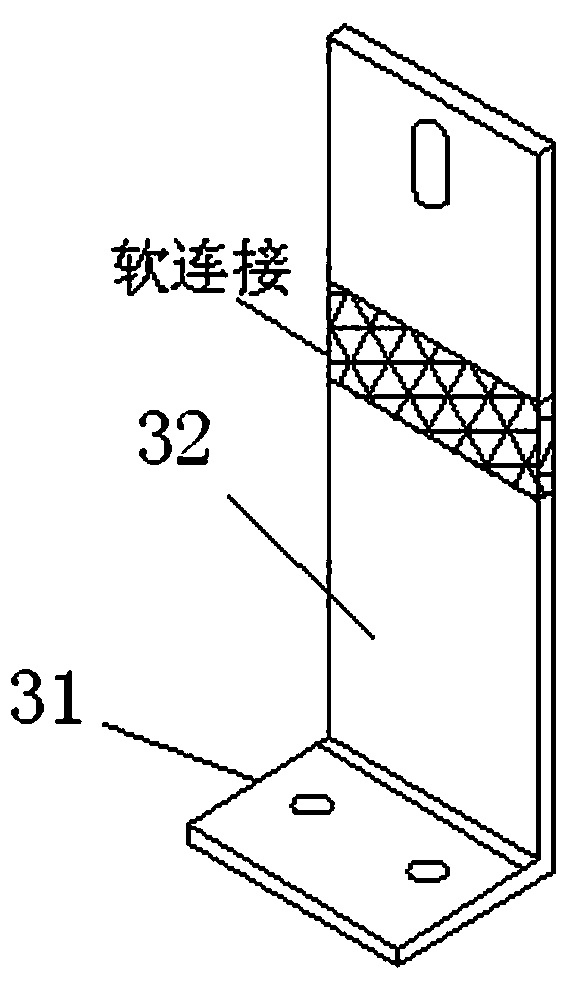

Copper bar connection device between UPS circuit boards

PendingCN108565566AHigh defective rateSimple structureFixed connectionsClamped/spring connectionsEngineeringElectrical and Electronics engineering

The present invention relates to a copper bar connection device between UPS circuit boards. The device comprises an upper PCB, a lower PCB and a copper bar connected with the upper PCB and the lower PCB, the lower PCB is provided with a lower connection terminal with internal threads, a lower screw hole of the lower connection terminal is located above a wiring terminal, the upper PCB is providedwith an upper connection terminal with internal threads, an upper screw hole of the upper connection terminal is located at the side of the wiring terminal, a slit capable of allowing the copper bar to pass through is arranged beside the wiring terminal on the upper PCB, a separator is arranged between the upper PCB and the lower PCB, and the separator is taken as a support piece of the upper PCB.The copper bar connection device simplifies design difficulty and requirements of the connection copper bar so as to save the processing cost of the connection copper bar, simplify the installation process, the installation is convenient, and the safety is improved.

Owner:BAINADE CHINA YANGZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com