Sole grinding machine

A technology of grinding machine and sole, applied in the direction of shoe-making machinery, grinding machine, footwear, etc., can solve the problems of high defective rate, quality can not be guaranteed, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

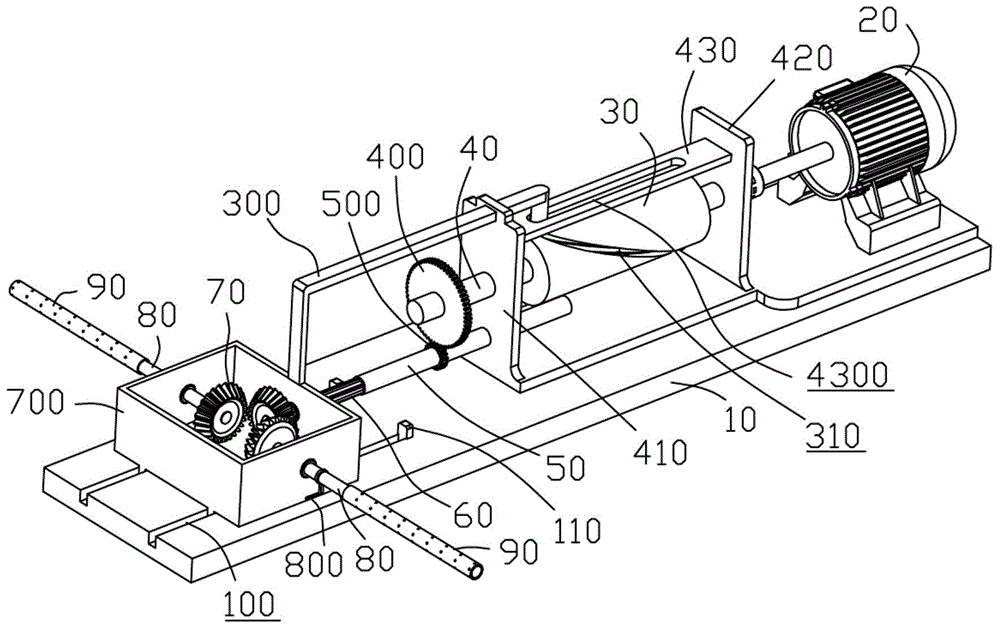

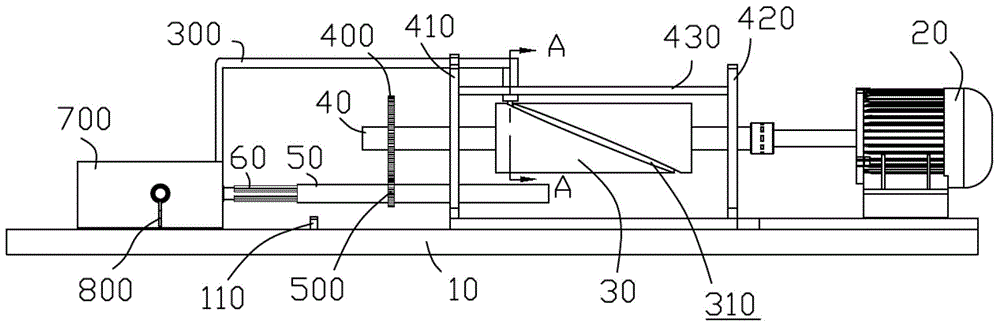

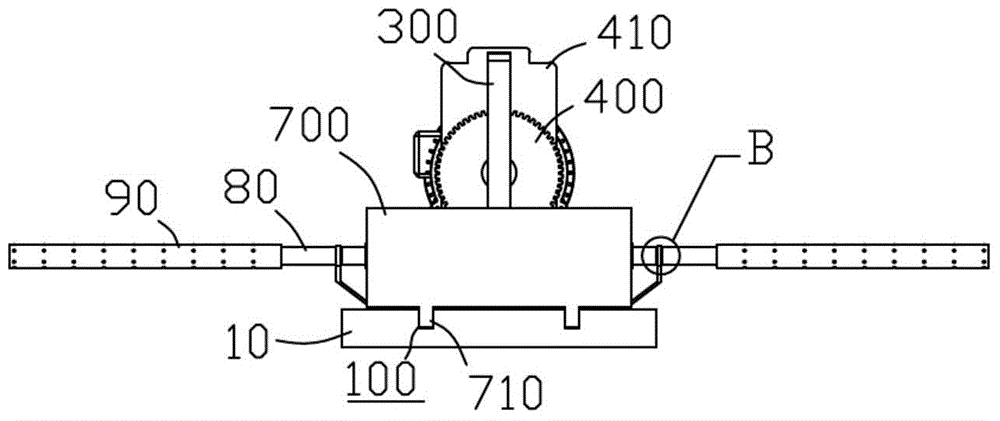

[0022] combine Figure 1 to Figure 8 , a shoe sole grinding machine, comprising a base 10, a motor 20, a rotary cylinder 30, a rotary cylinder shaft 40, an inner spline shaft 50, an outer spline shaft 60, a box body 700, a grinding rod 90 and a grinding rod shaft 80; The base 10 is located at the bottom of the equipment, and the other components are all located on the base 10. A motor 20 is arranged on the upper tail of the base 10, and the output shaft of the motor 20 is connected with the rotary cylinder shaft 40, and the rotary cylinder shaft 40 The front and rear ends are respectively installed on the front bracket 410 of the rotary drum shaft and the rear bracket 420 of the rotary drum shaft, and the rotary drum shaft 40 can rotate in the two brackets; The cylinder shaft 40 is fixedly connected, the surface of the rotary cylinder 30 is provided with a rotary groove 310, and the rotary groove 310 is a closed arc notch; the inner spline shaft 50 is located below the rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com