Full-automatic sole grinding machine

A kind of grinding machine, fully automatic technology, applied in the direction of shoemaking machinery, grinding machines, footwear, etc., can solve the problems of unguaranteed quality, high defective rate, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

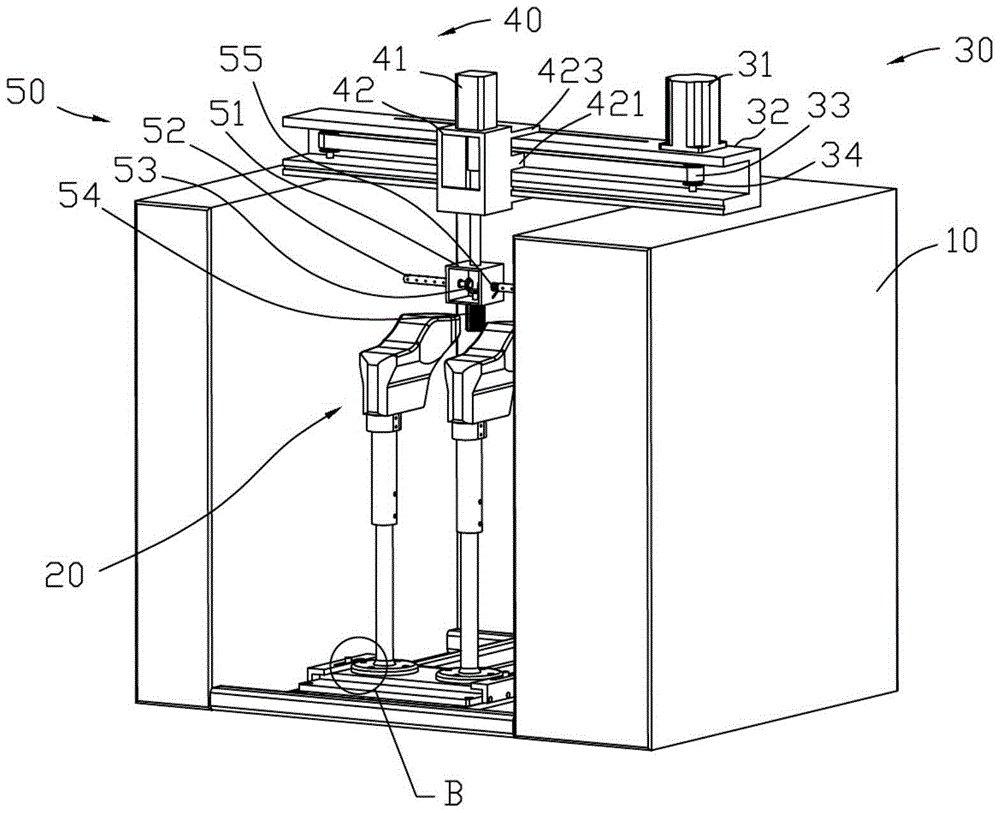

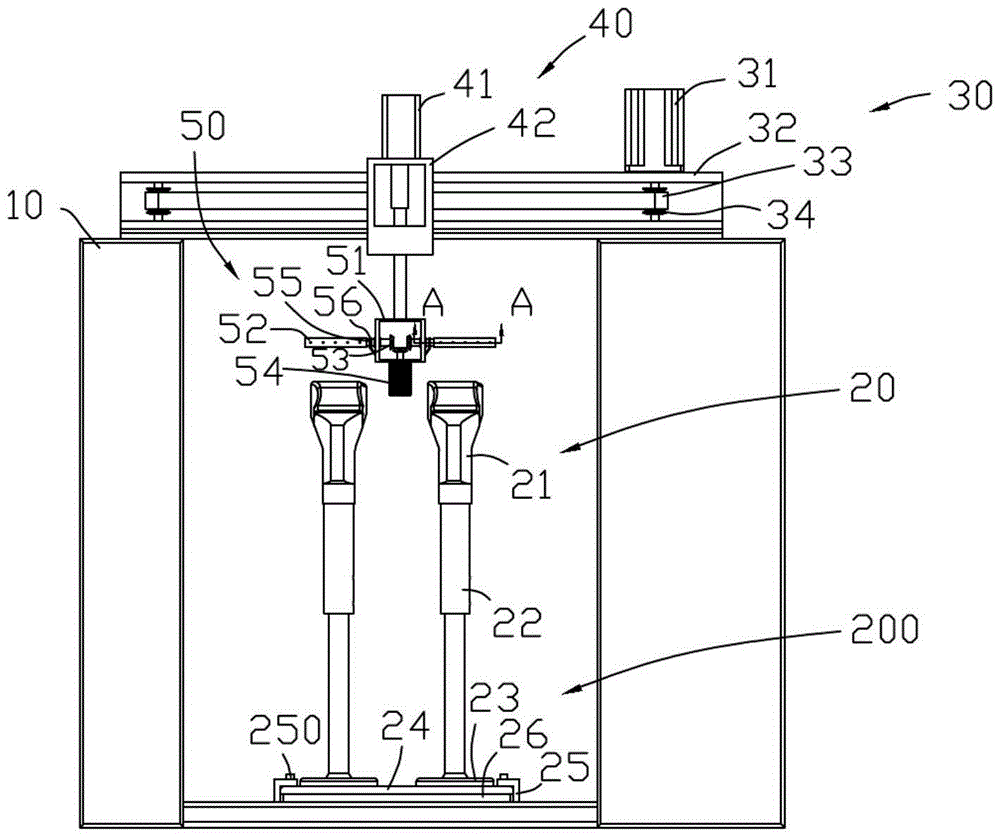

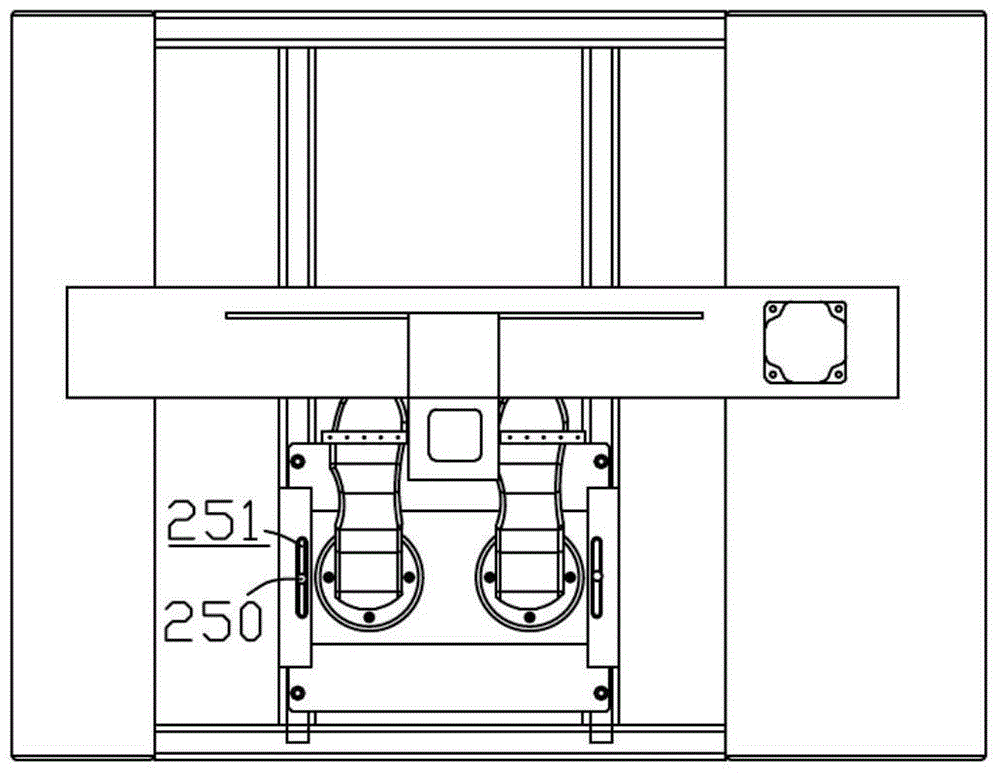

[0018] combine Figure 1 to Figure 7 , a fully automatic shoe sole grinding machine, comprising a frame 10, a shoe mold assembly 20, a lateral adjustment assembly 30, a vertical adjustment assembly 40 and a grinding assembly 50; the frame 10 is composed of two vertically set up frame plates , the shoe mold assembly 20 is located between two rack plates, the top of the shoe mold assembly 20 is a shoe 21, the bottom of the shoe 21 faces upward, and a grinding assembly is arranged above the shoe mold assembly 20 50, the grinding assembly 50 includes two horizontally arranged grinding rods 52, the two grinding rods 52 are symmetrically installed on the grinding box 51, and the two grinding rods 52 are fixed on the grinding rod shaft 55, The bottom of described grinding case 51 is installed grinding motor 54, and the output shaft of described grinding motor 54, the end of two grinding rod shafts 55 are all installed bevel gears 53, and the bevel gears of described two grinding rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com