Environment-friendly unsaturated polyester resin button and preparation method thereof

A polyester resin, unsaturated technology, applied in the field of environmentally friendly unsaturated polyester resin buttons and its preparation, can solve the problems of refractory degradation, environmental pollution, waste of resources, etc., to reduce waste emissions, ensure comprehensive characteristics, and save resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

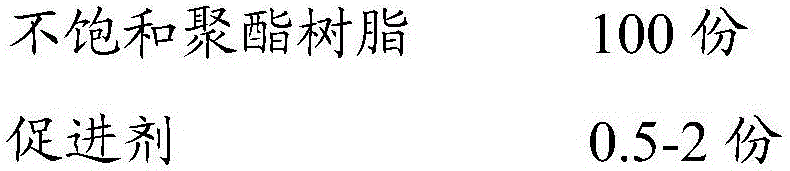

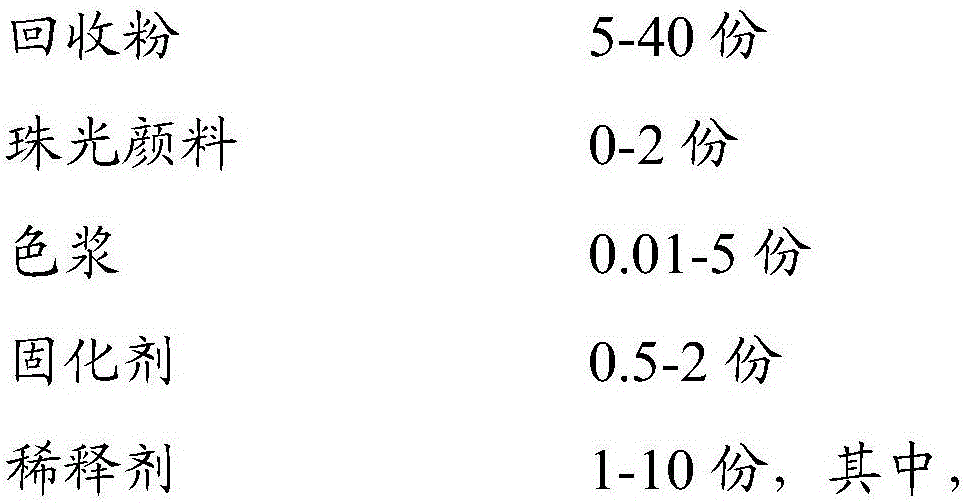

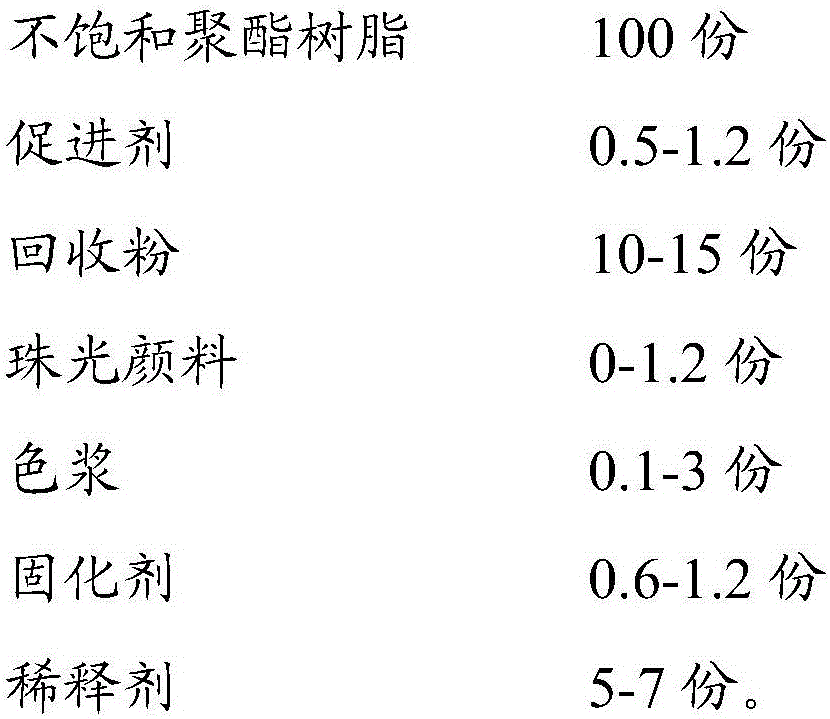

Method used

Image

Examples

Embodiment 1

[0040] A kind of environment-friendly unsaturated polyester resin button of the present embodiment, its raw material and preparation method are as follows:

[0041] 1.1 Embryo making: In 100 parts by weight of o-phthalic unsaturated polyester resin, add 1.2 parts by weight of cobalt naphthenate, 1.2 parts by weight of pearl powder, and 0.3 parts by weight of color paste, and then add 10 parts by weight in batches The reclaimed powder (particle size is 100 meshes), and high-speed agitation and dispersion with a pneumatic agitator for 10 minutes, then adjust the viscosity with 7 parts by weight of styrene, the viscosity is adjusted to 200Pa.s, then add 1 part by weight of curing agent peroxide Methyl ethyl ketone, stirred again for 1 minute, after dispersing evenly, pour the prepared mixed slurry into the tablet machine within 1 minute, and centrifugally disperse at a speed of 60 rpm for 30 minutes to make a sheet, and the mixed slurry was coagulated After the glue is cured for ...

Embodiment 2

[0047] A kind of environment-friendly unsaturated polyester resin button of the present embodiment, its raw material and preparation method are as follows:

[0048] 2.1 Embryo making: In 100 parts by weight of m-benzene type unsaturated polyester resin, add 0.5 parts by weight of cobalt isooctanoate, 0.15 parts by weight of color paste, and then add 15 parts by weight of recovered powder (particle diameter is 150 order), and use a pneumatic agitator to mix and disperse at high speed for 10 minutes, then adjust the viscosity with 5 parts by weight of styrene, the viscosity is adjusted to 210Pa.s, then add 1 part by weight of curing agent methyl ethyl ketone peroxide, stir again for 1 minute, and disperse After uniformity, pour the prepared mixed slurry into the tablet machine within 1 minute, and centrifugally disperse for 20 minutes at a speed of 80 rpm to make a sheet. After the mixed slurry is solidified by gel for 40 minutes, the tablet When the hardness of the material rea...

Embodiment 3

[0054] A kind of environment-friendly unsaturated polyester resin button of the present embodiment, its raw material and preparation method are as follows:

[0055] 3.1 Embryo making: In 100 parts by weight of o-phthalic unsaturated polyester resin, add 1 part by weight of cobalt isooctanoate, 0.35 parts by weight of pearl paste, 2.2 parts by weight of color paste, and then add 10 parts by weight of Recover the powder (particle size is 200 mesh), and stir and mix and disperse for 10 minutes with a pneumatic agitator at high speed, then adjust the viscosity with 6 parts by weight of styrene, the viscosity is adjusted to 300Pa.s, and then add 1 part by weight of curing agent methyl ethyl ketone peroxide , Stir again for 1 minute, after the dispersion is uniform, pour the prepared mixed slurry into the tablet machine within 1 minute, and centrifugally disperse for 20 minutes at a speed of 100 rpm to make a sheet, and the mixed slurry is gelatinized After curing for 40 minutes, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com