Accurate adjusting device before gelatinizing skin paper of paper box and gelatinizing system and gelatinizing method

A technology for adjusting devices and gluing devices, applied in paper/cardboard containers, packaging, papermaking, etc., can solve the problems of glue running, position deviation of gluing, glue leakage, etc. rate, reduce the effect of defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

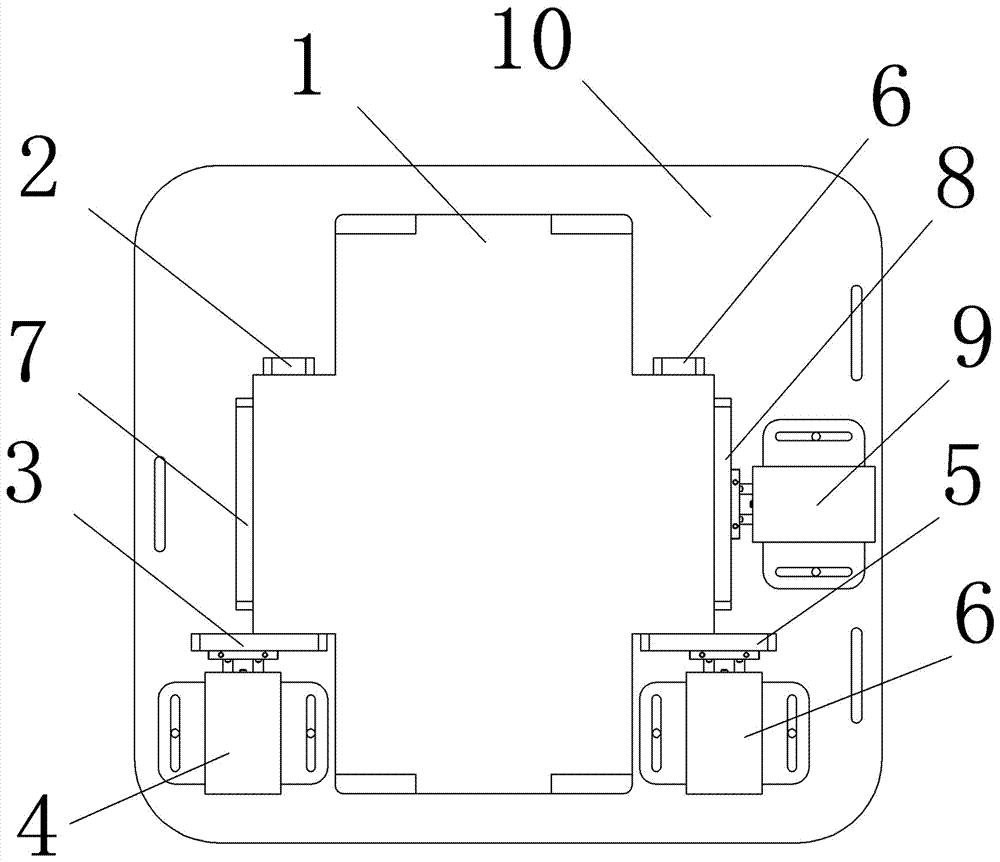

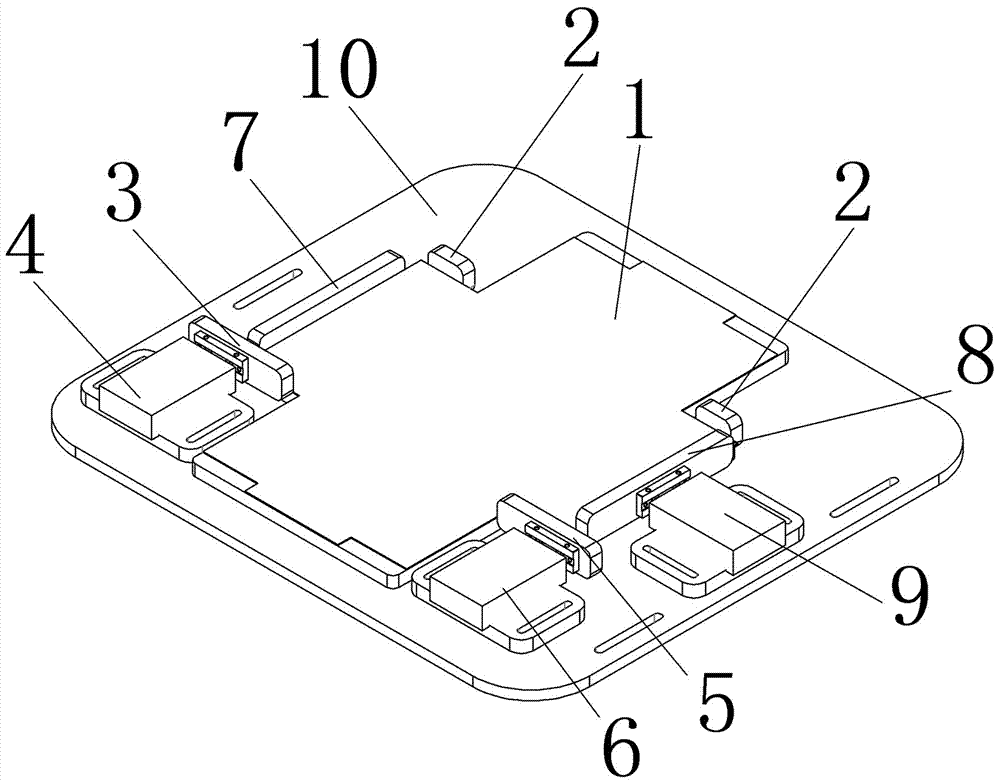

[0032] Embodiment one: see Figure 1-3 , an accurate adjustment device for carton skin paper before gluing in the figure, including a backing plate matching the shape of the skin paper, and two sets of ribs A and B arranged perpendicularly to the backing plate are arranged around the backing plate, A and B The working surfaces of the two sets of ribs face the inner direction of the backing plate and are higher than the surface of the backing plate. The working surfaces of the two sets of ribs of A and B are perpendicular to each other, so that the positioning of the skin paper in two directions can be realized. The positions corresponding to the two groups of ribs of A and B are respectively provided with corresponding telescopic adjustment mechanism A and telescopic adjustment mechanism B. Of course, the relationship between telescopic adjustment mechanism A and B is also perpendicular to each other. The telescopic adjustment mechanism A Both B and B include the push plate at...

Embodiment 2

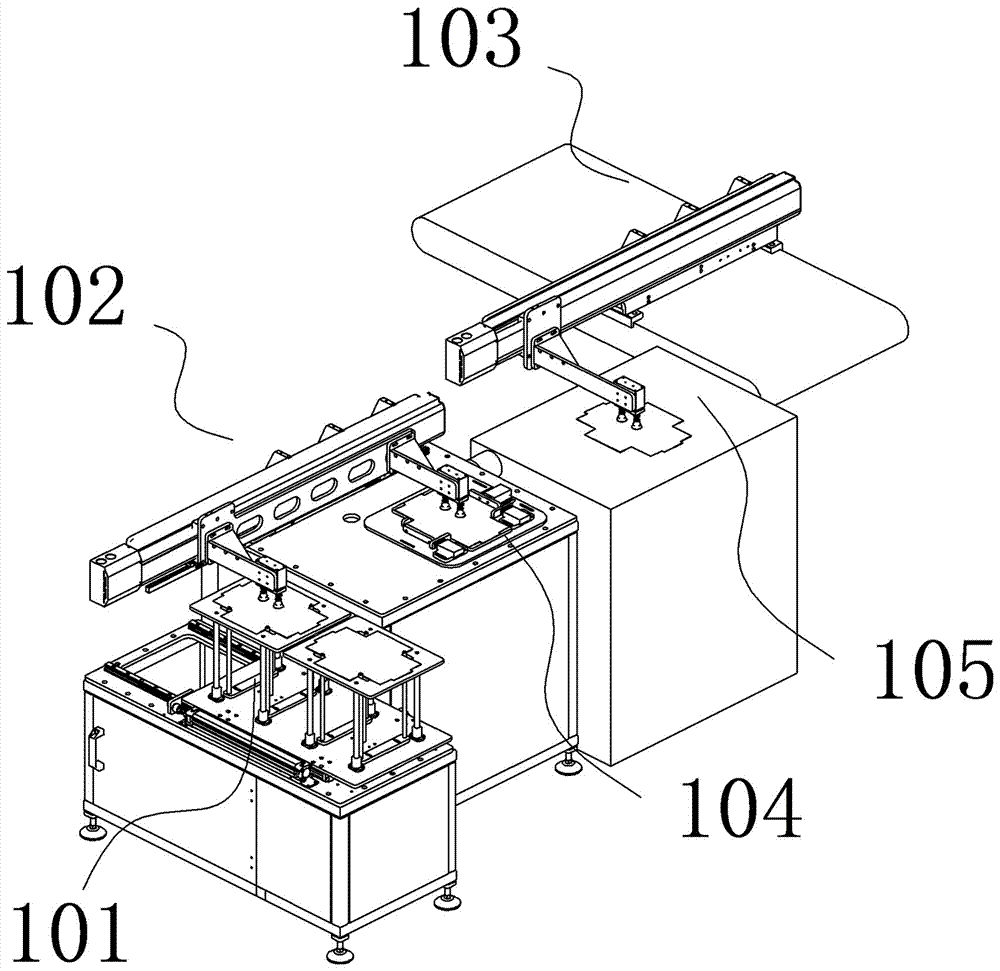

[0034] Embodiment two: see Figure 1-8 In the figure, a carton skin paper secondary positioning and gluing system includes an adjustment device, a silk screen gluing device, and a skin paper transfer device arranged between the adjustment device and the silk screen gluing device. The adjustment device includes rough The adjustment device and the accurate adjustment device are provided with a skin paper transfer device A between the coarse adjustment device and the accurate adjustment device, and a skin paper transfer device B is provided between the accurate adjustment device and the silk screen glue application device; near the silk screen glue application device There is also a skin paper transfer device C for blanking;

[0035]The accurate adjustment device includes a backing plate that matches the shape of the skin paper, and the periphery of the backing plate is provided with two sets of ribs A and B arranged vertically with the backing plate, and the working surfaces of ...

Embodiment 3

[0041] Embodiment three: a kind of accurate gluing method of packaging box skin paper secondary adjustment, comprises the following steps:

[0042] a. Coarse adjustment

[0043] First place a stack of cut skin paper on the supporting plate of the coarse adjustment device, and use several positioning sliders to match and position with several corners around the skin paper;

[0044] b. Fine adjustment

[0045] The uppermost page of the positioned stack of skin papers is transferred to the backing plate of the accurate adjustment device through the transfer device A, and the telescopic adjustment mechanism A and the telescopic adjustment mechanism B above the accurate adjustment device act in sequence, respectively. Cooperate with the fixed two sets of ribs A and B, and make two-way fine adjustment of a single sheet of skin paper;

[0046] c. Glue

[0047] The finely adjusted single sheet of skin paper is transferred to the screen printing gluing device through the skin paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com