Integrated structure of double-side punching and double-side hole flanging of progressive die for double-hole shielding cover

A technology of shielding cover and side flanging, which is applied to perforating tools, forming tools, manufacturing tools, etc., can solve the problems of low production efficiency, high design cost, high processing and manufacturing cost, complicated manufacturing process, etc., so as to prolong the service life and improve the The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

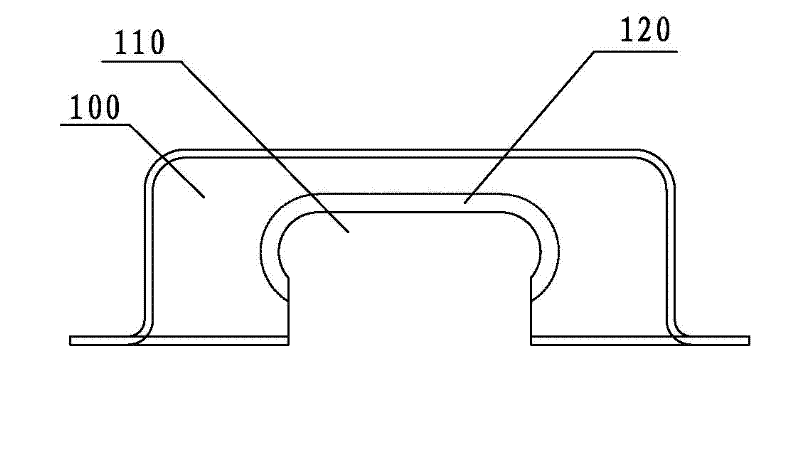

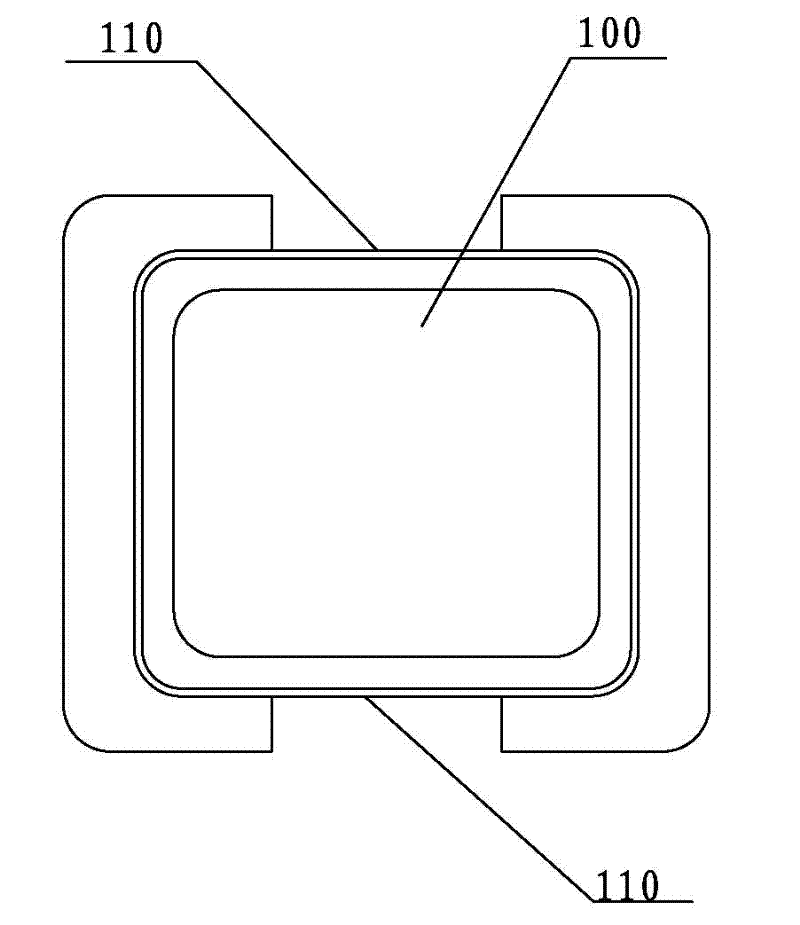

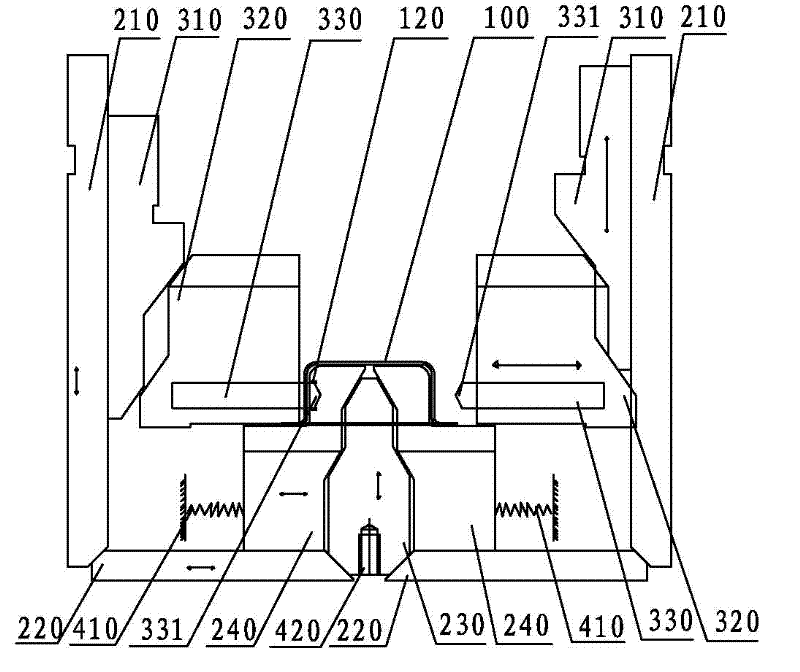

[0041] The integrated structure of double-side punching and double-side hole flanging of the double-hole shield progressive die of the present invention is as follows: Figure 1~6 shown. The double-hole shield progressive mold includes an upper mold base, an upper mold, a stripper plate, a lower mold and a lower mold base, as well as a punching guide hole station, a half-cutting station, a stretching station and a punching station for the corresponding assembly settings. Drop off the product station. The integrated structure of double-side punching and double-side hole flanging of the double-hole shield progressive mold is used in conjunction with the double-hole shield progressive mold. The double-hole shield progressive mold includes: upper mold, stripper plate and Lower mold.

[0042] The integrated structure of the double-side punching and double-side hole flanging of the double-hole shield progressive die includes the three-stage punch 210 of the inner slide block of th...

Embodiment 2

[0053] The integrated structure of double-side punching and double-side hole flanging of the double-hole shield progressive die of the present invention is as follows: image 3 , Figure 4 As shown, the main structure is the same as the above-mentioned embodiment 1, the difference is:

[0054] The side impulse force of the flanging and stripping slider 320 is transmitted by two inclined surfaces. The included angles a and b between the first punching surface 311 and the second punching surface 312 of the flanging and stripping slider punch 310 and the vertical direction are between 20 and 70 degrees. Between, the angles c and d between the first inclined surface 321 and the second inclined surface 322 of the corresponding flanging and stripping slider 320 and the vertical direction are also between 20 and 70 degrees, and the angles a and c are the same, and the angles b and d are the same. same.

[0055] Adopting this structure facilitates the transmission of the impulse bet...

Embodiment 3

[0057] The integrated structure of double-side punching and double-side hole flanging of the double-hole shield progressive die of the present invention is as follows: image 3 , Figure 4 As shown, the main structure is the same as the above-mentioned embodiment 1, the difference is:

[0058] The side impulse force of the flanging and stripping slider 320 is transmitted by two inclined surfaces. The preferred angle between the first punching surface 311 and the second punching surface 312 of the flanging and stripping slider punch 310 and the vertical direction is between 30 and 60 degrees. . The included angles c and d between the first inclined surface 321 and the second inclined surface 322 of the corresponding flanging stripping slider 320 and the vertical direction are also between 30° and 60°, and the angles a and c are the same, and the angles b and d are the same.

[0059] Adopting this structure facilitates the transmission of the impulse between the flanging and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com