Fully-automatic vertical type circular seam welder

A girth seam welding machine, fully automatic technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of the overall quality of the rear axle reducing, it is difficult for welding workers to reduce errors, waste product resources, etc., to shorten the welding time. Time, compact structure, easy to make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

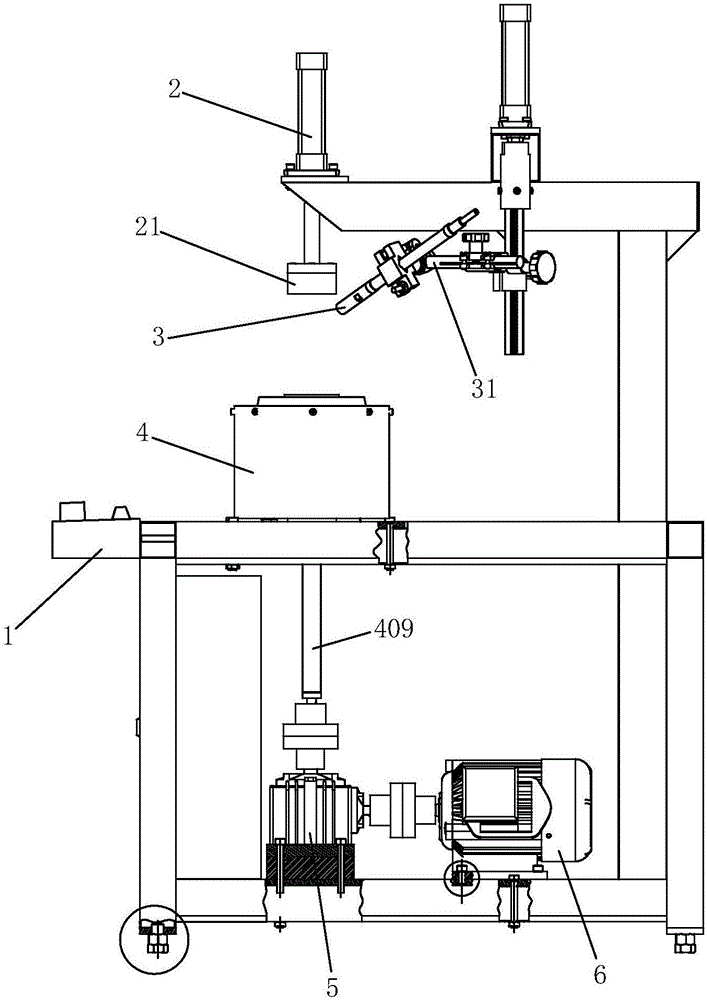

[0029] A fully automatic vertical girth welding machine, including a console 1, a pressing mechanism 2, a welding torch 3, a rotary mechanism 4, a reducer 5 and a motor 6, and the rotary mechanism 4 is vertically fixed on the console 1, the rotary mechanism 4 is connected to the motor 6 through the reducer 5, and the pressing mechanism 2 and the welding torch 3 are arranged above the rotary mechanism 4 through a bracket, and the pressing mechanism 2 is provided with a workpiece Compression column 21, the workpiece compression column 21 is connected to the air cylinder control, the welding torch 3 is arranged on the bracket through the welding torch clamp 31 and is connected to the air cylinder control, the cylinder on the compression mechanism 2 (i.e. cylinder I ), the cylinder connected to the welding torch 3 (i.e. cylinder II) and the motor 6 are all connected to the relay control, and the welding torch 3 is CO 2 Protect the welder.

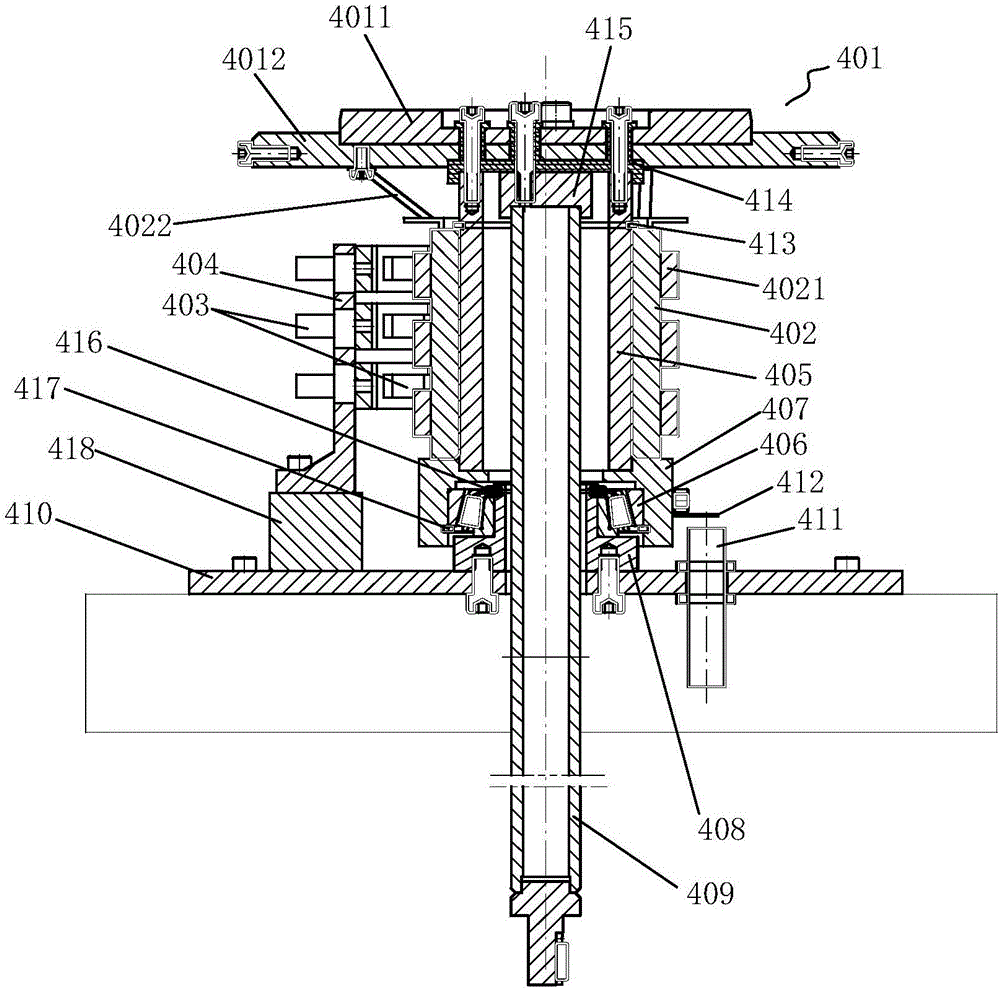

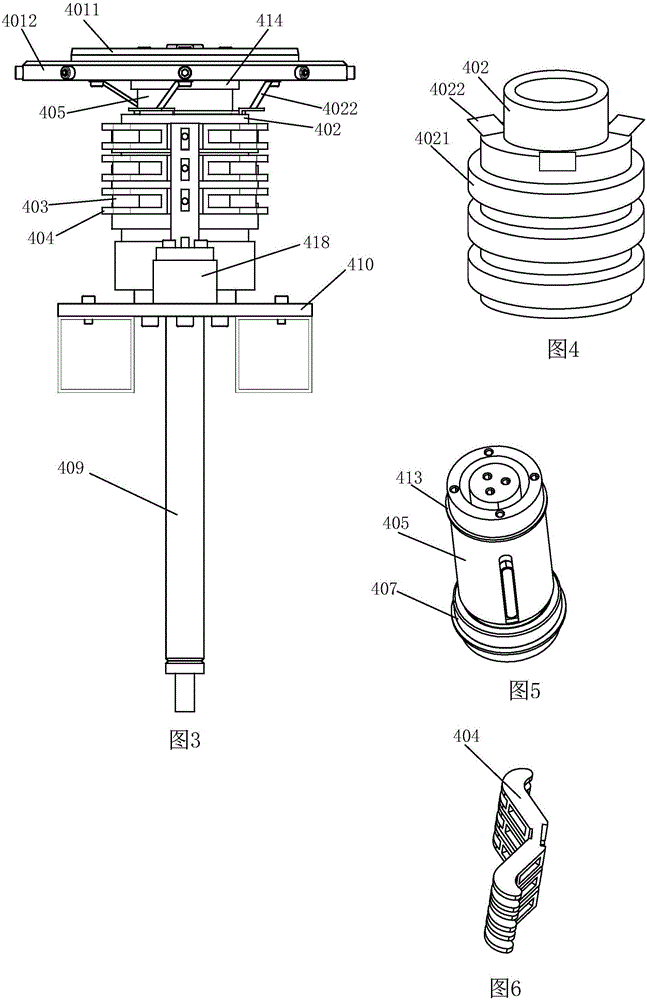

[0030]The slewing mechanism 4 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com