Safety mould for automobile storage battery panel

A battery and panel technology, applied in the field of safety molds for automotive battery panels, can solve the problems of difficult uniform molding, non-destructive demoulding, low production efficiency, large area, etc., to improve interchangeability, save occupancy, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

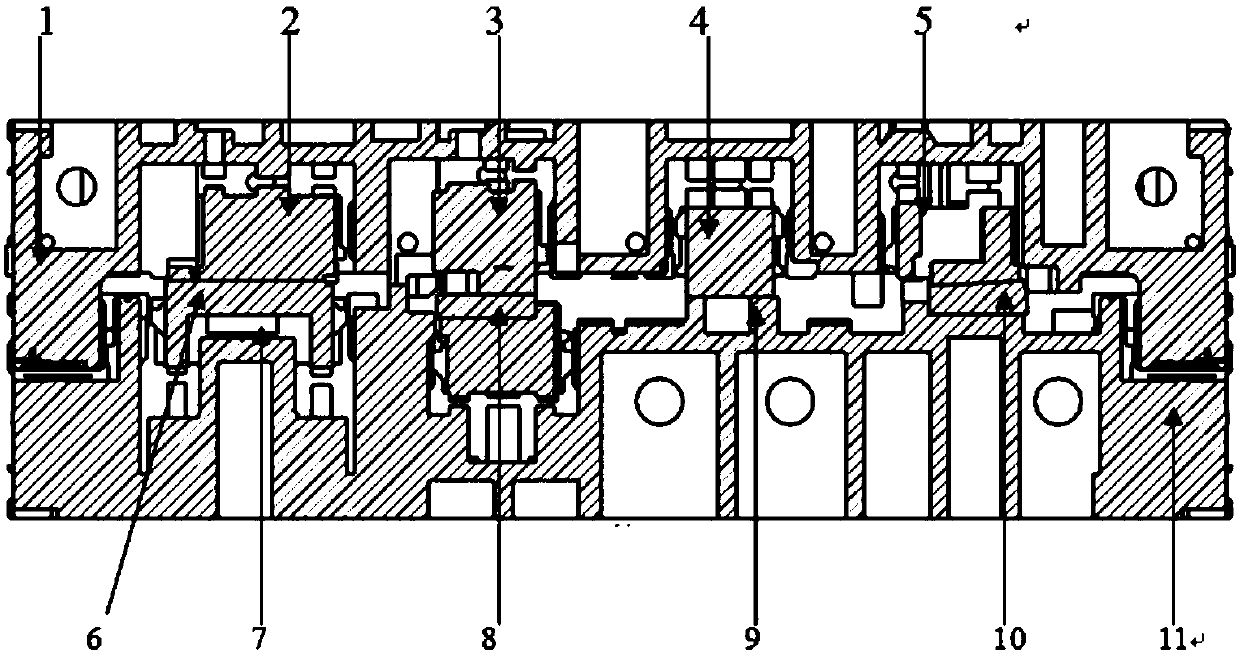

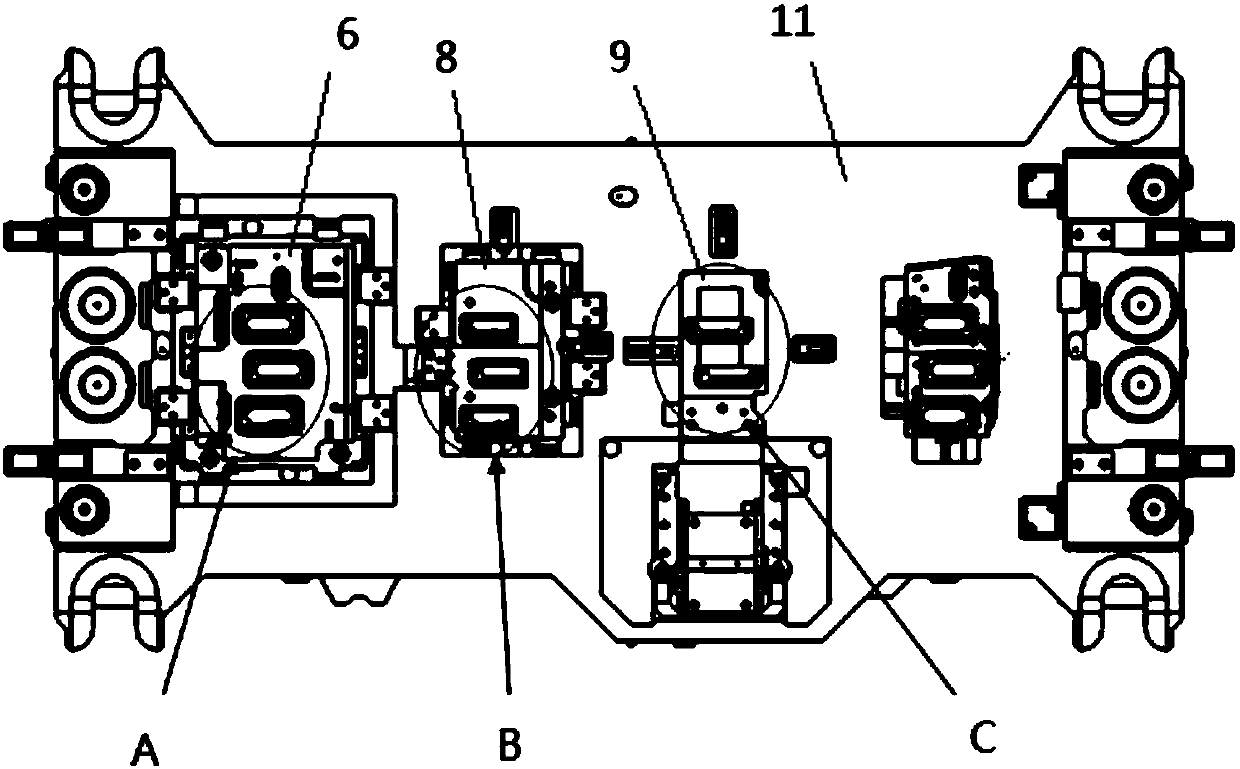

[0031] Such as figure 1 As shown, a safety mold for an automobile battery panel, the mold includes an upper mold and a lower mold,

[0032] Wherein, the upper die includes an upper die frame 1, an upper die die 2 arranged on the upper die frame 1, an upper die pressing material core a3, an upper die pressing material core b4, and an upper die pressing material core c5;

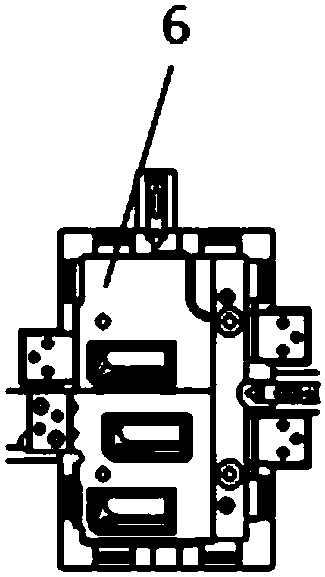

[0033] The lower mold includes a lower mold frame 11, a lower mold pressure core a6 arranged on the lower mold frame 11, a lower mold punch a7, a lower mold pressure core b8, a lower mold punch b9, and a lower mold punch c10.

[0034] Among them, the upper mold die 2 corresponds to the lower mold pressing material core a6, and the lower mold pressing material core a6 is located above the lower mold punch a7, the upper mold pressing material core a3 corresponds to the lower mold pressing material core b8, and the upper mold pressing material core b4 Corresponding to the punch b9 of the lower die, the pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com