Concrete column with sea sand concrete and core rubber concrete

A technology of rubber concrete and concrete, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of insufficient strength and bearing capacity, low stiffness and bearing capacity, collapse of building structures, etc., to expand the applicable field of engineering, High bearing capacity, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

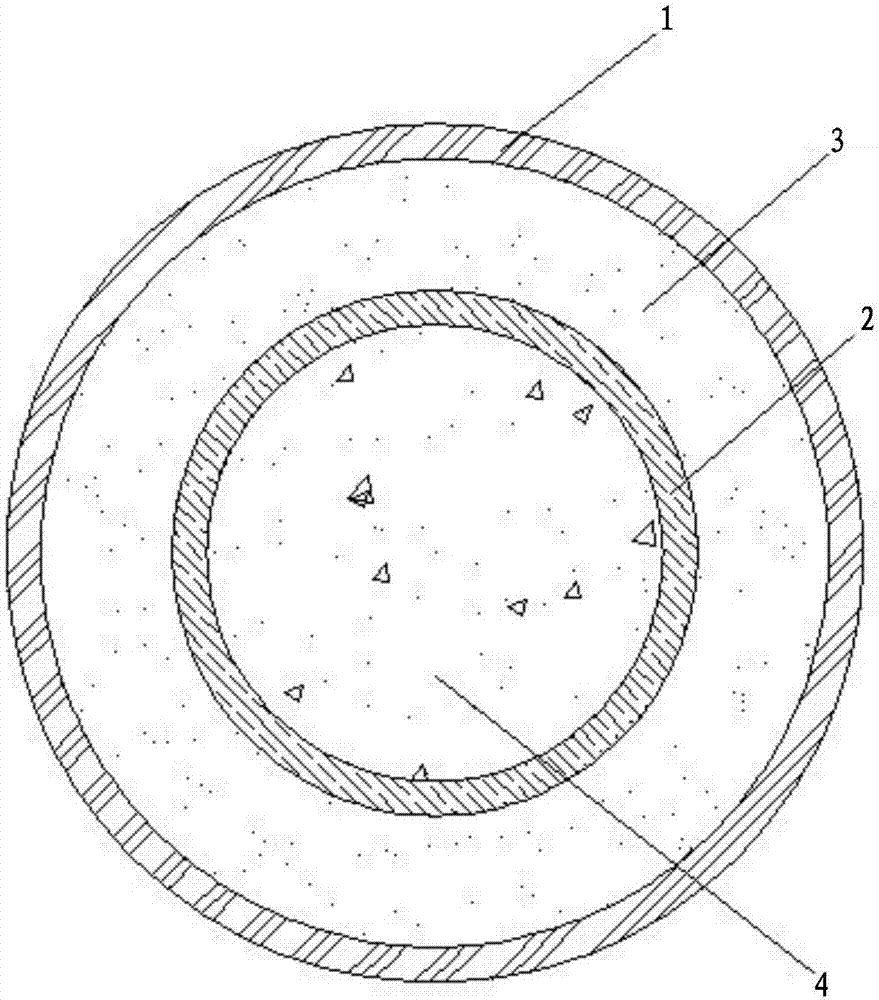

[0027] refer to figure 1 , this embodiment relates to a sea sand concrete core rubber concrete column, comprising an outer FRP pipe 1, an FRP-steel composite pipe 2, a sea sand concrete 3 and a rubber concrete 4, and the FRP-steel composite pipe 2 is arranged on the In the outer FRP pipe 1, and the sea sand concrete 3 is filled between the FRP-steel composite pipe 2 and the outer FRP pipe 1, and the FRP-steel composite pipe 2 and the outer FRP pipe 1 are fixedly connected together; The rubber concrete 4 is filled in the FRP-steel composite pipe 2; the FRP-steel composite pipe 2 includes a steel pipe and an FRP fiber cloth coated on the outer surface of the steel pipe.

[0028] In this structure, FRP-steel composite pipe 2 is set in sea-sand concrete 3, and rubber concrete 4 is filled in FRP-steel composite pipe 2, which reduces the overall weight of the concrete column and improves its ability to resist shock and absorb energy. -Under the support and restriction of the steel ...

Embodiment 2

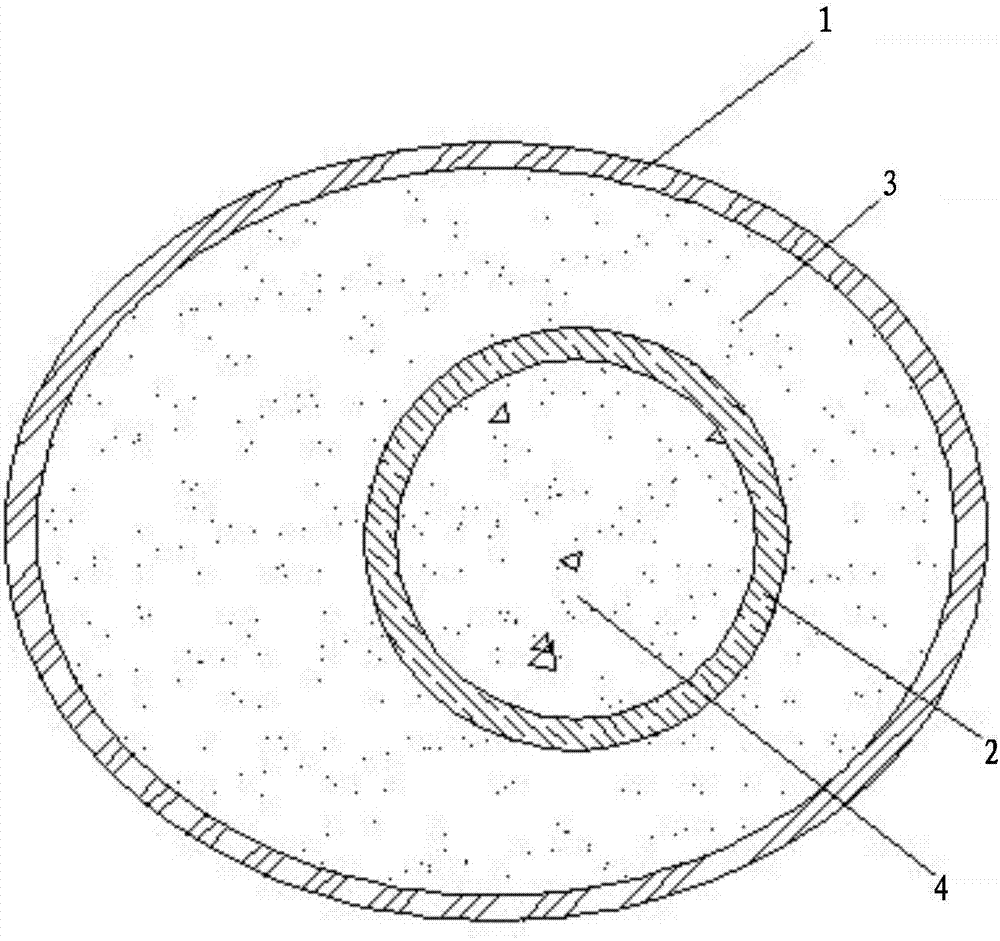

[0037] In this embodiment, on the basis of Embodiment 1, as an improvement to the location of the FRP-steel composite pipe 2, the concrete column in this embodiment is suitable for the situation of eccentric compression, such as figure 2 As shown, the section of the outer FRP pipe 1 is oval, the section of the FRP-steel composite pipe 2 is circular, and the FRP-steel composite pipe 2 is arranged at an eccentric position in the outer FRP pipe 1 . The outer FRP pipe 1 of this structure adopts an elliptical cross-section, and the FRP-steel composite pipe 2 is built in the eccentric position of the outer FRP pipe 1. Due to the eccentric compression of the concrete column, the FRP-steel composite pipe 2 can better improve the concrete Column capacity and stiffness.

Embodiment 3

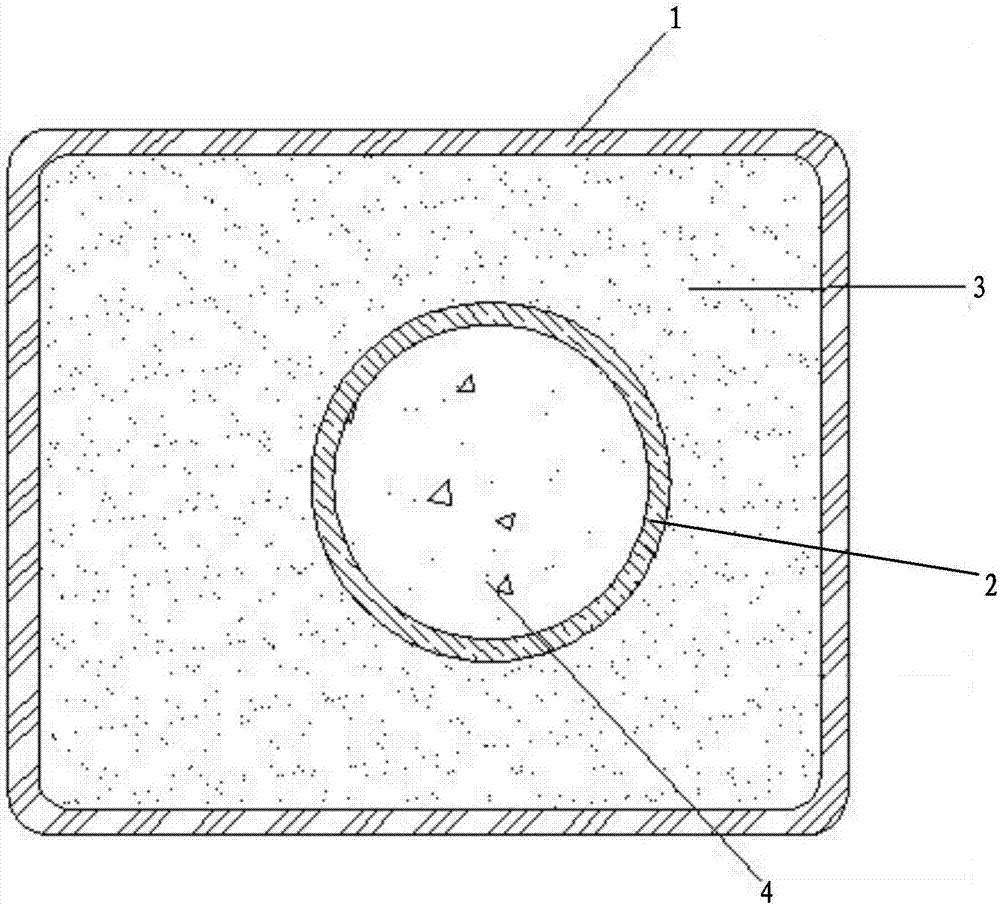

[0039] This embodiment is based on embodiment 2, as the improvement of the outer layer FRP pipe 1, such as image 3 As shown, the cross section of the outer FRP pipe 1 is rectangular, the cross section of the FRP-steel composite pipe 2 is circular, and the FRP-steel composite pipe 2 is arranged at an eccentric position inside the outer FRP pipe 1 . The outer FRP pipe 1 of this structure adopts a rectangular cross-section, and the FRP-steel composite pipe 2 is built in the eccentric position of the outer FRP pipe 1. Due to the eccentric compression of the concrete column, the FRP-steel composite pipe 2 can better improve the concrete column. bearing capacity and stiffness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com