Liquid crystal display panel and manufacturing method thereof as well as array substrate

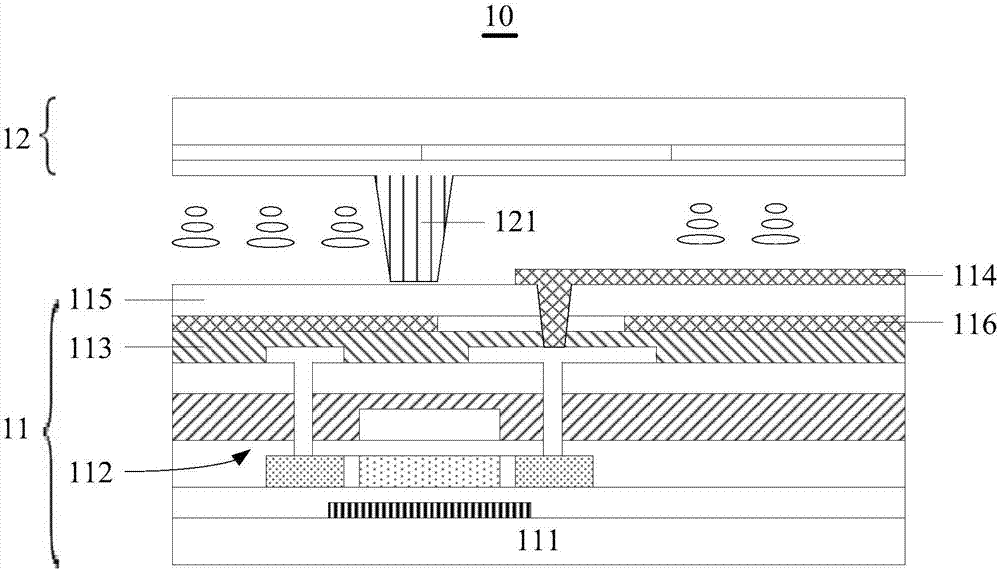

A technology for liquid crystal display panels and array substrates, applied in nonlinear optics, instruments, optics, etc., can solve the problems of reducing the light transmittance of liquid crystal display panels 10, high manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of each exemplary embodiment provided by the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention. In the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

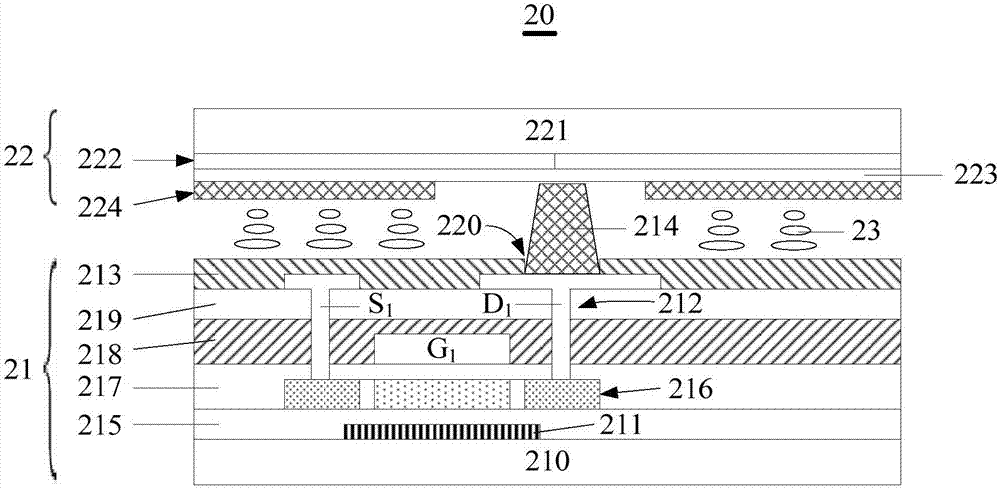

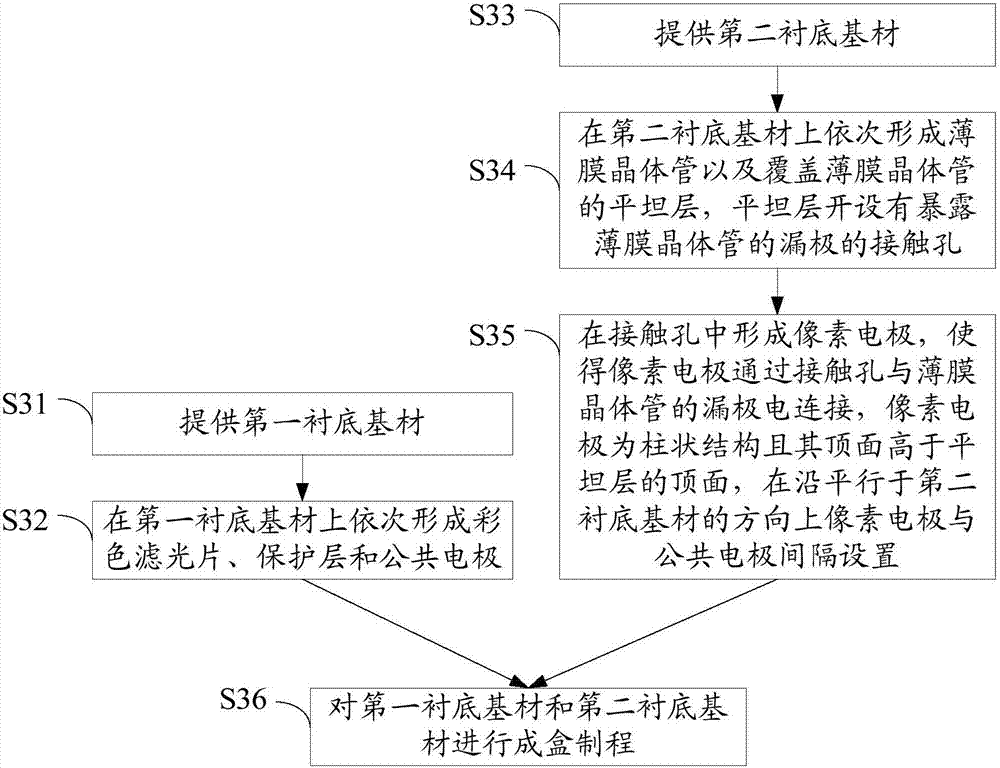

[0014] See figure 2 , Is the liquid crystal display panel of the first embodiment of the present invention. The liquid crystal display panel 20 includes a relatively spaced array substrate (Thin Film Transistor Substrate, referred to as TFT substrate, also referred to as thin film transistor substrate or Array substrate) 21 and a color filter substrate (Color Filter Substrate, referred to as CF substrate, also referred to as color filter substrate). Sheet substrate) 22 and liquid crystal (liquid crystal molecules) 23 filled between the two substrates. The liquid crystal 23 is located in a liquid crystal cell formed by superimposing and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com